Pilot fatally injured during ground operations

Wilderness Seaplanes Ltd.

de Havilland DHC-2 Mk. I, C-FDSG

Port Hardy Water Aerodrome, British Columbia

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

History of the flight

On 07 December 2020, the pilot of the Wilderness Seaplanes Ltd. de Havilland DHC-2 Mk. IFootnote 1 aircraft (registration C-FDSG, serial number 892) planned to transport 3 passengers from Port Hardy Water Aerodrome (CAW5), British Columbia (BC), to a local logging camp.

At approximately 0745,Footnote 2 the pilot arrived on the dock to begin preparing the aircraft for departure at 0830. The pilot turned the aircraft battery master switch on and the aircraft electrical system momentarily flickered, but it did not stay powered up. The pilot suspected the battery was dead and, per the company operations manual,Footnote 3 he notified the dispatcher and the person responsible for maintenance (PRM).

A closed-circuit television camera from a nearby building, located approximately 140 metres south-southwest of the aircraft, recorded the pilot moving to the front of the aircraft at 0759. The propeller was manually rotated, causing the engine to momentarily fire and accelerate the propeller. The pilot was struck by the propeller and then fell into the water at 0759:35.

Between 0800 and 0806, the 3 passengers arrived at the CAW5 parking lot and unpacked their luggage. At 0813, one of the passengers walked down to the dock and found the pilot face down in the water. The passengers recovered the pilot from the water, contacted 911, and administered first aid with guidance from the 911 operator. An ambulance arrived at 0823 and transported the pilot to the hospital. The pilot died from his injuries 32 hours later.

Water aerodrome information

CAW5 is located 5 nautical miles west-northwest of the Port Hardy Airport (CYZT), BC, and is a registered water aerodrome for public use. The single dock has access to aviation fuel, fresh water, and electrical shore power.

The aircraft was moored on the right side of the dock with a plank spanning the front of the floats (Figure 1).

There were no other people or aircraft at the water aerodrome at the time of the occurrence.

Pilot information

The pilot had been employed by Wilderness Seaplanes Ltd. from June 2019 to October 2019 and then returned in November 2020. He held a commercial pilot licence - aeroplane with a valid Category 1 medical certificate and had accumulated 2853.2 total flight hours with approximately 1388.1 flight hours on the DHC-2 aircraft.

The pilot also held a Transport Canada (TC) aircraft maintenance engineer licence; however, he was not working for the company in this capacity, and was only authorized to perform elementary workFootnote 4 on the occurrence aircraft.

Weather information

The nearest aviation weather reporting station to the occurrence site is CYZT. The aerodrome routine meteorological report issued at 0800 for CYZT indicated a temperature of 9 °C, a dewpoint of 8 °C, a few clouds at 2000 feet above ground level (AGL), and a ceiling of 5300 feet AGL. Sunrise occurred approximately 18 minutes after the occurrence, at 0818.

Weather was not a factor in this occurrence.

Aircraft information

The occurrence aircraft was manufactured by de Havilland Aircraft of Canada Ltd. in 1953 and was equipped with a Pratt & Whitney USA R-985-AN-14B engine and EDO 679-4930 floats. Records indicate the aircraft was equipped and maintained in accordance with existing regulations.

The aircraft ignition system is independent of the battery master switch and the battery system. The ignition system uses 2 magnetos that are coupled to the engine crankshaft and an ignition switch that is mounted in the cockpit. The rotary ignition switch has 4 positions: OFF (OFF for both magnetos), R (ON for the right magneto), L (ON for the left magneto), and BOTH (ON for both magnetos). Under normal operations, there are only 2 conditions that must be met for one or both of the magnetos to function:

- The engine crankshaft must be rotating.

- The ignition switch must be in one of the ON positions.

When the ignition switch is in one of the ON positions, the engine crankshaft rotation and, consequently, the magneto rotation enable the magneto(s) to generate a high voltage and create the spark required for ignition. Therefore, the engine can be started with manual rotation of the propeller regardless of the position of the battery master switch or the charge of the battery.

