Sinking - Fishing Vessel "MARWOOD"

alongside the Government Wharf

Ucluelet, British Columbia

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

On 14 August 1994, the "MARWOOD" was berthed starboard side to the government wharf. After being replenished with fresh water, the vessel was left unattended with about seven degrees starboard list and slack tanks. The spare trawl doors were stowed aft on the starboard side of the main deck with their top edges overhanging the ship side. As the vessel rose with the incoming tide, the spare trawl doors caught under the wale of the wharf front and water found its way onto the shelter deck by way of the open valve in the conveyor well drain line. Downflooding ensued and the vessel eventually sank at wharf. The chief engineer lost his life when he became trapped below deck.

The Board determined that, while the vessel lay alongside the wharf unattended with a starboard list, the overhang of the spare trawl doors on the starboard side caught under the wale of the wharf on a rising tide, causing the "MARWOOD" to list heavily to starboard. The shelter deck then flooded by way of the open overboard drain valve to the conveyor well and of the non-watertight covers/openings to the holds/tanks. Downflooding of the spaces below deck ensued until the "MARWOOD" lost reserve buoyancy and sank. The fact that the overboard discharge was below the load waterline and that the conveyor well drain line was not fitted with a non-return valve, coupled with the practice of leaving the overboard drain valve open when not in use, contributed to the occurrence.

1.0 Factual Information

1.1 Particulars of the Vessel

| Name | "MARWOOD" |

|---|---|

| Official number | 301571 |

| Port of registry | Nanaimo, B.C.Note de bas de page 1 |

| Flag | Canadian |

| Gross TonsNote de bas de page 2 | 237 |

| Length | 35 m |

| Crew | 4 |

| Built | 1959, Gateshead, England |

| Owners | Marwood 5 Fishing Ltd., Prince Rupert, B.C. |

1.1.1 Description of the Vessel

The "MARWOOD" is a stern trawler with a shelter deck and a main deck (which is also the weather deck). The main accommodation is located aft below the shelter deck between the engine-room and the steering compartment. The vessel's basic layout is shown in Appendix A (Figures 1 and 2).

1.1.2 History of the Vessel

The "MARWOOD" was built, registered, and rigged as a side trawler in the United Kingdom in 1959, and entered Canadian Registry in 1973. In 1979, the vessel was converted to a stern trawler in Vancouver and a continuous upper deck was added flush with the original forecastle and wheel-house decks. The original main deck became the fish-processing shelter deck and the new deck became the main deck of the vessel. The accommodation was retained but the galley portholes were blanked off with metal inserts welded into the hull.

1.2 History of the Voyage

The "MARWOOD" arrived in Ucluelet at 1800Note de bas de page 3, 13 August 1994, to effect repairs and change crew. The vessel secured starboard side to the government wharf stemming the flood tide. (See photograph 1 at Appendix B.) There was no cargo or catch on board and the vessel arrived in port trimmed slightly by the head and upright. The spare trawl doors were stored in a rack on the starboard side of the main deck with their top edges inclined outboard and overhanging the ship side.

The chief engineer replenished the starboard fresh-water double-bottom tank with a hose from the dock; the tank was positioned abaft amidships (see No. 7 at Appendix ANote de bas de page 4). This gave the vessel a starboard list and a trim by the stern.

The rest of the crew members were engaged in cleaning up the fishing gear until mealtime. At about 2030, the master and the chief engineer went to a local restaurant for dinner where the chief engineer consumed some alcohol with his meal. The master was a teetotaller. Meanwhile, the senior deck-hand visited some friends ashore where he had a meal and drank several beers. The junior deck-hand remained on board.

At 2230, the fishing vessel "JO MARC" arrived and secured port side to the "MARWOOD". The owner/master of the "JO MARC", who is also a part owner of the "MARWOOD" (hereinafter referred to as the owner of the "MARWOOD"), made a round of the "MARWOOD" before proceeding ashore at about 2300. He noted that the vessel had a list of about five to seven degrees, that the filling cap for the starboard double-bottom fresh-water tank was off, and that no hose was connected to any tank. Shortly thereafter, the junior deck-hand of the "MARWOOD", accompanied by a deck-hand from the "JO MARC", went ashore to the hotel bar.

