Nose landing gear failure to extend

Air Georgian Limited

Beechcraft 1900D, C-GORF

Calgary International Airport, Albert

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

On 12 July 2016, an Air Georgian Limited Beechcraft 1900D (serial number UE-330, registration C-GORF) was operating as Air Canada Express flight GGN7212 from Lethbridge Airport, Alberta, to Calgary International Airport, Alberta, with 2 crew members and 15 passengers on board. When the landing gear was selected down for the approach into Calgary, the flight crew observed that there was no gear-safe indication for the nose landing gear. The flight circled east of Calgary for about an hour while the pilots attempted to rectify the problem. An emergency was declared. The aircraft landed at 0720 Mountain Daylight Time, during daylight hours, with the nose gear in a partially extended position. No fire occurred, and there were no injuries.

Le présent rapport est également disponible en français.

1.0 Factual information

1.1 History of the flight

Air Georgian Limited (Air Georgian) flight 7212 (GGN7212) was a scheduled Air Canada Express flight from Lethbridge Airport (CYQL), Alberta, to Calgary International Airport (CYYC), Alberta, on 12 July 2016. The flight was operated using a Beechcraft 1900D, registration C‑GORF, with 15 passengers (including 1 infant) and 2 pilots on board. The first officer was the pilot flying and occupied the right-hand seat; the captain was the pilot not flying and occupied the left-hand seat.

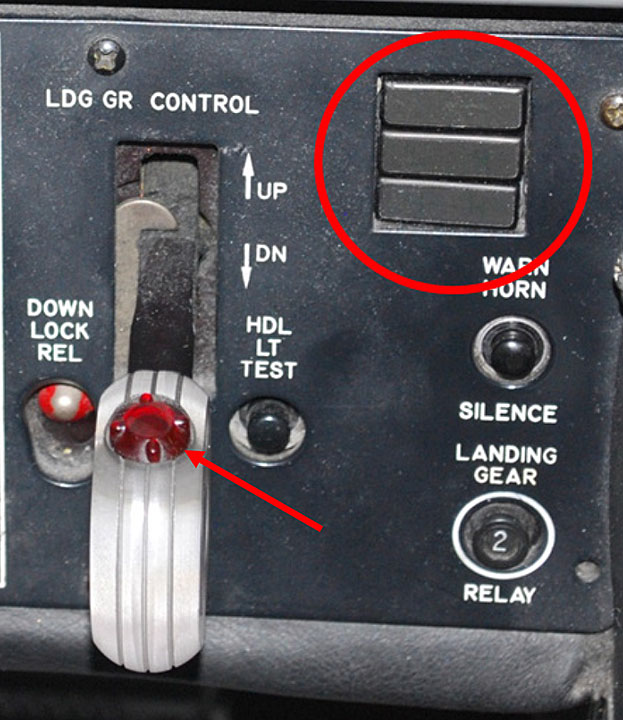

GGN7212 departed CYQL at 0531Footnote 1 and climbed to the flight-planned altitude of 11 000 feet above sea level (ASL). The flight progressed normally into CYYC until 0610, when the flight crew selected the landing gear down. When the landing gear began to extend, a grinding, banging noise was audible. When the landing gear extension sequence stopped, the flight crew observed 1 green down indicator light for each of the main landing gears, but no green indicator light for the nose landing gear. The in-transit light in the landing gear handle was extinguished (Figure 1).

The flight crew requested radar vectors in order to perform the appropriate checklist and to cycle the landing gear. They observed the same indication as before. At 0640, they performed a flyby of the control tower. The personnel in the tower observed that the nose landing gear was not in the fully extended position. The nose landing gear was trailing about 20° to 30° below the horizontal retracted position.

At 0650, GGN7212 entered a holding pattern east of the airport at 8000 feet ASL. The flight crew was in contact with Air Georgian maintenance, and troubleshooting continued. The landing gear was cycled again, both hydraulically and manually, with no change in the indication. A Calgary Police Service aircraft was in the area and its crew offered to look at the aircraft. They communicated that the nose landing gear was in a trailing position, but they could not see any fluid leaks.

At 0700, GGN7212 had 800 pounds of fuel remaining, and it was decided to land the aircraft. The flight crew and Air Georgian management discussed considerations of what to do with a partially extended nose landing gear. It was decided that a normal landing configuration would be used and that the nose would be lowered to the runway surface as smoothly as possible.

The flight crew requested vectors for the visual approach to Runway 35R at 0705 and declared an emergency. A few minutes later, they requested that airport rescue and firefighting vehicles be put in position. At this time, the captain took over pilot-flying duties from the first officer. At 0710, the captain briefed the passengers on the landing and asked them to review the emergency exits and brace position on the briefing card. He also stated that no one was to get up and exit the aircraft until instructed to do so by the flight crew.Footnote 2

At 0717, GGN7212 was on final approach to Runway 35R and was switched from the control tower frequency to the emergency frequency. A few minutes later, at about 300 feet above ground level (AGL), the captain instructed the passengers to brace. At 0720, GGN7212 touched down on the main landing gear. The first officer feathered both propellers,Footnote 3 placed both engine condition levers in the fuel cut-off position, and pulled both FIRE PULL/T handles.Footnote 4 About 20 seconds later, the nose touched the runway. The aircraft slid on its nose for another 20 seconds before coming to a stop 6950 feet from the runway threshold (Figure 2). Emergency vehicles reached the aircraft in 30 seconds, and all passengers and crew deplaned within 1 minute.

Some smoke and fumes were present in the cabin due to the nose scraping along the runway, but there was no fire. The actions of the flight crew resulted in minimal damage to the aircraft and no injuries to the passengers.

1.2 Injuries to persons

All passengers and crew exited the aircraft without injury.

1.3 Damage to aircraft

Damage to the aircraft was limited to the nose landing gear components, the nose gear door and gear light, as well as 2 propeller tips on each side of the aircraft that contacted the runway.

1.4 Other damage

Not applicable.

1.5 Personnel information

| Captain | First officer | |

| Pilot licence | Airline transport pilot licence (ATPL) | Airline transport pilot licence (ATPL) |

| Medical expiry date | 01 March 2017 | 01 July 2017 |

| Total flying hours | 3621 | 3069 |

| Flight hours on type | 1564 | 608 |

| Flight hours in the last 7 days | 24.8 | 4.2 |

| Flight hours in the last 90 days | 141.5 | 131.3 |

| Flight hours on type in the last 90 days | 141.5 | 129.5 |

| Hours on duty prior to occurrence | 2.5 | 2.5 |

| Hours off duty prior to work period | 8 | 13 |

1.6 Aircraft information

1.6.1 General

The Beechcraft 1900D is a 19-passenger, pressurized twin-engine turboprop fixed-wing aircraft manufactured by Raytheon Aircraft Company. It was designed as a regional aircraft and is generally used as such, on airports with shorter runways. Its usual trip length is about 600 miles. The 1900D is a common aircraft model; 439 of them have been built. Raytheon ended production of the 1900D in October 2002. Detailed information about C-GORF is shown in Table 2.

| Manufacturer | Raytheon Aircraft Company |

| Type, model and registration | B190, 1900D, C-GORF |

| Year of manufacture | 1998 |

| Serial number | UE-330 |

| Certificate of airworthiness/flight permit issue date | 30 October 1998 |

| Total airframe time | 33 958.3 hours |

| Engine type (number of engines) | Pratt & Whitney Canada, PT6A-67D (2) |

| Propeller/rotor type (number of propellers) | Hartzell HC-E4A-3J (2) |

| Maximum allowable take-off weight | 7688.39 kg |

| Recommended fuel type(s) | Jet A, Jet A-1, Jet B |

| Fuel type used | Jet A |

1.6.2 Landing gear description

The Beechcraft Corporation Model 1900D Airliner Maintenance ManualFootnote 5 describes the 1900D as equipped with a retractable tricycle landing-gear system. The nose and main landing‑gear assemblies are extended and retracted by a hydraulic system consisting primarily of an actuator located in each wheel well, a hydraulic power pack located in the left wing, and hydraulic plumbing. During extension and retraction, the nose gear actuator exerts pressure through an aluminum yoke fitting attached to the end of the actuator piston (Figure 3). This yoke is attached to the middle of the upper and lower drag braces, and causes the drag braces, when folding or unfolding, to extend or retract the nose gear. The yoke (item 8 in Figure 3) is attached and pivots through the braces by means of a pivot/stop bolt, part number 114-820107-1 (item 34 in Figure 3).