Aircraft examination

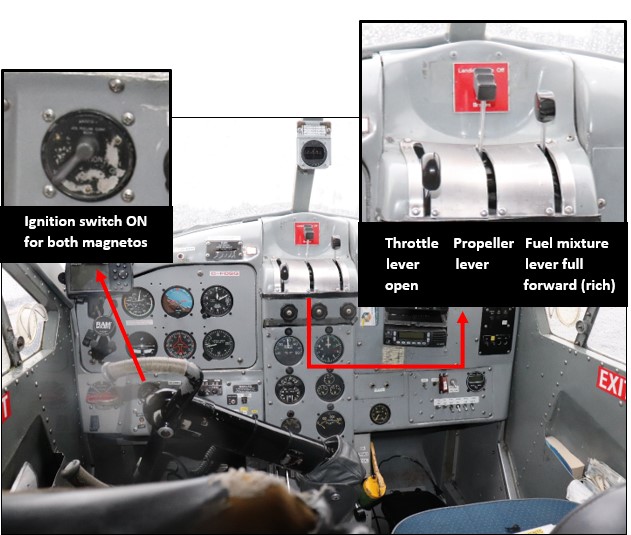

Approximately 45 minutes after the occurrence, the PRM examined the aircraft and found the battery master switch in the OFF position and the aircraft engine controls configured for a normal engine start, as outlined by the airplane flight manual (AFM):Footnote 5 the throttle lever was slightly open, the fuel mixture lever was in the full forward (rich) position,Footnote 6 and the ignition switch was in the ON position for both magnetos (Figure 2). The investigation could not determine the exact time at which the pilot configured the engine controls for start.

During this examination, the PRM also observed the following:

- The control column and the handwheel were locked by the left-hand seat belt as outlined in the AFM.Footnote 7

- The engine cover had been removed and was lying on the dock.

- A glove was resting inside the front of the engine cowling at the 6 o’clock position.

The PRM function tested the battery master switch and found that when the battery master switch was turned on, the master relay for that circuit would not connect the battery to the aircraft electrical system to supply electrical power. The following day, maintenance replaced the relay and then tested the aircraft electrical system, including the battery master switch and the battery, with satisfactory results.

Propeller safety

During the daily inspection of the occurrence aircraft, the pilot had to check the propeller for water damage, per the company standard operating procedures (SOPs),Footnote 8,Footnote 9 but the procedure does not define the steps or the techniques used to complete the inspection.

The AFM for the aircraft describes 2 cases in which the manual rotation of the propeller is warranted:

- to ensure there is no hydraulic lock in the cylinders from excess oil;Footnote 10 and

- to clear excess fuel from the engine if over-primed.Footnote 11

In both cases, the AFM indicates that all switches must be off and the mixture lever must be set to idle cut-off to prevent an unintentional start during propeller rotation. TC’s Flight Training ManualFootnote 12 and From the Ground UpFootnote 13 also identify that the aircraft ignition (magneto) switches must be off during any inspection or hand movement of the propeller before starting the engine.

Hand propping, the procedure wherein an aircraft engine is intentionally started by rotating the propeller by hand, is the only time the engine controls are set to the start position while the propeller is manually rotated. The FAA Airplane Flying HandbookFootnote 14 warns that “a spinning propeller can be lethal should it strike someone”Footnote 15 and that hand propping should be the last option to start an aircraft. The handbook also says that “[i]t is critical that the procedure never be attempted alone.”Footnote 16 In the case of a floatplane, TC’s Flight Training ManualFootnote 17 adds that the propeller must be rotated from behind with the person standing and bracing on the right-hand float. The company SOPs and the aircraft AFM do not have a hand-propping procedure for the occurrence aircraft.

In this occurrence, the pilot was standing on a plank in front of the aircraft when the propeller was manually rotated with the engine controls configured for start, but the video resolution from the closed-circuit television camera was insufficient to enable the investigation to determine whether the propeller rotation was intentional (oil scavenging, inspection, or hand propping) or unintentional (pilot bracing due to a loss of footing or falling).

Aircraft ground operations on water

Ground operations at a water aerodrome expose flight and ground crews to the risk of drowning. This risk can be mitigated with the implementation of physical defences. TC’s Flight Training ManualFootnote 18 notes that the surface on the aircraft floats is typically wet and suggests that “floatplane pilots should wear shoes or boots that afford a good grip.” In addition, the Canada Occupational Health and Safety RegulationsFootnote 19 state that “if there is a risk of injury due to slipping in a work place, the employer must ensure that slip-resistant footwear is worn.”

The company does not have a policy on footwear, and the investigation could not determine if the pilot slipped during his pre-flight duties in this occurrence.

Wearing a personal floatation device (PFD) will increase the probability of survival in water by keeping a person afloat.Footnote 20 The Canada Occupational Health and Safety RegulationsFootnote 21 require an employer to provide a PFD for every person exposed to the risk of drowning in the workplace unless a fall-protection system is in place.

The company had supplied CAW5 with 1 PFD for employees to use during dock operations. The pilot was not wearing the PFD, nor was he required to wear it by company policy or regulations.

Due to the propeller strike and the pilot’s resultant injuries, it could not be determined whether the outcome of the occurrence would have been altered had the pilot been wearing a PFD.

Safety actions taken

In response to this occurrence, Wilderness Seaplanes Ltd. now requires all staff at CAW5 to wear a PFD while working on the dock and to complete propeller safety training.

Safety message

If an aircraft propeller is manually rotated, operators and crews need to be aware that inadvertent engine ignition can occur, potentially causing fatal injuries. Flight and ground crews are reminded to exercise extreme caution while working in close proximity to aircraft propellers.

This report concludes the Transportation Safety Board of Canada’s investigation into this occurrence. The Board authorized the release of this report on . It was officially released on .