The master of the "MARWOOD" returned on board alone at approximately 2345, and observed that the vessel had a starboard list of about seven degrees. He then went to the clothes drier located in the starboard after part of the shelter deck (N). There was no water in this area. As he was to sail on the "JO MARC", he transferred his belongings there and went to bed at about 0100.

Shortly before 0200, the remaining crew of the "JO MARC" and the junior deck-hand of the "MARWOOD" returned to their respective vessels. The junior deck-hand saw water being discharged "full bore" from the overboard discharge of the shelter deck bilge pump (photograph 3), located in the forward tunnel, but did not notify the master. The owner had the crew check the mooring lines to ensure that they were not caught under the dock piles. The inspection found nothing wrong with the moorings. No round of the "MARWOOD" was made to ensure that everything was in order before the departure of the "JO MARC". The junior deck-hand helped to cast off the mooring lines, watched the "JO MARC" sail with both masters aboard, and then went to bed.

Shortly afterward, the senior deck-hand arrived on board and, after talking briefly to the junior deck-hand, he also went to bed. Soon after, finding the cabin to be too hot, the senior deck-hand went to sleep on the forward main deck.

The chief engineer left the hotel bar at approximately 0230 and returned on board some 15 minutes later. No one can verify his subsequent actions. However, when his body was recovered from the dry store, he was clad in his work clothes.

The junior deck-hand awoke to find about 38 cm of water on his cabin deck (A). He headed forward toward the ladder (B) leading to the shelter deck, checking the cabins for occupancy as he went, but finding no one there.

By the time he reached the foot of the ladder (B) leading to the shelter deck, large volumes of water were downflooding from above. He fought his way up the ladder to the shelter deck (photograph 4). At the shelter deck landing, there was about 1 m of water and it was pouring through the open doorway to the accommodation (G). He had to overcome the water pressure to open the door (F) leading to the engine-room (photograph 5).

Crossing the engine-room platform, he opened the forward engine-room door (H) and gained access to the ladder (J) leading up to the wheel-house. He then exited via the wheel-house onto the main deck. He ran forward to wake the senior deck-hand.

Upon being awakened, the senior deck-hand dashed across the deck, gained access to the dock ladder, and rapidly climbed to the dock apron. The junior deck-hand stayed at the port rail while the ship continued to heel further to starboard and sink. He was subsequently rescued from the water by a dinghy operator.

The vessel came to rest on the bottom at an angle of about 45· to starboard with the port forward main deck above water.

The time of sinking was noted as 0335 by a yachtsman berthed on the other side of the wharf.

1.3 Search and Rescue

Following arrival on the scene of Search and Rescue (SAR) technicians from Comox at 0515, search for the chief engineer commenced. The search of the lower accommodation was hampered by oil trapped in the alleyway.

The falling tide caused the search to be suspended, as the vessel was settling further to starboard and there was concern for diver safety.

When the tide was right, the diving resumed with a special dive team from the Canadian Forces Base Esquimalt. The chief engineer was found in the dry store (L) off the galley/messroom area at 1550.

1.4 Injuries to Persons

As a result of this occurrence, the chief engineer lost his life when he became trapped below deck.

An autopsy on the chief engineer established the cause of death to be drowning and his blood alcohol concentration to be 190 milligrams per 100 millilitres (MGM%).

1.4.1 Blood Alcohol Concentration

Studies have been conducted into blood ethanol concentration and its effect on performance. One such study, entitled A Brief Guide to the Units and Interpretation of Blood Alcohol Measurements, was conducted by the Defence and Civil Institute of Environmental Medicine. According to the study, a 150-pound person who is a moderate drinker and has attained a blood alcohol concentration of 190 MGM% will stumble and fall and such a person may be considered to be "under the influence". Some of the effects include impairment of vision or visual acuity, lengthened reaction time, overestimation of capabilities or an underestimation of errors, and a greater proneness to recklessness.

1.5 Damage

1.5.1 Damage to the Vessel

The vessel sustained damage to the starboard side of the main A-frame gantry and to the trawl door booms, and water damage to the machinery and electrical equipment.