1.7 Meteorological information

The CYYC hourly meteorological observation for 0700 was as follows: wind direction 310° true (T) at 8 knots, visibility 30 statute miles, a few towering cumulus clouds based at 2500 feet AGL, scattered clouds at 10 000 feet AGL and 21 000 feet AGL, a broken layer of cloud at 24 000 feet AGL, temperature 15 °C, dew point 8 °C, and an altimeter setting of 29.87 inches of mercury. The density altitude was 4400 feet ASL.

Weather was not considered a factor in this occurrence.

1.8 Aids to navigation

All aids to navigation were serviceable and had no impact on this occurrence.

1.9 Communications

There were no communication problems between the aircraft and air traffic control or on the company frequency.

1.10 Aerodrome information

CYYC has 2 parallel runways: Runway 35L/17R is asphalt and 12 675 feet long, and Runway 35R/17L is concrete and 14 000 feet long. It also has Runway 29/11, which is asphalt and 8000 feet long, and Runway 08/26, which is asphalt and 6200 feet long.

There were no issues involving any aerodrome systems.

1.11 Flight recorders

The digital flight data recorder (DFDR) was a Loral model F1000 solid-state unit (part number S703‑1000-00, serial number 01685). The unit was undamaged. The data were downloaded using Loral equipment, and approximately 102.7 hours of flight data were recovered, including that of the occurrence flight.

No parameters associated with the landing gear or hydraulics were recorded by the DFDR. The recorded information was consistent with the reported maneuvering to troubleshoot the gear problem, including the hold and subsequent tower flyby.

The main landing gear touched down at approximately 97 knots indicated airspeed. Within 6 seconds of main gear contact, the propeller revolutions per minute were reduced and the propeller then stopped, consistent with the FIRE PULL/T-handles being pulled and the propellers moving into the feathered position. The nose gear was held off the runway with progressive aft control‑column input until the nose settled on the runway about 28 seconds after main gear contact. Nose contact with the runway occurred at approximately 52 knots indicated airspeed.

1.12 Wreckage and impact information

There was minor damage. See Section 1.3.

1.13 Medical and pathological information

There were no medical conditions noted or relevant to this report.

1.14 Fire

There was no pre- or post-incident fire.

1.15 Survival aspects

Not applicable.

1.16 Tests and research

1.16.1 Nose landing gear actuator yoke

The failure of the retract-and-extend mechanism of the nose landing gear was initiated by a yoke lubrication problem. The bolt with part number 114-820107-1 on the occurrence aircraft was not lubricated as required. The yoke should turn freely around the yoke's pivot/stop bolt; however, the occurrence yoke's pivot/stop bolt was seized in the yoke due to deteriorated grease and corrosion for 2 reasons: First, the deteriorated grease did not provide lubrication. Second, insufficient lubrication allowed the penetration of moisture between the bolt and the bore surface, causing corrosion on both surfaces. The bolt seizure resulted in abnormal loading on the yoke's pivot/stop bolt and the actuator clevis during retraction and extension of the nose landing gear. This led to fatigue cracking and failure of the yoke's pivot/stop bolt ends.

From 31 August to the end of September 2016, the operator examined the condition of nose landing gears in its fleet and found 5 more Beechcraft 1900D aircraft with non-airworthy nose landing gear yoke pivot/stop bolts, as well as several other nose landing gear bolts.

1.16.2 TSB laboratory reports

The TSB completed the following laboratory reports in support of this investigation:

- LP167/2016 – Failed NLG [nose landing gear] Parts

- LP270/2016 – Examination of NLG [nose landing gear] Bolts

1.17 Organizational and management information

1.17.1 Air Georgian

1.17.1.1 General

Air Georgian, a subsidiary of Regional Express Aviation Ltd., was formed in 1984. The company operates Beechcraft 1900D and Bombardier CL-600-2B19 (CRJ-100 and -200) series aircraft. Since 2000, it has operated as a Tier IIIFootnote 6 air carrier for Air Canada and done business under the brand name of Air Canada Express.Footnote 7 The company provides scheduled passenger and executive charter flights under Canadian Aviation Regulations (CARs) subparts 705 and 704, as well as aircraft maintenance, management, and training services to major airlines, corporations and individuals. Its head office is located in Toronto, Ontario. The company has approximately 350 employees, including pilots, maintenance personnel, office staff, and management. These employees work at the various bases.

1.17.1.2 Air Georgian approved maintenance organization

Air Georgian is a Transport Canada (TC)–approved maintenance organization (AMO). According to the company's Maintenance Policy Manual,Footnote 8 its main maintenance base is located at Toronto/Lester B. Pearson International Airport (CYYZ), Ontario, and its sub-bases are located at CYYC, as well as at Charlottetown Airport (CYYG), Prince Edward Island, and at Kingston/Norman Rogers Airport (CYGK), Ontario.

The AMO is managed by the vice president of maintenance / person responsible for maintenance (PRM), who is responsible for all work performed on the company aircraft. The PRM manages all work performed, with the assistance of base managers, shift supervisors, and crew chief personnel.

1.17.1.3 Air Georgian safety management system

Potential deficiencies in defences against performance error can be mitigated by a formal safety management system (SMS). A formal SMS may contain multiple mechanisms to monitor and improve safety, such as proactive risk assessments, quality control and assurance, and reactive reporting mechanisms. Regulations require TC-approved maintenance organizations, working for CARs Subpart 705 operators, to establish and maintain a formal SMS. Air Georgian is the holder of an AMO certificate and works on CARs Subpart 705 aircraft, so it has an approved SMS.

Air Georgian's SMS ManualFootnote 9 sets out how the company will comply with CARs Subpart 107 (Safety Management System Requirements). It was initially assessed and approved by TC in 2013 and is subject to periodic evaluation.

Air Georgian's SMS ManualFootnote 10 states that the SMS manager reports indirectly to the accountable executive, and directly to the vice president of aircraft maintenance. The company organizational chart, however, shows that the SMS manager reports only to the vice president of aircraft maintenance.

1.17.1.4 Air Georgian hazard identification

Air Georgian's SMS Manual stated that hazard identification is

Footnote 11A principal method for identifying both potential (proactive) and actual (reactive) hazards is the use of aviation safety reports (ASRs).Footnote 12 Employees or their supervisors can submit ASRs through the SMS. Anonymous reports can also be made. Employees are required to receive instruction on submitting ASRs as part of their SMS training.

Based on information gathered during the investigation, the following determinations were made:

- Screenshots of Air Georgian's ASR interfaceFootnote 13 indicated that any reportable hazard could be reported by means of an ASR or a maintenance safety report (MSR). Maintenance employees referred to the hazard reports only as ASRs, not MSRs. The database did not contain any MSRs.

- If an MSR was required, the employee would select the report type from the ASR main-page drop-down menu.

- The list of 43 types of "reportable events"Footnote 14 listed in the SMS Manual was not considered exhaustive, and there were provisions for the user to enter any event. However, some maintenance employees considered only aircraft system issues or health and safety issues to be maintenance-related reportable events.

- Any maintenance event that resulted in additional work was captured using additional work cards. There was no process or practice to follow up on an additional work card with an ASR or MSR, if appropriate.

- Everyday maintenance hazards were occasionally reported to the crew chief, although they were not captured by any ASR or MSR. For example, Transportation Safety Board of Canada (TSB) investigators observed an instance in which incorrect grease cartridges had been loaded into grease guns, and this was reported to the crew chief. Investigators also observed an instance in which old grease was not expelled from the bolt outer edge/yoke surface when fresh grease was applied, which indicated a dry bolt; this was not reported. (See Section 1.17.2.10 for details.)

