Break-up and sinking

the bulk carrier "FLARE"

Cabot Strait

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

On 16 January 1998, en route from Rotterdam, Netherlands, to Montreal, Quebec, in severe weather conditions, the "FLARE" was approximately 45 miles southwest of the islands of Saint-Pierre-et-Miquelon. The vessel broke in two and the stern section sank within 30 minutes. Thebow section sank four days later off Nova Scotia, on the western side of Banquereau Bank. Twenty-one of the crew perished and four survived. There was widespread, non-recoverable, fuel oil pollution from the sunken stern section.

Section 3 of this report contains the Board's findings as to causes and contributing factors and other findings. The Board has also identified safety deficiencies related to the accessibility and stowage of the Emergency Position Indicating Radio Beacon, the carriage of immersion suits on vessels operating in waters where hypothermia can reduce the survival time of persons in the water, the effect of high frequency stresses in structural failure associated with inadequate ballasting and the need for stricter adherence to approved loading manuals. Section 4 lists the relevant safety action taken by the marine industry, Transport Canada and the TSB. The Board has issued five safety recommendations to address the identified safety deficiencies.

1.0 Factual Information

1.1 Particulars of the Vessel

| Name | "FLARE" (ex "FLAME" - 1989, ex "DORIC FLAME" - 1987) |

|---|---|

| Official number | 708220 |

| Port of registry | Limassol, Cyprus |

| Flag | Cyprus |

| Type | Geared bulk carrier |

| Gross tonsFootnote 1 | 16,398 |

| Length | 180.8 m |

| Breadth (moulded) | 23.1 m |

| Depth (moulded) | 14.5 m |

| Draught (departure) | FFootnote 2: 3.07 m A: 6.93 m |

| Built | Hakodate Dock Co. Ltd., Japan, 1972 |

| Propulsion | Sulzer Ishikawajima-Harima Heavy Industries (I.H.I) 8,827 kW |

| Service Speed | 15.1 knots |

| Owners | ABTA Shipping Co. Ltd., Limassol, Cyprus |

| Operators | Trade Fortune Inc., Piraeus, Greece |

1.1.1 Description of the Vessel

The "FLARE" was built in Japan in 1972, as a single-deck, dry bulk cargo vessel of all-welded steel construction. The vessel was propelled by a marine diesel engine driving a single, fixed-pitch propeller. The propelling machinery, steering gear, wheel-house, life-saving equipment and all crew accommodation were arranged at the after end of the vessel. The locations of the seven dry cargo holds and all water ballast tanks and oil fuel tanks were as shown in Figure 1, Outline General Arrangement. The hull was strengthened for the carriage of ore cargoes, such that holds Nos. 1, 4 and 6 could remain empty, and hold No. 4 could be used as a water ballast tank. The hull was subdivided by nine transverse, watertight bulkheads, together with an inner bottom tank top, which extended fore and aft in way of all of the cargo holds and the engine-room. The main deck, upper wing tanks, inner bottom and bottom shell plating throughout the length of the cargo holds were framed

The hull was generally constructed with Lloyd's Grade A steel, and the main deck plating outboard of the cargo hatchways, radiused gunwale and sheer strake, were of more notch- (fracture-)resistant Lloyd's Grade D steel.

The principal construction and general layout of the cargo hatchways, holds, upper wing water ballast tanks, double-bottom tanks, and duct keel were as shown in Figure 2, Typical Cross Section.

1.2 History of the Voyage

Before departure, a portable welding machine and various pieces of steel plating and flat bars were placed on board, so various repairs could be carried out during the voyage by a fitter/welder who was a member of the crew.

The vessel, in a lightly ballasted condition, departed Rotterdam on 30 December 1997, bound for Montreal.

Reportedly, there was little conversation between the harbour pilot and the master before the pilot's disembarkation. It was dark during the time that the pilot was on board; however, he noted that the ship had a light forward draught and was trimmed by the stern.

After the "FLARE" cleared the English Channel, the weather deteriorated and, on 01 January 1998, gale force westerlies with heavy seas were experienced. In an endeavour to find better weather, the master decided to proceed as far south as 45 north latitude (N) and to follow that parallel in a westerly direction (see Chart 1, Atlantic Crossing).

Throughout most of the passage, westerly gale to storm force winds were encountered, with seas reaching a height of 16 m or more. Although speed was adjusted in response to the prevailing conditions, the vessel continued to pitch, pound and slam heavily.

Some of the welding repairs planned for completion during the voyage were carried out when the weather conditions permitted.

During the voyage, radio messages were sent from the ship to the vessel's operators, reporting the following:

| Date (January 1998) |

Distance (nautical miles) |

RPM of main engine |

Reported average speed (knots) |

Calculated average speed (knots) |

|---|---|---|---|---|

| 1 - 4 | 204 | 80 | 3.19 | 2.83 |

| 4 - 7 | 320 | 88 | 3.16 | 4.44 |

| 7 - 9 | 181 | not given | 6.0 | 4.35 |

| 9 - 10 | 332 | 91 | 10.6 | 10.55 |

| 10 - 13 | 782 | 94 | 10.7 | 10.86 |

| 13 - 16 | 359 | not given | not given | 5.57 |

Mechanical problems were experienced in the engine-room and it was reported that the governor was repaired with a jury-rigged mechanism to prevent the main engine from over-speeding.

Survivors reported that they had difficulty sleeping and eating because of the hull flexing. One of the survivors reported seeing the main deck flexing such that deck cranes appeared to be touching each other. One survivor was so apprehensive that he kept his cabin light on and practised dressing in warm clothing as quickly as possible.

On January 13 the vessel's course was altered to approach the recommended traffic separation scheme in the Gulf of St. Lawrence (see Chart 2, Occurrence Area). As the vessel approached the Canadian coast, the master reported to the Eastern Canada Traffic System (ECAREG) that the forward and after draughts were 11 feet (3.35 m) and 21 feet (6.4 m), respectively. He also reported that seawater ballast had been exchanged during January 10, 11, and 12. On January 14 the vessel's operators requested the master to ensure all ballast tanks were full in order to have maximum draught to avoid damage to the propeller in ice. The master replied that he had advised ECAREG that the ballast tanks were full.

At about 0000 ship's time (0400 coordinated universal time [UTC]Footnote 3) on January 16, a very loud bang was heard (due to the slamming of the forefoot), which was followed by severe whipping and longitudinal flexing of the hull. Approximately four and a half hours later, another particularly loud bang was heard, which also was followed by severe hull whipping and vibration.

The survivors reported that some of the crew members were startled by the severity of the latter vibrations, which were followed by the sound of the general alarm ringing. Shortly thereafter, upon their arrival on deck, they saw that the vessel had broken in two. The whole crew was on the after part of the vessel.

The stern section listed approximately 30 to 35 degrees to starboard, which precluded the use of the starboard side motor lifeboat. It was reported that, due to the vessel's motion and vibration, the lifeboats' securing arrangements had required frequent readjustment and additional lashings during the voyage. These extra lashings retarded the clearing away of the port side lifeboat and all attempts to launch it were unsuccessful. The crew's ability to clear away the boat and liferaft, while maintaining a safe footing, was more difficult because the boat deck was in darkness and there was ice and snow on the decks.