1.5.2 Environmental Damage

Diesel and lubricating oil leaked from the tanks. The Canadian Coast Guard (CCG) placed a containment boom around the sunken vessel at approximately 1000, 14 August, and recovered about 11,000 litres (L) of oil with a skimmer and some 41 barrels of oily debris during the clean-up operation.

1.5.3 Other Damage

One wale on the dock apron front was broken. The wale and its securing bolts were bent upward by the force exerted against it (photographs 6 and 7).

There was minor damage to the face of the dock. Another wale was broken downward off the dock as the vessel rolled over and one pile was damaged by the ladder rungs on the A-frame gantry.

1.6 Vessel Certification

Under the Large Fishing Vessel Inspection Regulations (LFVIR) made pursuant to the Canada Shipping Act (CSA), the "MARWOOD" was required to undergo annual and quadrennial inspections. The quadrennial inspection requirement included, among others, examining and ascertaining the condition of the plating, floors, and tank tops. Section 38 (4)(h) of the LFVIR, dealing with periodic inspection of hulls of steel fishing vessels, states that "any alterations made to the vessel since the previous inspection shall be reported in detail by the inspector to the Chairman."

Between 1987 and 1994, the "MARWOOD" had undergone six annual inspections and one quadrennial inspection. Following her last inspection by the CCG Ship Safety Branch (SSB), the "MARWOOD" was issued a Steamship Inspection Certificate (SIC) in May 1994, valid for one year.

1.7 Personnel Certification and History

1.7.1 Master

The master held a Class III Fishing Master Certificate and a Watchkeeping Mate Certificate of Competency. He had 19 years' fishing experience.

1.7.2 Chief Engineer

The chief engineer, also a part owner of the vessel, held a Third Class Motor Certificate and had more than 10 years' experience. He had served on board the "MARWOOD" as chief engineer for eight years.

1.7.3 Deck-hands

The junior deck-hand had only one 10-day trip aboard the vessel for experience. His past experience had been aboard yachts in Australia.

The senior deck-hand had 20 years' experience in fishing and, although not required to by regulations, held a Class III Fishing Master Certificate.

1.8 Weather and Tidal Information

On 14 August 1994, low water at Ucluelet was predicted to be at 0037 with a height of 0.79 m above chart datum.

The height of tide at 0245 and 0330 was predicted to be 1.25 m and 1.58 m respectively above chart datum.

1.9 1979 Vessel Modifications

1.9.1 Shelter Deck Bilge Wells and Pumping Arrangement

In 1979, when the vessel was converted into a stern trawler, the (new) fish-processing shelter deck had bilge wells (K1 and K2) recessed into the deck port and starboard approximately 1 m aft of the forward engine-room bulkhead. A pump was installed in the forward tunnel to pump out the water from the shelter deck during fish-processing operations. All valves in the shelter deck bilge piping system are butterfly valves; there is no non-return valve.

Reportedly, the practice aboard this vessel was to run the shelter deck bilge pump continuously, irrespective of the vessel's activities.

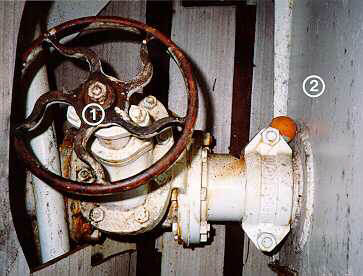

1.9.2 Conveyor System

In order to move fish forward from the fish holding tank (20) to the processing conveyors, an enclosed water-flushing chute system was installed. The bottom of the conveyor system is below the shelter deck level in a recessed drain well created for the purpose (Figure 5). This drain well has a ship-side 150 mm overboard drain (gate) valve (photograph 8) to allow the water to run off from the chute/conveyor system. There is neither a non-return valve nor a means to pump out water accumulated in this well. The overboard discharge does not drain the shelter deck nor is it intended to.