- When everyday maintenance hazards were reported to the crew chief, they were not always documented in the crew chief's shift hand-over log.Footnote 15 There were variations in criteria for recording events in this log. Even when events were recorded, there was no documented process or practice to confirm that each report was followed up with an ASR or to track log entries as part of the SMS.

1.17.1.5 Air Georgian quality assurance program

Air Georgian has a quality assurance program, as required by CARs Subpart 573 (Approved Maintenance Organizations) and Part VII (Commercial Air Services).

As stated in Air Georgian's Maintenance Policy Manual,

sic Footnote 16The manual states that quality assurance covered all functional areas of the organization to ensure effectiveness, quality, and safety, as required by the CARs.Footnote 17 This includes an audit of company processes, procedures, and production of corrective action plans (CAPs) for audit findings.

Air Georgian's quality assurance activities did include a process whereby

Footnote 18The Audit of the Audit SystemFootnote 19 ensures that the root causes of these audit findings are identified, and that corrective actions are appropriate to the root cause and are taken within the specified time frame.

1.17.1.6 Air Georgian audit system

The Air Georgian quality assurance program consists of internal audits and CAPs to address items of non-conformity. Individual audits are conducted progressively on an annual basis with a tolerance of +/− 30 days. The audits are intended to identify and document areas that do not comply with regulations, standards, processes, or company policy and procedure manuals. Audit checklists are developed by Air Georgian and are required by regulationFootnote 20 to cover all functional areas and activities controlled by the company.

Records are kept to document each instance of compliance or non-compliance found through the audit. Any findings of non-compliance are communicated to the appropriate process manager using a company‑generated CAP form. The process manager then implements the required CAP to ensure that the actions taken remain effective.

The CAP is required to list immediate, short‑term (30-day), and long‑term (90‑day) actions put in place by the company to prevent these findings from recurring. CAPs are tracked by company software. When corrective actions cannot be implemented within the short‑term and long‑term time frames, an extension may be justified and may be approved, by the PRM or applicable operations manager only, with documentation to support the extension.

To evaluate the effectiveness of Air Georgian's audit system, the investigation examined 14 of the company's previous CAPs. The investigation determined that 12 of the CAPs did not meet the timelines specified in Air Georgian's Maintenance Policy Manual.

In the case of CAP 1192, for instance, which addressed incorrect actions to accomplish service bulletins on the Bombardier Regional Jet fleet, the internal audit date was 10 March 2016, and the CAP's issue date was 01 April 2016. The immediate actions section stated that Aircraft Programs had started to review mandatory service bulletins for applicability. The short‑term actions should have been completed as of 01 May 2016 (30 days) and the long‑term actions should have been completed as of 30 June 2016 (90 days). The short‑term actions section states that none were taken; the short‑term action completion date was not recorded. The long‑term actions were not started until 03 January 2017, about 180 days after they should have been completed. The CAP contained no comments or explanations for timeline extensions, nor were there any documented extension approvals.

In another instance, CAP 1129 identified a lack of required SMS training for managers. The internal audit date was 30 September 2015, and the issue date was 01 October 2015. The short‑term actions should have been completed at 30 days and the long‑term actions should have been completed at 90 days. Immediate actions taken were documented 122 days after the CAP was issued. Although the short‑term actions section did not include any action date or completion date, the short‑term action quality assurance approval was dated 12 January 2016.

The long-term actions section for CAP 1129 had no recorded comments and the long-term action completion date was 104 days after the CAP was issued (13 January 2016). The long-term action quality assurance approval date was 5 days later (18 January 2016), and final approvals by management and the accountable executive were not completed until 11 February 2016, and the CAP was closed on 11 February 2016, 133 days after the CAP was opened. The 6-month follow-up comments, dated 14 August 2016, stated that not all managers had been trained and that additional follow-up was scheduled for 12 December 2016.

As part of this investigation, the TSB visited Air Georgian's main base, in Toronto, from 30 January to 01 February 2017. During this time, the required SMS training for managers, as per CAP 1129, was still outstanding and incomplete.

Additionally, as of 30 January 2017, more than 6 months since the date of this occurrence, Air Georgian's related internal SMS investigation report into the events pertaining to flight GGN7212 remained at the short-term action stage (30 days). Air Georgian stated that it was waiting for the results of the TSB investigation before concluding the short‑term action of the internal SMS investigation. Additionally, no long-term plan had been initiated as of 30 January 2017.

1.17.1.7 Air Georgian quality control

Quality control inspections at Air Georgian, called "required inspection items," fall under 2 categories: independent checks and critical system checks (CSs).

According to CARs Standard 571.10 (Maintenance Release), whenever work is performed that disturbs engine or flight controls, an additional inspection of the system must be accomplished by an appropriately trained person for correct assembly and locking of any parts disturbed by the maintenance performed, including an operational check for proper sense and range of motion. The person performing this inspection cannot be the person who performed the initial work that disturbed the system. This inspection is often referred to as a "dual inspection" or "independent check," as described in Airworthiness Notice (AN) No. C010.Footnote 21 The technical record is to contain the signature of the person who performed the independent check and the signature of the person who signs the maintenance release for the completion of the check.

In addition to independent checks, Air Georgian also performs CSs,Footnote 22 which are not required by regulation. CSs can be initiated at the discretion of a technician or aircraft maintenance engineer (AME) to implement additional inspection requirements for systems deemed critical to aircraft operation and safety, excluding the items that would require an independent check.

CSs call for the system to be inspected for correct assembly and correct locking of any parts disturbed by the maintenance performed. CSs are recorded in the technical record (additional work cards, inspection sheets, or journey logbook) and contain the signatures of the persons conducting the check.

Air Georgian's Maintenance Policy ManualFootnote 23 states that a list of tasks requiring independent checks and CSs is found on the front cover of the journey logbook and/or Part 5.11 of the Maintenance Procedures Manual. Neither contained any task listing. The Maintenance Procedures Manual referred the reader to Part 7: Certification Procedures, part 7.6, for details. The procedures recorded in part 7.6 pertained to the procedural process for the technician or AME to receive certification authorization of independent checks and CSs.

1.17.1.8 Safety personnel

Key safety roles at Air Georgian included the PRM, quality assurance manager, SMS manager, and safety officer. In the 2 years before the occurrence, there were 2 different vice presidents of maintenance holding the delegation of PRM. During transitions, there were 3 other instances in which other individuals assumed the role of PRM on an interim basis. From time to time, for short periods, the quality assurance manager held the PRM delegation and the SMS manager assumed the responsibility of the safety officer. Changes in key personnel are one of the risk indicators used by TC in assessing a company's risk factors.

1.17.1.9 Air Georgian maintenance training program

Air Georgian's aircraft maintenance training program is documented in the company Maintenance Policy Manual,Footnote 24 in accordance with CARs section 573.06. This provision of the CARs is general in nature, requiring companies to develop their own training program to ensure that maintenance personnel are adequately trained on their assigned tasks. Other than human factors training, the CARs and applicable standards do not detail training syllabus requirements. The training program required by the CARs includes initial, recurrent, and update training programs with human factors and regulatory training elements.

Air Georgian's Maintenance Policy Manual documented the aircraft maintenance training program as required and stated that the syllabus of each training program, in the corresponding Maintenance Procedures Manual,Footnote 25 shall include the programmed time allotted and the subject matter to be covered. There were no documented training syllabi for any of the courses in the Maintenance Procedures Manual, including the human‑factors trainingFootnote 26 that was required by regulation. Training courses were labelled "no procedures required at this time."

Maintenance training was managed as part of the flight-training department, with operations personnel overseeing the maintenance training program and records. The flight-training manager signed the training summaries that were provided to the investigation.

1.17.1.9.1 Computer-based training

Air Georgian had an in-house computer-based system for some of the training, such as corporate policies and procedures, SMS, occupational health and safety, aircraft "minimum equipment list," and the Maintenance Policy Manual. Human factors training was also provided online; the Maintenance Policy Manual stated, in accordance with regulations, that it should include factors such as fatigue, stress, norms, complacency, distraction, and pressure. Each online course was followed by an exam that required a passing grade of 100% within 3 attempts. If the trainee did not obtain a grade of 100%, senior Air Georgian maintenance staff would coach and counsel the trainee until he or she did achieve a grade of 100%. This coaching was not documented in any training procedures, nor was there any record of such coaching taking place.