Crew members man-handled a liferaft down one deck, launched it over the stern and secured its painter to the poop deck rail. The master, who was nearby, ordered them not to abandon ship at that time because the ship's propeller was still turning. Shortly thereafter, the painter reportedly chafed through and the liferaft drifted away.

The stern section sank in about half an hour. As it was sinking, some of the crew on the port side of the poop deck saw the bow of a vessel apparently approaching on a near reciprocal course. Their immediate impression was that a rescue vessel was at hand; however, they were dismayed to find that it was the bow section of the "FLARE". The propeller was still turning and had likely caused the stern section to follow an erratic course which returned it to the vicinity of the separated bow section.

A hurried MAYDAY message was transmitted from the ship on very high frequency (VHF) radiotelephone channel 16 shortly before the stern section heeled further to starboard and sank. The signal, as picked up by a remote antenna on Ramea Island linked to the Coast Guard Radio Station at Stephenville, Newfoundland, was indistinct and incomplete. The duty officer there called the station supervisor to have the tape recording of the MAYDAY message replayed for clarification in order to assist in the search and rescue (SAR) response.

The crew, except reportedly the chief and third engineers and one other person, were wearing hastily donned clothing and lifejackets and abandoned the stern section as it sank. The port side lifeboat broke or floated free and capsized. Six of the crew managed to swim to, and climb on, the capsized lifeboat. Of these six, four survived to be rescued by a SAR helicopter and transported to hospital on the island of Saint-Pierre.

The bow section remained afloat and drifted for four and a half days before sinking.

1.3 Search and Rescue (SAR) Response

At 0832 on January 16, Marine Communications and Traffic Services (MCTS) at Stephenville received a MAYDAY from an unidentified vessel on VHF channel 16 through a remote antenna sited on Ramea Island off the south coast of Newfoundland (see Chart 2).

The message was indistinct and incomplete. Requests for further information went unanswered; however, the duty watch officer at the station believed the position of the calling station to be 46°57′ N, 056°51′ W.

Operations policy and equipment layout did not allow the MCTS lone watch officer to have immediate playback capabilities of all Safety, Urgency and Distress Traffic. However, to better decipher the indistinct and unclear transmission, a replay of the tape was necessary.

At 0834, MCTS Stephenville advised St. John's Marine Rescue Sub-centre (MRSC) of the situation, and at 0837 the MRSC advised the Rescue Coordination Centre (RCC) Halifax, Nova Scotia. MCTS Stephenville, giving the assumed position of the unidentified vessel, transmitted a MAYDAY relay on VHF channel 16, on MF (medium frequency) 2182 kHz, and on 500 MHz. At the request of RCC Halifax, a broadcast was made through the United States Coast Guard Radio Station, Boston, Massachusetts, on high frequency digital selective calling (HF DSC), and by NAVTEX through Sydney MCTS located in Cape Breton, Nova Scotia. An International Maritime Satellite Communication System (INMARSAT C), Enhanced Group Call (EGC) was issued for vessels within a 100-mile radius to assist.

Responses were received from the following commercial vessels:

"STOLT ASPIRATION"; "THORSRIVER"; "HOEGH MERIT"; "B.T. NAVIGATOR"; "KASTNER"; "ISOLA SCARLATTA"; "COLBY"; "IMPERIAL ST. LAWRENCE"; "ATLANTIC MAPLE"; "SAUNIERE"; "LAKE CARLING"; "ATLANTIC FREIGHTER"; "IMPERIAL ST. CLAIR"; "FEDERAL VIBEKE" and "FEDERAL WIGGY".

Only the "STOLT ASPIRATION", "THORSRIVER", "HOEGH MERIT" and "FEDERAL VIBEKE" were tasked and the latter two were later released.

It was determined that the occurrence was in Canadian waters and the marine coordinator at St. John's MRSC was appointed Search and Rescue Mission Coordinator (SMC). The MRSC was assisted by RCC Halifax, where the air coordinator tasked air resources.

On board the tanker "STOLT ASPIRATION", the officer of the watch heard the faint and broken MAYDAY and, later, the MAYDAY relay transmitted by Stephenville MCTS. The master of the "STOLT ASPIRATION" reported his vessel's position, course and speed to MCTS and at 0840 was tasked by the SMC. At 0845, the master of the "STOLT ASPIRATION" reported that his vessel was approximately 18 miles from the assumed position and that there was no radar target in the area.

An INMARSAT C distress alert was received at 0833 by the Coast Earth Station in Southbury, Connecticut. The alert was identified as originating from the vessel "FLAME", which was the former name of the "FLARE". The vessel's owners and operators were identified and requested to supply a crew list and a complete list of the life-saving appliances on board.

The INMARSAT C alert reported that the ship was about to be abandoned. It reported the ship's position 0221, January 16, as 46°08′ N, 057°10′ W, course 280° true, speed three knots. This was some 45 miles south of the MAYDAY position assumed by Stephenville MCTS. Attempts by other stations to contact the "FLARE" using INMARSAT C were unsuccessful. The distress alert also indicated that the position had not been updated in the previous 24 hours--but this information was neither consistent with the position reported in the alert nor with the position 1200, January 15 of the "FLARE" as reported to ECAREG. The 0221 INMARSAT C position was therefore treated as valid. It was subsequently confirmed that the validation flag was erroneous as a result of a land-based computer software print-out error.

The "FLARE" was not equipped with digital selective calling (DSC) distress alert and her INMARSAT C was not integrated with the vessel's satellite navigation system, nor was there a regulatory requirement for the vessel to be so fitted before 01 February 1999. The vessel was also outside the nominal range of VHF coverage to communicate with Stephenville MCTS.

At 0845, RCC Halifax requested RCC Norfolk, Virginia, to establish through the Automated Mutual Assistance Vessel Rescue System (AMVER) what commercial marine resources were nearest to the assumed MAYDAY position. At the same time, Port-aux-Basques MCTS advised that, in its immediate area, there was no vessel available to render assistance.

At 0855, RCC Halifax tasked Labrador helicopter R303, from 103 Rescue Squadron, which was on primary stand-by at Gander, Newfoundland, to proceed to the assumed MAYDAY position. At 0900, Hercules fixed-wing aircraft R306, from 413 Rescue Squadron at Greenwood, Nova Scotia, and the "STOLT ASPIRATION" were also instructed to proceed to the same area. R303 was airborne at 0945, arrived on scene at 1115 and commenced an expanding square search covering 100 square miles. R306 was airborne at 1025.

At 0927, Stephenville MCTS notified St. John's MRSC that the audio tape of the MAYDAY had been reviewed. The latitude had been deciphered as 46°37′15″ N, and the longitude was possibly 054°W. From the information at hand, including the ECAREG position of 1200 on January 15 and the 0221 INMARSAT C position, MRSC/RCC plotted the predicted track of the "FLARE" to intercept the deciphered latitude of 46°37′15″ N which it did at 058°W. The 0221 INMARSAT C position was also advanced along the vessel's projected track toward Cape Ray for six hours to the time of the MAYDAY. This resulting position was also at 058°W.

