Taking on Water

Fishing Vessel "SCOTIA GOLD"

Bay of Fundy

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

On 22 January 1997 the fishing vessel "SCOTIA GOLD" departed Digby, Nova Scotia, for Deer Island, New Brunswick. While crossing the Bay of Fundy in rough weather, the vessel began to take on water which both the vessel's main bilge pump, and the portable de-watering pump carried on board, failed to pump out. A Canadian Coast Guard Cutter, the "CUMELLA", and a Coast Guard helicopter were dispatched to the scene. The helicopter supplied a portable de-watering pump made by the same manufacturer as the vessel's portable pump; it also failed. The "CUMELLA" escorted the "SCOTIA GOLD" to Dipper Harbour, New Brunswick, where the situation was stabilized and the flood water pumped out.

The Board determined that the "SCOTIA GOLD" took on water through poorly secured deck hatches. Displaced cover plates in the fish hold permitted ice slurry to enter the shaft tunnel/drain well, block the suction line to the main bilge pump and render the pump ineffective. As a result of previously undetected corrosion or damage, the portable de-watering pumps failed to operate. The portable pumps were not designed for the type of marine operation in which they were employed.

1.0 Factual Information

1.1 Particulars of the Vessel

| Name | "SCOTIA GOLD" |

|---|---|

| Official number | 328690 |

| Port of registry | Annapolis Royal, Nova Scotia |

| Flag | Canada |

| Type | Fishing (scallop dragger) |

| Gross Tons | 51 |

| Length | 17.2 m |

| Built | 1974, Parkers Cove, Nova Scotia |

| Propulsion | Single-screw, GM diesel, 253 kW |

| Crew | 3 |

| Owners | Deep Brook Trawlers |

1.1.1 Description of the Vessel

The "SCOTIA GOLD" is a wooden scallop dragger of closed-deck construction with accommodation forward, a wheel-house, engine-room, fish hold and steering gear. The bulkhead between the fish hold and the engine-room is not watertight.

1.2 History of the Voyage

The "SCOTIA GOLD" departed Digby on 22 January 1997 at 0930, with a crew of three, bound for Fairhaven, Deer Island. The vessel had taken on four tonnes of ice prior to departure. The skipper planned to stay the night in Fairhaven and begin fishing the next day.

At about 1500, while crossing the Bay of Fundy, the skipper became aware of excess water in the engine-room. The vessel's main-engine-driven bilge pump was running but could not pump out the vessel; the vessel's portable, gasoline-powered Honda de-watering pump did not start. The skipper called the Canadian Coast Guard (CCG) for assistance while the crew attempted to repair the portable pump. The pull-start cord was jammed and the recoil mechanism had to be removed to free it. The gasoline motor eventually started and ran, but the pump itself did not work.

In response to the call for assistance, the CCG dispatched a helicopter from Yarmouth, Nova Scotia, and a rescue vessel from Grand Manan Island, New Brunswick. CCG helicopter 361 departed Yarmouth at 1600 and arrived on the scene at 1640. The helicopter lowered a portable gasoline-powered Honda de-watering pump assembly to the "SCOTIA GOLD". When attempts were made to start the pump motor, the pull-start cord jammed in its housing. The recoil starting mechanism was removed, repaired and replaced. The gasoline motor then started, but the unit failed to pump water. Despite the crew's efforts, the pump did not remove any water from the vessel.

The Canadian Coast Guard Cutter (CCGC) "CUMELLA" arrived on scene at 1747 and escorted the "SCOTIA GOLD" to Dipper Harbour. At 1913, when both vessels were safely secured in Dipper Harbour, the engineer from the "CUMELLA" boarded the "SCOTIA GOLD". Employing the Honda portable de-watering unit provided by the CCG helicopter, he attempted to pump out the water but was also unsuccessful.

The "CUMELLA" was equipped with a portable Search and Rescue (SAR)-approved de-watering pump made by another manufacturer. When used on board the "SCOTIA GOLD", this unit started without difficulty and the flood water was pumped from the vessel.