It was noted during the investigation that human-factors training for technicians and AMEs did not include any practical opportunity for group discussion on error prevention or previous maintenance error examples. It was not possible to determine whether technicians and AMEs had any applied knowledge relating to human factors or potential hazards.

1.17.1.9.2 On-the-job training

Air Georgian also had an in-house, on-the-job technical training program. Once a trainee had completed this training, the trainer was to fill out an Occupational Standard Assessment form. It included 43 technical points to be checked off, such as "knowledge of standard practices." Air Georgian could not provide any completed versions of these forms.

There was no documented training syllabus for the on-the-job training program in the Maintenance Procedures Manual. On-the-job training was marked as "no procedures required at this time." On-the-job training was assessed by peer review only. There were also no company standards documented for any on-the-job competency or for any of the 43 technical points listed on the Occupational Standard Assessment form. Specifically, there were no training standards for "grease fittings," the success criterion of seeing new and old grease, "free rotation," or "determining the cause" if no free rotation. Therefore, there was no company standard to be trained or examined on for the lubrication or inspection tasks. The knowledge, rules, and skills required for these tasks were not detailed in any Air Georgian documentation or taught as part of any Air Georgian training syllabus.

There was no process in place to standardize on-the-job training. It was therefore not possible to determine the level of standardization of the on-the-job learning outcomes, particularly with regard to knowledge, rules, and skills related to the lubrication and inspection tasks.

1.17.1.9.3 Aircraft certification authority training

Except where maintenance is performed outside Canada or where TC has issued a restricted certifying authority, only the holder of an appropriately rated AME licence can sign a maintenance release for work performed on a Canadian-registered aircraft. In the case of an AMO, the AMO may authorize the holder of an appropriately rated AME licence to sign a maintenance release by granting an Aircraft Certification Authority (ACA), provided that the holder meets the requirements of section 571.11 of the CARs and successfully completes the AMO's training program. The CARsFootnote 27 require that the training and experience needed for an individual to qualify for ACA status, and the documentation needed to substantiate the ACA credentials, be documented in the AMO's Maintenance Policy Manual.

In line with CARs requirements, Air Georgian's Maintenance Policy Manual stated that

sic Footnote 28It was established that, in practice, for the Beechcraft 1900D fleet, an AME was required to complete on-the-job ACA training and a Beechcraft 1900D technical exam,Footnote 29 which contained 15 randomly generated questions on the Beechcraft 1900D. When the applicant was considered ready for ACA status, an ACA Nomination form was to be completed and sent to the corporate training department. This form included a checklist of training, such as "initial training," "6 months experience on type," and "company training requirements current."

There were no details in either the Maintenance Policy Manual or Maintenance Procedures Manual on what constituted an ACA's "combination of training and experience appropriate to that aircraft" or "required competencies," or on what was included in ACA on-the-job training. On-the-job ACA training was assessed by peer review only. There were no standards documented for any ACA on-the-job competency or for any of the training pre‑requisites listed on the ACA Nomination form. There were also no training standards for inspecting lubrication-related tasks.

TC-approved aircraft type courses are required for persons signing a maintenance release for work performed on transport-category aeroplanes or turbine-powered helicopters. These courses are intended to provide AMEs with the necessary level of knowledge in all aspects of aircraft maintenance, including all major systems of the aircraft type, powerplant, system or equipment in order to be compliant with CARs subsection 571.11(4) and to sign a maintenance release for the work performed on the aircraft type. For transport-category aeroplanes, such as the CRJ-200, CARs subsection 571.11(4) requires persons to have successfully completed a TC-approved type course before they may be authorized to sign a maintenance release.

However, the Beechcraft 1900D is categorized as a commuter aeroplane and persons working on only the Beechcraft 1900D are not required to receive type-specific training under CARs subsection 571.11(4). Therefore, the AMO's training program should ensure that persons performing maintenance on aircraft receive appropriate training in line with the person's maintenance responsibilities. An aircraft type course may be appropriate in some cases. For such non-transport category aircraft, the AMO is required to develop a means of testing and recording the AME's knowledge and skill on all applicable aircraft systems, and on a representative selection of practical tasks.

There was no company process in place to standardize on-the-job ACA training. It was not possible to determine the degree of standardization of on-the-job ACA learning outcomes, particularly with regard to knowledge, rules, and skills related to inspecting lubrication tasks.

Detailed maintenance training records were not made available for investigators to review; however, the investigation reviewed 11 ACA training record summaries. None of these, including the summaries for AMEs who had worked on the occurrence aircraft, indicated that the AME had taken the Beechcraft 1900D qualifying examination. Ten aircraft technicians' training records were also provided, and 2 of these indicated that the aircraft technician had taken the exam, but was not granted ACA status. However, training records for a separate Beechcraft 1900D exam list indicated that all 11 AMEs had taken the exam. It was not possible to determine, based on individual training summaries, which AMEs had taken a qualifying ACA exam and which AMEs were ACAs.

1.17.9.4 Training the trainers

Air Georgian's Maintenance Policy Manual stated the following:

Footnote 30In practice, a "qualified individual" was the in-charge base manager, the crew chief, an ACA, or an AME, and would be responsible for peer‑reviewing online and on-the-job training. The in‑charge base manager, the crew chief, and other ACAs were also responsible for peer‑reviewing on-the-job ACA training and completion of the Occupational Standard Assessment form and ACA Nomination form. Air Georgian's Maintenance Policy Manual stated that base managers should have at least "three years experience in the performance or direct supervision of maintenance activities"Footnote 31 and "[a]ssist in the instruction of on the job training."Footnote 32 Crew chiefs, ACAs, and AMEs were responsible for "[p]roviding practical on-site training and coaching to maintenance personnel."Footnote 33

There was no requirement or provision for individuals in any of these roles to receive instructor‑based training related to the competency and validity of their "demonstration and practice techniques,"Footnote 34 nor was this required by regulation. The knowledge, rules, and skills required for teaching, demonstrating, and assessing the lubrication and inspection tasks were not detailed in any Air Georgian documentation or taught as part of any Air Georgian instructor-based training syllabus. There were also no training or supervision-related competencies listed on the ACA Occupational Standard Assessment form or the ACA Nomination form.

1.17.1.10 Maintenance training records

According to subsection 573.07(1) of the CARs, AMOs are required to keep records of all qualifications, signing authorities, and training for all maintenance personnel. Not having or maintaining these records may lead to uncertainty about whether maintenance personnel are qualified or authorized to perform the required tasks.

The maintenance training records reviewed for Air Georgian's Calgary sub-base personnel were summaries only. These summaries were incomplete and not up to date. At the main base, in Toronto, there was no indication of the standards used to verify knowledge and ability before personnel were approved in any knowledge, process, or certification areas.

Air Georgian's standards, used for all training except computer-based, were simply a peer review with boxes to be checked off, and no records were provided to the investigation for this portion of Air Georgian's maintenance training. Similarly, the company had an Occupational Standard Assessment form for aircraft technicians, with 43 areas of assessment. These, too, were assessed simply by peer review. The form contained a checkbox to indicate that there were attached documents proving that the standard was met. Detailed maintenance training records and attached documents were not made available for investigators to review.

Only a licensed AME may sign a maintenance release and/or be granted ACA status at Air Georgian. At the time of the occurrence, there were 13 maintenance personnel at the Calgary sub-base; 7 of these were AMEs designated as ACAs for the Beechcraft 1900D. However, records provided by the Toronto base, dated 01 September 2016, listed 2 personnel at the Calgary sub-base as ACAs for Air Georgian Beechcraft 1900D airplanes who were both maintenance technicians and not licensed AMEs.Footnote 35 In February 2017, TC reviewed training records for both the Toronto base and the Calgary sub-base and found them to be compliant with the CARs.

1.17.2 Lubrication and inspection processes

The investigation examined the processes for lubrication and inspection of the nose landing gear.

