Wire strike and collision with terrain

Apex Helicopters Inc.

Robinson R44 (helicopter), C-FVPA

Brantford, Ontario

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

On 25 July 2021, at 0656 Eastern Daylight Time, the Robinson R44 helicopter (registration C-FVPA, serial number 0846), operated by Apex Helicopters Inc., departed from a field on the outskirts of Brantford, Ontario, on a visual flight rules flight for the purpose of agricultural spraying.

The pilot, the sole occupant on board, began a reconnaissance of the fields to be sprayed, starting with the field where the occurrence would take place.

One minute and eight seconds later, the helicopter struck wires at the eastern edge of the southernmost field to be sprayed. The helicopter became uncontrollable and crashed approximately 270 feet from the wire strike location, coming to rest upright.

The pilot was seriously injured. The helicopter was destroyed. There was no post-impact fire. The emergency locator transmitter did not activate.

1.0 Factual information

1.1 History of the flight

On 25 July 2021, at approximately 0500Footnote 1, the pilot of the Robinson R44 helicopter (registration C-FVPA, serial number 0846), operated by Apex Helicopters Inc. (Apex), a company specialized in agricultural spraying, began her duty day as a passenger in the operations support vehicle (known as the mix rig),Footnote 2 driving to the field where the helicopter had been parked following the previous day’s spraying operations. She was expecting to take-off at sunrise or just after 0605.

The pilot conducted pre-flight preparations, while the mix-rig driver mixed the fungicide to be loaded onto the helicopter. Because of reduced visibility caused by mist, the take-off was delayed. At approximately 0646, having determined that the visibility was now suitable for flight, the pilot started the helicopter. Following an engine run-up, the helicopter was fueled and the fungicide loaded.

At 0656:36, the pilot, who was the sole occupant on board and sitting in the right front seat, departed on a visual flight rules (VFR) flight and proceeded southeast towards the corn fields to be sprayed.

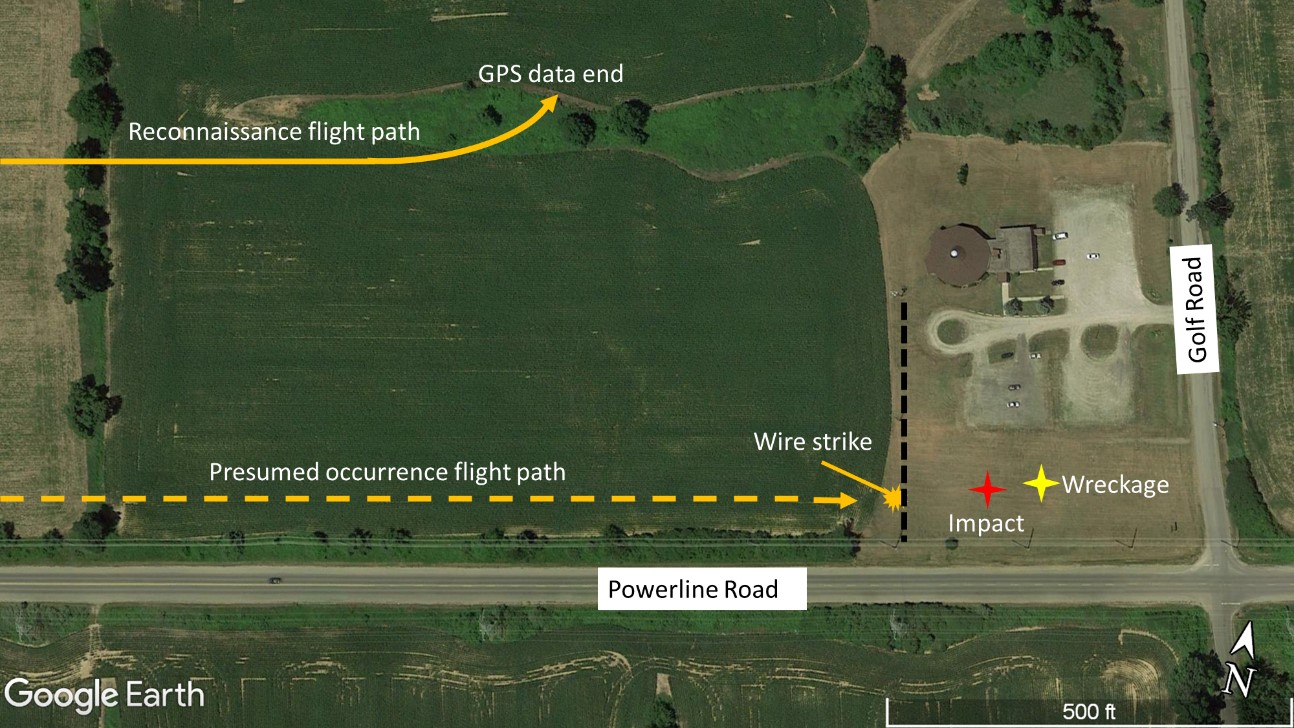

At 0658:30, the pilot reached the fields and first conducted a reconnaissance to assess hazards in the area where spraying would soon take place. The reconnaissance began over the north end of the first field to be sprayed, at approximately 150 feet above ground level (AGL). After flying eastbound parallel to the intended direction of the first spray run, the pilot made a left turn towards the north in order to assess other fields that would be sprayed that morning. The last point recorded by the GPS (global positioning system) aboard the helicopter shows the beginning of this left turn at 0658:36. Although the precise track could not be determined after this time, it is presumed, based on wreckage and occurrence site information, that the pilot then completed a reconnaissance, continuing counter-clockwise around the fields to be sprayed, before positioning the helicopter for the first spray run along the south end of the occurrence field, parallel with Powerline Road (Figure 1).

The helicopter presumably flew parallel to the south edge of the field, on a heading of approximately 077° magnetic (M). At 0659:44, it struck wires at a height of approximately 30 feet AGL. Control of the helicopter was lost, and the helicopter collided with the ground before coming to rest on a grassy field approximately 270 feet beyond the wire strike location.

1.2 Injuries to persons

The pilot, who was alone on board the helicopter, received serious injuries.

1.3 Damage to aircraft

The helicopter was destroyed as a result of the wire strike and collision with terrain.

1.4 Other damage

The wires that were struck and severed by the helicopter resulted in the power to the nearby church being cut off, and in a local power outage because they fed from the main wires along Powerline Road, one of which had become disconnected due to the wire strike.

1.5 Personnel information

At the time of the occurrence, the pilot held the appropriate licence and a valid medical certificate, and met the recency requirements for the flight in accordance with existing regulations.

The pilot began flight training in September 2016 and received her commercial pilot licence – helicopter in November 2017.

