Grounding

OIL TANKER "JADE STAR"

SAINTE-CROIX, QUEBEC

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

On 24 April 1994, the Canadian oil tanker "JADE STAR" departed the Ultramar Canada port facilities at Saint-Romuald, Quebec, bound for Montreal, Quebec, with a full load of gasoline and diesel oil.

Off Sainte-Croix, the bulk carrier "BAMIA" was about to overtake the "JADE STAR" when a series of audible alarms was triggered and indicator lights came on both on the bridge and in the engine-room of the "JADE STAR". As soon as the alarms went off on the bridge, the pitch of the propeller was reduced to zero. The "JADE STAR" yawed to port, cut across the track of the "BAMIA", then ran aground on the southern edge of the channel.

The Board determined that the rupture of a cover retaining pin in one of the fuel filters of the No. 2 generator caused an electrical problem. Believing a black-out to have occurred, the officer of the watch set the propeller pitch to zero; he did not attempt steering, and the vessel sheered out of the channel and grounded. The crew of the "JADE STAR" lacked experience with the on-board automated system and was therefore unable to react quickly and effectively enough to recognize and rectify the problem.

1.0 Factual information

1.1 Particulars of the Vessel

| "JADE STAR" | |

|---|---|

| Official number | 814370 |

| Port of registry | Halifax, Nova Scotia |

| Flag | Canadian |

| Type | Oil tanker |

| Gross TonsFootnote 1 | 6,262 |

| Length | 118.16 m |

| Draught | FFootnote 2: 8.0 m A: 8.6 m |

| Crew | 15 (including the master) |

| Built | 1993, Wismar, Germany |

| Propulsion | 3,700 kW diesel engine driving a controllable-pitch propeller |

| Thruster | Bow thruster fitted |

| Operators | Rigel Shipping Canada Inc. Shediac, New Brunswick |

| Owners | Rigel Schiffahrts GMBH Bremen, Germany |

1.1.1 Description of the Vessel

The oil tanker "JADE STAR" is registered and operated in Canada. The vessel complies with the construction standards for double-hulled oil tankers. The navigation bridge has an integrated central navigation console that the officer of the watch (OOW) can operate unassisted. The vessel's degree of automation is such that the engine-room may be left unmanned for extended periods, but, at the time of the grounding, the engine-room was manned.

1.2 History of the Voyage

The "JADE STAR" departed the Ultramar Canada port facilities at Saint-Romuald at approximately 0455Footnote 3 on 24 April 1994, bound for Montreal. The voyage was proceeding normally and without incident. All the mechanical, electrical and navigation systems were operating satisfactorily. Visibility was relatively good, and the tide was rising. The deck watch was made up of the OOW, the helmsman, and the pilot.

At about 0638, the "JADE STAR" was off Sainte-Croix on the Saint-Antoine course and was about to be overtaken by the "BAMIA". The pilot ordered a reduction of speed to allow the "BAMIA", a relatively faster vessel than the "JADE STAR", to pass. The OOW was preparing to call the engine-room to inform them of a speed reduction when a series of alarms was triggered both on the bridge and in the engine-room. When the alarms went off on the bridge, the OOW assumed that there was a complete power failure and he reduced the propeller pitch from 90 per cent to zero. The pilot asked the "BAMIA", which was three cables astern, to keep clear of the "JADE STAR".

The "JADE STAR" was then steering a course of 252 True (T). She was slightly north of the ranges, and buoy Q46 was on her starboard beam. As soon as the propeller pitch was set to zero, the vessel yawed to port, and the rotary motion accelerated. The starboard anchor was dropped to try to prevent the vessel from running aground. The master was in his office and, noticing the lights going out, he went to the bridge where he was informed by the OOW that a black-out had occurred. The helm was midships and the pitch set at zero, so he ordered the helm hard-a-starboard. The action of the rudder decreased the speed of rotary motion, but the "JADE STAR" had already cut across the track of the "BAMIA" and run aground on the southern edge of the channel on a heading of 190(T).

1.3 Injuries to Persons

No one was injured as a result of the occurrence.

1.4 Damage

An internal inspection of the hull of the "JADE STAR" indicated that it had been slightly dented, but no perforation was reported.

1.4.1 Environment

As a safety precaution, the Canadian Coast Guard (CCG) and Ultramar Canada quickly dispatched vessels equipped with booms to the scene of the grounding. However, there was no release of oil or environmental damage.

1.5 Certification

1.5.1 Vessel

The vessel met the Canadian certification, manning and equipment requirements for the planned voyage. The vessel had been inspected and certificated by the CCG at Halifax on 07 March 1994.