At 0935, RCC Halifax asked the Canadian Mission Control Centre (CMCC) for information on activated Emergency Position Indicating Radio Beacons (EPIRBs) in the area. None had been detected. RCC Halifax had incomplete information on the position of the "FLARE" with which to direct SAR resources. All that was known with certainty was that the crew members of the bulk carrier "FLARE" had indicated that they were about to abandon ship at 0832.

An aircraft on charter to the Department of Fisheries and Oceans was equipped with a sophisticated radar system, infrared and other high-tech equipment, making it an ideal search platform. It was preparing to depart on a routine surveillance flight but was SAR-tasked at 1006, designated R01 and was airborne at 1015. The aircraft was directed to proceed to a position off Cape Race, 46°37′ N, 053°00′ W, and to commence a radar and visual search westerly along this parallel of latitude to 056°51′ W. This longitude was that of the original assumed MAYDAY position. The westerly search began at 1042 from the position off Cape Race.

At 1156, upon arrival at the designated position at the end of the westerly search track, R01 was ordered by MRSC/RCC to carry out an expanding square box search to the north, centred on position 46°57′ N, 056°51′ W, at an altitude of 1,500 feet and track spacings of six miles.

The "STOLT ASPIRATION" arrived at the assumed MAYDAY position at 1012 but found no trace of the "FLARE" or her crew. She was then directed by MRSC to proceed to 46°37′ N, 056°51′ W. Sunrise was at 1145. The vessel arrived at the given position at 1149. Visibility was good but again there was no trace of the "FLARE" or her crew.

Shortly after take-off, R306 experienced communication difficulties with RCC due to radio wave propagation. Although able to relay traffic through Sydney (VCO), R306 eventually lost this contact and was not able to communicate with RCC until 1140. Difficulties were also experienced between R306 and R01 due to low altitude and aircraft proximity.

At 1035 the Maritime Operations Centre (MOC) at Halifax was asked for assistance with the search. The Centre provided a position of a potential target which later proved to be that of the "STOLT ASPIRATION". Tasking of some resources to this area continued for 1 hour and 22 minutes, until it was confirmed at 1157 that this was not the position of the "FLARE".

At 1130, Labrador helicopter R304 was tasked from Sydney and was airborne at about 1145 en route to the island of Saint-Pierre. Some minutes into the flight, a suspected hydraulic problem in the aft transmission was experienced and the aircraft returned to base to carry out repairs. R304 was again airborne at 1225 and tasked to proceed to an area south of the assumed position of the "FLARE" which had not been covered by R303.

Also at about 1140, R306, originally tasked to the assumed MAYDAY position, was re-tasked to the INMARSAT C position.

While in approximate position 46°43′ N, 056°55′ W, both R306 and R01 were to commence their expanding square searches; R306 to cover the area to the south and west and R01 to the north and east. Between the two fixed-wing aircraft, this gave coverage in an area between the INMARSAT C position (R306) and the original assumed MAYDAY position (R01), while the Labrador helicopter R303 was also doing an expanding square search around the assumed MAYDAY position.

Between 1114 and 1156, the tasking instructions of the R01 were changed three times as updated information became available. However, at 1156, R01 arrived in position 46°43′ N, 056°55′ W, and identified the "STOLT ASPIRATION" both on radar and visually and a second target off to the southwest. Since R01 was about to start on a northerly heading, this second target was reported to R306, the on-scene commander. The second target had also been detected by R306, which was preparing to commence the expanding square search, configuring data marker buoys, flying at low altitude and handling multiple communications on various frequencies.

At about 1209, R306 was at the INMARSAT C position (46°08′ N, 057°10′ W) and proceeded on a track crawl to a position of approximately 46°11′ N, 057°35′ W where two data marker buoys were dropped at 1223. These buoys were configured to represent a) a person in the water, and b) a liferaft, for drift plot purposes. The search pattern was then commenced.

At 1226, R01 communicated with the "STOLT ASPIRATION" on VHF channels 16 and 10, and at 1300, informed R306 and R303 that it would complete the assigned square box search pattern in 45 minutes. At 1328, R01 was advised to complete its assigned task before proceeding to Saint-Pierre to refuel, and then to return for additional tasking.

At 1330 the French patrol vessel "FULMAR" was in Saint-Pierre, some 30 miles distant from the scene. Tasked by MRSC St. John's, the vessel departed Saint-Pierre at 1345 and arrived on scene at 1600.

At 1340, R303 had sighted no wreckage and departed the scene to refuel at Saint-Pierre.

At 1406, R01 called R306, the on-scene commander, for further instructions and asked if the previously observed and reported radar target in the area west of the "STOLT ASPIRATION" had been investigated. On being told that it had not been investigated, R01 indicated that it would fly over the target before proceeding to Saint-Pierre.

At 1409, R01 identified the target as the bow section of the "FLARE" which was in position 46°28.46′ N, 057°12.82′ W. At this time, helicopter R304 was close to the distress area and about 15 miles from R01. After overflying the bow section of the "FLARE", R304 proceeded to an oil slick about five miles to the southwest. At 1423, R304 sighted an overturned lifeboat with four persons clinging to it.

Search and rescue technicians (SAR TECHs) from R304 carried out a difficult but successful rescue. All four survivors, who had endured approximately six hours on the upturned lifeboat in appalling conditions, were safely on board the helicopter at 1434. They were wearing lifejackets and were mostly clad in light clothing. Three were severely hypothermic and could barely move their limbs during the rescue. The survivors reported that there had been six of the crew on the overturned lifeboat but two became too weak to hold on and were swept off by heavy seas about three hours before the rescue.

While hovering over the area, R304 also sighted a second capsized lifeboat some 500 m from the first, and two liferafts. No other survivors were seen but the position was marked with smoke flares. R304 left the scene to land the survivors and to refuel at Saint-Pierre. Having refuelled, R303 departed Saint-Pierre at 1445 in company with Labrador helicopter R113. R303, R113 and surface craft were directed toward the position that R304 had marked with smoke flares.

R303 and R113 were first tasked to the area in which the bow of the "FLARE" had been sighted, and then to an area southwest of the bow where two overturned lifeboats, two liferafts, and the large oil slick had been sighted. The oil slick extended some 10 miles to the west and about 3 miles in a north-south direction.

On scene, SAR TECHs from R113 were lowered to a liferaft that was covered with oil but found no survivors. The liferaft was deliberately punctured and deflated to prevent a duplication of effort by other search craft.

Two SAR TECHs from R303 were hoisted down to the overturned lifeboat from which the survivors had been rescued. They found a body underneath, tangled in ropes. Since there was no scuba gear on board the helicopter, an attempt was made to dive under the boat using emergency breathing apparatus that allowed only two minutes of air. However, the body was so badly entangled that it was not possible to recover it at this time, and a Coast Guard vessel was later dispatched to recover it. (After a Labrador helicopter crash in British Columbia, weight restrictions on Labrador helicopters were imposed and some gear, including scuba gear, was no longer carried as standard equipment and carried only if it was determined beforehand that it would be necessary.)