She began working at Apex in July 2017 as a mix-rig driver for the crop-spraying season. During the 2018 and 2019 seasons, she performed the roles of mix-rig driver and pickup truck driver. During the 2020 season, she received aerial application training on the Robinson R44 and the Bell 206B helicopters. She then conducted 65.7 hours of aerial application flying between 23 July and 01 September 2020, all on the Robinson R44 helicopter, while sharing duties as a mix-rig driver. The 2021 season was to be her first full season as a pilot on the Robinson R44 helicopter. Between 14 July 2021 and the occurrence flight, she had accumulated 50.9 flight hours, 47.7 of which were flown during aerial application flights and 3.2 were flown during training or positioning flights.

The occurrence pilot completed company recurrent training on 18 July 2021.

| Pilot licence | Commercial pilot licence – helicopter (CPL – H) |

|---|---|

| Medical expiry date | 01 July 2022 |

| Total flying hours | 263.1 |

| Flight hours on type | 182.9 |

| Flight hours in the 7 days before the occurrence | 49.6 |

| Flight hours in the 30 days before the occurrence | 50.9 |

| Flight hours in the 90 days before the occurrence | 50.9 |

| Flight hours on type in the 90 days before the occurrence | 50.9 |

| Hours on duty before the occurrence | 1.5 |

| Hours off duty before the work period | 17 |

1.6 Aircraft information

| Manufacturer | Robinson Helicopter Company |

|---|---|

| Type, model and registration | R44, Raven I, C-FVPA |

| Year of manufacture | 2000 |

| Serial number | 0846 |

| Certificate of airworthiness date | 05 May 2001 |

| Total airframe time | 2180.8 hours |

| Engine type (number of engines) | Textron Lycoming O-540-F1B5 (1) |

| Rotor type (number of blades) | Semi-rigid (2) |

| Maximum allowable take-off weight | 2400 lb (1088.6 kg) |

| Recommended fuel type(s) | 100, 100 LL, 100VLL, UL91, UL94 |

| Fuel type used | 100 LL |

The most recent maintenance on the occurrence helicopter had taken place on 16 July 2021, and a 100 hour inspection had been completed on 12 July 2021. The engine had accumulated 88.9 hours since overhaul.

The investigation revealed nothing to indicate that any airframe, flight control, or engine malfunctions contributed to this occurrence, nor were there any indications that installed equipment had prevented the aircraft from operating normally during the occurrence flight.

Apex had purchased the occurrence helicopter in June 2020; however, the previous owner did not cancel his registration until 11 January 2021. Apex submitted an application for registration to Transport Canada (TC) on 15 January 2021 and made multiple attempts to follow up regarding the status of the registration document during the months leading up to the occurrence. On 13 August 2021, 19 days after the occurrence—and 210 days after the application was first made—TC contacted Apex to request further details about the application.

The occurrence helicopter was not registered at the time of the occurrence because the interim certificate of registration, dated 15 July 2020, was only valid for 90 days.

1.6.1 Aerial spray system supplemental type certificate

The helicopter had been modified with an Apollo Spray model DTM-4 spray system in accordance with Supplemental Type Certificate (STC) SR01215CH, which had been approved by the Federal Aviation Administration on 15 June 2000 and accepted by TC on 27 March 2009.

The system consists of a 92 gallon plastic tank mounted between the skids of the helicopter on a steel frame, a small gasoline engine mounted outboard of the left side of the fuselage, and a spray bar assembly located approximately in line with the front seats and extending up to 12 feet on each side of the helicopter (Figure 2).

The gasoline engine is serviced by the mix-rig driver before the first flight of the day, and when the helicopter returns to reload. The pilot is not required to monitor or control the gasoline engine during flight.

The spray system is activated and deactivated by the pilot using a toggle switch on the cyclic control stick. The pump draws the chemical from the plastic tank and routes it to the spray bar assembly under pressure, after which the chemical is dispensed from a series of nozzles attached to the spray bar. The toggle switch interfaces with the TracMapFootnote 3 GPS system to indicate and record when and where the chemical has been applied.

The STC does not alter the allowable centre of gravity range or maximum allowable gross weight of the helicopter that are detailed in the pilot’s operating handbook.Footnote 4

It is reported that, during spray operations, a film of the spray chemical is often deposited on the windshield of the helicopter, which can adversely affect visibility. This requires the windshield to be cleaned when the helicopter is shut down during a work day as well as at the end of the duty day. It was reported that the windshield had been cleaned the morning of the occurrence flight.

1.6.2 TracMap GPS guidance

Apex uses a GPS to facilitate and record the aerial application of chemicals. The device in use on the occurrence helicopter was a TracMap Flight1 (Figure 3), which was introduced in 2007 by TracMap New Zealand, a company specializing in GPS devices and software for agricultural spray purposes.

The Flight1 GPS was mounted next to the instrument cluster in a position roughly above the pilot’s knees where it could be easily referenced in flight by the pilot.

Before spraying begins, a shape file containing the outlines of the field(s) to be sprayed is loaded into the GPS using a USB (universal serial bus) key.

The GPS receives input when the pilot toggles the spray bar on or off, which allows it to depict where spraying has been completed on a moving map. If the device were to malfunction, the pilot would discontinue the spraying until the device was back online, as the coverage of the chemical would not be documented, and thus could not be verified by, or billed to, the customer.

Upon completion of spray operations, the file is downloaded from the device onto the USB key and given to the customer, who can verify that their fields have received adequate coverage of the requested chemical.

The Flight1 GPS recovered from the occurrence helicopter was found with minor damage to the screen and the outer casing. It was sent to the TSB Engineering Laboratory in Ottawa, Ontario. It functioned normally when it was examined.

Partial flight data for the occurrence flight were recovered from the device memory, providing track, ground speed, and altitude data covering the time period between 0646 and 0658 on 25 July 2021, as well as data from many previous flights. The final 5 points of data show the helicopter flying eastbound over the occurrence field at approximately 150 feet AGL and a ground speed of 80 knots, before beginning a gradual turn towards the north. One minute and eight seconds elapsed between the last GPS data point and the collision with wires.

During examination of the data, it was noted that there were gaps in the continuity of the data in each of the recorded flights, most often between 10 and 15 seconds long, with some lasting between 4 and 10 minutes. Because there was no evidence of data corruption, internal processing priorities within the software were considered the most likely reason for the gaps, including the missing 1 minute 8 seconds of flight data at the end of the occurrence flight.

1.6.3 Weight and balance

Based on the information gathered during the investigation, the weight and centre of gravity of the helicopter were within the prescribed limits at the time of the occurrence.

1.7 Meteorological information

The weather reported by the Kitchener/Waterloo Airport (CYKF), Ontario, and the Hamilton Airport (CYHM), Ontario, both about 17 nautical miles from the occurrence site, met the minimum requirements for VFR flight at the time of the occurrence.