1.5.2 Personnel

1.5.2.1 Master

The master held a Canadian Master Mariner certificate. He had 45 years' experience at sea, 20 of which as a master. He had been in command of the "DIAMOND STAR" for a short time before assuming command of her sister ship, the "JADE STAR", in March 1994.

1.5.2.2 Chief Engineer

The chief engineer held a Canadian First-Class Engineer certificate issued on 24 September 1990.

1.5.2.3 Pilot

The pilot held a Canadian Pilot certificate. He had worked as a pilot for 22 years in District No. 1, the Québec/Trois-Rivières area, of the Laurentian Pilotage Authority. This was his first assignment on board the "JADE STAR".

1.6 Weather and Tidal Information

1.6.1 Weather Conditions Recorded by the Vessel

At the time of the grounding, the winds were from the north-east at 10 knots, the weather was foggy with rain, and visibility was four to five miles. The sea was calm and the air temperature was 6C.

1.6.2 Tidal Range

The grounding occurred at approximately 0642 on 24 April 1994, and high tide at Sainte-Croix was predicted for 0720. The tide gauge at Portneuf, Quebec, recorded 16.5 feet and rising. The "JADE STAR" was refloated at the next high tide, at about 2000, 13 hours and 18 minutes after grounding.

1.7 Design of the Computer System

1.7.1 Bridge and Engine-room

Monitoring of the vessel's propulsion, steering, navigation and cargo management systems is handled by a central computer with its own power supply (24 V). The status and configuration of the various systems can be monitored from the central console on the bridge and from the engine control room. When a system is operating outside specified limits, an indicator light on the control console comes on and an audible alarm is triggered. Any malfunction in the system is also identified on the monitor screen.

1.8 Management of Alarms

On the "JADE STAR", alarms warn the watch personnel of any malfunction of a system. When an alarm goes off, an officer on the bridge or an engineer in the control room can trace its source. By using the on-screen menus, they can then identify the malfunction, make a diagnosis and take appropriate action, that is, either deactivate the alarm if the automated system has activated the required emergency systems or call upon the appropriate personnel. The automated system allows the ship's staff six seconds to react before it takes action.

The various mechanical and electrical systems can be configured electronically from the bridge or the control room. In an emergency, the systems can also be configured and operated manually. If the main generator fails, the vessel's computer is programmed to bring the stand-by generator on-line after seven seconds.

In this occurrence, the No. 2 generator, which was on-line, partially failed. The engine driving the generator would speed up when it was supplied with fuel and would slow down when the fuel flow was inadequate. The alarms were triggered, and the computer started the stand-by generator. However, it could not be brought on-line because the automated system is not designed, or able, to synchronize the stand-by generator when there is a considerable variation in cycles. The stand-by generator can be brought on-line only after the No. 2 generator circuit breaker trips, and the breaker did not trip automatically in this instance because the fluctuations of voltage on the No. 2 generator did not reach the under-voltage limit on the main breaker.

1.9 Automation of the Power-generating System

The power-generating system of the "JADE STAR" has a recently designed automated system now in use on several vessels. The electrical system includes a shaft generator with a capacity of 500 kW; three auxiliary generators with a capacity of 540 kW each; and an emergency generator. Normal electricity demand, when the vessel is at sea, is of 200 to 240 kW.

The system is designed so that the shaft generator is used at sea and the other three are used automatically as backups. In port, the auxiliary generators are used alternately. At the time of the occurrence, only one auxiliary generator was on-line although the vessel was operating in confined waters, because of a cooling problem experienced prior to the accident. The shaft generator was not in use because of an ongoing difference of opinion, since the arrival of these three sister ships in Canada in 1993/94, between the operator and the Ship Safety Branch of the CCG (now TC Marine), who maintain that the ship should operate on auxiliary generators in confined waters.

1.10 Condition of the Generators on Departure

When the "JADE STAR" departed Saint-Romuald, the No. 1 and No. 3 generators were on-line and overheating. Therefore, the No. 2 generator was used so that the other two could be inspected. The thermovalve of the No. 1 generator's cooling system was removed, and a blank flange was installed to force the water through the heat exchanger. It was set back on automatic, but the diesel engine could not start automatically because of a defective solenoid valve on the starter. The diesel engine therefore had to be started manually. The blank flange installed on the No. 3 generator's cooling system two and a half months earlier was found to be corroded through. The cooling water was passing through the bypass line instead of through the generator's cooling line. The problem was fixed and the generator was put on automatic stand-by. Spare parts for the defective starter solenoid valve had been on order for some time.

1.11 Power Failure

Inspection of the No. 2 generator revealed that a pressure drop on the diesel supply line was causing the voltage to fluctuate. The pressure drop was caused by a ruptured metal cover retaining pin in the filter housing.