R303 sighted 13 bodies in the oil slick, of which 4 were recovered by the SAR TECHs. However, the SAR TECHs were not equipped with dry suits or face protection and entering the fuel oil-covered water became hazardous. The helicopter crew became nauseous from the fuel oil fumes and the helicopter work area was coated with oil, and dangerous. It was therefore decided that the aircraft would locate bodies and direct surface vessels to retrieve them. R303 and R113 had each recovered four bodies before it was decided that marine resources would recover the other bodies.

A sea survival model indicates that, in seawater of 2°C, a 25-year-old male who is not fatigued, of heavy build, of medium height, and who is 100 per cent immersed while wearing a heavy parka has, on average, 1.8 hours to thermal instability, 2.6 hours to incapacitation and 4.1 hours to unconsciousness. A further sea survival model, developed by the Canadian Defence and Civil Institute of Environmental Medicine, was employed to estimate survival times for the "FLARE" survivors. A water temperature of 2°C, the height and weight of the survivors, and the actual clothing worn by the survivors were used for the calculation. Since survivors were immersed prior to reaching the lifeboat and would have remained wet due to the weather conditions, complete wetness was assumed. It was also assumed that 20 per cent of their bodies would have been continuously immersed. The model indicated that the best-clothed survivor would lose consciousness within 6.4 hours while the other survivors would reach this state in 2.0 to 2.3 hours. The model also indicated that the use of immersion suits would have increased survival times to between 12 and 14 hours, depending on the clothing worn.

The Canadian Coast Guard vessel "W.G. GEORGE", a 16-m Arun-class lifeboat based in Burgeo, Newfoundland, recovered four oil-soaked bodies with great difficulty. Her decks became so slippery with the thick fuel oil that the crew could not operate safely with the vessel pitching and rolling heavily. She then stood by near three more bodies, which were recovered by HMCS "MONTREAL".

The recovered bodies had lifejackets on, but were lightly clothed. Most were not wearing shoes or socks and all were covered with fuel oil. The survivors confirmed that no one had time to use any of the six immersion suits that were on board the "FLARE". These several factors were considered when the decision to reduce the search was taken at 1600.

At 2014, when all the lifeboats and liferafts from the "FLARE" had been accounted for, the search continued for persons in the water. HMCS "MONTREAL" assumed on-scene commander duties for surface vessels at 2017. By 2100, in addition to the 4 survivors, 14 bodies had been recovered and 7 persons remained unaccounted for. When the search was concluded, 15 bodies had been recovered.

R303 departed the scene to refuel at 1830 and arrived in Saint-Pierre at 1845. The helicopter was released from tasking on January 17.

The airborne SAR response involved a Provincial Airlines Ltd. fixed-wing Beech King Air aircraft, equipped for aerial surveillance; two Aurora fixed-wing aircraft, three Hercules fixed-wing aircraft; two Labrador helicopters from Canadian Forces Base (CFB) Greenwood, Nova Scotia; and two Labrador helicopters from CFB Gander, Newfoundland.

Airborne resources searched an area of 4,371 square nautical miles, for a combined total of 56.5 hours. In addition, a further combined total of 35 hours was spent in transit to and from the various search areas.

The seaborne SAR response involved two commercial vessels, the "STOLT ASPIRATION" and the "THORSRIVER"; five Canadian Coast Guard (CCG) vessels: the "W.G. GEORGE", the "W. JACKMAN", the "J.E. BERNIER", the "ANN HARVEY"and the "EARL GREY"; HMCS "MONTREAL"; and French patrol vessel "FULMAR".

Marine resources searched an area of 1,702 square nautical miles, for a combined total of 99 hours. In addition, a combined total of 99 hours was spent in transit to and from the various search areas.

1.4 Injuries to Persons

| Crew | Passengers | Others | Total | |

|---|---|---|---|---|

| Fatal | 15 | - | - | 15 |

| Missing | 6 | - | - | 6 |

| Serious | 4 | - | - | 4 |

| Minor/None | - | - | - | - |

| Total | 25 | - | - | 25 |

The recovered bodies (most of which were covered with fuel oil) were taken to St. John's, Newfoundland, by Canadian Naval and CCG vessels. The bodies were identified and examined by the Chief Medical Examiner, who pronounced that the cause of death of all 15 men was by drowning/hypothermia.

The four survivors were landed at Saint-Pierre, where they were hospitalized for two days and treated for hypothermia (their body core temperatures were recorded as 26°to 28°C) and for minor abrasions. They were then repatriated via St. John's and Montreal.

1.5 Departure Loading, Draughts and Trim

While the "FLARE" was in the port of Rotterdam from 22 to 30 December 1997, draught and deadweight surveys were conducted by an independent marine surveyor and the results recorded. Initial draughts and tank-sounding surveys determined the total displacement of the loaded vessel, together with the quantities and distribution of water ballast, oil fuels, lubricants and other consumables remaining on board, prior to cargo discharge.

After the cargo was discharged, off-hire draughts and tank soundings were taken by the independent marine surveyor, who verified the unloaded vessel's displacement. He determined that the deadweight of the unloaded cargo was 27,127.6 tonnes.

The tank soundings facilitated precise on-hire/off-hire financial settlement by accounting for the differences between the quantities of residual and additional oil fuel and other consumable oils and stores taken on board in preparation for the intended voyage to Montreal. It was established that 847.75 long tons (LT) of oil fuel, 168.15 LT of diesel oil and 145.62 LT of fresh water were on board at that time.

Draughts of 3.07 m forward and 6.93 m aft were recorded and a related displacement of 15,105 LT determined. A total of 6,976 tonnes (6,864 LT) of water ballast was recorded as being on board. Nos. 1, 2, 3, 4, 5 and 6 upper wing water ballast tanks and Nos. 2, 3 and 4 double-bottom water ballast tanks were filled, and the forepeak tank was 55 per cent full. Cargo hold No. 4, which also served as a water ballast deep tank, and the afterpeak water ballast tank were empty.

The total weight of ballast on board after cargo discharge was significantly less than the 8,113 LT shown in the light ballast departure condition included in the vessel's Loading Manual. The manual indicated that all water ballast tanks except the deep tank be filled to ensure forward and after draughts of 3.65 m and 7.0 m. The actual recorded forward draught was 0.58 m less than that shown for the light ballast departure condition and, while the after draught was also less, the top of the propeller was submerged by 0.5 m.

Lloyd's Rules and Regulations for the Construction and Classification of Steel Ships, that were applicable at the time the vessel was built, contain guidance concerning minimum forward draughts (in order to avoid excessive forefoot exposure in rough seas) and state in part:

For the purpose of this section a Bulk Carrier is a single deck ship exceeding 400 feet (122 m) in length [L] with machinery aft.

Attention should be given to the amount and distribution of water ballast. It has been found that satisfactory service has been obtained when the forward draught is not less than 0.027 L . . . .

On this basis, the minimum forward draught for the "FLARE" was 4.6 m. The forward draught shown for the light ballast departure condition in the vessel's Loading Manual (and that recorded at Rotterdam prior to sailing) was significantly less than this minimum. Consequently, in the event of rough weather, the vessel's forefoot was vulnerable to pounding and slamming.