1.3 Vessel Secured in Dipper Harbour

While the vessel was alongside in Dipper Harbour, the following observations were made:

- The portable cover plates over the shaft tunnel/drain well in the fish hold were not set in place. Crushed ice, which had been loaded in the fish hold prior to departure, had fallen down past the displaced cover plates into the drain well and blocked the bilge suction line.

- A seawater pump used for washing down is located in the engine-room. The discharge piping from this pump extends to the weather deck at the after wheel-house bulkhead where a hose was usually connected to the pipe. The practice was to run this pump continuously while at sea and to direct the seawater overboard during those times when it was not required for fish handling or washing down. The hose was missing. Reportedly, it was washed overboard after it became disconnected during the voyage.

- Securing dogs to the deck hatches were found to be functional but the hatches were improperly secured. This allowed water shipped on deck and water from the

- wash-down pump to drain into the fish hold and through to the engine-room.

- The crew of the "CUMELLA" repacked the helicopter-supplied Honda pump unit into its container for delivery back to the CCG repair depot. It was discovered at this time that the container had been designed for a different pump assembly made by another manufacturer.

1.4 Injuries to Persons

No one was injured.

1.5 Damage

1.5.1 Damage to the "SCOTIA GOLD" Portable Honda De-watering Pump

The portable Honda pump, carried as ship's equipment onboard the "SCOTIA GOLD", was dismantled ashore soon after the occurrence. The interior of the aluminium pump casing and steel impeller parts were found to be so heavily corroded that the pump could not work. (See Appendix A, Photo 2.)

1.5.2 Damage to the CCG Helicopter-supplied Portable Honda De-watering Pump

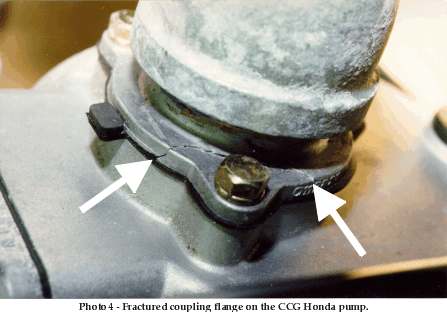

The portable Honda pump supplied to the "SCOTIA GOLD" by CCG helicopter 361 had a fractured coupling flange at the pump's suction flap valve, which rendered the pump inoperative. (See Appendix A, Photo 4.)

1.6 Certification

1.6.1 Vessel

The vessel was not required by regulation to carry a properly maintained auxiliary pump designed to operate in a marine environment.

The "SCOTIA GOLD" was certificated and equipped in accordance with existing regulations and was authorized to carry a maximum crew of five persons, including the master.

1.6.2 Personnel

The skipper held a Fishing Master Class 3 certificate. The remainder of the crew was not certificated, nor was this a requirement under existing regulations.

1.7 Personnel History

1.7.1 Skipper

The skipper of the "SCOTIA GOLD" had approximately 16 years' fishing experience. He had newly taken command of the vessel.

1.8 Weather Information

1.8.1 Weather as Reported by Rescue Coordination Centre, Halifax

The weather reported by the Rescue Coordination Centre at the time of the occurrence was southwesterly winds at 35 knots, wave height of 4 metres and visibility of 2.5 nautical miles.

1.8.2 Weather as Reported by the Skipper of the "SCOTIA GOLD"

The weather reported by the skipper of the "SCOTIA GOLD" was winds southwesterly at

45 knots, wave height of four metres and poor visibility.

1.9 Canadian Coast Guard

1.9.1 CCG Helicopter 361

The CCG provides a Yarmouth-based helicopter, as a secondary SAR resource. It is equipped with a hoist and is capable of delivering portable de-watering pumps to vessels that are taking on water. The method of delivery is either to drop the watertight drum containing the pump unit from the helicopter or to lower the assembly at a controlled rate. An attached long line is guided to the distressed vessel and used to retrieve the floating drum from the sea. On this mission, the drum container was lowered into the water, and the "SCOTIA GOLD" retrieved it using the attached line.