1.9.3 Fish Holds

The fish holds (14, 15, 16, 17, 18 and 19) were converted for carriage of fish in liquid brine or champagne, as were the two forward ballast/fish tanks (12 and 13). The fish hold hatch covers on the shelter deck were changed to aluminium with round access holes set into them for loading fish (photographs 9 and 10). Neither the hatch covers nor the access covers were watertight, nor were they provided with means of securing. No air vents were installed when the holds were converted.

1.9.4 Ballast/Fish Tanks

The two ballast/fish tanks (12 and 13) were each fitted with two manholes to provide access for loading and discharging fish. The manhole covers were installed flush with the shelter deck and were each fitted with a single-action locking device. Ventilation to these tanks was provided by a 20 cm-long, 50 mm-diameter pipe coupling welded to the deck at its mid-point, which protruded only 10 cm above the deck (photograph 11).

1.9.5 Scupper Requirement

The LFVIR applicable to the "MARWOOD" stipulate that:

Side scuppers shall not be fitted from the tween deck area of a fishing vessel when the tween deck is situated less than 760 mm or 2% of the length, whichever is the greater, above the deepest load water line.

In this instance, the "MARWOOD" had undergone major modifications, the CCG SSB had approved the Stability Booklet, and the overboard drain for the fish conveyor well, which was positioned below the shelter deck, was fitted with a gate valve.

1.9.6 1987 Vessel Modifications

In 1987, an additional net drum was installed above the trawl ramp and the pipe frame over the ramp was changed to a full gantry frame, thereby adding topside weight.

1.10 Vessel Stability

1.10.1 Regulatory Stability Approvals

When the vessel was first converted to a stern trawler, an inclining experiment was carried out on 17 February 1979. The CCG SSB approved the Stability Booklet on 06 November 1979. A notation on the Stability Booklet stipulated that there was an unknown quantity of ballast in the after bottom which should not be removed.

1.10.2 - 1987 Modifications Affecting Stability

The 1987 modifications required an additional eight tons of permanent ballast to be installed in the engine-room bilge adjacent to the gearbox and in the intermediate propeller shaft recess space. The calculations, done by a naval architect on behalf of the shipyard, indicated a bodily sinkage of 38 mm, with corresponding extra trim by the stern.

The additional stern trim required that the forward ballast/fish tanks (12 and 13) and the forward fish holds (14 and 15) be filled with water ballast when the vessel had no cargo/catch on board. This was necessary to bring the bow down enough to give clear vision forward from the wheel-house.

1.10.2.1 History of Shelter Deck Flooding

The additional sinkage and stern trim resulted in the gate valve for the fish conveyor well effectively remaining below the waterline under all operating conditions, even when the vessel was in a lightly loaded condition.

Following the modifications and while the vessel was at sea, the crew occasionally experienced flooding of the shelter deck due to water ingress from the gate valve to the drain well which was kept open at all times. As the fish conveyor is boxed in to a height of 45 cm above the shelter deck level (photograph 12), water must reach this level to flood the deck. Whenever flooding of the shelter deck occurred, the practice on board was to close the gate valve to stop water ingress from this source.

1.10.2.2 Stability Approval

The 1987 modifications were neither submitted to nor approved by the CCG SSB, and the Stability Booklet was never updated to include these changes. The onus is on the owners of the vessel to report such changes to the CCG SSB.

1.11 Locking Arrangement for the Galley Dry Store and the Refrigerator

The door to the galley dry store (L) is hinged on the after side and has a manually operated hook to hold it open. To enter the store, a person has to bend to pass under the fish conveyor drain well, recessed into the deck above. The upright refrigerator/freezer (photograph 13) is of domestic design with two doors side by side. The refrigerator/freezer (M) is located outside the dry store and its doors are at right angles to the door of the dry store when closed. When the dry store door is closed and the outboard refrigerator door is open, the handles of the two doors become interlocked when an attempt is made to open the dry store door from the inside. This would effectively trap a person within the dry store and prevent the door from opening.

1.12 Arrival Condition

On arrival in port, the forward ballast/fish tanks (12 and 13) were 87 per cent full with seawater, the forward fish holds (14 and 15) were full with seawater ballast, and the two middle fish holds (16 and 17) contained approximately four tonnes of ice per side. The port fresh-water double-bottom tank (6) and both wing tanks (8 and 9) were full. The starboard fresh-water double-bottom tank (7) was slack with an unknown quantity remaining.