With the deep tank (No. 4 hold) filled at Rotterdam, in addition to the water ballast actually loaded, the forward draught on departure would have been increased to 4.65 m, and would have exceeded the minimum for satisfactory bow immersion.

In addition to the light ballast loading condition, the vessel's Loading Manual also included a full (or deep) ballast condition intended for longer or more exposed ocean passages. In this condition, the deep tank (No. 4 hold) is filled with 3,906 LT of water ballast. When the vessel is thus ballasted, the propeller is more deeply immersed and the forward draught exceeds the minimum forward draught limitation.

The vessel was not fitted with a hull stress monitoring system, nor was one required by regulation. However, details of the still water bending moments related to each of the loading conditions were included in the vessel's Loading Manual provided for the guidance of the master.

On departure, the forepeak water ballast tank was partially full and the afterpeak water ballast tank was empty. This reduction of weights acting at the ends of the vessel lowered the still water bending moment below that of the light ballast departure and arrival conditions included in the Loading Manual such that, on departure, the still water bending moment was approximately 69 per cent of the approved maximum permissible level.

1.6 Riding Repairs During the Atlantic Crossing

Prior to sailing from Rotterdam, a portable welding machine and 1.69 tonnes of assorted pieces of steel plates and flat bars were taken on board. It was intended that riding repairs to various damaged items and replacement of some corroded parts of the vessel's structure would be carried out during the voyage.

Items for attention during the voyage included the renewal of face flat bars on some coaming brackets and bracket flanges, and repairs in way of the corroded circumferences of openings in the transverse wash bulkheads in some of the upper wing ballast tanks. The latter work required access to some of the upper wing tanks and would necessitate their being temporarily emptied of the water ballast taken on board before departure.

All four survivors held junior positions on board the vessel and their involvement with, and knowledge of, the location, extent, and times of any particular repair work carried out was fragmentary. In media interviews in the Philippines and in later signed statements made available to the TSB, survivors corroborated and added to their initial statements made in St. John's. They commented more generally on welding repairs carried out during the voyage.

Survivors initially reported that a leak from a fracture some 2 m long in the sloping underside of the No. 3 upper wing ballast tank (on the starboard side of the No. 4 hold) was sealed by welding and the tank refilled. A similarly located but smaller leak in the No. 2 port side upper wing ballast tank (in cargo hold No. 3) was also welded and the tank re-ballasted. A fracture found in the corrugated plating near the base of the transverse watertight bulkhead between cargo holds Nos. 6 and 7 was reportedly brought to the attention of one of the ship's officers on January 14. At that time the vessel was experiencing severe weather conditions and there is no information of any further structural repairs or replacements having been carried out before the sudden structural failure in the early hours of January 16.

It was also reported that there was a small hole in the main deck beneath the poop deck access ladder on the port side. The ladder weld was broken and it was possible to see water leaking out onto the main deck from the topside tank as the vessel moved in the seaway.

No indication of any recent welding, external structural repair or steel replacement was observed during the underwater survey of the sunken bow section. Identification of any internal repair work carried out during the voyage was not possible because the wreck was inverted, which limited access to the relevant areas by the remotely operated vehicle (ROV) cameras.

1.7 Damage

1.7.1 Aerial and Seaborne Photographic Details

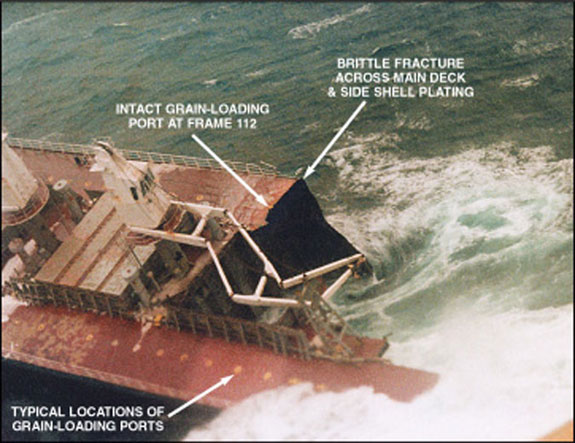

The damaged--but still floating--bow section of the "FLARE" was located by SAR aircraft on the morning of January 16, some five and a half hours after the vessel broke in two. Aerial photographs and videotape recordings were taken that show the trimmed attitude of the damaged bow section, the general configuration of the separation, and the nature of the damage incurred by the principal upper members of the hull girder.

Videotaped recordings of the floating bow section were also taken from on board the "STOLT ASPIRATION" later that same morning; these show the principal damage to the starboard side shell plating from a lower perspective, together with a sea-level view of the more moderate wave and sea motions acting on the hull at that time.

The forward and after locations of the main deck and upper hull damage shown in the aerial photographs, as well as the estimated configuration of the bottom structural damage, are illustrated in Figure 3, Structural Separation Location.

The aerial photographs show the general configuration of the upper hull damage and also indicate the distribution and location of many of the flush-fitting grain-loading ports fitted in the main deck plating. These ports are designed to facilitate the stowage of grain cargoes in the upper wing tanks of the vessel by way of circular removable covers that provide a 320 mm-diameter clear opening in the main deck plating. The circular perimeter coaming of each port is recessed and welded into the main deck, has an inside diameter of 460 mm, and is the same thickness as the main deck plating. Reportedly, the grain-loading ports on the "FLARE" had not been used for grain cargo loading for a considerable time. The ports were generally kept closed with their recessed upper area filled flush with cement in order to prevent corrosion of the main deck by entrapped standing water (see Photos 1, 2 and 3).

The trimmed attitude of the damaged bow section indicated that the forepeak tank and upper wing ballast tanks were virtually empty. Water ballast from these previously filled or partially filled tanks had drained away by gravitating through severed ballast piping, which passed through the damaged double-bottom tanks and duct keel.

Indication of the distribution of water ballast in some of the forward upper wing tanks prior to the hull separation is revealed by the pattern of the ice and snow retained on the main deck directly over the tank boundaries (see Photo 2).

The ice and snow was retained on deck only in way of the wind-chilled steel directly over those areas of the ballast tank crowns that were not in direct contact with, or subject to the effect of, the latent heat of the water ballast contents. The extent and configuration of the ice and snow patterns show the starboard side upper wing tanks Nos. 1, 2 and 3 to have been filled, while port side tanks Nos. 1 and 2 were clearly less than full. The wracking and torsional effects due to such an asymmetric transverse weight imbalance would have caused localized stresses and also contributed to the global stress loading imposed on the hull.

Photos 1 and 2 also show that the corrugated transverse bulkhead forming the after boundary of the water ballast deep tank (cargo hold No. 4) was substantially intact. It remained virtually watertight during four days of direct exposure to severe weather before the accumulation of seawater in the hold initiated the sinking sequence.

