Explosion

Tanker AlgoCanada

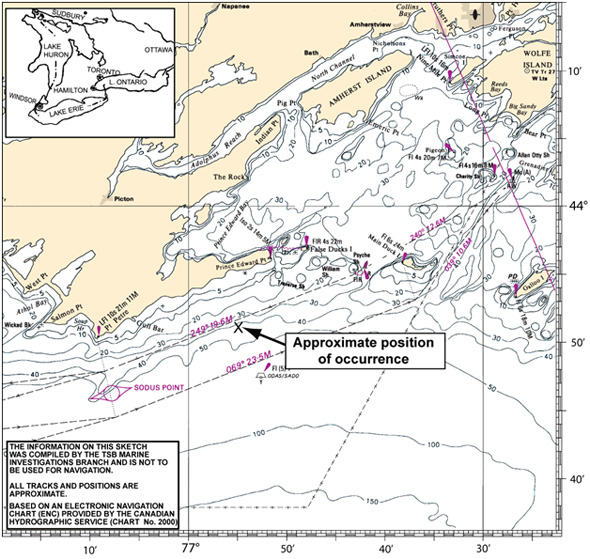

Near Prince Edward Point

Eastern Lake Ontario, Ontario

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content.

Summary

On 24 July 2009, while proceeding westward in eastern Lake Ontario, the petro-chemical tanker AlgoCanada experienced an explosion in the bow thruster compartment. The vessel sustained minor damage to the bow thruster compartment and forecastle. There were no injuries or damage to the environment and the vessel continued its voyage.

Factual information

Particulars of the vessel

| Vessel | AlgoCanada |

|---|---|

| IMO Number | 9378591 |

| Port of registry | St. Catharines, Ontario |

| Flag | Canada |

| Type | Chemical/petroleum products tanker |

| Gross tonnage | 8009 |

| Length overallFootnote 1 | 129.84 m |

| Draught | Forward: 7.59 m Aft: 7.59 m |

| Built | Turkey, 2008 |

| Propulsion | MAK 9M32C / 4500 kW Single, controllable-pitch propeller |

| Cargo | Vessel in ballast |

| Crew | 14 |

| Registered owner | Algoma Tankers Ltd., St. Catharines, Ontario |

| Manager | Algoma Tankers Ltd., St. Catharines, Ontario |

Description of the vessel

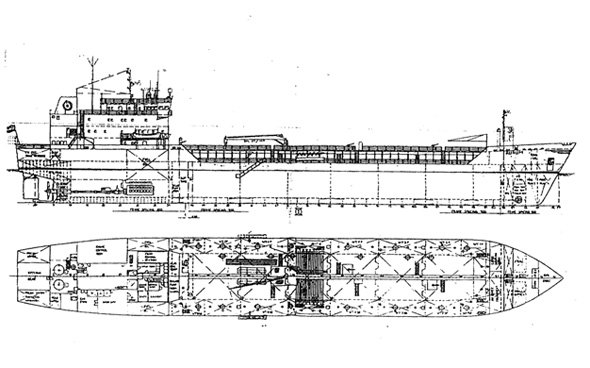

The AlgoCanada was built in 2008 and is a sister ship to the AlgoNova, both built in Eregli, Turkey, and operated by Algoma Tankers Ltd. The vessel is of double hull construction and was built to Bureau Veritas (BV) class survey as a Chemical Class II, 1A Ice Class (mixed chemical/petroleum) tanker. The vessel has 14 cargo tanks and 2 slop tanks. The deckhouse and bridge are located aft and the vessel is fitted with a bow thruster. Cargo, inert gas (IG) and tank-drying lines are located within an enclosed trunk on the main deck.

The forecastle is entered via a door and stairs on the forecastle head, from which there is access to the bow thruster compartment below. This compartment is equipped with a thermostatically controlled heater unit, electrical lighting fixtures and a ventilation fan. None of these are explosion-proof, nor is this required by regulation.