1.9.2 CCG Helicopter-supplied Honda De-watering Pump

The CCG de-watering pump unit lowered to the "SCOTIA GOLD" was similar to the ship's own portable Honda unit, which had failed earlier. After the crew overcame mechanical problems and started the CCG Honda pump's gasoline motor, the pump did not work. The pump was later dismantled, and the interior was found to be in the initial stages of corrosion.

The Honda pump consists of impeller parts manufactured from steel and a pump body of aluminium alloy. A warning in the Honda pump owner's manual cautions "to avoid pump corrosion, never pump sea water."

The CCG pump unit had been packaged for SAR using a drum container originally designed for a portable pump unit made by another manufacturer. As purchased from the dealer, the Honda pump unit will not fit into the mismatched aluminium drum container. This unit had been adapted to fit the drum container by a local industrial equipment rental company. The pump's carrying frame had been shortened by sawing off and reshaping one end. Fitting of the adapted pump unit into the container forced the flanged suction pipe hard against the inside of the container wall. (See Appendix A, Photo 5.)

Service history of the helicopter-supplied Honda de-watering pump was not recorded in the maintenance records received from the CCG. There were no records of formal approval by a marine authority of the Honda de-watering pumps for use on ships.

1.9.3 CCGC "CUMELLA"-supplied SAR-approved De-watering Pump

The CCG also uses a de-watering pump manufactured by Briggs & Stratton/Ohler. This unit is an earlier generation in a series of portable de-watering pumps being phased out by the CCG in favour of the Honda unit. The Briggs & Stratton/Ohler or latest /Scot series of pump assemblies have been approved by the United States Coast Guard (USCG), and Canada's Department of National Defence (DND). Their primary purpose is for SAR use as air-droppable assemblies or for ship-to-ship delivery to discharge fresh or salt water from vessels in danger of sinking.

Briggs & Stratton-type portable pump assemblies, such as that carried on the "CUMELLA", are referred to herein as "SAR-approved". (See Appendix A, Photo 6.)

According to records received from the CCG, the SAR-approved pump successfully used by the engineer of the "CUMELLA" to pump out the "SCOTIA GOLD" had been serviced on 04 June 1996.

1.9.4 Related Incidents Involving the CCGC "HOWE POINT" and the CCGC "SOURIS"

In a similar incident off Prince Edward Island on 20 August 1997, the CCGC "HOWE POINT" was taking on water but was unable to start the portable Honda de-watering pump on board. Fortunately, the CCGC "SOURIS" was close by and able to assist. Records received from the CCG indicate that three and a half years had elapsed since that unit had last been checked by a CCG depot (02 March 1994). It was also reported that the Honda de-watering pump carried on the fast rescue craft assigned to the "SOURIS" was removed from its SAR container and it, too, failed to start. Service records for that pump were unavailable. The carburettors of the Honda pumps were overhauled by a crew member and both units subsequently started.

1.9.5 CCG Maintenance of SAR De-watering Pumps

The CCG is responsible for the maintenance of its SAR de-watering pump assemblies. At the time of the occurrence, the CCG depots within the Maritimes region were required to service this emergency equipment, maintain records and arrange to have the reconditioned pump assemblies re-allocated to the various CCG stations, vessels and helicopters as necessary. The CCG Rescue, Safety and Environmental Response (RSER) reported that all pumps are tested at the beginning of every work period after each crew change (i.e., every one to three weeks maximum). RSER also reported that every region is satisfied with the Honda portable pumps and has attested to their reliability and durability.