1.17.2.1 Lubrication task

The lubrication task process at Air Georgian was the same for

- the lubrication schedule;

- a bolt inspection;

- a detailed inspection; and

- a lubrication following aircraft cleaning.

Technicians and AMEs would reference the applicable sections of the Beechcraft Corporation Model 1900D Airliner Maintenance Manual to determine which bolts and parts needed lubrication and which grease was required to complete the task. A table of greases was provided to ensure that the technician or AME used the correct grease.

Some senior maintenance personnel reported that the task required the technician to do the following:

- Wipe away the old grease.

- Attach the tube of the grease gun to the bolt nipple and manually squeeze the grease gun handle until sufficient grease is expressed.

- Monitor for old grease seeping from all applicable seams of the bolt, indicating that the bolt is lubricated and serviceable.

- Monitor for new grease seeping from all applicable bolt seams, indicating that new grease is successfully expressed and has penetrated all relevant areas.

- Wipe away excess grease as necessary.

Some senior maintenance personnel reported that bolt lubrication deficiencies could be monitored during the lubrication task by performing step 3, above. If no old grease was seen being expelled, or if it was not possible for the new grease to enter the lubrication point in step 2, this could indicate that the bolt or part was dry and/or blocked with old, hardened grease, and therefore unserviceable. The defect would then be recorded and actioned on an additional work card.Footnote 36

1.17.2.2 Inspection tasks

As part of the periodic bolt inspection and detailed inspection, technicians and AMEs were required to perform the lubrication. Technicians and AMEs were then required to test the pivot/stop bolt (and others) for free rotation to determine whether the bolt was sufficiently lubricated and serviceable. This required technicians and AMEs to dismantle the bolt and use their fingers to freely rotate it. If any inspection discrepancies were found, technicians and AMEs were required to "determine the cause and replace parts as necessary."Footnote 37 If any new parts were required, an additional work card was to be completed.

1.17.2.3 Maintenance release

The lubrication schedule, bolt inspection, and detailed inspection were signed off as part of the aircraft maintenance release by an appropriately authorized AME who was an ACA.

CARs subsection 571.10(1) specifies that

Airworthiness Manual Footnote 38If the tasks were completed by a technician who was not an ACA, an ACA would have to check that the tasks had been correctly performed according to the CARs requirements before signing the maintenance release. If the tasks were completed by an ACA, the maintenance release could be signed by that same ACA, and additional checks were not required to be carried out by another qualified person.

1.17.2.4 Potential task errors

The lubrication schedule, bolt and detailed inspections, and maintenance release involved mechanical knowledge, maintenance rules, and visual and physical techniques. They were therefore vulnerable to knowledge-based, rule-based, and skill-based errors.Footnote 39 Footnote 40

Knowledge-based performance is largely conscious, occurring as technicians learn new situations and outcomes. As they progress, rules are learned, producing a more regulated "if/then" performance. Knowledge- and rule‑based mistakes may occur as a result of insufficient education, training, or experience. Technicians and AMEs may not know how to deal with certain scenarios, they may apply inappropriate rules to the task, or they may not apply appropriate rules, such as following known procedures (Appendix A).

As technicians and AMEs gain experience and practice, they may execute more automatic skilled performance, such as in the application or inspection of grease. During this time, technicians and AMEs may make skill-based errors, such as missing deficiencies or omitting tasks, especially if they are interrupted, tired, or biased by pre-conditions such as expectation and assumptions.

Performance errors can be mitigated by appropriate defences, such as suitable education, training, procedures, equipment, operating environment, scheduling, supervision, and safety management. These defences can reduce the likelihood of errors and detect errors should they occur.

1.17.2.5 Technical competencies

Aviation maintenance technician students in Canada usually attend a TC-approved training organization (ATO) to complete basic training prior to starting work at an AMO. During maintenance education, CARs aircraft maintenance standardsFootnote 41 require students to be taught about "human factors in maintenance" and the "classifications, functions, principles and properties of lubricants," and to perform "servicing of lubrication, fuel, oil and hydraulic systems."

The CARs do not specify the level or details for each subject taught; it is up to each individual ATO to determine how and what to teach. The investigation queried 9 ATOs to determine how lubrication tasks were taught. No standard methodology was found and the information taught varied among the ATOs. The investigation could not find any description of a training standard for a lubrication technique taught in typical student training material or any description in the technicians' logbooks, or other records, other than the instruction to "grease aircraft." Therefore, not all technical competencies are standardized, and, as a result, it is not possible to determine a student's technical competencies related to the lubrication and inspection tasks unless these competencies were tested and validated when the student was hired at an AMO.

After graduating from an ATO, maintenance technician students may apply to work at an AMO. They then receive further training from the AMO in accordance with applicable CARs provisions. As with initial education, the CARs do not specify the level or details for each subject taught; it is up to each AMO how and what to teach in order to train employees on applicable tasks.

There were no entry examinations, nor any test on lubrication or inspection techniques, for employees prior to starting at Air Georgian. After being hired, new technicians were subject to a probationary period with various levels of peer and supervision assessments.

1.17.2.6 Air Georgian lubrication and inspection maintenance schedule

Air Georgian maintenance personnel were required to lubricate and inspect the occurrence bolt on the nose landing gear at times specified in the Beechcraft Corporation Model 1900D Airliner Maintenance Manual. The manual included the following information:

- Lubrication schedule: Chapter 12Footnote 42 documented the lubrication schedule to be performed at every 400-hour interval. This required personnel to "grease fittings" using greases specified in an associated table. Chapter 12 also listed the required lubrication practices, but simply referred back to the lubrication schedule.

- Bolt inspection: Chapter 32Footnote 43 documented the bolt inspection to be performed at every fifth 200-hour interval. Paragraph C(4) required the technician to "[l]ubricate the drag brace grease fittings with grease" and then, in paragraphs C(11) to C(13), to disconnect the relevant parts of the occurrence bolt to test for "free rotation." If the yoke did not rotate freely, "determine the cause and replace parts as necessary." Chapter 32Footnote 44 also listed the required lubrication practices,but this, too, simply referred back to the lubrication schedulein Chapter 12.

- Detailed inspection: Chapter 05Footnote 45 documented a detailed inspection to be performed at every fifth 200-hour interval. Subparagraph C(9)(b) required the technician to "[i]nspect for proper lubrication of bolts" in accordance with the lubrication schedule. Subparagraph C(9)(c) required the technician to "[i]nspect bolts for freedom of movement"Footnote 46 in accordance with the bolt inspection.

The occurrence bolt was also required to be lubricated after each aircraft external washing:

- Airplane washing: Chapter 12, Section 3F, stated that "the landing gear [...] should be washed with low pressure and mild detergent as soon as is practical following operation on salty or muddy runways."Footnote 47 General instructions in Chapter 12, Section 3, included "[u]se special care to avoid washing away grease from any lubricated area" and "[l]ubricate after cleaning as necessary."Footnote 48 This requirement was also stated below the lubrication instruction table for the lubrication schedule in Chapter 12Footnote 49 : "After washing airplane, lubricate all lubrication points."Footnote 50

If the maintenance manual is followed correctly, the occurrence bolt is required to be greased every 400 hours, at every fifth 200-hour interval, and after airplane washing, as necessary. Documentation indicated that the occurrence aircraft received its most recent 400‑hour lubrication at the Calgary sub-base in May 2016 and its most recent detailed inspection at the Toronto main base in March 2016. There was no record of any lubrication conducted after washing.

1.17.2.7 Grease guns and grease management

When greasing the pivot/stop bolt, a technician is required to grease other bolts on the nose landing gear as part of the same schedule; some of these bolts have different grease requirements. The lubrication schedule referenced a specific table of greases for each bolt or set of bolts to ensure that the technician used the correct grease. The Beechcraft Corporation Model 1900D Airliner Maintenance Manual warned against using the wrong grease on the wrong parts, given that some greases wash off easily and some cause corrosion.