It is reported that the vessel consumes approximately 50 L of fuel per hour of operation. Approximately 8,300 L (7 tonnes) of fuel would have been used since the last bunkering. The port middle double-bottom tank (3), always the first used after bunkering, would have had approximately 1 tonne remaining. All other fuel double-bottom tanks (three in all) were still full.

The warps, bobbins and net used during the previous trip were ranged down the port side of the main deck and the warps were wound onto the port gilson winch. Other fishing gear was stored in a pen in front of the wheel-house and throughout the shelter deck. Also, there were nets on both net drums on the after main deck.

1.13 Post-Casualty Examination Upon Salvage

Divers closed all the sea suctions and the overboard and inboard brine circulation/bilge pump valves during the salvage operation, and such closures were noted in the dive log.

The inboard brine circulation/bilge pump valves were set up to pump out the starboard shelter deck bilge well (K2), and the pump electrical control had tripped due to an overload condition.

The small shelter deck bilge pump in the forward tunnel was shut down and its isolation valves were closed.

The filling valves for the starboard forward ballast/fish tank (13) and the port middle fish hold (16) were open, making these two tanks common.

The gate valve for the fish conveyor drain well was closed.

Various electrical lighting circuit breakers had tripped out on overload, as had the lubricating oil circulating pump used for pumping the main engine sump oil through the centrifuge when the engine was shut down.

The salt-water cooling systems throughout the vessel were pressure-tested and only two very minor leaks were apparent. These leaks were not significant and did not contribute to the sinking.

1.14 Accommodation Emergency Escape Blockage

In addition to the forward access ladder, the accommodation had an emergency escape route. A door in the after part of the accommodation (C) provided access into the steering compartment. This door was partially blocked by cleaning mops and buckets. A ladder from the steering compartment provided access onto the shelter deck by way of an emergency escape hatch (D) which was positioned in the under-ramp space. This under-ramp space was full of spare net pieces which partially blocked the emergency escape hatch out of the steering compartment. These net pieces fell into the steering compartment and completely blocked the exit during the sinking. An escape hatch from the shelter deck, positioned to the starboard of the fish holding tank, provided access to the main deck.

2.0 Analysis

2.1 Time of Flooding of the Shelter Deck

There was no water on the shelter deck when the master of the "MARWOOD" visited it at about 2345, at which time the tide was still falling. Further, at about 0200, the junior deck-hand observed water being discharged from the overboard discharge for the shelter deck bilge pump. This would suggest that water had found its way onto the shelter deck sometime between 2345 and 0200, before the "JO MARC" sailed. Furthermore, being new to the vessel, the junior deck-hand did not realize the significance of his observation and, consequently, did not bring it to the attention of anyone else.

2.2 Action by the Owner of the "MARWOOD"

At 0215, the deck-hands of both vessels, at the behest of the owner of the "MARWOOD", checked the mooring lines to ensure that none were caught under the wharf fixtures. The owner of the "MARWOOD", who was aware that the shelter deck occasionally flooded while at sea, was to sail on the "JO MARC". However, the shelter deck was not inspected before the owner of the "MARWOOD" boarded the "JO MARC", even though the practice on board was to leave the gate valve for the conveyor drain line open at all times.

2.2.1 Action by the Chief Engineer

After docking, the chief engineer filled the starboard fresh-water tank, creating a five- to seven-degree starboard list, and then proceeded ashore at 2030. A similar list was observed by the owner at 2230 and by the master around midnight. Further, after ensuring that the mooring lines were not entangled with the wharf structure, both masters sailed aboard the "JO MARC" around 0215. The owner was not overly concerned about the list, which would indicate that it had not increased markedly.

The fact that the filling valves for the starboard forward ballast/fish tank (13) and the port middle fish hold (16) were found open, and that the water level in the former was at a higher level than in the latter, would indicate that these valves had been opened to counter the effect of the starboard list and that the valves had been opened by the chief engineer following his return to the vessel.

