Rollover upon landing

Canadian Helicopters Limited, (dba Acasta HeliFlight Inc.)

Bell 206L-1 (helicopter), C-GIKX

Hope Bay Aerodrome, Nunavut, 8 NM SSW

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

History of the flight

On 14 September 2021, at approximately 0643,Footnote 1 the Canadian Helicopters Limited (doing business as Acasta HeliFlight Inc.) Bell helicopter 206L-1 (registration C-GIKX, serial number 45672) departed the Hope Bay Aerodrome (CHB3), Nunavut, to conduct a series of visual flight rules (VFR) flights. The flights consisted of moving people and equipment in the Hope Bay mine area. Between 0643 and 1300, the pilot conducted 13 takeoffs and landings, including a landing and takeoff at Drill Site 10, located 8 nautical miles (NM) south-southwest of CHB3. The purpose of the flight to Drill Site 10 was to deliver core boxes and conduct a shift change. The helicopter landed at 0709. The drillers unloaded the core boxes and placed them on the ground to the right of the helicopter, which took off at 0715 to go back to CHB3.

At 1454, the helicopter departed the CHB3 helipad again for Drill Site 10 to drop off a hand-held radio and pick up 2 phones. The pilot, who was the sole occupant on this flight, was seated in the right seat and was wearing a lap belt, shoulder harness, and helmet. Wind conditions were not recorded at the drill site; however, it was determined that as the helicopter approached to land there was a quartering headwind from the left of approximately 10 to 15 knots. During the approach the pilot noticed the core boxes to the right of the landing area and a driller who was waiting for the helicopter to land. The driller had positioned himself facing the helicopter. As the helicopter neared the ground the pilot noticed the driller was in a crouched position and was looking at the helicopter tail area. This caught the attention of the pilot, who was concerned that the tail may be in conflict with the upsloping terrain.

At 1501, the helicopter landed on its skid gear and maintained a 52% torque power setting. While the helicopter was in this light-on-the-skids position, the pilot removed his left hand from the collective,Footnote 2 and then opened the right seat pilot’s door, though it could not be determined with which hand. The pilot leaned out and turned his head to look back at the helicopter tail. While the pilot’s head was turned, the helicopter began to roll over on its right side, and the pilot attempted to regain a hold of the collective. During this dynamic rollover, the main-rotor blades contacted the ground and broke apart. The driller was fatally injured when he was hit by rotor blade debris. The pilot, who was not injured, shut down the engine and exited the helicopter through the broken front windscreen. There was smoke, but no fire. The 406 MHz emergency locator transmitter activated and a signal was received by the Joint Rescue Coordination Centre in Trenton, Ontario.

Pilot information

The pilot held a Canadian commercial pilot licence – helicopter issued on 22 February 2017, and a valid Category 1 medical certificate. In March 2017, he was hired by Acasta HeliFlight Inc. for a ground position and was trained as a Canadian Helicopters Limited pilot in 2018. At the time of the occurrence, his licence was endorsed with the Bell 47, Bell 206, and Eurocopter EC30 ratings and he had accumulated 879.1 total flight hours, with 722.7 hours on the Bell 206. Records indicate that the pilot was certified and qualified for the flight.

Aircraft information

The occurrence helicopter was a Bell 206L-1. The helicopter is certified for land operations under day and night VFR non-icing conditions. The minimum flight crew consists of 1 pilot, who operates the helicopter from the right seat. The occurrence helicopter was built in 1981, had a 2-bladed rotor system with an 18.5 feet (5.63 m) rotor radius, and was powered by a single Allison 250-C30P engine. At the time of the occurrence, the helicopter had accumulated 15 746.2 hours total air time.

On 27 July 2021, a 150-hour/12-month airframe inspection was completed. At the time of the occurrence, the helicopter had flown 62.4 hours since this last inspection, and no abnormalities had been reported.

The helicopter had been modified in accordance with several supplemental type certificates that included the installation of an AAI high skid gear,Footnote 3 Dart bear paws,Footnote 4 an Aero Design cargo basketFootnote 5 (installed on the right side), a Bristol wire strike protection system,Footnote 6 and an Aero-Dyne engine performanceFootnote 7 monitoring system.

Site examination

The TSB did not travel to the accident site. The Cambridge Bay RCMP (Royal Canadian Mounted Police) and coroner attended the site, which was located at 68°01'05.46" N and 106°40'06.43" W. The terrain was soft to a depth of approximately 5 inches, uneven, and pockmarked by small depressions and mounds.