The technician was required to source the correct grease from either the hangar grease cabinet or a pre-loaded grease gun. The Calgary sub-base had transparent grease guns to provide a visual indication of which grease was in which grease gun. In addition, the two primary greases for the Beechcraft 1900, the only aircraft type serviced in Calgary, were of contrasting colours.

The Toronto maintenance main base was responsible for 2 aircraft types and multiple grease types of varying colours. The Toronto maintenance base did not have transparent grease guns, and it was not possible to view the actual grease cartridge that had been loaded inside. It is not possible to determine the grease type by squeezing out the grease, as many types of grease are the same colour.

It was observed that not all grease guns had been loaded with the grease type matching the label on the gun. The investigation determined that this was not uncommon at Air Georgian. To reduce the risk that the wrong grease was used, a technician on one crew had been assigned the specific task of checking grease guns, and technicians in general were told by the Toronto base senior maintenance staff to remove cartridges before each use to make sure the gun contained the correct grease. These additional requirements and procedures were not documented in any Air Georgian manuals. The process of removing and checking the grease cartridges prior to each use added to the workload in Toronto.

Some personnel commented on the difficulty and inconvenience of the grease guns, as usability varied. Some of the grease guns required much more force than others to express the required grease and some leaked grease when in use. The Air Georgian Maintenance Procedures Manual, under Material Control, has instructions to identify unserviceable equipment with a tag and place in quarantine or leave on the hangar floor if equipment or material is large. There were no unserviceable grease guns observed in quarantine.

1.17.2.8 Operating environment

The pivot/stop bolt is located three-quarters of the way up the nose landing gear, nearly inside the wheel well.

However, some other bolts requiring servicing are located at the top of the nose landing gear, up inside the wheel well. Difficult access and shadows made the physical and visual aspects of the inspection and lubrication tasks more challenging, and supplemental lighting was required to perform the task.

1.17.2.9 Workload, tasking, and supervision

1.17.2.9.1 Workload and tasking

At the time of the occurrence, Air Georgian had recently procured more CRJ-200s, increasing the number of aircraft within the fleet. It was not uncommon for a shift to experience high workload, which could include a combination of scheduled and unscheduled tasks on the Beechcraft 1900D and the CRJ‑200. Unscheduled aircraft serviceability issues often took priority and scheduled tasks were deferred. Examples taken from the Air Georgian computer-tracking program indicated multiple task-extendedFootnote 51 entries, primarily due to workload and personnel shortage.

There was no standardized practice or procedure for transitioning between a deferred task and a new task. Technicians had a varied approach to task progress tracking. Some would initial each step, some would initial each section, and some checked off each page as a whole. If a scheduled task was interrupted and temporarily suspended, for example when a technician was halfway through lubricating the nose-wheel gear, it was not always possible to determine what had been done when the technician returned or a new technician took over the task.

1.17.2.9.2 Supervision of workload

The role of the ACA was to check that the required maintenance tasks had been adequately performed in accordance with the AMO's Maintenance Policy ManualFootnote 52 and the CARs standards of airworthiness.Footnote 53

To achieve this, CARs subsection 571.11(6) states the following:

It was common for a shift at the Toronto main base to be made up of a majority of junior technicians, with only 1 or 2 senior AMEs being ACAs. One or both of these senior AMEs with ACA status could be sick or assigned to tasks elsewhere, for example at the airport departure gates. In this case, a shift could remain with a majority of junior technicians.

It was typical practice not to supervise tasks that were considered basic, such as lubrication, or to check the lubrication of easy-to-reach or easy-to-lubricate bolts, such as the occurrence bolt, prior to signing the maintenance release. The focus was on the more complex tasks or bolts that were harder to lubricate or reach. Depending on workload, it was common for ACAs to sign off on tasks for which they had not been present and had not inspected, or to sign off on tasks many hours after multiple tasks had been completed.

There were no standardized supervision practices.

1.17.2.10 Performance reliability

The lubrication schedule, bolt inspection, detailed inspection, and maintenance release involved mechanical knowledge, maintenance rules, and visual and physical technique (skills).

Interviews and observations indicated variability in the knowledge, rules, and performance of lubrication and inspection tasks and variability in grease and grease gun management, use of additional lighting aids, management of task interruptions, and the degree of applied supervision. For example, employees' performance of old and new grease removal procedures varied: only some used a flashlight, only some checked for the expression of old grease as an indicator of a dry bolt, and only some correctly checked for the expression of new grease.

The investigation observed a technician performing the lubrication task when old grease did not expel before the new grease, indicating that the bolt was dry. The technician did not consider this a reason to report it or to perform a more detailed inspection.

There were also discrepancies in what was understood if it was difficult to push new grease into the bolt and different criteria for what constituted free rotation during an inspection task. Some technicians assumed that the aircraft was lubricated following airplane external cleaning, although they were not aware of who performed this task. Some did not know that this was a requirement.

1.17.3 Air Canada oversight of Air Georgian

Air Canada requires all of its Tier III operators to be compliant with the International Air Transport Association (IATA)Footnote 54 Operational Safety Audit (IOSA) and IOSA standards and recommended practices. To meet this requirement, Air Georgian undergoes an IOSA audit approximately every 2 years. The details of the audit are not made available to Air Canada. Through IATA, Air Canada is informed as to whether Air Georgian meets the standard.

Air Georgian passed the last 2 IOSA audits. These 2 audit reports were requested from Air Georgian but were not made available to the investigation.

1.17.4 Regulatory oversight of Air Georgian maintenance

The investigation examined the last 6 years of TC's surveillance of Air Georgian. From 2011 until the occurrence, TC conducted several surveillance activities. The activities that were relevant to the investigation included 2 program validation inspections (PVIs),Footnote 55 1 process inspection (PI),Footnote 56 and 1 SMS assessment.

TC's PVI findings were previously described in TSB Aviation Investigation Report A14W0046Footnote 57 :

Since 2011, Transport Canada (TC) has conducted 2 program validation inspections (PVI) on Air Georgian. The first was carried out from 28 February to 04 March 2011. One of the findings from this PVI related to the company's QA [quality assurance] program is that it did not adequately audit the training requirements of maintenance personnel. The company's corrective action plan (CAP) was accepted, follow-up was completed, and TC closed the PVI on 11 July 2011.

The second PVI was carried out from 04 to 14 February 2014. This PVI also generated some findings related to the company's QA program. The QA program did not meet required time lines for CAPs; it did not adequately audit the appropriate use of applied tolerances for scheduled maintenance; and it did not adequately audit the qualifications of maintenance personnel applying these tolerances.

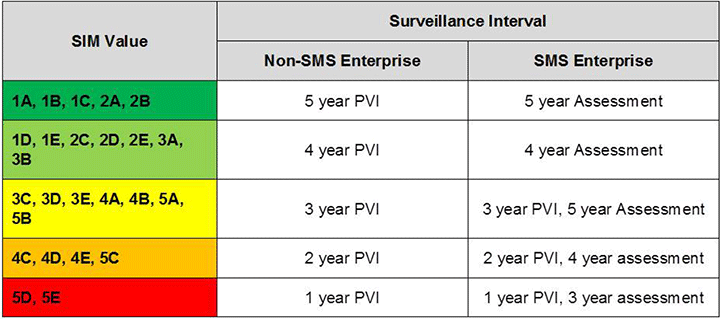

A company's risk indicator level determines how often it must undergo surveillance by TC. The company was rated at a 4D risk level for 2015–2016, and at 4E for 2016–2017 (at the time of the occurrence) (Figure 4). The company was again rated at 4E for 2017–2018. "E" is an impact value of "extensive" and 4 is a risk indicator level of "high," with a "low likelihood that risks are being managed."Footnote 58 A company's risk indicator level determines how often it must undergo surveillance by TC (Figure 5). As a result, Air Georgian was on a 2-year PVI schedule, with a 4-year assessment interval.

On 23 February 2015, TC began conducting a PI, and closed it on 13 October 2015. There was 1 finding:

- Finding 705-01: The documented process for CAPs was not being followed in accordance with section 5.1.5e of the SMS Manual.

From 08 to 19 June 2015, TC conducted a full SMS assessment on Air Georgian. There were 3 findings:

- Finding 107-01: Air Georgian's quality assurance program was not following up on CAPs within the timelines required by the CARs.