The automated system is programmed to try three times to put the stand-by generator on-line before giving up and sounding a failure alarm. Therefore, the No. 3 generator tried three times to parallel with the No. 2 generator and go on-line, but it failed due to the voltage fluctuations and surging of the No. 2 auxiliary generator.

1.12 Reaction of the Engine-room Personnel

There were three engineers in the engine-room when the alarms went off, and one of them immediately went to the control room. He realized that the voltage on the No. 2 generator was fluctuating and that the No. 3 generator, which was on stand-by, could not be brought on-line automatically. An engineer on the scene manually started the No. 1 generator. Another engineer in the control room manually tripped the circuit breaker of the No. 2 generator, and brought the No. 1 generator on-line.

1.13 Computerized Movement Log

The time used on the bridge printout was in Coordinated Universal Time (UTC), expressed in hours, minutes and seconds whereas the time on the engine-room printout was in local time, expressed in hours and minutes only. At the time of the grounding, when the OOW reduced the propeller pitch to zero, the bridge printout read 1037:23 UTC, and the engine-room printout read 0634 EDT, a difference of more than three minutes.

The bridge printout gives the following information: propeller pitch percentage and direction of rotation; revolutions per minute of the propulsion unit; engine movements; and position of the controls, whether they are activated from the bridge or the engine-room.

1.14 Yaw to Por

When the alarms went off and the propeller pitch was reduced from 90 per cent to zero, the "JADE STAR" was travelling at an average speed over the ground of 13 knots. As soon as the propeller pitch was reduced to zero, the "JADE STAR" began to yaw to port, slowly at first and then more quickly. During that time, the helm was midships. The master, seeing the vessel heading rapidly toward the southern edge of the channel, ordered the helm hard-a-starboard. The action of the rudder decreased the speed of rotary motion, but not enough to prevent the vessel from running aground.

1.15 Crew Reaction Time

When the alarms went off on the bridge and the propeller pitch was set to zero, the "JADE STAR" was slightly north of the middle of the channel at buoy Q46. From there to the position of the grounding, the vessel travelled approximately four cables. According to the pilot, the anchor was dropped when the vessel was south of the Saint-Antoine ranges and yawing quickly to port. Based on an estimated steady speed of 13 knots, the crew would have had about 1.8 minutes to rectify the generator problem.

1.16 On-board Manuals for the Automated System

The manuals for the automated system were on board, but they and some other system manuals were written in German, a language not understood by the shipboard personnel.

2.0 Analysis

2.1 Introduction

This analysis deals with the automated system of the "JADE STAR", crew training, the laboratory tests conducted on the ruptured retaining pin and the reasons for the vessel yawing quickly to port.

2.2 Automated System of the "JADE STAR"

All the systems on board the "JADE STAR" are monitored by computer. When a system malfunctions, alarms are triggered, and the essential systems are automatically replaced by backup systems. With the information obtained from the computer, the operator can diagnose the problem and determine a remedial course of action.

When the alarms went off, the propeller pitch was reduced to zero, and no attempt was made to control the vessel with the rudder until the master ordered the helm hard-a-starboard. Lack of familiarity with the vessel's system prevented the personnel from pinpointing the cause of the problem and determining an effective course of action. If the problem had been diagnosed correctly, the engineer could have shut down the No. 2 generator, and the stand-by generator would have come on-line automatically after seven seconds, thus quickly restoring power.

2.3 Training on the Automated System

Different tasks and duties require different methods of training. Training, when properly designed and delivered, yields dividends in terms of efficiency and safety. On-the-job training can be very effective as it allows for a smooth transition between training and work because the conditions are virtually identical.

Personnel trained solely on the job can be well prepared to perform their duties under normal circumstances. On-the-job training unaccompanied by formal instruction or personal study, however, provides poor preparation for unusual situations that require a thorough understanding of the design and operating parameters of the system.

In the case of the grounding of the "JADE STAR", the engine-room and bridge personnel had to deal with an unusual situation for which they were not trained. An inadequate knowledge of the system rather than a software design defect exacerbated the problem. More adequate training might have helped the crew members diagnose the problem properly, find the solution and restore power more quickly.

2.4 Interpretation of the Printout

The printout shows that, by 0634 EDT, there was a problem on the electrical system caused by a voltage fluctuation. In less than a minute, three variations in voltage caused an overload of the controls of the steering gear and triggered a series of alarms. This temporary overload would not normally have impaired the operation of the steering gear. The voltage fluctuations caused the breaker for non-essential equipment to trip twice. When this breaker tripped, the bridge personnel assumed that there was a complete power failure. The OOW reduced the propeller pitch to zero and did not try to keep the vessel in the channel.