Two repair depots in the Maritimes were visited and their pump placement and maintenance records were examined. The maintenance facilities were well equipped, but maintenance records were found to be inadequate, incomplete, and in some cases, non-existent. According to available records, some of the field-allocated pumps were long overdue for return to their respective depots. No follow-up program was found to be in place to ensure an effective rotation cycle, i.e., notices were not sent to unit supervisors to inform them when servicing of the pump assemblies was overdue. According to the information received from the two repair depots at the time, SAR pumps were tested, sealed in drums and either put on the shelf or allocated to SAR field units as required. If units were deployed in an emergency, it was the field supervisor's responsibility to return the pump assembly to the depot for servicing immediately after use. If they were not deployed, it was the field supervisor's responsibility to return the pump assemblies to the depot every 12 months. In practice, some of the pump units remained sealed in their respective drums for much longer periods.

One of the CCG depots visited did not keep Honda pumps in its inventory as it was felt that the units, being prone to corrosion by seawater, were not suitable for marine use.

At the time of this occurrence, no standard was found to exist within the individual CCG depots or between the various depots with respect to record-keeping procedures and inventory control.

1.9.6 CCG Decision to Replace Briggs & Stratton/Ohler Pumps

The RSER reported that the SAR-approved Briggs & Stratton portable pumps have been replaced gradually with Honda pumps because of their greater reliability, simpler operational and maintenance procedures, and the availability of spare parts.

There is no indication that a formal specification or a change of use proposal was drafted prior to the decision to replace the SAR-approved Briggs & Stratton/Ohler de-watering pumps with Honda units. Thus far, it has not been determined by what authority the Honda assembly found its way into the system, nor whether any particular authority was indeed required.

The Honda pump assemblies cost considerably less than the SAR-approved models presently in use by DND and the USCG. The CCG SAR Branch supports the ongoing use of Honda portable pumps.

1.10 Transport Canada Marine Safety Surveyors' Requirements

There are occasions when Transport Canada (TC) Marine Safety surveyors in the Maritimes region, upon request for certification of a small fishing vessel such as the "SCOTIA GOLD", may call for or require the carriage of a portable de-watering pump over and above all other regulatory requirements, due consideration being given to the vessel's age, the nature of the intended voyages and the watertight/weathertight integrity of hatch coamings, bulkheads, closing appliances, etc.

The "SCOTIA GOLD" was equipped accordingly, but the shipboard portable Honda pump had no drum container protection from the elements as provided in a SAR pump assembly. The bare unit was stowed in a compartment on the weather deck. (See Appendix A, Photo 3.)

1.11 Honda Canada

Honda Canada stipulates that the company's portable gasoline-driven de-watering pumps, as selected for SAR use by the CCG, "are intended to be used as economical drainage pumps for most general purpose water pumping applications." Warnings respecting improper usages which affect the safe operation of these units are specified in Honda manuals. In particular, the owner's manual cautions "to avoid pump corrosion, never pump sea water." Honda Canada also added that it "does not manufacture a pump assembly specifically suitable to a salt water environment."

2.0 Analysis

2.1 Preparations for Sea

The skipper was new to the "SCOTIA GOLD" and this may have been why he overlooked several things before determining that the vessel was ready for sea. The hatches on deck were not properly secured and, as fishing operations were not intended during the transit voyage, operation of the deck wash-down system was unnecessary. There was no notice that the deck wash-down hose leading overboard had disconnected nor were steps taken to shut down the system or redirect the flow to prevent seawater being pumped onto the deck, thus contributing to flooding of the vessel through the unsecured deck hatches. Also, the cover plates over the propeller shaft/drain well in the fish hold were improperly placed, which lead to the blockage of the bilge suction line by crushed ice and the inability of the main bilge pump to drain the fish hold and engine-room.

The vessel was not inspected prior to departure nor were periodic rounds made of the vessel during transit. No deck watch system was in place which could have served to alert the crew of the conditions or circumstances that allowed water ingress. This permitted the ingress to go unnoticed for several hours.