- Finding 573-01: A quality assurance program was not fully established and maintained under the management of an appropriate person; areas of the quality assurance program did not have sufficiently detailed checklists; and internal audits were not performed as per Air Georgian's 2014 and 2015 internal audit schedule.

- Finding 573-02: The use of 2 vendors for maintenance that did not appear on Air Georgian's list of approved vendors.

To evaluate CAPs submitted in response to TC-issued findings, a CAP evaluation formFootnote 59 is used. The form contains questions to evaluate the CAP submitted by the company for short‑term corrective action, root cause analysis of the non-compliance, and proposed long‑term corrective actions. The CAP submission is reviewed against the questions on the form, which must all be answered either "yes" or "no." Additionally, the TC inspector conducting the CAP review is to provide sufficient details in the decision/justification column to support the response. It is noted on the evaluation form that a "no" does not necessarily mean that the CAP should be rejected. The size and complexity of the company and the severity of the finding are to be considered during the evaluation of the CAP and completion of the CAP evaluation form.

Air Georgian's original response to the findings from the June assessment was rejected by TC. Air Georgian's assertion was that the findings were not findings and should be revoked. Following discussions with TC, Air Georgian submitted CAPs on 22 October 2015. The CAPs for findings 107-01 and 573-02 were found acceptable. The CAP for finding 573-01 was found unacceptable.

A final CAP submission for finding 573-01 was provided to TC, and the evaluation was conducted on 26 November 2015. The CAP evaluation form completed by TC identified 3 items that generated a "no" response, but there were no documented comments in the decision/justification column of the form. The questions that generated a "no" response were the following:

- Has the enterprise listed all significant processes, procedures, practices, and/or culture that allowed the non-compliance to occur?

- Has the enterprise included confirming evidence demonstrating how the root cause was determined?

- Does the CAP confirm that a review was conducted to ensure that potential hazards inadvertently introduced with the implementation of the corrective action(s) have been assessed, mitigated, or eliminated?

From February 2015 (when the PI was conducted) until the occurrence, TC took 2 actions with regard to its oversight of Air Georgian. Ramp inspections on several aircraft were carried out at CYYZ on 09 June 2016 and 12 July 2016. The first found only minor defects with the aircraft that were examined, and the second looked at only the defects from the first ramp inspection and noted that there had been no time to inspect the other aircraft. There was no follow-up inspection done at the Toronto main base.

In response to this occurrence, a ramp inspection was carried out on Air Georgian Beechcraft 1900D aircraft at CYYC on 16 September 2016. That inspection examined 3 aircraft and found minor discrepancies in the aircraft documents that were inspected.

The TSB visited Air Georgian's main base in Toronto from 30 January to 01 February 2017 as part of this investigation. During this visit, numerous safety deficiencies were observed; these required the TSB to notify TC in accordance with the Memorandum of Understanding between the TSB and Transport Canada Civil Aviation.

In response to the concerns noted by the TSB, TC conducted a PI at Air Georgian's Toronto main base on 14 February 2017. This inspection was on Air Georgian's maintenance process, including training, standards of maintenance, maintenance corrective action process, aircraft maintenance task control, and risk management. According to the PI report, all areas were acceptable, and the maintenance processes at Air Georgian were compliant with the applicable CARs provisions.

The investigation was unable to determine if the training records supplied to the TSB during the investigation differed from those subsequently made available to TC.

1.17.5 Safety issues identified by the TSB regarding Transport Canada oversight activities

Challenges in the timely detection of non-conformity have been identified in a number of previous TSB investigations.Footnote 60 For example, in TSB Aviation Investigation Report A13W0120,Footnote 61 although TC had assessed the operator involved as high risk and was conducting frequent surveillance activities, the focus had not shifted to verifying regulatory compliance and had remained at a systems level. TC's surveillance activities did not identify the operator's unsafe operating practices related to weight and balance and net take-off flight path calculations.

If the systemic causes of non-conformity are not identified and addressed, it is likely that unsafe conditions will persist. The TSB has also previously identified this pattern in a number of investigations.Footnote 62 For example, TSB Aviation Investigation Report A13H0001Footnote 63 identified weaknesses in the oversight of an operator with a transitioning SMS. In that case, the operator had difficulty producing acceptable CAPs and meeting its proposed implementation time frames. This resulted in repeated delays in addressing deficiencies. During this period, TC postponed any additional surveillance activities pending CAP implementation. The suspension of surveillance activities while waiting for the CAP process to run its course effectively reduced the frequency of oversight for an operator that was considered high risk. It also left the operator with less than the planned level of oversight for an extended period.

While an effective SMS will help, companies vary in degrees of ability or commitment to manage risk effectively. Some are more effective than others. Less‑frequent surveillance that is solely focused on an operator's safety management processes can be sufficient for some companies. However, the regulator must be able to vary the type, frequency, and focus of its surveillance activities to provide effective oversight to companies that are unwilling or unable to meet regulatory requirements or effectively manage risk. This could include regulatory compliance inspections. Further, the regulator must be able to take appropriate enforcement action in these cases.

Therefore, the Board recommended that

the Department of Transport conduct regular SMS assessments to evaluate the capability of operators to effectively manage safety.

Transportation Safety Recommendation A16-13

TSB Aviation Investigation Report A13H0001 highlighted the fact that, when faced with an operator that is unable to address identified safety deficiencies, TC has difficulty adapting its approach to ensure that deficiencies are effectively identified and that they are addressed in a timely manner, or at all.

TC's risk-based approach to surveillance planning has resulted in higher-risk operators being scheduled for more surveillance. In the case of Air Georgian, high-risk ratings resulted in several surveillance activities in a 6-year period. TSB Aviation Investigation Report A13W0120 found that unsafe conditions went unidentified when the surveillance remained focused on systems rather than processes.

Therefore, to ensure that companies use their SMS effectively, and to ensure that companies continue operating in compliance with regulations, the Board also recommended that

the Department of Transport enhance its oversight policies, procedures and training to ensure the frequency and focus of surveillance, as well as post-surveillance oversight activities, including enforcement, are commensurate with the capability of the operator to effectively manage risk.

Transportation Safety Recommendation A16-14

In its response in December 2016, TC indicated that it had launched a Civil Aviation Surveillance Program Evaluation and Update Program that was scheduled to be completed in December 2017. The Board was encouraged that TC committed to evaluating its surveillance program, and to considering opportunities for further improvements to ensure the effectiveness of its surveillance program.

In its December 2016 assessment, the Board noted that TC had implemented some concrete actions, such as the establishment of a National Oversight Office, the implementation of an Oversight Advisory Board, the creation of a dedicated team working on surveillance policies and procedures, strengthened oversight planning, risk-based decision making, timely enforcement actions, and temporary measures to increase the number of inspections on higher-risk areas while the program evaluation and update are underway.

The Board also acknowledged TC's efforts to find the right balance between planned and reactive oversight activities, as well as in the use of the various types of oversight tools available. Although TC has implemented numerous improvements, it is too early to assess whether or not TC's actions will adequately address the safety deficiency associated with this recommendation.

The Board considered the response to the recommendation to demonstrate Satisfactory Intent.

On 05 March 2018, TC briefed the TSB on its activities to mitigate the issues identified in TSB recommendations A16-13 and A16-14. TC stated that it would launch Civil Aviation Surveillance 2.0 in April 2018. The program is to consist of the following:

- process inspections that assess whether an SMS is working;

- an amended surveillance planning system to ensure the frequency and focus of surveillance is commensurate with the risk profile of the enterprises across the industry;

- a stronger finding process to better support enforcement, including a new staff instruction and online training;

- new approaches to capture better surveillance results requiring surveillance managers to be responsible for data accuracy;

- targeted inspections, including a new surveillance tool to collect data regarding the program and aviation safety, and to focus on risks; and

- a stronger continuous improvement and standardization program that is founded on the principle of organization-wide collaboration.

1.17.5.1 TSB Watchlist

The Watchlist identifies the key safety issues that need to be addressed to make Canada's transportation system even safer.