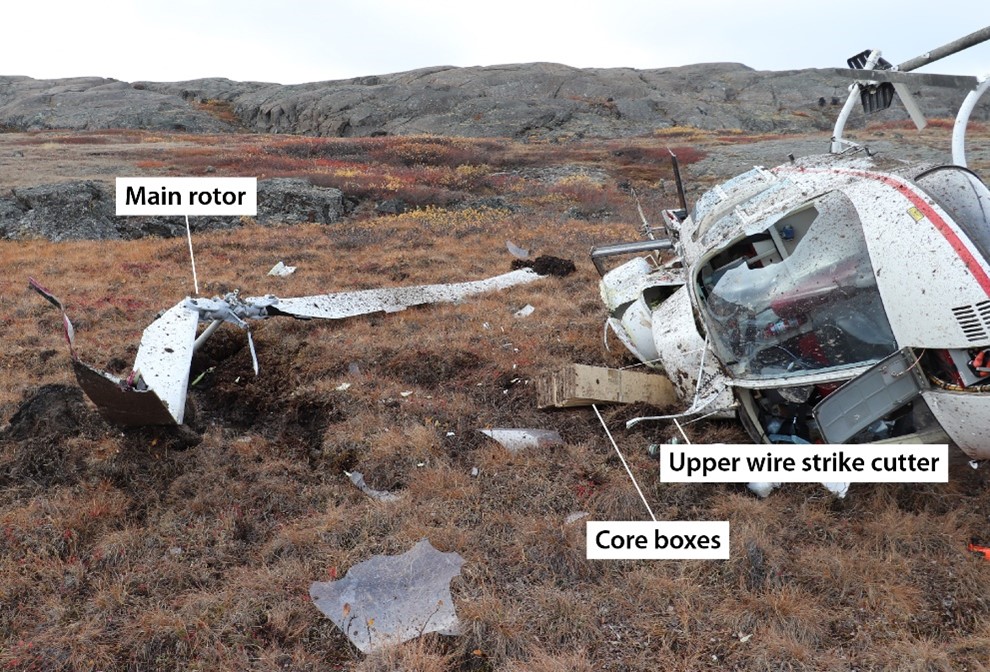

The helicopter sustained significant damage and was lying on its right side on an easterly heading. Most of the debris was located within a small area near the helicopter; however, pieces of the main-rotor blades were found further away. The main-rotor blade assembly and mast separated from the transmission and were found lying beside the helicopter. The engine exhaust duct and cowling were crushed, and deformation of the upper wire strike cutter indicated that the helicopter may have rolled almost 180° before falling back and coming to rest on its right side (Figure 1).

The helicopter tail boom was damaged, with the vertical fin and tail boom rotated 180°. The tail rotor remained attached with damage to one blade indicating a low-energy impact with the ground (Figure 2).

The driller was found in front and to the left of the helicopter nose, 29 feet and 6 inches (9.02 m) from the mast of the helicopter. A piece of the main rotor blade was found approximately 41 feet (12.4 m) beyond the driller.

The Aero-Dyne engine monitoring system data was sent to the TSB Engineering Laboratory in Ottawa, Ontario, for analysis. The analysis did not identify any abnormalities with the engine or rotor system, which were likely functioning normally at the time of the accident.

Weight and balance

A review of the empty and operational weight and balance information supplied by the company revealed that the helicopter was within the specified limitations for the occurrence flight. At the time of the occurrence, the helicopter had approximately 380 pounds of fuel on board.

Dynamic rollover

One of the hazards associated with helicopter operations is dynamic rollover, which may occur during takeoff, landing, or hovering.Footnote 8,Footnote 9 The principles of dynamic rolloverFootnote 10 are covered during initial and recurrent training and were discussed during the pilot’s recurrent ground training in March 2021.

Dynamic rollover occurs when angular momentum causes a helicopter to roll or pivot around a skid or landing gear, rather than its centre of gravity, until its critical rollover angle is reached. The average angle at which it is impossible to stop an already rolling helicopter is approximately 15 to 17° depending on the helicopter, winds, and loading.Footnote 11 Once the helicopter reaches the critical rollover angle, the thrust produced by the main rotor, combined with the rolling moment, causes the roll to continue, and recovery using cyclic input in the opposite direction may not be possible. If the collective lever is increased during dynamic rollover, the increase in angular thrust will cause the roll rate to increase. As a result, the corrective action for a dynamic rollover is to gently lower the collective control. This action reduces the thrust produced by the main rotor, thereby reducing the lateral thrust component responsible for the initiation of the rolling moment.

Dynamic rollover can be exacerbatedFootnote 12 if there is a lateral centre of gravity on the same side as the direction of roll (e.g., dynamic rollover to the right with a right lateral centre of gravity). A crosswind in the same direction as the rollover may also increase the roll rate. In this occurrence, the pilot was seated in the right seat, a cargo basket was installed on the right side, and the helicopter rolled to the right.

Safety action taken

Following the accident, Canadian Helicopters Limited / Acasta HeliFlight Inc. published 2 articles in the company’s newsletter, one on dynamic rollovers and the other on the accident, drawing attention to the facts and circumstances.

Safety message

This fatal occurrence highlights how important it is for helicopter pilots to be vigilant with their flight controls when on the ground or light-on-the-skids to minimize the conditions that could lead to a dynamic rollover.

This report concludes the Transportation Safety Board of Canada’s investigation into this occurrence. The Board authorized the release of this report on It was officially released on