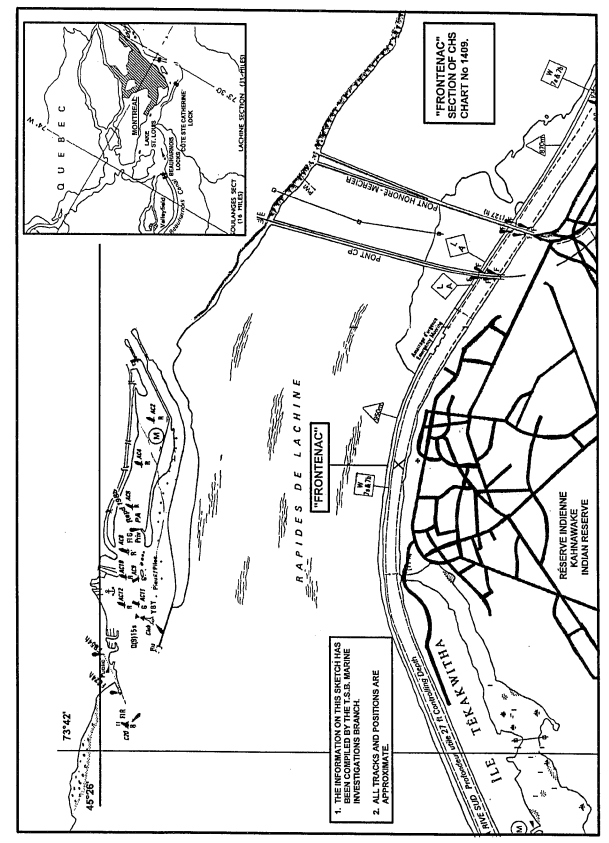

Striking of a concrete wall - Bulk Carrier "FRONTENAC"

Canal de la Rive Sud

St. Lawrence Seaway, Quebec

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

The "FRONTENAC" was transiting the St. Lawrence Seaway on 29 October 1993 bound for Hamilton, Ontario. When the vessel was off Kahnawake (Quebec), the main engine was stopped because of engine problems. The vessel drifted off course and struck the concrete wall bordering the southern edge of the canal. The vessel sustained some hull damage, and the Seaway was closed to shipping for nine and a half hours as a result of the occurrence. No one was injured, and no pollution was reported.

The Board determined that the engine problems resulted from one of the piston stud securing nuts of the No. 3 unit "backing off" and hammering against the piston rod gland diaphragm plate, which eventually fractured.

1.0 Factual Information

1.1 Particulars of the Vessel

| "FRONTENAC" | |

|---|---|

| Official number | 329342 |

| Port of registry | Montreal, Quebec |

| Flag | Canadian |

| Type | Bulk carrier |

| Gross TonsFootnote 1 | 17,808 |

| Length | 217.04 m |

| Draught | FFootnote 2: 7.92 m A: 7.92 m |

| Cargo | 24,187 tonnes of iron ore pellets |

| Complement | 28 |

| Built | 1968, Lauzon, Quebec |

| Propulsion | Sulzer 2SA, type RD 76, two-stroke, six-cylinder, turbocharged engine, capable of 7,061 kW, driving a single controllable-pitch propeller |

| Thruster | 1,000 HP bow thruster |

| Owners | The CSL Group Inc. (CSL) Montreal, Quebec |

1.1.1 Description of the Vessel

The "FRONTENAC" is an all-steel, self-unloading bulk carrier built for service on the Great Lakes and in the St. Lawrence River. She is fitted with a controllable-pitch propeller and a bow thruster. The main engine can be controlled from the engine-room or directly from the wheel-house.

1.2 History of the Voyage

On 29 October 1993, the "FRONTENAC", out of Sept-Îles, Quebec, was transiting the Canal de la Rive Sud in the St. Lawrence Seaway bound for Hamilton.

At about 0230Footnote 3, as the vessel was approaching Kahnawake, the engine-room staff called the bridge team and informed them that the main engine had to be stopped because of engine problems.

At about 0235, the pitch of the propeller was set to neutral. As the "FRONTENAC" was in a narrow passage in the canal, the bridge team had to try to steer the vessel using the anchors and the bow thruster. These manoeuvres, however, were not enough to keep the vessel in the centre of the canal, and at 0240, the "FRONTENAC" struck the concrete wall bordering the southern edge of the canal. Temporary repairs were carried out to enable the vessel to clear the Seaway and proceed to destination. Shipping was disrupted in the Canal de la Rive Sud for nine and a half hours.