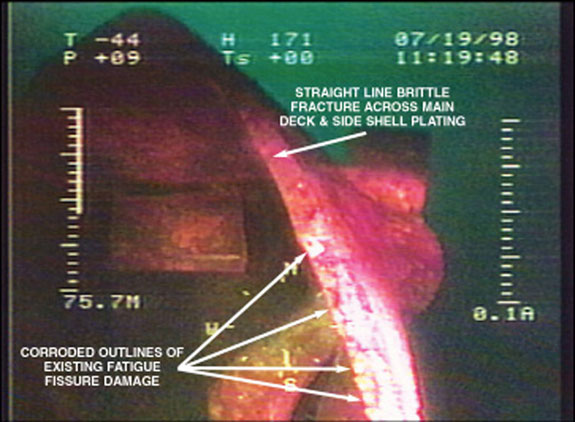

The location and nature of the principal fracture across the starboard side main deck plating (abreast and just aft of the forward end of cargo hatchway No. 5) are clearly seen in Photo 3. The athwartships fracture crosses the main deck in a straight line at about 90 degrees to the fore-and-aft axis of the vessel, and continues through the radiused gunwale and down the starboard side shell plating. The fracture bisects a grain-loading port located near Frame 112--the welded perimeter coaming and bolted cover of which remained intact. The deck plating, deck longitudinals and side shell plating show no signs of buckling or local ductile distortion, and the fracture edges appear square and vertical to the inner and outer surfaces of the deck and shell plating. All of these features are characteristic of a rapid brittle fracture.

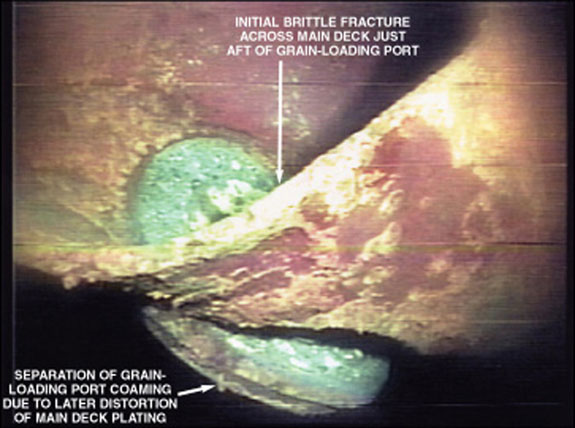

The principal fracture across the port side of the main deck plating is located abreast and just forward of the after end of cargo hatchway No. 6 (immediately abaft a grain-loading port near Frame 76). The main deck plating inboard of the grain-loading port is distorted; most likely this occurred just prior to the final separation of the deck from the adjacent hatch side girder and coaming. The fracture across the main deck plating outboard of the grain-loading port is not visible in the aerial photographs; however, underwater inspection shows no significant buckling or local deformation.

1.7.2 Sinking of the Bow Section

The tug "ATLANTIC MAPLE" was standing by the bow section of the "FLARE" on January 20. At 1115 (ship's time) those on board reported that the damaged hull gradually up-ended and started going down stern first, with large quantities of air escaping as the forward cargo hold hatch covers became dislodged. The forecastle remained above the water for some time as the hull remained nearly vertical before sinking.

The depth of water was some 100 m, and the maximum length of the port side of the damaged hull was approximately 120 m. Consequently, the after port side was the first part of the wreck to come in contact with the seabed. Due to the heaving motions in the prevailing rough sea conditions, it sustained some impact damage in addition to that incurred during the hull separation.

The sand and shingle sea floor in the vicinity of the wreck was uneven and was disturbed by the impact of the damaged hull. The initial bottom impact area was clearly defined by a large crater in the seabed--approximately 30 m astern of the sunken bow section--which was found during the subsequent underwater survey of the wreck.

1.7.3 Underwater Survey Photographic Details

To identify the configuration and nature of the separation of the lower structural members of the hull girder, an underwater inspection of the sunken bow section was conducted between 15 and 22 July 1998. Local on-site weather history was taken into account to ensure reasonably calm operating conditions for the underwater inspection.

The CCGS "EARL GREY" was used as a stable dive platform from which an ROV was deployed to carry out the underwater photographic examination of the wreck. The ROV was controlled from an operation centre on board the "EARL GREY" by an "umbilical cord," which relayed the electrical power and signals required to manoeuvre the vehicle's thrusters, to operate floodlights, a stereographic still camera and a video recording camera. The ROV was also equipped with a sonar locating device to assist in determining the location of the wreck and the configuration of the surrounding seabed.

The sunken bow section was found to be almost upside down, with the bulbous bow, forefoot, and forward bottom shell intact and more exposed above the seabed than the damaged after end. The heeled attitude of the wreck was such that the starboard side of the main deck and side shell and part of the starboard side bottom shell plating were deeply buried. This precluded close-up photographic examination of the fractured edges of the starboard side main deck plating in way of the grain-loading port near Frame 112 and of the adjacent side shell plating.

The exposed bilge keel, turn of bilge and bottom shell plating on the port side of the inverted bow section were generally intact and showed no localized or global deformation. The turn of bilge abaft the after end of the port side bilge keel near Frame 72 and the lower half of the side shell at the after end of the wreck showed localized buckling and deformation attributable to compressive structural loading (and to bottom impact damage).

The principal athwartships fracture in the port side deck plating near Frame 76 crossed the main deck in an almost straight line at about 90 degrees to the vessel's fore-and-aft axis, and was immediately aft of the adjacent grain-loading port (see Photos 3 and 4). The exposed fracture edge continued directly through the radiused gunwale and halfway down the port side shell plating. The face of the fracture showed no ductile distortion and was vertical to the inner and outer surfaces of the plating. Such characteristics are consistent with the occurrence of a rapid brittle fracture.

The deck transverse at Frame 78 inside the No. 5 port upper wing ballast tank was damaged. Its face flat boundary stiffening was detached and extensively buckled. The deck longitudinals inside the ballast tank were completely detached from the underside of the main deck plating for some distance forward of the principal athwartships fracture at Frame 76. The fractures at the ends of the longitudinals showed no plastic deformation and were at 90 degrees to the normal deck plating surface (see Photo 4).

Close-up examination of the fracture edge at Frame 76 revealed the corroded outlines of several small clamshell-shaped fissures in the inner surface of the radiused gunwale plate. The outline of these shapes is a typical characteristic of fatigue fissure damage. Notwithstanding the six-month time frame, their corroded surfaces indicate that this weakened structural condition had existed for some time before the occurrence. The subsequent initiation and rapid propagation of a brittle fracture across the main deck at this location is consistent with the existence of such discontinuities (see Photo 5).

The distorted main deck port side plating near Frame 76 and the adjacent grain-loading port coaming are shown in Photo 6. The separation of the deck plating from the grain-loading port coaming is consistent with the ductile distortion of the deck having occurred as the inboard hull girder members finally separated. This separation occurred some time after the principal initial athwartships brittle fracture located just aft of the grain-loading port coaming.