At 0657, the automated reporting station at CYKF reported visibility of 5 statute miles (SM) with mist and a few clouds at 600 feet AGL. At 0708, 9 minutes after the occurrence, the station reported 3 SM visibility in mist, and a broken ceiling at 600 feet AGL.

At 0643, an observation at CYHM showed 9 SM visibility with shallow fog and a few clouds at 1500 feet AGL, and few clouds at 21 000 feet AGL. The next observation at 0700, less than 1 minute after the occurrence, reported 12 SM visibility and a few clouds at 1500 feet AGL and few clouds at 21 000 feet AGL.

The weather was not considered to be a factor in this occurrence.

1.8 Aids to navigation

Not applicable.

1.9 Communications

Not applicable.

1.10 Aerodrome information

Not applicable.

1.11 Flight recorders

The helicopter was not equipped with a flight data recorder or a cockpit voice recorder, nor was either required by regulations. As noted in this report, the incomplete data provided by the onboard GPS resulted in uncertainty about the flight path and speed of the helicopter in the moments preceding the wire strike.

The benefits of recorded flight data in aircraft accident investigations are well known and documented.Footnote 5 Following an occurrenceFootnote 6 on 13 October 2016 in which a privately operated Cessna Citation 500 collided with the ground and fatally injured the pilot and 3 passengers, the Board recommended that

the Department of Transport require the mandatory installation of lightweight flight recording systems by commercial operators and private operators not currently required to carry these systems.

TSB Recommendation A18-01

In its September 2021 response to this recommendation, TC indicated that it agreed in principle with this recommendation and that proposed changes to the regulation mandating the installation of lightweight data recorders in existing aircraft and their installation in newly manufactured aircraft are expected to be published in the Canada Gazette, Part I in late 2023, and in the Canada Gazette, Part II between mid-to-late 2024. In its March 2022 assessment of TC’s response, the TSB stated it was encouraged by TC’s proposed amendments, but was concerned by the recently announced delays. If regulations are implemented as proposed, the risks associated with the safety deficiency identified in Recommendation A18-01 should be addressed. Therefore, the response to Recommendation A18-01 was assessed to be Satisfactory Intent.Footnote 7

1.12 Wreckage and impact information

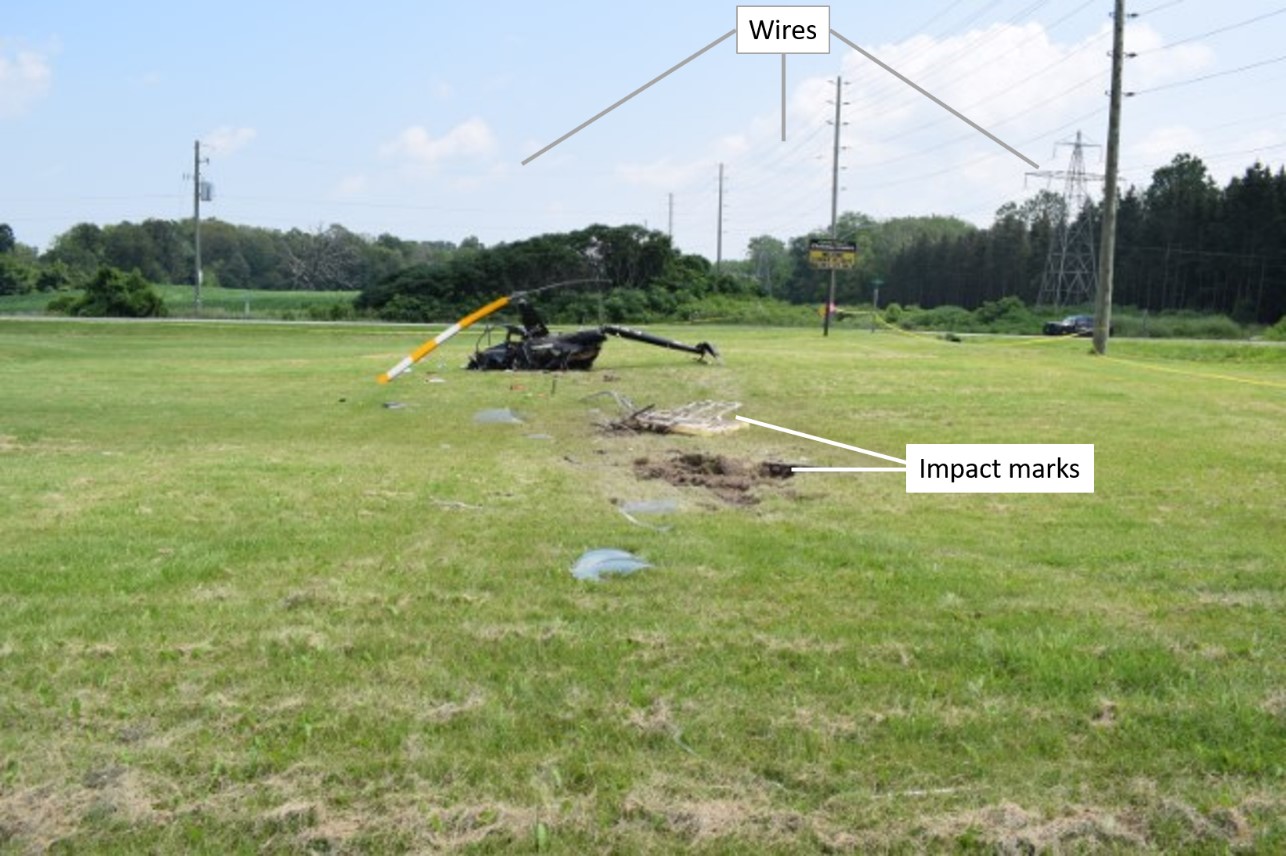

The main wreckage was found approximately 270 feet east of the wires that were struck; the fuselage, main rotor blades, tail boom, and tail rotor remained mostly attached, while the skids, spray bar, and chemical tank became detached on initial contact with the ground (Figure 4).

The top 3 of 4 wires were severed by the helicopter. The lowest wire, which remained intact, was at a height of approximately 25 feet AGL, while the top wire was approximately at 37 feet AGL. Sections of wire were found wrapped around the top of the main rotor mast just below the hub, and at the bottom of the mast pylon. The lowest wire struck appears to have been severed by the skid assembly mounted below the helicopter.