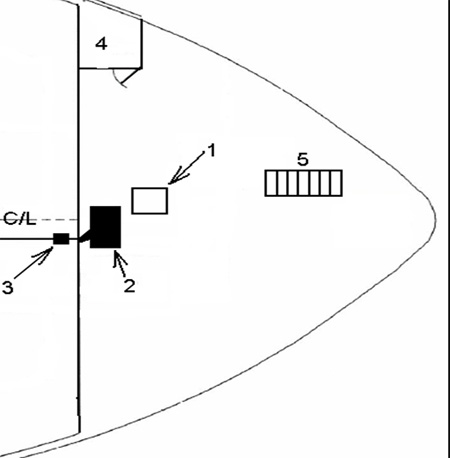

The vessel was initially equipped with an approved tank-drying systemFootnote 2, as well as portable water-driven air fans for ventilating. The tank-drying system includes a fan unit located in the forecastle adjacent to the aft bulkhead. This fan unit was connected to piping, which penetrates the bulkhead and was in turn affixed to a double, non-return valve situated in the deck trunk (see Figure 1).Footnote 3

The vessel is equipped with a fixed IG system for the cargo tanks. The IG system on board the AlgoCanada, although operational, was not used. The purpose of the IG system is to prevent the formation of a flammable atmosphere in cargo tanks by introducing an IG or mixture of gases that contain insufficient oxygen to support combustion.

The International Convention for the Prevention of Pollution from Ships, 1973, as modified by the Protocol of 1978 relating thereto (MARPOL),Footnote 4 Annex II Chapter II, requires that each ship that is certified for the carriage of noxious liquid substances in bulk shall be provided with a Procedures and Arrangements Manual (P&A Manual). The P&A Manual deals with the marine environmental aspects of cargo handling, cleaning of cargo tanks and discharge of residues and mixtures from these operations. It is not intended to be a safety guide, nor does it specifically evaluate safety hazards.

At the time of the vessel handover by the builder, in addition to passing along standard documentation and certification, the builder provided a P&A Manual to Algoma Tankers. This manual, which had been approved by the classification society (Bureau Veritas) could not be found on board at the time of the investigation.Footnote 5 However, the manual for the similarly equipped sister ship AlgoNova explicitly states that the venting of cargo tanks is to be conducted using portable water-driven fans.

History of the voyage

On 21 July 2009, after discharging a cargo of gasoline and fuel oil at Sydney, Nova Scotia, the AlgoCanada proceeded in ballast toward the next port of loading at Nanticoke, Ontario. The cargo tanks were left in an "over-rich" condition.Footnote 6

On the morning of 24 July 2009, the master, a pilot, the helmsman and the second officer were on the bridge. At around 0700,Footnote 7 the first officer (1/O) discussed the day's work with 2 general purpose ratings (GPs). This work entailed venting cargo tanks, starting with No. 1 (port and starboard), which had contained gasoline. The 1/O indicated that the venting was to be performed after the upcoming pilot transfer at Tibbetts Point, New York. As there were no written procedures on board for venting, the GPs only had the verbal instructions from the 1/O to understand how to perform their task.Both GPs had previous experience performing these venting operations under supervision and without incident.

At 0830, in preparation for venting operations, the GPs laid out flexible hoses beside the tank-cleaning hatches at tanks No. 1 port and starboard and manually opened the tanks' pressure/vacuum (PV) valves.

At about 0930, the GPs removed the tank-drying flange covers and hooked one end of the flexible hoses to the tank-drying system (see Photo 2). At 0944, the other ends of the flexible hoses were inserted through the tank-cleaning hatches close to the bottom of tanks No. 1 port and starboard. The GPs then proceeded aft to assist with the pilot transfer.

At 0945, the vessel arrived at the pilot station at Tibbet's Point in the St. Lawrence River. At 1010, following the change of pilots, a GP informed the 1/O that the flexible hoses had been inserted into tanks No. 1 port and starboard and that they were now ready for venting. As the tank-drying fan was not yet running and because he had previous experience with vapour migrating through these hoses into the forecastle, the 1/O proceeded forward and removed the hoses from the tanks and closed the tank-cleaning hatches. He then went to the forecastle, but before reaching the door, he smelled gasoline vapour. He left the door open to ventilate the forecastle area, but did not start the bow thruster ventilation fan in case it might cause a spark.