In addition, and based on the status of the electrical switches/systems, the position of the valves, and the operational mode in which the equipment was found upon salvage, it would appear that the chief engineer carried out a number of activities upon his return to the vessel, which included the following:

- he changed to work clothes;

- he shut the small bilge pump and started the large brine circulation/bilge pump to pump out water from the shelter deck;

- he closed the gate valve for the fish conveyor drain well on the shelter deck located in the galley dry store, a known source of water ingress to the shelter deck in the past.

2.3 Alcohol Consumption and Performance

Although the chief engineer had consumed a quantity of alcohol which, according to blood alcohol measurements, would have put him under the influence, he nonetheless took a series of purposeful actions, based on his assessment of the situation, which was most likely influenced by his experience of past flooding. It is not known if the amount of alcohol consumed could have impaired his operational ability.

The chief engineer's efforts to prevent the vessel from sinking were overcome by the rapidity of the developing situation.

2.4 Chief Engineer Trapped Below Deck

When the chief engineer was in the dry store to shut the gate valve to the conveyor well, the vessel's list was continually increasing. A large starboard list would have shifted the consumables in the refrigerator. As the refrigerator door was held closed by a magnetic catch only, the weight of the consumables in and against the door would have permitted it to swing open. When the refrigerator door was opened, its handle would have become interlocked with the dry store door handle, effectively trapping the chief engineer inside the dry store. This is consistent with the circumstances in which the chief engineer's body was found.

2.5 Sequence of Events

After being replenished with fresh water, the vessel had developed a list of five to seven degrees. The list increased the amount of overhang of the spare trawl doors on the starboard after main deck. The hazard associated with leaving a vessel unattended with such a list was not fully appreciated by the crew. Between the time when the chief engineer and the master proceeded ashore and the time when the master visited the shelter deck (when no water was

noted), the tide was falling. By the time the crew returned to the vessel shortly before 0200, some water had to have found its way onto the shelter deck for the pump to be discharging "full bore".

At the time the vessel was left unattended, the tide was falling; having reached low water at about 0037, it was rising when the "JO MARC" sailed from port. With the mooring lines unattended and the vessel stemming the flood, the bow would be able to swing away from the wharf and the stern into the wharf. The actions of the chief engineer following his arrival on board at about 0245 would suggest that, by this time, the vessel's list had increased. This probably meant that the overhanging trawl doors, by then, were inextricably caught under the wale of the dock apron. The actions taken by the chief engineer were consistent with those required to rectify the list and address possible flooding from a known previous source of ingress. In any event, the situation had progressed to such an extent that it could not have been remedied by the chief engineer's action(s) alone. With the vessel restrained, the rising tide would have caused the vessel's list to starboard to increase. The open gate valve for the fish conveyor drain well and the non-watertight fish hold hatch covers would have allowed the water to accumulate rapidly onto the starboard side of the shelter deck. The cumulative effect of this additional weight further outboard would have exacerbated the starboard list. By the time the gate valve to the conveyor drain line was shut, the situation had deteriorated substantially.

With the deck edge submerged and the watertight doors leading to the accommodation/engine-room being left open/not securely shut, rapid downflooding into those compartments ensued, further increasing the list. The downflooding continued until the vessel lost reserve buoyancy and sank.

2.6 Fish Conveyor Overboard Drain

Although the overboard drain for the fish conveyor well was positioned below the shelter deck and was submerged even in the lightly loaded condition, the CCG SSB permitted the fitting of a gate valve and did not require the installation of a non-return valve. The hazard associated with such an arrangement is reflected in the "MARWOOD" experiencing flooding of the shelter deck. Further, during fish loading/processing, the overboard drain valve had to be kept open to allow water to be drained into the sea. This resulted in the practice, albeit unsafe, aboard the "MARWOOD" of keeping the valve open at all times. Although the "MARWOOD" was alongside the wharf, the valve was left open and contributed to the sinking of the vessel. The fitting of a non-return valve would have prevented ingress of water onto the shelter deck through this source.