1.3 Injuries

There were no injuries as a result of this occurrence.

1.4 Damage

The vessel sustained minor hull damage in way of the No. 1 port ballast tank. Two web frames and a few shell frames were twisted.

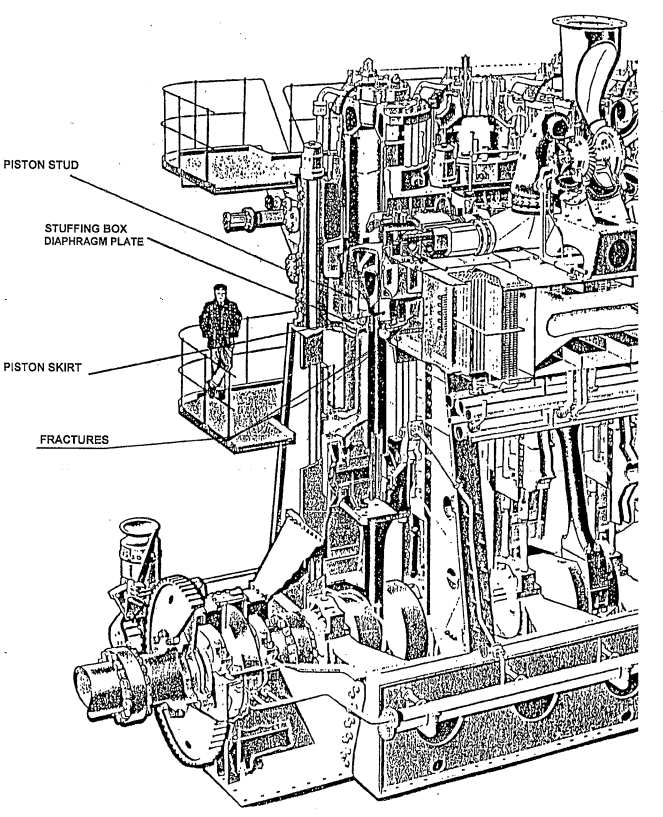

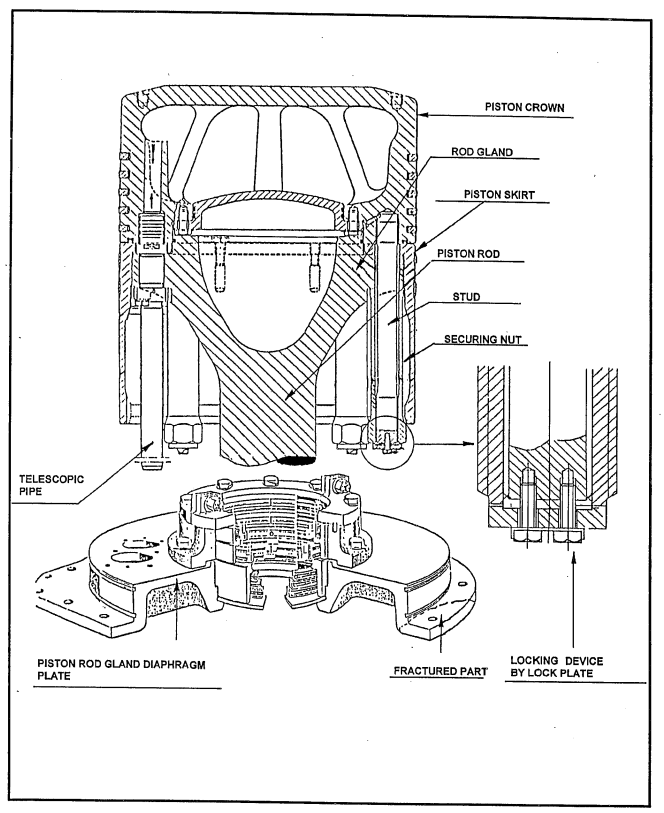

The engine problems began with a knocking in way of the No. 3 unit, which worried the engineer of the watch. When the engine was stopped and inspected, a piston stud securing nut was found to have backed off. It was hitting against the piston rod gland diaphragm plate whenever it reached bottom dead centre. The piston rod gland diaphragm plate fractured as a result of this repeated hammering by the loosened nut.