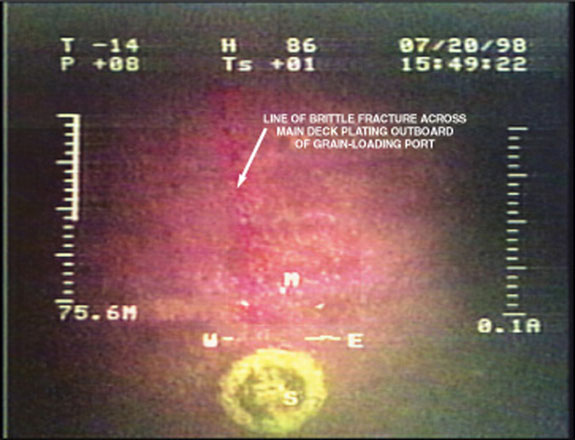

Examination of the port side main deck plating abreast the forward end of cargo hatch No. 5 (directly opposite the starboard side fracture near Frame 112) failed to reveal any corresponding damage. However, further close-up examination of the port side deck in way of the grain-loading port near Frame 110 revealed an athwartships fracture some 2.8 m in length, which extended from the outboard edge of the grain-loading port circular coaming toward the radiused gunwale.

The location and configuration of this fracture was clearly defined by the disturbed deck paint surface (see Photo 7). The top surface of the deck plating immediately forward and aft of the fracture was not misaligned and showed no sign of any localized ductile deformation. The fracture displayed characteristics consistent with its being newly incurred and of a brittle nature.

Access to the damaged structure at the after starboard end of the wreck was limited due to its trimmed attitude and the configuration of the sea bottom, which resulted in most of the side shell and part of the bottom structure on the starboard side being buried or covered by the seabed.

The outline of the damage face of the bottom structure was irregular and extended from the port side turn of bilge near Frame 72 diagonally across the bottom shell toward the buried starboard side. Its outline could not be precisely established but an estimate of the general configuration is given in Figure 3. It was determined that virtually all of the bottom structure of cargo hold No. 6, the transverse watertight bulkhead at Frame 95, and part of the bottom structure of cargo hold No. 5 remained attached to the after end of the vessel when the hull separated.

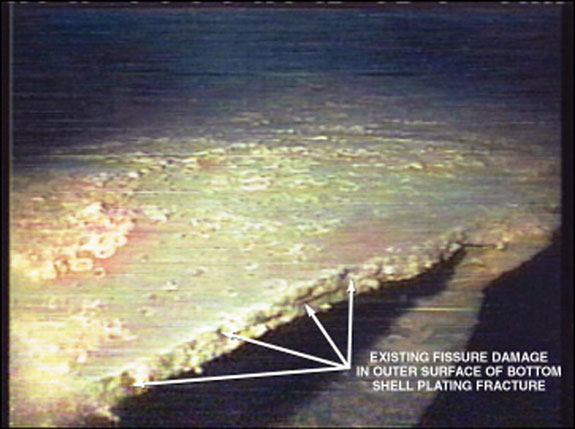

The port side turn of bilge and adjacent bottom shell plating were deformed and showed transversely oriented furrowing effects, which are typical of excessive compression loading. The exposed ends of the remainder of the fractured bottom shell and internal double-bottom structure showed little or no plastic deformation or ductile failure. The absence of any localized buckling or abrasion marks also indicated that this damage occurred during the hull separation and before bottom contact.

Close-up examination of the exposed fracture edges of several bottom shell plates revealed small clamshell-shaped markings in their outer surfaces (see Photo 8). The outline of these shapes is typical of fatigue fissure damage. The presence of these markings in the principal line of the structural failure is indicative of their having contributed to the concentration of localized stress levels in excess of those which the bottom shell plating could physically withstand.

1.7.4 Damage to the Environment

There was a slick of fuel oil on the surface of the sea approximately 10 miles downwind of where the stern section sank. Attempts by SAR, in conjunction with Environment Canada, to ignite this oil were unsuccessful and it eventually dissipated by wind and wave action.

Oil continued to leak from the stern section until July 1998--diminishing over time.

Environment Canada monitored the escape of oil from the stern section. While consideration was given to exploring the stern section to find the leak, and seal it, Environment Canada deemed such action to be unnecessary.

1.8 Certification

1.8.1 Master, Officers and Crew

The certificates of competency of the master and officers were valid and complied with the provisions of the International Convention on Standards of Training, Certification and Watchkeeping for Seafarers (STCW). These certificates were appropriate to the service in which the vessel was engaged.

The qualifications of the crew were also valid, and conformed with regulatory requirements.

1.8.2 Vessel

The vessel's Certificate of Cyprus Registry and Certificate of Class were in order. The International Load Line Certificate (1966), the Cargo Ship Safety Construction Certificate and the International Oil Pollution Prevention Certificate were valid until November 2000. The vessel's Cargo Ship Safety Equipment Certificate was valid until September 1998 and the Cargo Ship Safety Radio Certificate was valid until November 1998. All these certificates were issued by the Lloyd's Register of Shipping on behalf of, and under the authority of the Government of the Republic of Cyprus.

1.9 Survey and Inspection--Classification Societies

In addition to being subject to compliance with international conventions and National Ship Registry requirements, most commercially operated vessels are also built, maintained, inspected and approved in accordance with the rules and regulations of a recognized classification society.

Classification societies are independent, autonomous, non-governmental, self-regulating organizations or foundations that formulate rules for the construction of ships, monitor their construction, and carry out scheduled inspections to assure vessels' continued seaworthiness. Vessels built and subsequently maintained in accordance with the regulations of a particular society are assigned and retain a "Classification" appropriate to the vessel's type and service.

In the past decade, there has been a marked proliferation in the number of nations seeking to increase the number of vessels on their register. Many nations, some of which lack the necessary technical expertise and international infrastructure to provide worldwide service, delegate the conduct of some or all of their regulatory and registry certification inspection responsibilities to experienced classification societies.

Of the existing 47 classification societies, 10 are members of the International Association of Classification Societies (IACS), and conform with its agreed code of practice and quality assurance requirements. IACS has Observer status at IMO, and provides its members with a forum for the exchange of information and unification of technical standards. The principal objectives of IACS are "to promote the highest standards in ship safety and the prevention of marine pollution."

The Lloyd's Register of Shipping is a founder and current member of IACS, and a classification society operating 280 exclusively staffed offices worldwide. The society also undertakes regulatory certification inspections on behalf of 135 national administrations.

The classification-related inspections of the "FLARE" were carried out at the request of the owners by the Lloyd's Register of Shipping surveyors. International regulatory and national registry certification-related inspections were carried out by the Lloyd's Register of Shipping on behalf of, and under the authority of the Government of the Republic of Cyprus.

1.10 Hull Survey Requirements

IMO Resolution A.744(18) "Guidelines on the Enhanced Programme of Inspections During Surveys of Bulk Carriers and Oil Tankers," which was adopted on 04 November 1993, and subsequently incorporated as Chapter XI into the International Convention for the Safety of Life at Sea (SOLAS), formally entered into force on 01 January 1996. Under the Enhanced Survey Programme, "Special Surveys" are conducted at five-year intervals by the classification society. The extent of the surveys depends on a vessel's age. The hull surveys become more rigorous as the age of the vessel increases. Additionally, "Annual Surveys" are routinely required, the second or third of which must be a more detailed "Intermediate Survey." The Special, Intermediate, and Annual survey reports may also incorporate memoranda that address and monitor specific, ongoing items of concern from any preceding survey.

1.10.1 Hull Survey History and Status

Special Survey

While at Shanghai, People's Republic of China, in November 1995, the (then) 23-year-old "FLARE" underwent a fourth "Special Survey" included in which are the requirements of the Enhanced Survey Programme. During this survey extensive hull and machinery inspections, equipment examinations, structural steel repairs and replacements were carried out, mainly while the vessel was afloat.