Furthermore, there is no regulatory requirement for fish holds converted for the carriage of fish in liquid to be treated as tanks. Hence, there is no requirement for increased bulkhead scantlings, for watertight tank lids instead of hatch covers, or for the holds to have vent pipes installed to relieve internal pressure or vacuum.

2.7 Hatch Covers

During the conversion to a stern trawler, the original fish hold watertight hatch covers were replaced by light aluminium covers of a non-watertight design. While this is permitted under the LFVIR, it exacerbated the deteriorating stability condition by allowing the water in the fish holds to flow onto the shelter deck due to the large list.

2.8 Quality of Steamship Inspections

As the "MARWOOD" had undergone modifications in 1987 which adversely affected her stability, the approved Stability Booklet was no longer valid. The vessel, therefore, had been operating without an approved Stability Booklet for over six years. The modifications, which included installation of the gantry and a large net drum, were obvious during inspections. Further, the presence of eight long tons of permanent ballast positioned in the shaft tunnel and the engine-room bilge in way of the gearbox should have been evident during quadrennial inspection. Although six annual inspections and one quadrennial inspection were carried out following the 1987 modifications, the CCG SSB reportedly only became aware of these modifications following this occurrence. As the main objective of steamship inspections is to ensure that vessels proceeding to sea are in a seaworthy condition, good inspection practice dictates that all aspects of seaworthiness should be considered when visiting a vessel for inspection.

It is the responsibility of the owner or master of the vessel to notify the CCG SSB of any alteration which may affect compliance with the regulations. However, it is also incumbent upon the steamship inspector to be vigilant and to inquire of the master or owner if any alteration has been carried out between inspections.

3.0 Findings

- The vessel was left unattended at the wharf with a starboard list at a tidal port, and the associated hazard was not fully appreciated by the crew.

- The spare trawl doors which were overhanging the starboard ship side became caught under the wale of the wharf on a rising tide.

- Water ingress to the shelter deck was through the open gate valve for the conveyor well.

- The authorities permitted the discharge from the conveyor well to be below the deepest load waterline and the fitting of a gate valve.

- The vessel's shelter deck was known to flood through the overboard discharge line to the conveyor well; despite this, the practice of keeping the gate valve on the line open continued.

- With the vessel's starboard side caught under the wale of the wharf on the rising tide, the rate of ingress through the overboard discharge pipe to the conveyor well increased, thereby increasing the starboard list.

- With the vessel in a listed condition, the non-watertight hatch covers allowed water to spill onto the starboard shelter deck, further exacerbating the situation and frustrating the attempts of the chief engineer to remedy the situation.

- The chief engineer's action to remedy the situation was consistent with the past history of the vessel's flooding.

- The junior deck-hand did not appreciate the significance of the overboard discharge from the shelter deck and did not notify the master.

- Despite the list, no round of the shelter deck was made to ensure that everything was in order before both masters sailed on the "JO MARC".

- The magnetic latch on the refrigerator door permitted the door to swing open when the vessel listed heavily to starboard.

- The position of the refrigerator door and the dry store door was such that the two door handles became interlocked when the refrigerator door swung open due to the heavy list.

- The interlocking of the door handles effectively trapped the chief engineer in the dry store.

- The owners carried out modifications to the "MARWOOD" which affected her stability but did not notify the regulatory authority.

- Despite several steamship inspections, the obvious modifications went unnoticed and Steamship Inspection Certificates were issued.

- The nets which were stowed on the after shelter deck were not secured and fell into the steering compartment, completely blocking the emergency exit access from the accommodation.

3.1 Causes and contributing factors

While the vessel lay alongside the wharf unattended with a starboard list, the overhang of the spare trawl doors on the starboard side caught under the wale of the wharf on a rising tide, causing the "MARWOOD" to list heavily to starboard. The shelter deck then flooded by way of the open overboard drain valve to the conveyor well and of the non-watertight covers/openings to the holds/tanks. Downflooding of the spaces below deck ensued until the "MARWOOD" lost reserve buoyancy and sank. The fact that the overboard discharge was below the load waterline and that the conveyor well drain line was not fitted with a non-return valve, coupled with the practice of leaving the overboard drain valve open when not in use, contributed to the occurrence.