The failure to maintain watertight integrity of compartments has been identified as a causal factor in a number of marine occurrences; the problem is predominantly in the fishing industry. The Board, concerned about shipboard practices that compromise watertight/weathertight integrity of vessels, made a number of recommendations to the Minister of Transport to address this issue. In response to the recommendations, the Minister of Transport instituted measures that included:

intensifying the examination of masters, mates and engineers on matters related to watertight/weathertight integrity.

Transportation Safety Recommendation M93-01

issuing/re-issuing several Ship Safety Bulletins (SSB), the most recent being 08/98 and 16/96--the latter addressing stability and seaworthiness issues.

Transportation Safety Recommendation M92-04

issuing a special edition of the SSB 02/93 to reach several thousand fishing vessel owners, listing titles of all SSBs since 1977, to address effectiveness of SSB distribution practices.

Transportation Safety Recommendation M93-02

Despite these initiatives by TC, the failure to maintain watertight/weathertight integrity of the vessel, particularly in the fishing industry, continues.

2.2 Acquisition of SAR Pumps by the Canadian Coast Guard

The CCG decision to replace the previously SAR-approved Briggs & Stratton/Ohler pump with the much less expensive Honda unit appears to have been initiated primarily as a cost-cutting measure.

It has been reported by some in the CCG that the Honda pump unit is easier to start and maintain. This could be the case when the units are new, carefully handled, used only for fresh water purposes and started on a relatively stable platform. However, differences of opinion exist within the ranks of CCG SAR personnel as to the practical attributes of the Honda pump unit versus the SAR-approved type. Given the manufacturer's strict warnings and specified limitations on the use of the pump, it seems that the Honda equipment has been adopted without the formal pre-acquisition/technical approval procedures normally required in the selection of such essential marine emergency equipment.

2.3 Suitability of Honda Pump for its Intended Use and its Compatibility with the Modified Container

In the CCG's selection of the Honda pump unit, adequate consideration was not given to the design of the container in which the new pump would be stored and to potential problems associated with dissimilar metal parts within the pump.

The use of an aluminium pump casing with steel impeller parts in the corrosive environment of seawater will cause galvanic action resulting in accelerated corrosive attack of the aluminium, besides the normal oxidization of ferrous metal parts.

The container is one component of an approved Briggs & Stratton/Ohler customized package and as such is designed to resist the forces normally associated with air drops and ship-to-ship handling of that particular assembly. The decision taken to make a pump unit from one manufacturer fit into the container made especially for a different pump unit compromised the protection afforded by the container.

A fracture discovered in the helicopter-supplied Honda pump's suction flange was established as the cause of pump failure. Although it is unknown precisely when the fracture in the suction flange occurred, the pump must have been damaged sometime after leaving the maintenance depot, while on board or being lowered to the water by the helicopter, or during its recovery by the "SCOTIA GOLD".

Given that the flanged suction fitting was hard against the inside of the container, an impact load at this point of contact would cause a shearing force at the flange corner. The crack in the flange was found to have propagated from this point. The incompatibility of the pump unit and container was such that the pump suffered damage during its "normal" handling between the depot and being hauled aboard the "SCOTIA GOLD". It is thus unlikely that the assembly would have survived an air drop--the alternative method of delivery.

Unlike the Briggs & Stratton/Ohler portable de-watering pump assemblies, which are ruggedly constructed for marine use, the Honda replacements do not have special features found in such SAR-approved assemblies, including:

- A gasoline motor fitted with a protective device to prevent the pull-start cord from jamming the recoil starting mechanism.

- A pump casing and internal impeller parts made from the same metal alloy to resist electrolytic corrosion in seawater.

- The motor/pump unit with its carrying frame custom-designed to fit its drum container, allowing for appropriate protective clearance to resist equipment damage upon impact.

2.4 Transport Canada Marine Safety Surveyors' Requirements

Where vessels take on water, a portable de-watering pump can be a vital piece of safety equipment. However, Transport Canada (TC) Marine Safety regulations for small fishing vessels do not require the carriage of such a pump.

