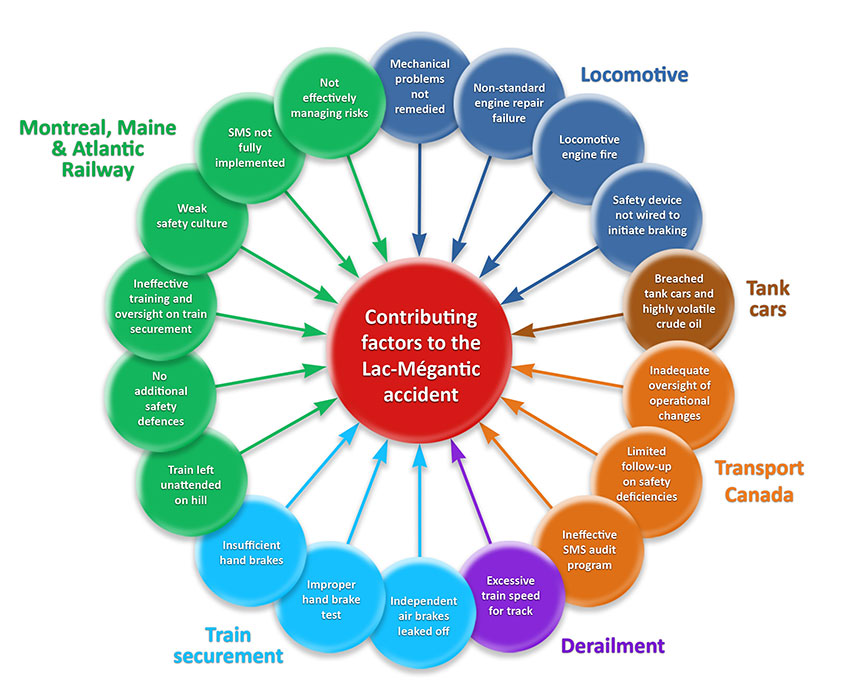

Investigation findings in the July 2013 rail accident in Lac-Mégantic, Quebec

The investigations conducted by the Transportation Safety Board of Canada (TSB) are complex, and it is never just one factor that causes an accident. The July 2013 train accident in Lac-Mégantic, Quebec, was no exception. There were many factors that caused this accident, the details of which are contained in the 18 findings as to causes and contributing factors. Furthermore, there were 16 additional findings as to risk as well as 6 other findings.

Findings as to causes and contributing factors

- MMA-002 was parked unattended on the main line, on a descending grade, with the securement of the train reliant on a locomotive that was not in proper operating condition.

- The 7 hand brakes that were applied to secure the train were insufficient to hold the train without the additional braking force provided by the locomotive’s independent brakes.

- No proper hand brake effectiveness test was conducted to confirm that there was sufficient retarding force to prevent movement, and no additional physical safety defences were in place to prevent the uncontrolled movement of the train.

- Despite significant indications of mechanical problems with the lead locomotive, the locomotive engineer and the Bangor, Maine, rail traffic controller agreed that no immediate remedial action was necessary, and the locomotive was left running to maintain air pressure on the train.

- The failure of the non-standard repair to the lead locomotive’s engine allowed oil to accumulate in the turbocharger and exhaust manifold, resulting in a fire.

- When the locomotive was shut down as a response to the engine fire, no other locomotive was started, and consequently, no air pressure was provided to the independent brakes. Further, locomotives with an auto-start system were shut down and not available to provide air pressure when the air brake system began to leak.

- The reset safety control on the lead locomotive was not wired to initiate a penalty brake application when the rear electrical panel breakers were opened.

- Because air leaked from the train at about 1 pound per square inch per minute, the rate was too slow to activate an automatic brake application.

- When the retarding brake force provided by the independent brakes was reduced to about 97 400 pounds, bringing the overall retarding brake force for the train to approximately 146 000 pounds, the train started to roll.

- The high speed of the train as it negotiated the curve near the Megantic West turnout caused the train to derail.

- About one third of the derailed tank car shells had large breaches, which rapidly released vast quantities of highly volatile petroleum crude oil, which ignited, creating large fireballs and a pool fire.

- Montreal, Maine & Atlantic Railway did not provide effective training or oversight to ensure that crews understood and complied with rules governing train securement.

- When making significant operational changes on its network, Montreal, Maine & Atlantic Railway did not thoroughly identify and manage the risks to ensure safe operations.