1.12.1 Occurrence site

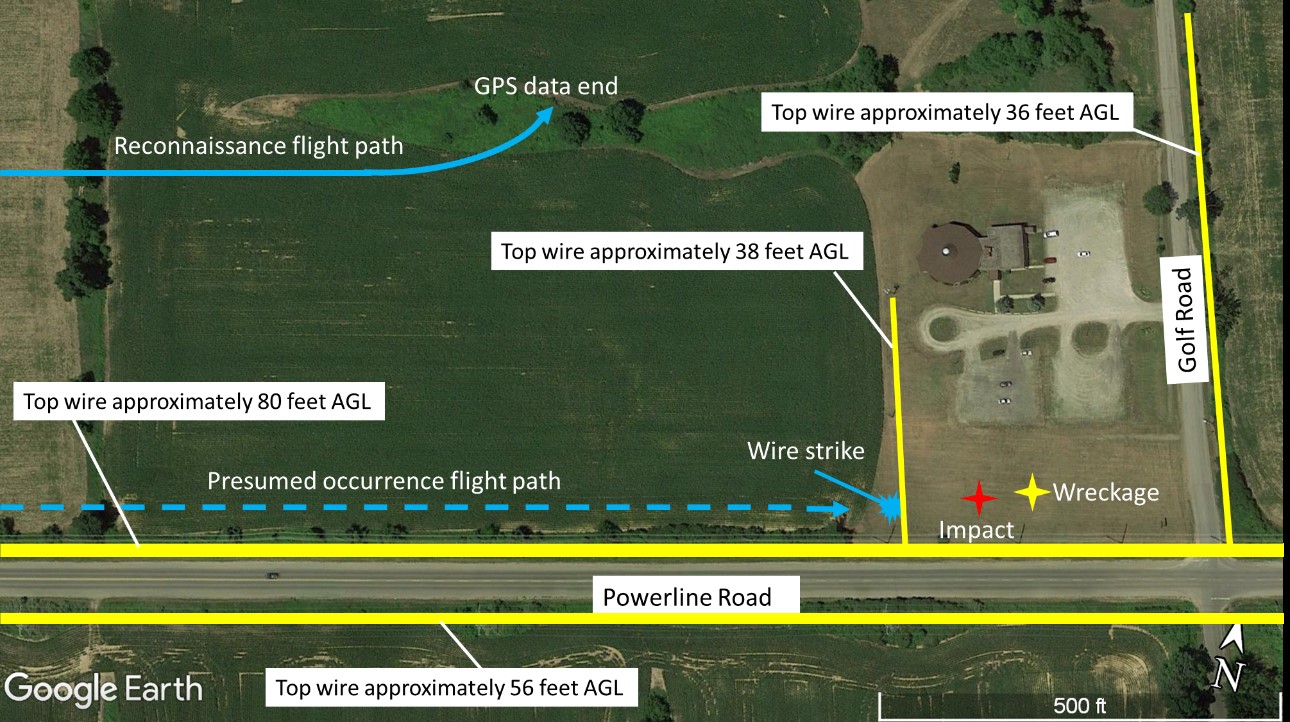

The wire strike occurred near the intersection of Powerline Road and Golf Road, at the boundary between the corn field and a church property located on Golf Road. Wires were running parallel to the occurrence flight path, on either side of Powerline Road, at heights of up to 80 feet AGL. There were also wires along Golf Road, 1000 feet to the east of the occurrence site; these were up to 36 feet AGL and parallel to the wires that were struck (Figure 5).

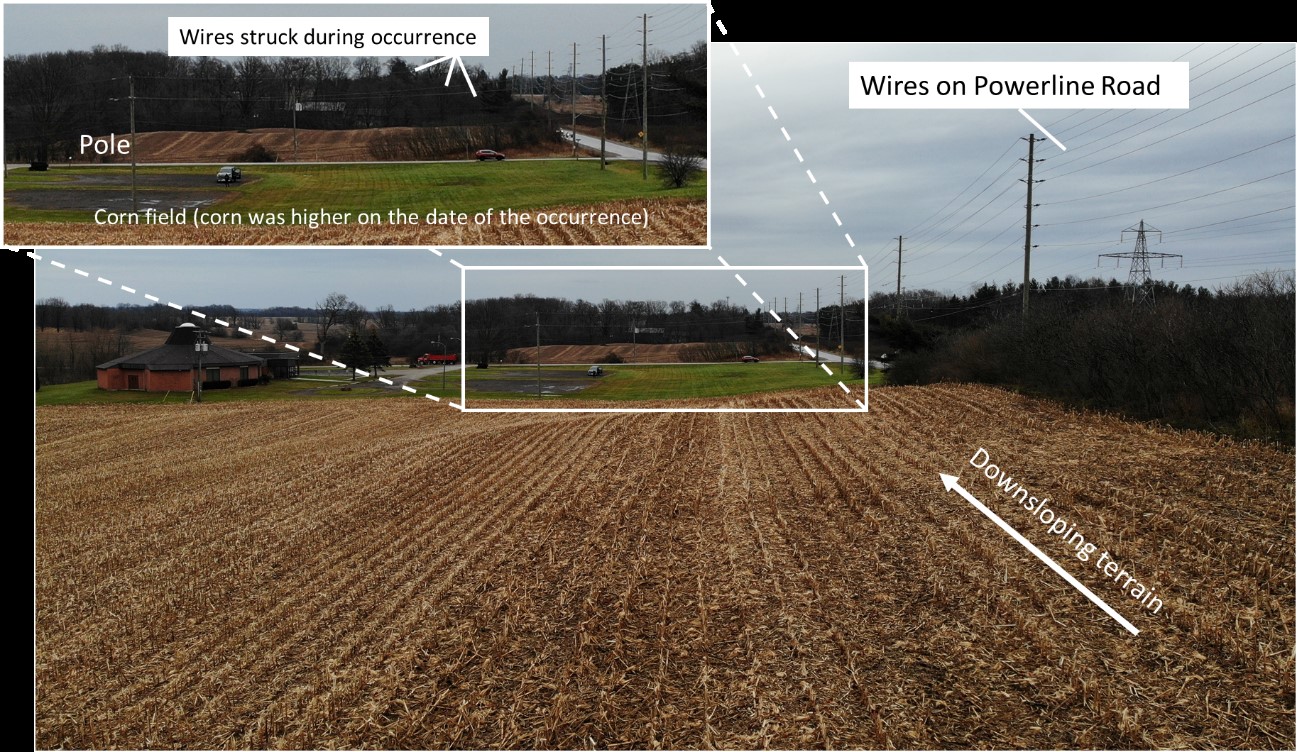

The wires that were struck by the helicopter supplied electricity to the church, and were adjacent to the corn field along the boundary between the properties. The wires originated from a 56-foot tall pole along Powerline Road, and sloped downwards towards the first of two 38-foot tall poles located on the church property and spaced 150 feet apart. These poles were situated along the edge of the corn field, between 10 and 20 feet from the edge of the corn. When viewed from the west, the corn obscured the bases of these poles.

The corn field, which the pilot had presumably been spraying before striking the wires, sloped downwards towards the church property, with a reduction in elevation of at least 30 feet (Figure 6).

1.13 Medical and pathological information

According to information gathered during the investigation, there was no indication that the pilot’s performance was affected by medical or physiological factors.

1.14 Fire

There was no fire either before or after the occurrence.

