Marine Investigation Report M01W0006

Fatal accident

Container ship Alligator Victory

Deltaport, Vancouver

British Columbia

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content.

-

Table of contents

Summary

On the afternoon of 09 January 2001, the Panama-flag container ship Alligator Victory departed from its berth at Deltaport, Vancouver, British Columbia. Soon after, the deck crew began the routine task of raising the starboard-side accommodation ladder to its stowage position in preparation for the vessel's trans-Pacific voyage. The operation was almost complete when a pad eye, welded to a supporting steel deck post, broke in two. This sudden fracture violently released a steel snatch block that was shackled to the pad eye. The snatch block then struck and killed a member of the crew.

Factual information

Particulars of the vessel

| Name | Alligator Victory |

|---|---|

| Official number | 17784 - 88CH |

| Port of registry | Panama |

| Flag | Panama |

| Type | Container carrier-Flush decker with forecastle deck |

| Gross TonnageFootnote 1 | 42809 |

| Length | 253.27 m |

| Built | February 1988, Imabari Shipbuilding Co. Ltd., Japan |

| Propulsion | Diesel, Mitsui B & W - 9L80MC, 25 083 kW at 88 rpm |

| Number of Crew | 21 |

| Registered Owner | Karakoram Maritima S.A., Republic of Panama |

Description of the vessel

The Alligator Victory was built in February 1988 in Japan as a container vessel and is designed to carry 2912 twenty-foot equivalent units. The wheelhouse, the accommodation block, and the engine room are at the after end of the ship. The containers are carried in cargo holds and on deck, both forward of and abaft the accommodation block in an arrangement common to container ships.

The vessel carries two accommodation ladders (gangways) outboard of the accommodation, one ladder on either side of the vessel block. Two other accommodation ladders, used mainly for embarking and disembarking the pilot, are near midships.

Accommodation ladders

The accommodation ladder is stored on the ship and is considered an attachment. It provides access to the ship and enables its personnel, stevedores, and officials to embark and disembark. The accommodation ladder was rigged as shown in Figure 1.

The falls are reeved through sets of sheaves that are fixed to a davit arm, one end of which is hinged to the deck. Through another system of sheaves and snatch blocks mounted on various deck and side posts, the falls are wound around the drums of an electric winch. To hold the .winch, and thence the ladder, in its last set position, the electric motor has an electromagnetic disc brake. A second manual band brake, intended for emergency use in case the main brake fails, is also fitted around one of the winch drums.

When the winch is used for hoisting the ladder, the falls wrap themselves around a drum and the ladder moves from its inclined position toward the horizontal, pivoting about its hinge on the turntable.

Snatch blocks are arranged above and inboard of the ladder. Any additional hauling in of the falls turns the entire ladder and the turntable sideways. The complete assembly now pivots about the hinge between the turntable and the deck, until the assembly becomes vertical and lies on its side. The assembly can now be secured for an ocean passage. The ladder's and the turntable's stowed position is vertical, inboard of the ship side but outboard of the railings (Figure 2).

Accommodation ladder maintenance

The vessel has an internal planned maintenance program, set up to meet anticipated International Safety Management Code (ISM Code) requirements. The plan does not specify inspection and overhauling of the accommodation ladder's various components. Instead, maintenance on accommodation ladders was limited to general chipping, painting, and renewal of falls. Under this program, the falls had been renewed on 06 October 2000. In July 2000, this gangway had been chipped and repainted, and the sheaves, pulleys, and other deck fittings had been greased. All the work had been done on site; there are no records to indicate that the electric motor, the davit and its sheaves, or the turntable had ever been routinely dismantled and overhauled.

Description of the accident

The Alligator Victory finished discharging and loading its cargo of containers at Deltaport on the morning of 09 January 2001. The pilot boarded the vessel at 1200 and, after completing all required formalities, it was ready to depart by 1201. Once all the officials were off the ship, the deck crew lifted the gangway off the jetty and into a horizontal position well away from any shore-side obstructions. In this position, the gangway would not hinder the tugs in their operations.

Some of the crew members and the second officer then went to their aft stations on the poop deck, where they let go the stern lines and made fast a tug. By 1220, the ship was clear of the berth and was moving ahead. The tugs had been cast off, and the second officer instructed his crew to finish stowing the accommodation ladder in preparation for the voyage.

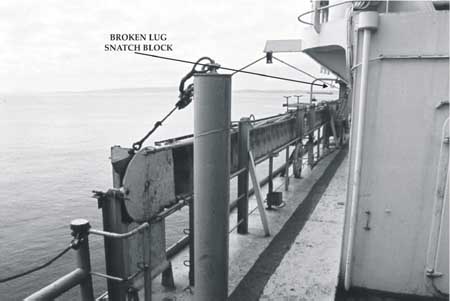

One of the crew members operated the controls of the electric winch while another stood under the snatch block by the railings, watching the ascent of the ladder and guiding the operator. Just before the gangway reached its final stowage position, the pad eye securing the snatch block to the side post suddenly parted. The abrupt releasing of the snatch block, when there was still tension on the falls, caused it to swing violently outward and strike the seaman standing in its path. Though he was wearing a hard hat, the snatch block hit him on the forehead and face; he later succumbed to his injuries. Ship damage was limited to one broken pad eye.