- Montreal, Maine & Atlantic Railway’s safety management system was missing key processes, and others were not being effectively used. As a result, Montreal, Maine & Atlantic Railway did not have a fully functioning safety management system to effectively manage risk.

- Montreal, Maine & Atlantic Railway’s weak safety culture contributed to the continuation of unsafe conditions and unsafe practices, and compromised Montreal, Maine & Atlantic Railway’s ability to effectively manage safety.

- Despite being aware of significant operational changes at Montreal, Maine & Atlantic Railway, Transport Canada did not provide adequate regulatory oversight to ensure the associated risks were addressed.

- Transport Canada Quebec Region did not follow up to ensure that recurring safety deficiencies at Montreal, Maine & Atlantic Railway were effectively analyzed and corrected, and consequently, unsafe practices persisted.

- The limited number and scope of safety management system audits that were conducted by Transport Canada Quebec Region, and the absence of a follow-up procedure to ensure Montreal, Maine & Atlantic Railway’s corrective action plans had been implemented, contributed to the systemic weaknesses in Montreal, Maine & Atlantic Railway’s safety management system remaining unaddressed.

Findings as to risk

- If a proper hand brake effectiveness test is not performed, equipment may not be adequately secured, increasing the risk of a runaway.

- If hand brakes are applied on the operating locomotive(s) during a hand brake effectiveness test, this may result in an inaccurate effectiveness test, increasing the risk of runaways.

- Given the variable condition of locomotive hand brakes, counting them as part of the total number of hand brakes required can lead to overestimating the braking force, thereby increasing the risk of a runaway.

- If equipment is left unattended without additional physical safety defences, there is an increased risk that it will run away leading to an accident.

- If railways implement single-person train operations without identifying all risks, and if mitigation measures are not implemented, an equivalent level of safety to that provided by multi-person crews will not be maintained.

- If there are no rules and regulations for single-person train operations, nor a requirement for Transport Canada to approve and monitor railways’ plans, then single-person trains may operate without all of the necessary defences in place.

- If trains are left unattended in easily accessible locations, with locomotive cab doors unlocked and the reverser handle available in the cab, the risk of unauthorized access, vandalism, and tampering with locomotive controls is increased.

- If poor rail and joint conditions are not addressed, there are increased stresses on wheels and rails, which may lead to damaged equipment or infrastructure, thus increasing the risk of derailment.

- If systematic testing is not conducted on representative samples of petroleum crude oil at an appropriate frequency, there is an increased risk that these dangerous goods will be improperly classified.

- If not properly classified and documented, dangerous goods may be moved and handled incorrectly, increasing the risk of injury to people, and of damage to property and the environment.

- Without monitoring and effective enforcement of compliance with applicable classification provisions of the Transportation of Dangerous Goods Regulations, there is a risk that improperly classified dangerous goods will enter the transportation system.

- If Class 111 tank cars that do not meet enhanced protection standards transport flammable liquids, there is an ongoing risk of product loss and significant damage to persons, property, and the environment when these cars are involved in accidents.

- If the shipper has not developed an adequate, regulator-approved emergency response assistance plan, the required resources to assist local responders may not be available in the event of an accident involving large quantities of liquid hydrocarbons.

- If route planning, analysis and follow-up risk assessments are not conducted by railways along routes where dangerous goods are carried, comprehensive safety measures to mitigate the risks may not be introduced.

- If Transport Canada does not audit the safety management systems of railways in sufficient depth and frequency and confirm that corrective actions are effectively implemented, there is an increased risk that railways will not effectively manage safety.

- Without sufficient national monitoring, Transport Canada does not have adequate assurance that its Regions are providing effective oversight of regional railways to ensure that the risks to the public are being properly managed.

Other findings

- It could not be concluded whether single-person train operations contributed to the incorrect securement of the train or to the decision to leave the locomotive running at Nantes, Quebec, despite its abnormal condition.

- The petroleum crude oil being transported by the train was improperly classified; it was assigned packing group III (lowest hazard), despite meeting the criteria for packing group II.

- The Nantes Fire Department had to shut down the locomotive to stop the flow of oil, which was feeding the fire. Their actions were consistent with railway instructions.

- The track geometry condition was adequate for the existing traffic and was acceptable for the speed allowed (15 mph) for trains travelling through Megantic Station.

- Despite the challenges of responding to a major disaster not specifically covered by many firefighters’ practical training, the emergency response was conducted in a well-coordinated and effective manner.

- The regulatory requirements in place at the time of this accident did not ensure an increase in risk was reflected in Montreal, Maine & Atlantic Railway’s insurance coverage.