At 1030, the 1/O informed the bridge of the forecastle atmosphere and instructed the next watch to stay clear. The forecastle was naturally ventilated for the next hour and 40 minutes.

At 1220, the 1/O returned to the forecastle and verified the atmosphere with a gas indicator. The reading was at 0 LEL.Footnote 8 He then proceeded to the trunk space to verify the valve settings on other tanks.

At 1232, an explosion occurred in the forecastle. From the bridge, the master and pilot saw debris ejected from the forecastle doorway, followed by dark gray smoke. At the same time, the flexible hoses separated from the tank-drying system, which began emanating smoke. The fire alarm sounded automatically and the general alarm sounded from the bridge soon afterward.

At that time, the vessel was approximately 4 nautical miles south of Prince Edward Point in eastern Lake Ontario.

The crew immediately proceeded to muster stations and a fire team of 2 crew members suited up before assembling outside the forecastle doorway. Once inside, they reported no visible fire. Adjacent compartments were checked for heat sources; none were found.

After determining there was no fire, the master reported the explosion to the company. At 1400, the master informed Transport Canada (TC).Footnote 9 Saint Lawrence Seaway Management Corporation (SLSMC) was informed 3.5 hours after the occurrence and Marine Communication and Traffic Services (MCTS), which normally alerts other appropriate agencies, was notified some 72 hours later by the TSB.

The vessel proceeded to Nanticoke and then Sarnia, Ontario, where it entered layup.

Venting and tank drying

The vessel was equipped with a fixed tank-drying systemFootnote 10 that was designed and approved to supply relatively low volumes of ambient air to dry tanks following washing and ventilating. This system was not approved for ventilation.

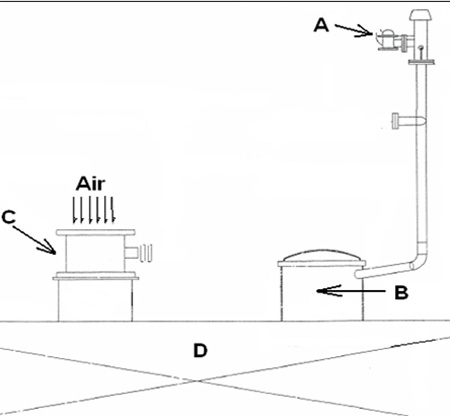

The AlgoNova P&A Manual states that tank ventilation is to be performed using portable water-driven air fans placed at the tank-cleaning hatches (see Figure 2). The practice of using the fixed tank-drying system for ventilation had been carried over from another company vessel, the AlgoScotia.

Valve modifications

Classification society rules require that 2 non-return devices be fitted to a tank-drying system, in order to avoid the return of flammable or toxic cargo vapour to the safe space (in this case, the forecastle).

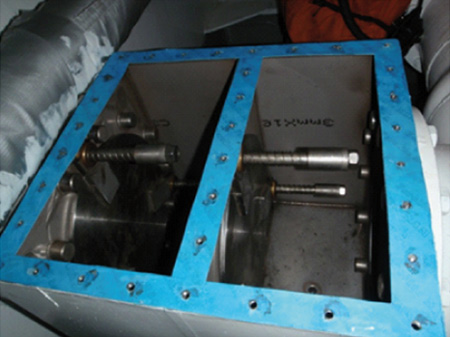

Prior to this voyage, a modification on the tank-drying system was performed by the vessel's crew in order to speed up venting times.Footnote 11 The company was aware of the modification and had provided instructions for the removal of 1 of the 2 baffle plates in order to improve the air flow of the tank-drying system (see Photo 3). However, neither the valve's manufacturer nor the classification society was consulted.

Damage to the vessel

There was no structural damage to the vessel. The paint locker door, however, was ripped from its hinges. Air ducting to the bow thruster compartment and ducting to the air drying unit were also damaged, as were some lights in the forecastle area and all lights in the bow thruster compartment. The bow thruster compartment was blackened with soot, including burn patterns on the heater.