During the voyage from Kahnawake to Hamilton, the telescopic pipes and stuffing box were damaged by the spare piston installed at Kahnawake.

The inspection carried out after the vessel reached Hamilton revealed that the engine block and the piston rod had also sustained damage.

No damage was reported to the infrastructure of the Seaway.

1.5 Certificates

1.5.1 Vessel Certificates

The vessel's certificates, manning and equipment were in compliance with the Classed Ships Inspection Regulations.

1.5.2 Personnel Certificates

The master, the chief engineer and the officers of the watch all held certificates appropriate to the vessel's class and trade.

1.6 Personnel History

The chief engineer held a Canadian First Class Engineer certificate. He had been employed by CSL since 1983.

The engineer of the watch held a combined Second Class Engineer certificate issued in February 1990. He had been on board the "FRONTENAC" for only 10 days, but he had worked on the vessel for two and a half months the previous season. He had worked for CSL since 1985 and had approximately 23 years' of sea service.

1.7 Weather Information

The sky was clear, visibility was good, and the winds were light.

1.8 Sequence of Events

1.8.1 Engine-room

The master and the chief engineer were informed as soon as the engine-room staff heard a knocking coming from the No. 3 unit of the main engine.

After assessing the situation, the chief engineer called the master and informed him that the engine had to be stopped immediately in order to prevent a crankcase explosion. Nearly 30 minutes elapsed between the noise first being heard and the engine actually being shut down.

1.8.2 Wheel-house

The main engine had to be stopped when the "FRONTENAC" was in an area which was not suited to this manoeuvre because of the limited sea room. The vessel's speed was reduced, then the bow thruster and the anchors were used in an effort to keep the vessel in the centre of the canal, but to no avail. The controllable-pitch propeller was set to neutral, but the order "finished with engine" was not transmitted to the engine-room until requested by the chief engineer at about 0300.

1.9 Repairs

1.9.1 Temporary Repairs

Temporary repairs were carried out immediately in order to clear the Seaway as quickly as possible. The spare parts available on board were used for the purpose.

A preassembled unit comprising the piston and piston rod was installed to replace the defective parts. However, no spare was available for the piston rod gland diaphragm plate (see Appendix C). After consultation with a specialized firm, it was agreed to cut the fuel supply to the faulty cylinder and complete the voyage.

1.9.2 Spare Parts

When the vessel reached Hamilton, it was discovered that the preassembled spare unit used for the temporary repairs had a machining defect. The lower part of the piston, called the skirt, had not been machined precisely. There was insufficient clearance between the inside of the skirt and the stuffing box of the telescopic pipes (see Appendix B). This preassembled unit was not a part from the manufacturer (Sulzer).

1.10 Danger of a Crankcase Explosion

1.10.1 In the Canal de la Rive Sud

A similar mechanical failure in which the piston rod securing nut backed off and damaged the piston rod gland diaphragm plate occurred on the "RALPH MISENER" in 1980. The damage was greater on that occasion and resulted in a crankcase explosion.

1.10.2 During the Voyage to Hamilton

Because of the machining defect of the spare part used for the temporary repairs, the

No. 3 unit piston made contact with the telescopic stuffing box. The vessel proceeded to destination in this condition. The repeated hammering by the piston moved the parts out of alignment and probably caused further damage. It should be noted that the bottom of the stuffing box is situated inside the crankcase.

There was a possibility that the friction combined with the hammering of the damaged parts might cause a crankcase explosion.

1.11 Inspection

1.11.1 Inspection of the Temporary Repairs

The Seaway inspector who proceeded to the scene was not qualified in marine engineering. However, a superintendent from the CSL Engineering Division who was on board the "FRONTENAC" was in contact with a specialized firm. Therefore, the Seaway inspector did not consider it necessary to call in a Canadian Coast Guard Ship Safety inspector.

1.11.2 Inspection at the Destination

Inspectors from the Ship Safety Branch and the Lloyd's Classification Society as well as a representative of a specialized firm that services this type of engine boarded the vessel when she reached Hamilton. The inspections showed that the No. 3 unit had sustained further damage during the voyage.

The "FRONTENAC" was out of service for 10 days while waiting for the spare parts needed for the repairs to be carried out.