1.15 Survival aspects

The pilot was wearing a lap belt and shoulder harness, and a helicopter helmet. There was damage to the front and the back of the pilot’s helmet.

The emergency locator transmitter (ELT) (a Kannad model 406AF-Compact) did not activate during the occurrence. The ELT selector was found in the OFF position, rendering the ELT unable to transmit a distress signal. It is unknown if the selector was turned off before the flight or during the impact sequence.

This model of ELT is the subject of a TSB Air Safety AdvisoryFootnote 8 that was issued following 2 other helicopter occurrences where the ELT was found in the OFF position. The safety advisory recommends periodic inspections of the ELT to verify the integrity of the switch locking mechanism. In these previous instances, the switch locking mechanism was found to be damaged, while the switch locking mechanism in the ELT from this occurrence was found undamaged.

1.16 Tests and research

While it is possible that the switch of the occurrence ELT had been in the OFF position before flight, this model of ELT has also been found in the OFF position at the site of other occurrences, Footnote 9 prompting a series of drop tests on the occurrence ELT to determine whether impact could affect the switch position.

Preliminary testing Footnote 10 of the occurrence ELT was conducted at the TSB’s Ontario regional office. A series of drops from heights of 5 feet and below at various angles onto a hard surface was completed. It was found that, with the unit oriented approximately 45° from vertical as required by the manufacturer and how it was installed in the occurrence helicopter, the mode switch on the ELT would frequently move from the ARM position to the OFF position due to the impact forces, despite the spring and mechanical guard designed to prevent this behaviour remaining intact. Footnote 11 This was shown to occur from heights as low as 3 feet. Before the drop testing commenced, the ELT was operating normally and producing a distress signal.

Following the preliminary testing, the unit was sent to the TSB laboratory for further examination and testing. X-ray imagery confirmed that the mode switch, including the mechanical guard and spring, was undamaged. Examination of the electronic components, however, revealed that the ELT was no longer functional. The cables leading from the internal battery to the unit had not been correctly routed during battery installation, exposing them to damage during the impact and the preliminary drop testing. Drop and impact testing at the TSB laboratory confirmed the results of the initial testing, and indicated that the inertia of the mode switch itself, imparted by the impact, was likely overcoming the spring pressure and allowing the mode switch to move from the ARM position to the OFF position. This testing was not intended to replicate certification testing and was only intended to confirm whether the switch position could be affected by impact.

1.16.1 TSB laboratory reports

The TSB completed the following laboratory reports in support of this investigation:

- LP097/2021 – TracMap GPS – Data recovery

- LP137/2021 – ELT Analysis

1.17 Organizational and management information

1.17.1 Operator

Apex is based at the Wingham/Richard W. LeVan Aerodrome (CPR7), in Wingham, Ontario. It operates in accordance with Subpart 702 (Aerial Work) of the Canadian Aviation Regulations (CARs). Aerial work includes aerial application, vertical reference work (long-lining), banner towing, pipeline patrol, and aerial photography.

Flight operations at Apex are almost exclusively related to aerial application,Footnote 12 and are conducted between July and October. During the week leading up to the occurrence flight, and during the occurrence flight itself, fungicide was being applied to corn fields.

At the time of the occurrence, the Apex fleet consisted of 1 Robinson R44 helicopter, 1 Bell 206L helicopter, and 2 Bell 206B helicopters, which were all equipped for aerial application.

1.17.1.1 Temporary bases

Apex conducts aerial application flights on corn fields across southern Ontario. As it is not practical to operate out of its main base for each flight, temporary bases are set up to allow crews and their equipment to be closer to the work sites. Each crew is assigned a travel trailer in which to live and sleep during the season.

Each morning, the helicopter and mix rig are repositioned to be as close as possible to the fields to be sprayed. When the day’s work is complete, the helicopter and mix rig normally return to the staging area for overnight parking. Occasionally, one or both are left near the work site overnight for a variety of reasons, including a stoppage of work due to weather.

On the day before the occurrence flight, the spraying operations had been interrupted by weather. The helicopter had been left parked near the work site, in a field away from public view, as it was anticipated that the spraying would resume once the weather had improved. In this case, the weather did not improve, so the helicopter was left there overnight.

1.17.1.2 Aerial application crew

Each crew is normally composed of a helicopter pilot, a mix-rig driver, and a pickup truck driver. In this case, there was no pickup truck driver available, so the mix rig was being used to travel to and from the job site.

The mix-rig driver is responsible for finding an appropriate site and surface (level and free of obstructions) on which to park the rig before the helicopter can land on it. During spraying operations, the mix-rig driver coordinates with the pilot regarding the amount of fuel and spray chemical to be used during the next flight, and refuels and reloads the helicopter accordingly. He verifies the correct operation of the gasoline engine that powers the pump for the spray bar, and often helps the pilot with tasks such as cleaning the helicopter windshield, performing maintenance, and cleaning the spray nozzles and equipment.

1.17.1.3 Mix rig

The mix rig usually consists of a truck or a truck and trailer. In this occurrence, it was a box truck containing tanks for aviation gasoline, water, and chemical, and a platform on which to land the helicopter (Figure 7). The landing platform was 10 feet by 10 feet in size, with fold-out sections that are stowed when the truck is being driven. During operations, the helicopter is only parked on the landing platform when it is being refueled and reloaded with chemicals, which is accomplished while the helicopter is running with its engine at idle. During the work day, the mix rig is often repositioned in order to be as close as possible to the fields being sprayed, reducing flight hours and transit times and making the operation more efficient.

1.17.1.4 Flight operations

Before beginning the aerial application, Apex pilots are informally required to conduct a reconnaissance to identify hazards, such as structures and wires, in and around the fields, and to identify areas to avoid, including people, animals, and parked vehicles.

After the pilot calculates the amounts of fuel and chemical required, which will normally bring the helicopter close to its maximum gross weight, the mix-rig driver fuels and loads the helicopter accordingly. This procedure is repeated many times over the course of the day, as the pilot must return to refuel and reload at regular intervals, normally every 25-30 minutes. Approximately every 4 hours, the pilot parks on the ground and shuts down the helicopter to check the oil level. Most communications between the pilot and the mix-rig driver are accomplished using a VHF radio.

Using the Flight1 GPS, the pilot plans the spray runs, ideally along the longest edge of a field. The pilot aligns the helicopter with the intended flight path while approaching the field, and selects a visual cue beyond the end of the field to use as a reference point. The pilot is thus able to fly in a straight line while looking outside the helicopter. Subsequent spray runs are made by referencing the coverage as shown on the Flight1 GPS and aligning each run with a new outside reference point.

The pilot toggles a switch on the cyclic stick when beginning and ending a spray run, which activates and deactivates the spray system and records the coverage information on the Flight1 GPS. The ideal application of fungicide over a corn field should take place between 5 and 10 feet above the crop at an indicated airspeed of 60 to 65 knots.