Weather

The weather at the time of the occurrence was 21°C, with a relative humidity of 88%. Wind was south-southwest at 10 knots.

Certification

Vessel

The vessel was crewed, equipped and certified in accordance with existing regulations and held a valid Safety Management Certificate,Footnote 12 as required by the International Management Code for the Safe Operation of Ships and For Pollution Prevention (ISM Code).

Personnel

The master, officers and crew held certificates of competency appropriate for the intended voyage and type of vessel on which they were serving. This included appropriate tanker endorsements for those involved in cargo operations, with the exception of 1 GP who had not received formal IG training. The officers and crew had not received familiarization or training specific to the IG system on the vessel and were unfamiliar with its operation. This was not required in the Algoma's safety management system (SMS) for its tankers. The Marine Personnel Regulations require that each member of the complement be familiar with the shipboard equipment prior to operating it.Footnote 13

Prior occurrence

On the evening of 19 July 1997, an explosion and fire occurred on board the tanker Petrolab while the crew was washing cargo oil tanks in preparation for loading cargo.Footnote 14 The ship's owner was killed and 3 members of the crew, 1 of whom later died in hospital, were injured by the explosion. The Board determined that the explosion occurred due to an accumulation of gasoline vapour in the after cofferdam, tween-deck space and engine room. The owner and crew's lack of knowledge regarding tanker safe working practices as well as their improvised and unsafe working practices were contributing factors.

The Marine Safety Advisory (MSA) No. 02/98 apprised TC of several unsafe work practices, such as tank washing with improper equipment and slop transfer into inadequate spaces, which had been followed for many years on the Petrolab. Such practices were the result of crew members' insufficient awareness of the hazards inherent to tanker operations. Not all crew members held a petroleum tanker endorsement and those who did had never taken a petroleum tanker safety course. Consequently, unsafe work practices were perpetuated and reinforced. The MSA indicated the need for TC to reassess its requirements for the issuance and renewal of petroleum tanker endorsements. The Marine Personnel Regulations now require tanker endorsements to be re-validated every 5 years; specifically, those personnel who have not accumulated 1 year of sea time within the 5 previous years must take the Specialized Oil Tanker Training endorsement course.

Analysis

Source of combustible vapour and ignition

Three elements must be present for an explosion to occur: fuel, oxygen and an ignition source.

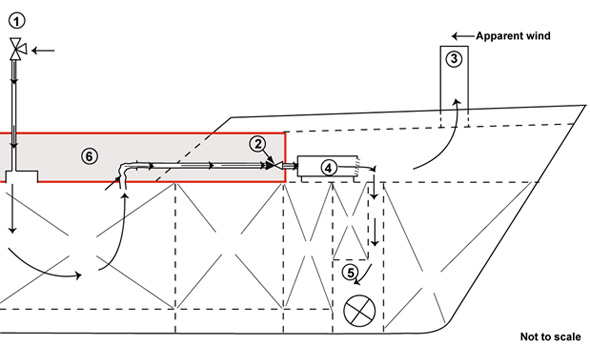

In this occurrence, given that the forecastle door was open, the apparent wind across the vessel's bow created an area of lower pressure in the forecastle. This, coupled with the open PV valves, induced a flow of gasoline vapours from the cargo tank into the forecastle through the drying unit and the modified non-return valve. Once the heavier-than-air vapours passed through the tank-drying unit, they settled downward and into the bow thruster compartment (see Figure 3).

This compartment contained a heater unit that was automatically controlled by a thermostat, along with electrical lighting fixtures and a ventilation fan, none of which were explosion-proof. Smoke and burn patterns on the electric heater indicated that it was likely the ignition source.

Valve modifications

It was the practice on the AlgoCanada to use the tank-drying system to vent and gas-free the cargo tanks. However, the air flow of the tank-drying unit was found to be inadequate for this purpose. Modifications to the double non-return valve were subsequently performed, which included the removal of 1 of the 2 valve plates. This improved air flow and shortened ventilation times.