Other observations

Though not related to the accident but indicative of the general condition of the accommodation ladder, other observations were made as follows:

- the band brake around the winch motor was found broken

- the securing pin on the lock nut of the central pin of the turntable was missing

- there was scale and corrosion built up around the lock nut, the pin, and on some sheaves

- the underside of the davit arm was corroded in certain places

- the side plates of the sheaves attached to the davit arm bore signs of contact with other external objects

Vessel and crew certification

The vessel was crewed and equipped in accordance with existing regulations for a vessel of its type and for the trade in which it was engaged. The vessel had a voluntary, internal safety management system and audit procedure, wherein nonconformities were identified and corrective action procedures initiated and executed. The vessel did not have a Safety Management Certificate (it did not have to comply with the ISM Code requirements until 01 July 2002), but its management company had been issued a Document of Compliance by Nippon Kaiji Kyokai in February 1998.

Other occurrence involving an accommodation ladder

On 05 February 1999, the Arabella was at anchor in English Bay, British Columbia, and disembarked six persons from the vessel and onto a waiting water taxi. While five of them were on the accommodation ladder, its turntable separated from its upper platform, catapulting two of them off the ladder and into the water. One of them bounced off the water taxi's bow and, as a result, sustained serious injuries.

A subsequent investigation by the TSB (Report N0 M99W0017) revealed the following:

- The construction of the accommodation ladder did not conform to the vessel's drawings or specifications.

- The port and starboard ladders differed in construction.

- The construction of the port-side accommodation ladder's turntable did not allow for regular inspection or for lubrication of the central pivot pin. Lack of lubrication led to the pivot pin deteriorating to a point where it seized in its housing. Finally, under the influence of external applied forces, it sheared in two.

Analysis

The accommodation ladder weighs about 2700 kg and is supported at one end by the turntable. Because of the ladder's inclination, a major portion of the weight is borne by the falls, acting at the point of suspension. This weight, via the snatch blocks and their fittings, is eventually transmitted to the winch drum.

A deployed gangway, the bottom platform of which rests on the dockside, withstands a large amount of wear and tear. It has to compensate for the constantly changing vertical distance between the jetty and the ship's deck, under the influence of different conditions of loading, ballast, tide, and the wake of passing ships. The bottom platform is mounted on a roller, which allows the gangway to change its inclination smoothly, as the vessel's freeboard changes. The gangway also has to clear shore obstructions, such as bollards, capstans, and mooring lines.

From its deployed position, the ladder is raised until it bears against its stops. The total load on the falls and thence on the deck fittings, at this stage, includes the weights of the ladder and the davit arm, as well as the frictional resistance in the sheaves, snatch blocks, and hinges.

In its stowed position, the accommodation ladder lies inboard of the ship's side but outside of the railings. Its underside faces away from an inspector, and there is a clear drop of about 15 m on the other side. The vulnerable parts of the ladder, the davit arm, and the turntable are thus difficult to access.

Inspection of the broken pad eye revealed two pre-existing cracks that had formed some time ago. The cracks were on the inside curvature of the pad eye and had escaped detection during preventive maintenance. The pad eye was subjected to repeated, nonuniform loading and unloading as the gangway was lowered and raised. Initially, the cracks were two points of stress concentration that slowly became enlarged, one of which had extended to almost 25% of the cross-sectional area of the pad eye. The failure occurred as a result of tensile overload when the remaining intact area was insufficient to carry the load imposed on it.

Inspection regulations

The International Convention on the Safety of Life at Sea, 1974 (SOLAS) does not address requirements for the installation, examination, or testing of accommodation ladders and their rigging. Classification societies and flag states do not have rules for their inspection or survey. Some classification societies have established criteria for the construction and the installation of new accommodation ladders on new vessels, but none for their continuous or periodic survey. Consequently, inspectors for a flag state, port state, or classification society may make a cursory observation of the accommodation ladder when boarding a vessel. Any defects or deficiencies in an accommodation ladder, especially those not readily observable, that could affect the safety of personnel may remain undetected. Time constraints due to an exigent loading or unloading schedule, coupled with the position and the stowage of the ladder, make a thorough on-site examination of the ladder difficult, especially of the parts subject to wear and tear. Vulnerable parts of the turntable (its pivot pin and bush), davit arm, sheaves, and bushings, hoist motor and gearing and braking arrangements, and other internal components of the accommodation ladder can only be inspected after disassembly.