2.5 Tests of the Ruptured Metal Pin

The ruptured metal retaining pin from the cover of the fuel filter mounted on the No. 2 generator of the "JADE STAR" was tested by the TSB Engineering Laboratory. The tests revealed that the fracture surfaces showed a uniform appearance with no evidence of precracking or progressive failure of any kind. The fracture surfaces showed only microvoid coalescence structures consistent with the overload failure of a nominally ductile material. The filter cover came loose while the generator was under full load, thus causing a voltage fluctuation on the electrical system.

2.6 Anchorage

According to the evidence, the starboard anchor was dropped when the "JADE STAR" was south of the centre line of the channel and yawing to port. The anchor chain probably passed under the vessel which was travelling at some 13 knots and accelerated the rotary motion to port. The bridge personnel of the "BAMIA" confirmed that the "JADE STAR" had been observed to yaw quickly to port and to run aground on the southern edge of the channel after the "JADE STAR" informed the "BAMIA" that she was experiencing a mechanical failure and asked to keep clear of her.

2.7 Sound Level of the Alarms

It was reported that the sound of the alarms was so loud as to interfere with portable radio communication between the wheel-house and the bow of the vessel. The audible alarms could have been deactivated by the navigation personnel.

3.0 Findings

- The electrical system on the "JADE STAR" was not being operated as it was designed to operate at sea.

- A ruptured retaining pin for the cover in one of the fuel filters of the No. 2 generator caused a voltage fluctuation.

- The bridge and engine-room personnel had to deal with an unusual situation for which they were not trained.

- The propeller pitch was reduced to zero, and no attempt was made by the bridge personnel to control the vessel with the rudder until the master ordered the helm hard-a-starboard.

- A more thorough knowledge of the system and of the parameters of the software could have helped the crew members make a more accurate diagnosis of the problem and restore power more quickly.

- The manuals for the automated system were on board, but they and some other system manuals were written in German, a language not understood by the shipboard personnel.

3.1 Causes and contributing factors

The rupture of a cover retaining pin in one of the fuel filters of the No. 2 generator caused an electrical problem. Believing a black-out to have occurred, the officer of the watch set the propeller pitch to zero; he did not attempt steering, and the vessel sheered out of the channel and grounded. The crew of the "JADE STAR" lacked experience with the on-board automated system and was therefore unable to react quickly and effectively enough to recognize and rectify the problem.

4.0 Safety Action

4.1 Safety Action Taken

4.1.1 New Directive

Immediately following the occurrence, the operator issued a directive to the "JADE STAR" and her two sister ships to operate on the shaft generator.

4.1.2 Engineering Laboratory Report

Following the occurrence, the TSB conducted an analysis of the broken stud from a fuel filter mounted on the No. 2 generator. The results of this analysis indicated an overload failure. The Engineering Laboratory report was forwarded to the owners/operators for their information.

4.1.3 Training on the Automated System

The importance of adequate crew training commensurate with the highly automated machinery and control systems installed on the "JADE STAR" and her two sister vessels was discussed at a meeting between TSB staff and representatives of the manufacturer, the charterer, the shipping agent, and the Canadian Coast Guard (CCG).

In 1996, a TSB Marine Safety Advisory was forwarded to the operating company with respect to the effectiveness of the operations and automated system manuals. It was also suggested that the operating company assess the need for additional crew training in the fleet's automated system.

This report concludes the Transportation Safety Board's investigation into this occurrence. Consequently, the Board, consisting of Chairperson, Benoît Bouchard, and members Maurice Harquail and W.A. Tadros, authorized the release of this report on .

Appendices

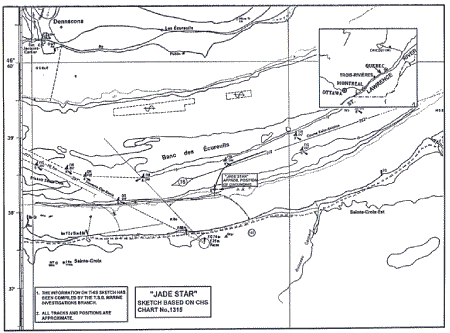

Appendix A - Sketch of the Area of the Occurrence

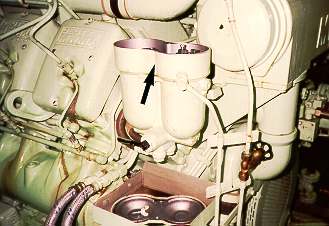

Appendix B - Photographs

Appendix C - Glossary

- A

- aft

- C

- Celsius

- CCG

- Canadian Coast Guard

- EDT

- eastern daylight time

- F

- forward

- IMO

- International Maritime Organization

- kW

- kilowatt(s)

- m

- metre(s)

- OOW

- officer of the watch

- SI

- International System (of units)

- T

- True (degrees)

- TSB

- Transportation Safety Board of Canada

- UTC

- Coordinated Universal Time

- V

- volt(s)

- °

- degree(s)