Neither the valve's manufacturer nor the classification society was consulted regarding the valve's modification, which had effectively rendered it a single, non-return valve. Given that the vapours were subsequently able to migrate into the forecastle and bow thruster compartment, the remaining single valve plate was not an effective seal.

Use of inappropriate ventilating equipment

When ventilating cargo tanks without first inerting, it is essential that a sufficient volume of air be supplied to ensure the atmosphere in the tank passes through the flammable range as rapidly as possible. The AlgoNova's P&A Manual stated that such volumes were to be moved by portable water-driven fans through tank-cleaning hatches. It was practice on board, however, to use the fixed tank-drying system, even though this had not been approved or designed for ventilation. Combined with the modification to the double non-return valve, this practice allowed migration of explosive vapours into the bow thruster compartment.

Use of inert gas

An effective method for reducing the risk of explosion in a cargo tank is to reduce the amount of oxygen to a level that does not support combustion. This can be done by replacing existing air with inert gas, which is a recommended best practice for all product tankers, regardless of tonnage. For example, the International Safety Guide for Oil Tankers and Terminals (ISGOTT) states that, "During a ballast passage, cargo tanks other than those required to be gas free should remain in the inert condition and under positive pressure to prevent ingress of air."

In this occurrence, when the AlgoCanada left Sydney, Nova Scotia, in ballast, the cargo tanks' atmosphere was in an "over-rich" condition. Although the vesselwas equipped with an IG system, this was not used. Moreover, the crew was not familiar with the ship's IG system, nor were there procedures to maintain cargo tanks in an inerted condition.

It is accepted practice to purge the tanks of hydrocarbon vapour using IG prior to venting cargo tanks with air. In this manner, the transition from the inerted condition to gas free is done without passing through the flammable range bounded by the upper and lower explosive limits.Footnote 15 Had the cargo tanks been inerted during discharge and subsequently purged before venting, there would have been insufficient explosive vapour available to migrate to the bow thruster compartment and the risk of an explosion occurring greatly reduced.

Further, as demonstrated by this occurrence, vessels that do not inert cargo tanks or follow accepted procedures for purging and tank venting are at increased risk of fire and explosion, particularly during critical ventilation operations.

Safety management systems

According to the International Management Code for the Safe Operation of Ships and For Pollution Prevention (ISM Code), a critical objective of a vessel's SMS is for a company to "assess all identified risks to ships, personnel and the environment and establish appropriate safeguards."Footnote 16 This is achieved through plans, instructions and written procedures for key shipboard special and critical operations to ensure safe operation of ships and protection of the environment. Typically, many of these plans and instructions are found in onboard documents used to detail a SMS.

The ISM Code also addresses the company's responsibilities for resources and personnel, making reference to qualifications, competence, manning, familiarization and, in particular, the training of officers and crew.

Shipboard procedures

At the time of this occurrence, Algoma's SMS did not ensure safeguards in the form of procedures and practices relating to ventilation and the requirement for the use of IG—2 common, critical safety tanker operations. Furthermore, the system did not refer to or incorporate the P&A Manual's guidance regarding the appropriate equipment to use for tank ventilation. This meant the crew relied on informal verbal instructions and their own previous experience when venting tanks, both of which proved insufficient.

As a consequence, without formal procedures and training to mitigate the risks associated with tanker operations, the effectiveness of the vessel's SMS was reduced, placing the vessel, crew and environment at greater risk.

Timely reporting

For vessels under the conduct of a pilot, the master retains overall responsibility for the safety of the vessel, but relies on the pilot's local knowledge and ability to handle the vessel in a safe and efficient manner. This includes being advised of the reporting requirements to which a vessel is subject.

As per Canadian regulations,Footnote 17 it is a requirement to report an accident as soon as possible to the closest, relevant authority while in Canadian waters. This allows resources to be activated or put on standby.

In this occurrence, as the vessel was in the Seaway, the master was required to report the explosion to the nearest Seaway, Canadian or U.S. Coast Guard radio or traffic station. The master, however, reported the explosion first to the company and then contacted Transport Canada about 90 minutes after the explosion. No one involved informed SLSMC until 3.5 hours after the occurrence. Moreover, MCTS, which normally alerts other appropriate agencies, was not notified until 72 hours after the incident and even then, only by the TSB.