Upon reaching the end of the field, the pilot performs what is known as a spray turn, which involves a climb to approximately 100 feet AGL (altitude variable based on obstructions or surroundings), a reversal of direction, and a descent to 5 to 10 feet above the crop before beginning a spray run in the opposite direction. This process is repeated until either the entire field has been sprayed, or until refueling and reloading is necessary.

1.17.2 Aerial work training requirements

Subpart 702 of the CARs requires that “[a]n air operator shall […] include a detailed syllabus of its ground and flight training program in its company operations manual.”Footnote 13

Subpart 702 of the CARs also requires that an air operator’s ground and flight training program shall include, among other things, “training in the aerial work to be conducted.”Footnote 14 Further detail is found in the associated Commercial Air Service Standard (CASS):

(6) Aerial Work Training

(a) Pilot training shall be provided where the aerial work requires particular flight manoeuvres, aircraft performance considerations or knowledge of equipment to safely conduct the operation.

Training shall include, as applicable:

(i) training related to contents and requirements of flight manual supplements or airworthiness approvals;

(ii) pre-flight inspection requirements of aerial work equipment;

(iii) procedures for handling malfunctions and emergencies related to the aerial work equipment;

(iv) operational preparation procedures related to reconnaissance of aerial work areas before low level flight operations;

(v) operational restrictions; and

(vi) flight training and practice in required flight manoeuvres.Footnote 15

There is no guidance about the amount of time required to be spent on any part of, or the entirety of, the required training.

Although reconnaissance of aerial work areas is specifically mentioned in subparagraph (iv), the interpretation and application of this requirement is left to the individual operators. TC does not provide guidance on how to train pilots in these procedures, nor does it require that airborne reconnaissance be practised during training or completed before conducting aerial work.

1.17.3 Apex training

Every year, at the beginning of the season, Apex conducts a pilot competency check (PCC) for each of the pilots and gives them additional training on aerial application flying, which is not evaluated during the PCC.

The Apex company operations manual (COM) details training as it relates to the PCC, but does not describe in detail the aerial application training. Apex has developed a separate document, titled Introduction to Aerial Application, to facilitate training and educate its pilots on this type of flying. This document is not mentioned in the COM.

Apex pilots are expected to conduct reconnaissance of each field before beginning spray operations. They are instructed to conduct the reconnaissance before fueling and loading the helicopter when possible, so that the helicopter performance and manoeuvrability is not hindered by heavier weights. These procedures are taught during the in-flight training given by Apex, and are evaluated during each year’s recurrent training.

There is no stated requirement in the COM or the training document that pilots must conduct a reconnaissance before aerial application begins; however, it is encouraged in the training document as a strategy to prevent wire strikes. Footnote 16 The training document provides procedures for various types of reconnaissance, Footnote 17 and Apex reportedly includes reconnaissance in its in-flight training for initial hires and returning pilots.

1.18 Additional information

1.18.1 Previous occurrences

The occurrence in this report is the 3rd wire strike involving a Robinson R44 helicopter operated by Apex since 2011.Footnote 18 Neither of the other 2 wire strikes resulted in injuries to the pilot.

The TSB also investigated a 2015 accident in which an Apex Robinson R44 helicopter collided with terrain during a repositioning flight, resulting in 2 fatalities.Footnote 19

1.18.2 Glare from the sun

The sun, which had risen approximately 55 minutes before the occurrence, was almost directly in front of the helicopter’s flight path during the initial—and crucial—portion of the reconnaissance, as well as the spray run which led to the wire strike. Solar glare Footnote 20 from direct or reflected sunlight affects visual performance by reducing visual acuity and contrast. Glare is most intense when the sun is low on the horizon, as it was during this occurrence.

The investigation was not able to determine whether there was any mist in the area at the time of the occurrence, which may have affected the intensity of the glare from the sun. Additionally, any dirt, debris, or film that accumulated on the windshield since it was last cleaned could also have affected glare from the sun and visibility of the wires in flight. However, this could not be verified as the windshield was destroyed during the accident sequence.

Based on damage to the pilot’s helmet, it was determined that she had been looking through a yellow-tinted visor that was incorporated into her helmet; a yellow tint visor is normally used during flight in hazy conditions.

1.18.3 Visibility of wires in flight

Wires can be difficult to see during flight. According to an article published in Aviation Week, “[w]ires aren’t consistently visible all of the time. Changing sunlight patterns can obscure them. [...] A wire that is perfectly visible from one direction may be completely invisible from the opposite.” Footnote 21

Many factors can increase the difficulty of seeing wires in a low‑level environment:

A pilot’s ability to see and avoid collision with wires is complicated by the flood of visual cues seen from a different perspective as low-level work is carried out; by vegetation, shadows and landforms blocking the pilot’s view of wires and wire support structures; by cockpit ergonomics; and by seemingly minor things like smudged handprints on the windscreen and insect [sic] that speckle the windscreen. Footnote 22

A 2006 report by the Australian Transport Safety Bureau (ATSB) based on data from 119 general aviation wire strike accidents found that, in 63% of the 82 accidents where it could be established whether or not the pilot had prior knowledge of the wire before it was struck, the pilot was aware of the location of the wires. Footnote 23 In addition, 81% of the wire strikes occurred during a manoeuvring phase of flight. Footnote 24 Out of the 119 accidents studied, 74 occurred during agricultural flights.

1.18.4 Very low-altitude flying

Aerial application flying requires pilots to fly as low as 5 feet above the crops being sprayed, often in areas surrounded by obstacles of many types, including wires, trees, and structures. In addition, pilots are trained and encouraged to make efficient use of time and space while making spray turns. These flying techniques are specific to aerial application, whether done with a rotary- or fixed-wing aircraft, and carry with them an inherently elevated level of risk.

When an airplane or helicopter is operated for the purposes of aerial work under Subpart 702 of the CARs, there is no requirement for pilots to remain above a minimum altitude AGL.

1.18.5 Risk perception

Risk is a function of likelihood and consequences. Risk perception is the recognition of the risk inherent to a situation. Helicopter pilots, particularly pilots who conduct low-flying operations, are well aware of the potentially fatal consequences posed by a wire strike. Their focus is to avoid it, i.e. eliminate its likelihood.

Risk perception can be altered and skewed from a pilot’s experience of a situation, and situations that present a high level of risk for one person may present only low risk for another. Footnote 25 Additionally, pilots who have experienced more hazardous events tend to have a lower perception of risks when compared to pilots who have experienced fewer hazardous events. Footnote 26 Likewise, individuals who repeatedly perform a dangerous activity with no, or few, negative repercussions may become desensitized or habituated to the high level of risk. Problems can arise when perceived risks no longer match the actual risks and dangers associated with an activity.