4.0 Safety Action

4.1 Safety Action Taken

4.1.1 Vessels Sinking at Dock

Following this accident, the Canadian Coast Guard (CCG) issued Ship Safety Bulletin No. 18/94, entitled Vessels Sinking at Dock, highlighting the need for vigilance and the precautions to be taken when leaving a vessel unattended.

4.1.2 Seaworthiness and Vessel Stability

The TSB has apprised Transport Canada - Marine, via two Marine Safety Advisories, of the potential flooding hazards associated with the fish conveyor well discharge valve arrangement. Transport Canada - Marine was also advised to consider re-assessing the requirements respecting fish tanks to ensure structural integrity and seaworthiness of fishing vessels that carry fish in tanks.

4.2 Safety Concern

4.2.1 Ship Inspection Procedures and Practices

Under Section 377-2 of the Canada Shipping Act, it is the responsibility of the owner or master of the vessel to inform the CCG of any alterations or modifications made to the vessel which may affect compliance with regulations. Often, however, fishermen and fishing vessel operators are not aware that the modifications they have made may affect the stability of the vessel and that the vessel, therefore, may not be in compliance. As a consequence, they do not notify the CCG of the modifications. Moreover, the Board has noted that, in some instances, potential safety hazards resulting from modifications to vessels have not been detected during subsequent periodical inspections by CCG marine surveyors.

To address these shortcomings in the reporting and inspection of modifications to fishing vessels, the Board previously recommended that:

The Department of Transport explore means to ensure that structural modifications and the addition of weight items are recorded and accounted for in re-assessing the stability of small fishing vessels.

(M94-32 issued December 1994)

In its response to this recommendation, the Department of Transport reiterated the requirements of the Canada Shipping Act, Section 377-2, and of the Small Fishing Vessel Inspection Regulations. There was no indication that any new action would be taken to ensure that structural modifications were recorded and that vessel stability was reassessed.

The vessel in this occurrence, the "MARWOOD", had undergone substantial modifications in 1987 that affected her stability. The "MARWOOD" subsequently underwent six annual and one quadrennial safety inspections; apparently, the CCG marine surveyors did not note these modifications. The original Stability Booklet would have been inaccurate over the six-year period, yet Steamship Inspection Certificates continued to be issued.

The Board recognizes that the circumstances surrounding the "MARWOOD" occurrence existed before the TSB issued Recommendation M94-32. However, initiatives have not been taken with respect to CCG inspection procedures and practices for the effective monitoring of vessel modifications. Therefore, the Board is concerned that existing unsafe conditions will continue to put the lives of fishermen and the safety of fishing vessels at risk. As such, the Board stands by the intent of Recommendation M94-32, that better means are needed to ensure that structural modifications and the addition of weight items are recorded and accounted for in reassessing the stability of small fishing vessels.

This report concludes the Transportation Safety Board's investigation into this occurrence. Consequently, the Board, consisting of Chairperson John W. Stants, and members Zita Brunet and Maurice Harquail, authorized the release of this report on .

Appendices

Appendix A - Figures

Appendix B - Photographs

Appendix C - Glossary

- B.C.

- British Columbia

- bilge well

- A partial depth well to collect bilge water which might find its way into the compartment.

- CCG

- Canadian Coast Guard

- champagne

- A mixture of seawater and ice used to chill the fish in the hold, may be force-circulated by pump(s).

- cm

- centimetre(s)

- CSA

- Canada Shipping Act

- IMO

- International Maritime Organization

- L

- litre(s)

- LFVIR

- Large Fishing Vessel Inspection Regulations

- m

- metre(s)

- mm

- millimetre(s)

- MGM%

- milligrams per 100 millilitres

- non-return

- A valve which allows fluid to flow through the piping system

- valve

- only, but will not allow any fluid to return and flow in the other direction.

- PDT

- Pacific daylight time

- SAR

- Search and Rescue

- SI

- International System (of units)

- SIC

- Steamship Inspection Certificate

- SSB

- Ship Safety Branch

- TSB

- Transportation Safety Board of Canada

- UTC

- Coordinated Universal Time

- °

- degree(s)