Although, in this case, there was no loss of life and the vessel was able to proceed to the next port without disrupting traffic, an explosion aboard a tanker in such a busy area still represents a significant event. Failure to report this to appropriate authorities can preclude organizations from launching a timely and coordinated response during an emergency.

Findings

Findings as to causes and contributing factors

- The inappropriate practice of using the tank-drying equipment for cargo tank ventilation allowed the migration of explosive vapours into the bow thruster compartment.

- The modification of the double non-return valve reduced its effectiveness and contributed to the migration of explosive vapours into the forecastle and bow thruster compartment.

- It is likely that an electric heater in the bow thruster compartment provided the ignition source for the explosion.

- Without formal procedures and training to mitigate the risks associated with tanker operations, the effectiveness of the vessel's safety management system (SMS) was reduced.

Findings as to risk

- Vessels that do not inert cargo tanks or follow accepted procedures for purging and tank venting are at increased risk of fire and explosion, particularly during critical ventilation operations.

- Failure to report accidents to appropriate authorities can preclude organizations from launching a timely and coordinated response during an emergency.

Safety action

Action taken

TSB

On 21 December 2009, the TSB issued a Marine Safety Advisory letter,Footnote 18 inviting Algoma Tankers to review the practices and procedures for tank gas freeing to ensure that the appropriate equipment and practices are used.

Algoma Tankers

After the occurrence, the following interim action was taken:

- The AlgoCanada's fixed tank-drying system was switched off and fitted with a lock so that it could not be operated. The master posted a notice indicating that the system was not to be used.

- Blanks were fitted to each of the tank-drying system's outlet covers on both AlgoCanada and AlgoNova. These blanks are fitted with locks, preventing connection of the cargo tanks to the tank-drying system and forecastle space.

- On the AlgoCanada and AlgoNova, both double non-return valve plates were reinstalled.

- On the AlgoCanada, a blank flange was fitted to the fixed tank-drying system between the fan unit and the distribution system.

With respect to gas monitoring, the fixed gas monitoring system was expanded to include the forecastle and bow thruster spaces.

The company has subsequently implemented a policy whereby this type of tank-drying system (fans fitted outside of the cargo block area) will not be used for ventilation. This system will only be used for tank drying and only after compartments have been ventilated using portable fans.

With respect to the vessel's Safety Management Manual (SMM), the following revisions and procedures were instituted:

- The SMM was revised on 30 September 2009 and fleetwide Tank Venting Permit and Procedures were implemented. Development and implementation of this process included a review of International Safety Guide for Oil Tankers and Terminals (ISGOTT) procedures, which were incorporated into the SMM. An Incident Sharing and Management of Change process presentation was also developed and communicated to the fleet. The cargo section of the manual was also revised to include a reference to the guidance offered in the P&A Manuals for both venting and cargo operations

- AlgoNova crew training was conducted on 26 August 2009, with the remaining fleet members being trained by 30 September 2009.

- Inert gas (IG) training was given to all shore staff and a large number of crew members.

- Effective 14 February 2010, all ships in the fleet that were equipped with IG systems had been operating in an inert condition. Service engineers from the IG system original equipment manufacturer were brought aboard all vessels for system inspections and training purposes. This was done on all ships fitted with IG systems in the Algoma fleet (AlgoNova, AlgoCanada and Algoma Dartmouth).

- Every ship in the fleet has performed 2 "safety standdowns," the purpose of which was to review the incident, share lessons learned and reinforce the use of the company's Management of Change process.

- IG and cargo tank-venting systems have been added to the list of critical equipment.

- A copy of each vessel's P&A Manual was sent to an outside resource for review. That review has been completed and Algoma is in the process of drafting all P&A Manuals in a uniform format. Once completed, the drafts will be reviewed prior to submission to Class for approval.

This report concludes the Transportation Safety Board's investigation into this occurrence. Consequently, the Board authorized the release of this report on .