Like all vessels with freeboards greater than 9 m, the Alligator Victory was equipped with another two accommodation ladders, positioned midships, that formed part of the pilot transfer arrangement. Under the IMO inspection regime, accommodation ladders used for pilot transfer are subject to inspection as part of the Safety Equipment Certificate requirement.Footnote 2 Therefore, some accommodation ladders on some vessels are subject to inspection, whereas those on other vessels are not. The IMO recognizes the need to inspect the accommodation ladder. Such inspection, however, is limited to ladders used for pilot transfer and does not extend to all accommodation ladders on a vessel.

Regulation 25(4) of the 1966 International Load Line Convention states that "satisfactory means (in the form of . . . gangways . . .) shall be provided for the protection of the crew in getting to and from their quarters . . . and other parts used in the necessary work of the ship." There is no corresponding requirement for safe access to, and egress from, the ship itself. Articles 3, 3.1.1, and 3.1.2 of the International Labour Organization's Code of Practice entitled Safety and Health in Dock Work stipulate that safe means of access to, and egress from, the vessel should be provided. The document places preference on a ship's accommodation ladder. However, no reference is made to the inspection requirement by a competent authority. Thus, accommodation ladders-used by crew members, officials, stevedores, and visitors-are not subject to inspection as part of a survey regime except when used for pilot transfer. The absence of a mandated inspection of accommodation ladders allows potentially unsafe ladders to be used as a means of access to and egress from the vessel.

In Canada, inspection of accommodation ladders may be carried out under the provisions of the Tackle RegulationsFootnote 3 or the Marine Occupational Health and Safety Regulations.Footnote 4 The Tackle Regulations deal with cargo-handling equipment and safe access to and egress from vessels. While they prescribe formal inspection, testing, and recordkeeping of cargo-handling equipment, they do not prescribe such a regime for accommodation ladders. Hence, under the current system, with no defined set of rules, examination of ladders may be no more than perfunctory and subjective, depending on an inspector's experience and knowledge.

Other occurrence and classification society inspection

The Arabella had changed its classification society from Nippon Kaiji Kyokai to the Korean Register of Shipping in 1994. Since the accommodation ladder was not subject to inspection, no information on the state of the ladder was recorded, nor did the new classification society conduct a survey of the ladder at the time of, or subsequent to, the change in classification society. As a result, the less-than-satisfactory condition of the ladder went undetected, compromising the safety of personnel, and remained undetected until the accident.

ISM certification and safety

The vessel was working toward obtaining a Safety Management Certificate and had a voluntary safety management system in place to comply with the ISM Code requirements. The vessel's management company was issued a Document of Compliance by Nippon Kaiji Kyokai.

The ISM Code requires that

- safety sensitive equipment such as accommodation ladders be inspected at appropriate intervals

- nonconformities be reported to the head office

- remedial measures be taken to remove nonconformities

- a record of these activities be maintained

Nevertheless, the safety management system documentation on the maintenance of accommodation ladders made no reference to those safety-critical parts that are subject to wear and tear.

Findings

Findings as to causes and contributing factors

- The pad eye securing the snatch block-through which the falls were reeved-parted and released the snatch block. The snatch block then violently hit in the forehead a crew member, who succumbed to his injuries.

- The pad eye broke in two; the failure was caused by shear from tensile overload.

- The pad eye was found to be cracked in two places. (These cracks were previously formed and had slowly become enlarged.) One of these cracks extended to about 25% of the cross-sectional area of the pad eye.

- The vessel's planned maintenance had failed to identify the existence of these two cracks.

Findings as to risk

- Under the current regulatory regime-international, flag state, or classification society-accommodation ladders used by pilots are subject to periodic inspection and survey. Accommodation ladders that are not used for pilot transfer but that constitute the main means of access to and egress from a ship are not subject to this requirement. This exposes individuals boarding and exiting the vessel to risk, precludes audit of maintenance records, and permits the continued use of ladders that may be unsafe.

Safety action

Safety action taken

- The TSB sent Marine Safety Advisory 002/01 to Transport Canada Marine Safety advising of the accident's salient facts and the need for an adequate inspection and testing regime for accommodation ladders by a suitable competent authority.

- The TSB is in the process of preparing a paper to submit to Transport Canada for eventual presentation to the appropriate subcommittee at the International Maritime Organization. This paper will address the requirements for a suitable inspection and testing regime for accommodation ladders.

- The operating managers of the Alligator Victory carried out the following corrective action when the vessel arrived at the next port of call:

- Both accommodation ladders were comprehensively overhauled. Proper operating instructions were posted near the control stand.

- All pad eyes in way of the accommodation ladders were renewed, and guide blocks and shackles were serviced/replaced as required.

- Both accommodation ladders were operationally tested, to the satisfaction of the attending Class NK surveyor.

This report concludes the Transportation Safety Board's investigation into this occurrence. Consequently, the Board authorized the release of this report on .