The portable Honda de-watering pump carried on board the "SCOTIA GOLD" was additional equipment to that required by TC regulations. Once on board, the pump's general purpose use, lack of frequent maintenance and inability to operate safely in a seawater environment resulted, over time, in the aluminium and steel pump parts becoming so severely corroded that the unit failed to operate when needed in this emergency.

TC Marine Safety does not approve pumps of any particular make or model, including those required by regulations in terms of number, type and rating.

It has not been determined how many fishing vessels and other craft are required by TC Marine Safety in the Maritimes region to carry portable de-watering pumps. However, the unreliability, over time, of portable pump units not designed for marine operations poses a serious threat to the safety of such ships and to their crews in emergencies.

3.0 Findings

3.1 Findings

- Good seamanship practices were not followed and the skipper did not ensure that the deck hatches were properly secured, and water on deck entered the fish hold, then passed through the non-watertight bulkhead to the engine-room.

- The crew was unaware that the deck wash-down hose leading overboard had become disconnected, causing seawater to be pumped onto the deck, thus contributing to flooding of the vessel through the unsecured hatches.

- The absence of a deck watch system allowed the ingress of water to go unnoticed for several hours.

- Displaced portable cover plates over the drain well in the fish hold permitted ice slurry to enter the drain well and block the suction pipe to the main bilge pump, rendering the pump ineffective.

- Both the "SCOTIA GOLD" and the Canadian Coast Guard (CCG) helicopter-supplied portable Honda de-watering pumps' starting mechanisms jammed.

- When started, both portable Honda de-watering units failed to pump. The ship's pump failed due to severe internal corrosion, and the CCG unit's failure was due to a broken suction flange.

- The Briggs & Stratton/Ohler portable de-watering pump supplied by the Canadian Coast Guard Cutter (CCGC) "CUMELLA", and used successfully to pump out the "SCOTIA GOLD", is a specially customized pump unit/container assembly approved for Search and Rescue (SAR) use by the United States Coast Guard (USCG) and Canada's Department of National Defence (DND).

- The portable Honda de-watering pump units lack fundamental safety features characteristic of a SAR-approved assembly, such as:

- means to prevent the pull-start cord from jamming;

- pump components designed to avoid electrolytic corrosion in seawater; and

- design-fit clearances between the pump unit and container wall customized so as to resist equipment damage upon impact from an air drop or during normal conditions of emergency deployment.

- Honda Canada declares that its portable gasoline driven de-watering pumps are intended to be used as economical drainage pumps for most general-purpose water pumping applications and warns that, to avoid pump corrosion, they should never be used to pump seawater.

- ]Honda does not manufacture a pump assembly specifically suited to a salt water environment.

- At the time of the occurrence, the CCG had almost completed its program to replace the Briggs & Stratton series of SAR-approved de-watering pump units with the Honda models.

- The portable Honda de-watering pump costs significantly less than the Briggs & Stratton unit, and this factor was taken into account during the CCG selection process.

- There is no formal approval process of portable SAR de-watering pumps by a recognized marine authority.

- Officials of the CCG SAR Branch support the ongoing use of Honda portable pumps; however, differences of opinion prevail within the ranks of CCG personnel as to the pumps' attributes in comparison with those of SAR-approved assemblies.

- One of the two CCG service depots visited did not maintain Honda portable de-watering pumps in its inventory, as the units were considered to be prone to salt water corrosion and unsuitable for marine use.

- The maintenance and inventory records of SAR de-watering pumps at two CCG service depots were found to be inadequate, incomplete, and in some cases, non-existent.

- Transport Canada (TC) Marine Safety does not approve portable de-watering pumps or ship's pumps, although regulations dictate the number, type and rating of pumps to be installed.