1.18.6 Wire strike avoidance

1.18.6.1 Physical markings

While markers can be installed on power wires in order to make them more visible, markers are not required when the wires are less than 90 m (295.3 feet) AGL. Markers are most often used on wires located under the approach path near a runway, or on wires that cross a river or valley.

There were no wire markers installed on any of the wires in the vicinity of the occurrence site.

1.18.6.2 Visual flight rules navigation charts

VFR navigation charts (VNCs) are

used by VFR pilots on short to extended cross-country flights at low to medium altitudes and at low to medium airspeeds. The chart displays aeronautical information and sufficient topographic detail to facilitate air navigation through the use of a unique colour scheme, layer tinting, and shaded relief. There are 52 charts in the series. The scale is 1:500,000. Footnote 27

While VNCs do depict obstacles and hazards, such as towers and some power wires, they do not provide the level of detail that would be necessary to assist aerial application pilots in assessing the hazards related to individual fields and their surroundings. As far as this occurrence is concerned, only the wires running along the south side of Powerline Road were depicted on the Toronto VNC, which covers the occurrence area.

1.18.6.3 Wire-strike protection systems

Passive wire-strike protection systems can be installed on fixed-wing and rotary-wing aircraft to help mitigate the hazards of a wire strike. These systems are designed to either cut or deflect wires to prevent them from damaging or arresting the motion of the aircraft, and they normally rely on the momentum of the aircraft to cut the wire(s). They are not completely effective in all aircraft attitudes or airspeeds. They also require adequate structure on which to be mounted because they must be able to withstand significant forces in order to function as designed.

There are no wire strike kits available for the Robinson R44 helicopter. It is uncommon to have these kits installed on smaller aircraft, given that in many cases these aircraft are not designed with adequate structure on which to mount them. Additionally, smaller and lighter aircraft may travel too slowly for the wire strike protection systems to be effective.

2.0 Analysis

The investigation determined that the aircraft was maintained in accordance with existing rules and regulations, and that the occurrence flight was operating within the rules and guidelines laid out in the Canadian Aviation Regulations (CARs), the Commercial Air Service Standards (CASS), and the company operations manual (COM).

There was no evidence of any pre-impact mechanical issues that would have affected the helicopter at the time of the wire strike. The wire strike most likely occurred during the first spray run of the morning, immediately following a reconnaissance of the fields to be sprayed.

Therefore, this analysis will focus on the risk perception by pilots who routinely operate at very low altitudes and in the vicinity of wires, the salience of hazards present at the site of the occurrence, and the factors that may have affected the pilot’s ability to detect those hazards, during both the reconnaissance and the presumed spray run.

The training received by the pilot relating to reconnaissance and hazard assessment will also be examined in light of Transport Canada (TC)’s training requirements for CAR 702 operators.

2.1 Location and prominence of power wires

Power transmission wires are difficult to see in flight. Although there are solutions to provide awareness to pilots of their locations, such as depiction on visual flight rules navigation charts, physical markings, and reconnaissance—these solutions are not infallible.

In the area of the occurrence, along with easily detectable hazards such as trees and buildings, there were 2 prominent sets of wires running east to west just south of the occurrence site and a 3rd set of wires running perpendicular to the occurrence flight path. These 3 sets of wires were all located along the roadsides, where pilots would expect to see them, making it likely that they would be easy to detect during a reconnaissance and to avoid during subsequent spraying operations.

The wires that were struck were significantly less prominent. Instead of running along a roadside or the church driveway, they ran along the edge of a corn field, which is not where pilots expect to see them, nor where they focus on scanning for hazards. These wires were lower than the 2 prominent sets of wires running east to west, and the bases of their associated poles were obscured by the corn. Consequently, they were more difficult to detect from the air, especially when viewed from the west.

Finding as to causes and contributing factors

The wires the helicopter struck were lower than other nearby wires, and were oriented along the edge of a corn field rather than the more common position alongside a road. As a result, in addition to the wires not being prominent, the pilot did not expect to encounter them in that location.

2.2 Forward visibility

A few factors likely affected the forward visibility available to the pilot during both the reconnaissance and the presumed spray run.

Both flight paths were eastbound and occurred shortly after sunrise. The position of the sun, which was almost directly in front of the flight path and low on the horizon, and the sun’s glare made identifying hazards more difficult. The pilot likely would have had to focus her attention to the side of or below the direct sunlight to avoid looking into the glare. When flying low to the ground in a helicopter, not being able to see straight ahead makes detection of objects such as wires very difficult.

Additionally, the windshield was known to accumulate a thin film during spray operations. Although it was reported to have been cleaned, any film, dirt, or debris accumulating on the windshield since it was last cleaned could have affected forward visibility and exacerbated the effects of the glare from the sun.

Finding as to causes and contributing factors

The eastbound portion of the reconnaissance flight path and the occurrence flight path were both conducted directly towards the sun; the sun’s glare, possibly combined with a film of spray fluid, dirt, or debris on the helicopter’s windshield, affected the pilot’s forward visibility.

2.3 Risk perception

Aerial application flying is a very low-altitude operation, especially during the application of fungicide to corn fields, which requires low flight in hazardous areas. Many aspects of the operation are repetitive as well, allowing pilots to become proficient in and habituated to operating in that environment and in the presence of wires.

Individuals who repeatedly perform a dangerous activity with no, or few, negative repercussions may become desensitized or habituated to the high level of risk. Problems can arise when perceived risks no longer match the actual risks and dangers associated with an activity.

Although several factors affected the occurrence pilot’s ability to see the wires feeding power to the church, the pilot’s frequent exposure to wire hazards without a negative outcome also likely affected the thoroughness of the reconnaissance.

Findings as to causes and contributing factors

The pilot’s frequent exposure to the risk of wire strike without a negative outcome likely altered the pilot’s risk perception and negatively influenced the thoroughness of the reconnaissance.

The reduced perception of risk, the unexpected location of the occurrence wires, and forward visibility impairments resulted in the pilot not identifying the wires during the reconnaissance.

2.4 The spray run

In addition to the factors that affected the perception of the wires during the reconnaissance, the presumed spray run was also affected by topography.

The terrain overflown at low level during the presumed spray run sloped downwards from west to east, lowering in elevation by approximately 30 feet. The pilot would have been descending during the occurrence spray run in order to follow the sloping terrain, requiring more of her attention to be diverted to altitude keeping during the moments before the wire strike.

Additionally, because the wires feeding power to the church were strung between poles that were 38 feet above ground level, they would not have been visible above the horizon, when viewed from a low-flying aircraft, until very late in the spray run. However, given that the exact height of the helicopter is unknown, it could not be determined at what point the wires would have appeared above the horizon.

Findings as to causes and contributing factors

During the presumed spray run, the downslope of the corn field being sprayed required the pilot to split her focus between maintaining the aircraft’s altitude and its track, reducing the amount of time available to scan for obstacles.