One of the repairs consisted in the remachining of the piston rod palm (upper part). Some 0.5 mm (0.020") was removed to correct the surface of the palm. This part had suffered some distortion over the years, and it had become impossible to properly adjust the unit comprising the piston crown, skirt and rod. As a result of the movement between these parts, the locking device of one of the piston securing nuts apparently failed. Without the locking device, the piston securing nuts can back off, and this appears to be what happened in this occurrence. The thread of the two bolts holding the lock plate of the locking device were found to have been stripped.

1.12 Permission to Proceed

At 1150 on 29 October 1993, as the temporary repairs had been completed to the satisfaction of the experts on the scene, the Seaway authorities granted the "FRONTENAC" permission to proceed.

1.13 Maintenance

The manufacturer's recommended inspection period for this type of engine is 8,000 hours which amounts to approximately two years of operation for most Great Lakes bulk carriers.

The No. 3 unit of the main engine had been replaced on 29 November 1992 following a mechanical problem. The palm was not examined at that time. The engine had

118,514 running hours when the unit was replaced in November 1992, and 122,800 at the time of the failure on 29 October 1993.

2.0 Analysis

2.1 Introduction

In the canals of the Seaway, when a vessel is unable to reach a berth, it is virtually impossible to stop without striking one of the sides of the canal. The main engine had to be stopped because of engine problems when the "FRONTENAC" was in a confined section of the Canal de la Rive Sud and, therefore, the vessel was unable to avoid striking the wall of the canal.

2.2 Main Engine

The engine problems were unforeseeable, and the situation was serious enough to warrant an emergency shutdown of the engine. The main cause of the problem was identified and detailed by marine surveyors. Engine maintenance was not an issue in this occurrence, although the source of the problem appears to have been the adjustment of the parts of the No. 3 unit. An information bulletin dated 20 May 1993, issued by a specialized firm that services this type of engine, confirmed the risk of wear of these parts.

2.3 Communication

Lack of communication between the bridge team and the engine-room staff delayed the engine shutdown. The engine-room staff were waiting for the bridge team to place the engine telegraph in the "finished with engine" position, while the bridge team, after setting the propeller pitch to neutral, thought that the engineers would stop the engine on their own. This contributed to further damage.

3.0 Findings

- The "FRONTENAC" experienced engine problems while transiting the Canal de la Rive Sud in the St. Lawrence Seaway.

- Although the anchors and the bow thruster were used to manoeuvre, it was impossible to prevent the vessel from striking the concrete wall bordering the southern edge of the canal at Kahnawake.

- The vessel suffered minor damage, but the Seaway infrastructure was not damaged.

- Because of a lack of communication between the bridge team and the engine-room staff, the engine shutdown was delayed.

- The time that elapsed between the problem first being detected and the engine being stopped apparently contributed to the extent of the damage and furthered the risk of a crankcase explosion.

- The faulty main engine unit was replaced at Kahnawake with a preassembled unit that, unbeknownst to the personnel, had a machining defect.

- This machining defect of the piston skirt caused further damage to the engine, thereby increasing the risk of a crankcase explosion.

- The preassembled spare unit used in the temporary repairs carried out at Kahnawake was not a part from the manufacturer (Sulzer).

3.1 Causes and contributing factors

The engine problems resulted from one of the piston stud securing nuts of the No. 3 unit "backing off" and hammering against the piston rod gland diaphragm plate, which eventually fractured.

4.0 Safety Action

The Board has no marine safety recommendations to issue at this time.

This report concludes the Transportation Safety Board's investigation into this occurrence. Consequently, the Board, consisting of Chairperson, John W. Stants, and members Zita Brunet and Hugh MacNeil, authorized the release of this report on .

Appendices

Appendix A - Sketch of the Occurrence Area

Appendix B - Main Engine Parts

Appendix C - Sketch of the Faulty Unit

Appendix D - Glossary

- A

- aft

- CSL

- The CSL Group Inc.

- EDT

- eastern daylight time

- F

- forward

- HP

- horsepower

- IMO

- International Maritime Organization

- kW

- kilowatt(s)

- m

- metre(s)

- mm

- millimetre(s)

- SI

- International System (of units)

- TSB

- Transportation Safety Board of Canada

- UTC

- Coordinated Universal Time

- "

- inch(es)