- Fishing vessels are not required by regulation to carry a portable de-watering pump. However, at the time of re-certification of fishing vessels, and duly considering the vessel's age, structure, nature of intended voyages and all aspects of safety, Marine Safety surveyors may require the carriage of a portable de-watering pump over and above all other regulatory requirements.

- The "SCOTIA GOLD" carried a portable Honda pump unit on board as additional equipment to that required by TC Marine Safety regulations for small fishing vessels.

3.2 Causes

The "SCOTIA GOLD" took on water through poorly secured deck hatches. Displaced cover plates in the fish hold permitted ice slurry to enter the shaft tunnel/drain well, block the suction line to the main bilge pump and render the pump ineffective. As a result of previously undetected corrosion or damage, the portable de-watering pumps failed to operate. The portable pumps were not designed for the type of marine operation in which they were employed.

4.0 Safety Action

4.1 Action Taken

4.1.1 Pump Maintenance and Packaging

In April 1997 the CCG was apprised of the lack of reliability of a particular model of de-watering pump used by the SAR units, as the pumps apparently degraded when used in sea water and were damaged when dropped from a SAR helicopter, causing mechanical failure. In response, the Coast Guard initiated an internal investigation to find out why this particular pump model was almost exclusively used by the SAR units, and why the pump delivered on the fishing vessel "SCOTIA GOLD" malfunctioned. As a result, a decision was made that the CCG will not purchase any further Honda pumps for SAR duties. Further, the CCG has begun to standardize SAR pumps with equipment that is better suited to the marine environment.

The CCG issued a memorandum to its regions to remind every CCG ship and CG base and SAR station to follow the scheduled maintenance according to the manufacturer's operator's manual, to rinse pumps and equipment with fresh water after use in sea water and to test pumps and equipment on a monthly basis on vessels and at CCG bases. The memorandum recommended that the Yarmouth-based CG helicopter carry a drum container--adequately packed for this purpose and capable of withstanding an air drop--similar to what DND aircraft carry, and also recommended that CCG ships, CCG bases and SAR stations be made aware of the danger of pump malfunction resulting from strong impact, and take appropriate measures regarding drum container packing.

TSB also apprised TC, via the Marine Safety Advisory No. 1/97, of the need to ensure proper maintenance and operation of various portable de-watering pumps now in service. TCMS issued Ship Safety Bulletin No. 4/98 alerting owners to the dangers of using inappropriate equipment and to the necessity of maintaining all equipment in good working condition.

This report concludes the Transportation Safety Board's investigation into this occurrence. Consequently, the Board, consisting of Chairperson Benoît Bouchard, and members Maurice Harquail, Charles Simpson and W.A. Tadros, authorized the release of this report on .

Appendices

Appendix A - Photographs

Appendix B - General Description of a Portable De-watering Pump Assembly

A typical de-watering pump assembly consists of a gasoline-engine-driven pump unit and auxiliary equipment packaged into a watertight container, and is itemized as follows:

- watertight, floating drum container;

- gasoline-driven pump unit with carrying frame or handles;

- list of instructions;

- suction hose;

- discharge hose;

- auxiliary fuel; and

- flashlight.

Special packing arrangements can be required for assemblies to be rendered air-droppable.

Appendix C - List of Supporting Reports

The following TSB Engineering Branch Report was completed:

LP 31/97 - SAR Pumps Examination

This report is available upon request from the Transportation Safety Board of Canada.

Appendix D - Glossary

- AST

- Atlantic standard time

- CCG

- Canadian Coast Guard

- CCGC

- Canadian Coast Guard Cutter

- DND

- Department of National Defence

- IMO

- International Maritime Organization

- knot

- nautical mile per hour

- kW

- kilowatt

- m

- metre

- RSER

- Rescue, Safety and Environmental Response

- SAR

- Search and Rescue

- SI

- International System (of units)

- SSB

- Ship Safety Bulletin

- TC

- Transport Canada

- TSB

- Transportation Safety Board of Canada

- USCG

- United States Coast Guard

- UTC

- coordinated universal time