The combination of the ineffective reconnaissance, the unexpected location of the wires, the impaired forward visibility, and the reduced time available to detect and avoid the wires resulted in the pilot not seeing the wires during the presumed spray run. Consequently, the helicopter struck the wires and crashed.

2.5 Training

2.5.1 Aerial work training requirements

The required training for aerial work operators set out in Standard 722 of the CASS includes reconnaissance of aerial work areas before low-level flight operations. However, the CASS does not elaborate on, or provide guidance for, the amount of time to be spent on this training.

The aerial work sector covers a wide variety of operations types, including but not limited to: aerial application, vertical reference work (long-lining), banner towing, pipeline patrol, and aerial photography. Each of these types of aerial work has its unique challenges and risks, but the training requirements in the CASS do not address the diversity in this sector. Instead, it is left to the individual operator to determine how to appropriately train their personnel for the specific tasks they will be required to perform.

An operator’s training program is outlined in its operations manual, which is approved by TC, but is not required to be specific about how the training will be accomplished. The approved training program is considered to be adequate as long as the training is provided to the pilots as set out in the manual. To assess compliance and ensure that all applicable training has been completed, TC can verify the completed training forms. There are very few required items that CAR 702 operators must include in their training program, and no required items relating to specific types of aerial work.

A CAR 702 operation often requires only a pilot competency check (PCC), which is meant to assess the pilot’s competency in flying the aircraft only, and does not include exercises related to the specific type of aerial work being done by the company.

In other sectors such as commuter operations (CAR 704) and airline operations (CAR 705), TC is much more prescriptive when it comes to training and testing elements, to the extent that pilot proficiency check (PPC) flights on large aircraft are almost entirely scripted. It would be difficult to prescribe appropriate training exercises or scenarios that would apply across the spectrum of operations that take place in the aerial work sector. Without job-specific training requirements mandated by TC, the onus is on the operators to tailor their flight training to the type of operation and aircraft on which the training occurs, taking into account the associated risk factors.

Finding as to risk

If aerial work training requirements are not specific to the various types of operations included in the sector, there is a risk that significant safety-related procedures will not be emphasized in training programs, or monitored by the regulator.

2.5.2 Hazard assessment training at Apex

Apex training with regards to reconnaissance and general hazard assessment consists mainly of classroom training, including watching videos about hazard awareness followed by group discussion. It is reinforced with practical training as part of the pilots’ in-flight spray training.

Apex pilots are trained to fly a reconnaissance around each field in which they will be spraying, in order to identify areas to avoid, such as people, animals, or parked vehicles, and assess hazards such as wires, towers, and structures. The reconnaissance is the primary means by which Apex pilots are trained to assess hazards.

The reconnaissance can be supplemented by other means, including online mapping resources such as Google Earth, ground-based reconnaissance, or a verbal briefing with the owners of the properties being sprayed. It should be noted, however, that use of additional methods of reconnaissance does not guarantee that all hazards will be identified. Apex neither encourages nor discourages the use of additional methods of hazard assessment, leaving the decision to augment their reconnaissance procedures to the pilots themselves.

Finding as to risk

If pilots rely on a single method of hazard assessment, such as a reconnaissance, there is an increased risk that hazards will go undetected, resulting in collisions or near-collisions with objects or terrain.

2.6 Survivability

2.6.1 Emergency locator transmitter

The emergency locator transmitter (ELT) installed in the occurrence helicopter likely switched to the OFF position during the impact with the ground, preventing it from sending a distress signal. The head of the toggle switch is held in the selected position by spring pressure and points forward and down (relative to a straight and level aircraft attitude) when installed in a helicopter. During impact, the inertia of the toggle switch itself can cause it to overcome the retaining spring pressure, allowing the switch to move and, in some cases, change positions during an impact sequence.

Finding as to risk

If an ELT becomes switched off or inoperable as a result of impact, there is a risk that an accident will go undetected, resulting in a delayed rescue or response, and a negative effect on survivability.

2.6.2 Helmet usage

At the time of the occurrence, the helicopter pilot was wearing her lap belt and shoulder harness as well as a helicopter helmet, which exhibited significant damage to the front and back resulting from the collision with terrain.

Finding: Other

Wearing a flight helmet and fastening the lap belt and shoulder harness helped to reduce the severity of the injuries to the pilot.

3.0 Findings

3.1 Findings as to causes and contributing factors

These are conditions, acts or safety deficiencies that were found to have caused or contributed to this occurrence.

- The wires the helicopter struck were lower than other nearby wires, and were oriented along the edge of a corn field rather than the more common position alongside a road. As a result, in addition to the wires not being prominent, the pilot did not expect to encounter them in that location.

- The eastbound portion of the reconnaissance flight path and the occurrence flight path were both conducted directly towards the sun; the sun’s glare, possibly combined with a film of spray fluid, dirt, or debris on the helicopter’s windshield, affected the pilot’s forward visibility.

- The pilot’s frequent exposure to the risk of wire strike without a negative outcome likely altered the pilot’s risk perception and negatively influenced the thoroughness of the reconnaissance.

- The reduced perception of risk, the unexpected location of the occurrence wires, and forward visibility impairments resulted in the pilot not identifying the wires during the reconnaissance.

- During the presumed spray run, the downslope of the corn field being sprayed required the pilot to split her focus between maintaining the aircraft’s altitude and its track, reducing the amount of time available to scan for obstacles.

- The combination of the ineffective reconnaissance, the unexpected location of the wires, the impaired forward visibility, and the reduced time available to detect and avoid the wires resulted in the pilot not seeing the wires during the presumed spray run. Consequently, the helicopter struck the wires and crashed.

3.2 Findings as to risk

These are conditions, unsafe acts or safety deficiencies that were found not to be a factor in this occurrence but could have adverse consequences in future occurrences.

- If aerial work training requirements are not specific to the various types of operations included in the sector, there is a risk that significant safety-related procedures will not be emphasized in training programs, or monitored by the regulator.

- If pilots rely on a single method of hazard assessment, such as a reconnaissance, there is an increased risk that hazards will go undetected, resulting in collisions or near-collisions with objects or terrain.

- If an emergency locator transmitter becomes switched off or inoperable as a result of impact, there is a risk that an accident will go undetected, resulting in a delayed rescue or response, and a negative effect on survivability.

3.3 Other findings

These items could enhance safety, resolve an issue of controversy, or provide a data point for future safety studies.

- Wearing a flight helmet and fastening the lap belt and shoulder harness helped to reduce the severity of the injuries to the pilot.

4.0 Safety action

4.1 Safety action taken

The Board is not aware of any safety action taken following this occurrence.

This report concludes the Transportation Safety Board of Canada’s investigation into this occurrence. The Board authorized the release of this report on . It was officially released on .