Safety management and oversight will remain on the TSB Watchlist until

- Transport Canada implements regulations requiring all commercial operators in the air and marine industries to have formal safety management processes and effectively oversees these processes;

- Transportation companies that do have an SMS demonstrate that it is working—that hazards are being identified and effective risk-mitigation measures are being implemented; and

- Transport Canada not only intervenes when companies are unable to manage safety effectively, but does so in a way that succeeds in changing unsafe operating practices.

Safety management and oversight is a Watchlist 2016 issue. As this occurrence demonstrates, a company may consider its safety measures to be adequate as long as they are in compliance with regulatory requirements, but the safety measures and resulting follow-up work have to be implemented in a timely manner in order to be effective. In addition, regulatory oversight must address systemic deficiencies and not just processes.

1.18 Additional information

Not applicable.

1.19 Useful or effective investigation techniques

Not applicable.

2.0 Analysis

There was no indication that Air Georgian's flight operations contributed to this incident. This analysis focuses on the maintenance and organizational factors that contributed to the incident, as well as on the Transport Canada (TC) regulatory oversight program.

The investigation could not determine the exact errors that contributed to the lubrication deficiencies, although an examination of the lubrication and inspection tasks made it possible to determine the likely errors. An examination of maintenance conditions also made it possible to determine the likely contributors to these errors.

2.1 Air Georgian maintenance practices

2.1.1 Lubrication performance

The failure of the retract-and-extend mechanism of the nose landing gear was initiated by a yoke lubrication problem. The lack of lubrication caused the pivot/stop bolt in the nose landing gear yoke to seize and break, which eventually prevented the nose landing gear from fully extending.

The investigation conducted an analysis outlining the steps that should typically be performed to ensure effective lubrication and avoid errors. Appendix A summarizes the types of errors that can occur, resulting in bolts not being lubricated, bolts being lubricated with greases that are inappropriate for the bolts in question, and/or bolts being lubricated ineffectively.

Company defences should be in place to optimize knowledge and performance reliability in order to reduce performance-related errors to as low as reasonably practicable. To complete these steps effectively, Air Georgian would have needed several defences in place. If any of these defences were deficient, the probability of error at one or more steps would be increased.

If maintenance personnel do not correctly perform maintenance procedures as required in maintenance schedules, there is a risk that the safety of flight will be compromised.

At Air Georgian's Toronto main base, there were pre-loaded, labelled grease guns that did not necessarily contain the grease type matching the label on the gun. This occurred so frequently that there was an informal practice whereby technicians would remove the cartridge before each use to make sure the gun contained the correct grease. This equipment issue could have contributed to errors in step 2 of Appendix A, for example by increasing the probability of selecting the wrong grease. The technician or aircraft maintenance engineer (AME) may not have been able to detect the error, given that many types of grease are the same colour.

Some maintenance personnel commented on the difficulty and inconvenience of the grease guns: certain grease guns required much more force than others to express the required grease. This equipment issue could have contributed to potential errors in step 3 of Appendix A, for example by masking the effect of a blocked grease nipple and leading the technician to attribute the additional pressure to the typical usability issues of the grease gun.

If there is no documented procedure for correctly loading, labelling, and servicing grease guns, or if grease guns are not correctly loaded and labelled, or serviceable and usable, there is a risk of inadequate lubrication that can lead to component failure.

2.1.2 Managing task interruptions

At Air Georgian, unscheduled aircraft serviceability issues often took priority, and scheduled tasks were interrupted. If a scheduled task was interrupted and temporarily deferred, there was no process or consistent practice in place to record how much of the task the technician or AME had completed. It was therefore not always possible to determine what had or had not been done when the technician or AME returned. This tasking and workload issue could have contributed to most of the potential errors in Appendix A, for example by increasing the chance that all or part of the lubrication task would be omitted through interruption, or that the quality of task performance would be affected.

If there are no documented procedures or standard practices to manage task interruptions safely and effectively, there is a risk of task-related error that could compromise the airworthiness of an aircraft.

2.2 Air Georgian maintenance training

The investigation revealed several gaps in knowledge and training at Air Georgian, including the absence of relevant processes, training syllabi, on-the-job technical training program procedures, qualification records of trainers, and training documentation or records.

As a result of these interrelated gaps, investigation interviews and observations indicated that there was a diverse standard of knowledge and performance concerning the lubrication task, and some technicians were not aware of a requirement to lubricate the aircraft following cleaning.

2.2.1 Lubrication technique training

The investigation determined that there was no standard lubrication technique taught in typical student training material, no technique description in the AMEs' logbooks, and no entry examination on lubrication techniques for new employees before they began working at Air Georgian. As well, Air Georgian maintenance documentation did not contain any grease fittings procedure, training standards, examination, or validation process. On-the-job training was assessed by peer review only, but none of the personnel who were considered peers had any formalized instructor training to validate the reliability of their demonstrated technique, and such training was not required by regulation.

These training and procedure issues likely contributed to the variable lubrication knowledge and techniques and therefore the potential errors at each step in Appendix A.

The nose landing gear pivot/stop bolt was not properly lubricated because maintenance personnel were not adequately trained on lubrication and the use of equipment.

2.2.2 Human-factors training for maintenance personnel

The human-factors training required by the Canadian Aviation Regulations was delivered and assessed online. There was no opportunity for maintenance personnel to participate in group discussion on recent maintenance errors. Human factors could have influenced any of the steps in Appendix A. For example, if a person expects grease to enter a bolt, or a supervisor has been told that a bolt has been successfully lubricated, he or she may be more likely to expect and therefore perceive a successful result. Pre-conditions such as expectation and assumptions could therefore have reduced the probability of the technician perceiving the level of grease present in step 4.

2.2.3 Supervision and on-the-job training for maintenance personnel

Neither the Maintenance Policy Manual nor the Maintenance Procedures Manual contained details about what constituted knowledge of a particular aircraft's systems for Aircraft Certification Authorities (ACAs) or what was included in on-the-job training for ACAs. On-the‑job training was assessed by peer review only. There were no standards documented for any ACA qualifications on the ACA Nomination form.

There is no CARs requirement for personnel delivering the training program in an AMO to have instructor training. The knowledge, rules, or skills required for teaching, demonstrating, and assessing the lubrication and inspection tasks were not detailed in any Air Georgian documentation or taught as part of any Air Georgian instructor-based training syllabus. There were also no training- or supervision‑related competencies listed on the ACA Occupational Standard Assessment form or the ACA Nomination form.

It was therefore not possible to determine how standardized, reliable, or valid the training was for any of the on-the-job training, particularly with reference to knowledge, rules, and skills related to lubrication and inspection tasks.

If AMO training programs do not provide aircraft maintenance personnel with appropriate training to reflect their responsibilities, there is a risk that variable on-the-job performance will compromise the validity of a maintenance release.

If maintenance personnel responsible for training are not provided with the necessary skills to teach, demonstrate, and validate competencies, there is a risk of variable on-the-job performance and task-related errors that could jeopardize the airworthiness of an aircraft.

If supervision practices in an AMO do not ensure that maintenance tasks have been completed in accordance with required procedures, there is a risk that task-related errors will remain undetected, jeopardizing the airworthiness of an aircraft.

2.3 Air Georgian maintenance training documentation and records

It was not possible to determine the degree of standardization of online learning outcomes, particularly with regard to knowledge and rules relating to human factors, the safety management system (SMS), and Air Georgian's Maintenance Policy Manual and Maintenance Procedures Manual.

If maintenance training documentation does not contain detailed and standardized information on course content, there is a risk of variability in training outcomes.

There were few detailed records of any maintenance personnel training at Air Georgian, other than for the in-house, computer-based training. No records, except for summary sheets, were provided to the investigation to show the qualifications of maintenance personnel. The training summary sheets for the range of personnel examined in this investigation did not reflect accurate training, certifications, or signing authorities.

If maintenance training records do not exist, or are not accurate or up to date, there is a risk that maintenance personnel will perform tasks that they are not qualified or authorized to perform, which could jeopardize the airworthiness of an aircraft.