Structural surveys, scantlings thickness examinations, and principal areas subjected to close-up inspection were noted in the hull survey record, and included :

- ultrasonic thickness gauging of principal hull girder members and cargo hold hatch covers;

- structural condition of cargo holds, including the No. 4 cargo hold/deep tank;

- internal structural condition of all upper wing water ballast tanks;

- condition of inner bottom plating and internal structure of double-bottom water ballast tanks, fuel oil tanks, and duct keel;

- internal structural condition of forepeak tank and chain lockers, and the afterpeak tank; and

- condition of hull shell, main deck, forecastle deck and poop deck plating.

The ultrasonic thickness gauging survey of the hull included measurements taken in bands around the vessel in way of Frames 74, 114 and 182. The gauge readings at each of these locations generally showed wastage of less than 1 per cent in the shell, bilge, keel and bottom structural members. There was a mean thickness reduction of some 2.4 per cent in way of the main deck, stringer plate and sheer strake plating. None of the material thickness wastage readings that were recorded exceeded the accepted limits at which replacement of the material would have been required.

Close-up structural inspections resulted in extensive fairing, cropping and renewal of transverse web frames, side framing and lower bottom brackets throughout the cargo holds, where these were found to have been corroded, distorted, or damaged by cargo-handling equipment. On completion of these repairs, all the cargo holds were grit-blasted and repainted.

Other extensive structural corrosion and wastage, discovered on close-up internal inspection, resulted in the renewal of four of the seven starboard side, and five of the seven port side main deck longitudinals throughout the entire length of all the upper wing water ballast tanks. A side shell longitudinal, throughout the length of upper wing tanks Nos. 1 to 5, was replaced on each side of the vessel. The deck longitudinal replacements, in 3 m lengths, were passed into the wing tanks by way of the tank access manholes and were generally installed while the vessel was afloat. The replacement deck longitudinals totalled some 1,015 m in length. Ten per cent of all of their newly welded butt joints were randomly selected, subjected to ultrasonic examination and found satisfactory.

The watertight bulkheads at Frames 95, 117 and 134, forming the ends of upper wing ballast tanks, the wash bulkhead at Frame 149, and various transverse web stiffeners inside the wing tanks, were also cropped and renewed in way of corroded and thinned areas. The condition of the upper wing tank coating was reported as poor and was referred for monitoring and attention in future surveys.

Extensive bottom shell plating indentations and the related internal bottom longitudinal and structural damage in way of the starboard side double-bottom tanks Nos. 1, 2, 3, 4 and 5 were cropped and renewed. The lower areas of the transverse watertight bulkheads at Frames 162 and 188 were also cropped and renewed. The internal structure of the double-bottom tanks was subjected to close-up inspection and found satisfactory. The tank coatings were reported to be in good condition.

Several areas of plating in the collision bulkhead at Frame 210 and in web Frame 220 were cropped and renewed where affected by corrosion. Thickness gauging found that the remainder of the forepeak water ballast tank internal structure was generally satisfactory.

The upper section of the afterpeak tank was found to be heavily corroded. The upper parts of the bulkheads at Frames 11 and 16 and the centre-line wash bulkhead were extensively cropped and renewed. An additional tank top, forming a void space 1.5 m deep, was installed below the crown of the tank and structurally braced from the existing deckhead.

All examinations, surveys, repairs and structural replacements were completed to the satisfaction of the attending class surveyors and the owners' representatives. Satisfactory completion of Special Survey No. 4 was duly assigned on 10 November 1995. A dry-docking survey and inspection of the underwater hull fittings and bottom shell plating was also satisfactorily completed in Shanghai, in January 1996, prior to the vessel's return to service.

First Annual Survey

On the first anniversary of Special Survey No. 4, and while the vessel was in Brazilian waters, a routine Annual Survey by Lloyd's surveyors was begun at Salvador and completed at Fortaleza on 30 November 1996.

As the "FLARE" was a bulk cargo ship over 15 years old, the Annual Survey called for the survey of all the cargo holds, and close-up survey of any one of the forward holds.

The surveys found the general condition of the holds to be satisfactory, and the side shell plating, side frames and lower side frame brackets showed no apparent damage. Existing puncture damage through the watertight bulkhead between cargo hold No. 1 and hold No. 2, which was the subject of a current "Condition of Class" (COC), was repaired, satisfactorily tested, and deletion of the COC recommended.

A second COC, referring to wastage and grooving of the steel in way of the tank top connection to the forward and after transverse bulkheads of cargo hold No. 6, was also addressed. Extensive ultrasonic thickness measurement showed localized wastage to be within accepted limits (before steel replacement would be required). The reported grooved indentations were found to have an average depth of 15 mm, with some localized maximum depths of 25 mm. These were attributed to mechanical damage incurred during loading or unloading operations. As a result of the examination, this COC was also deleted. The current structural condition was recorded by a memorandum in the vessel's hull survey record as an item requiring monitoring during future surveys.

The vessel's Safety Construction Certificate was accordingly endorsed on 30 November 1996 and an Interim Certificate of Class was issued by the Lloyd's Register of Shipping.

Second Annual/Intermediate Survey

A routine survey became due on the second anniversary of Special Survey No. 4. In accordance with the provisions of the Enhanced Survey Programme, the Intermediate Survey was deferred to the end of the third year. An Annual Survey was carried out by Lloyd's surveyors and completed at the Port of Cienfuegos, Cuba, on 28 November 1997.

Structural areas were subjected to routine and close-up inspection. The defects discovered, and the remedial actions taken to correct them were noted in the hull survey record. These included:

- internal structure of all upper wing water ballast tanks;

- localized inner bottom buckling and grooving at the end bulkheads of hold No. 6;

- areas of indented inner bottom plating in way of cargo holds;

- structural condition of the afterpeak tank and holds Nos. 1 and 7; and

- shell indentation and buckled port side framing in hold No. 2.

On completion of structural inspections, all except item a) were deemed to be currently satisfactory or were referred for routine attention at the next scheduled Intermediate Survey. The referred items included the ongoing monitoring of the structural condition in way of the end bulkheads of cargo hold No. 6.

Internal examination of the upper wing tanks recorded several and various wasted and corroded-through structural members, primarily comprising transverse webs and wash bulkheads in upper wing water ballast tanks (port and starboard) Nos. 1, 2, 4, and 6, and (starboard) Nos. 3 and 5. Because of a reported lack of approved thickness measurement expertise and other facilities in this port, no remedial action was taken. The attending surveyors imposed a COC requiring appropriate structural repairs and that renewals be carried out and approved before the end of February 1998.

The concurrent machinery annual survey was generally satisfactory but called for the operation of the vessel's exhaust gas auxiliary boiler to be discontinued until it was satisfactorily repaired. A related COC was imposed in this regard, also requiring that repairs be carried out and approved before the end of February 1998.

The Lloyd's Register of Shipping issued an Interim Certificate of Class and advised the owners on 27 November 1997 of the imposed COCs that required that remedial action be carried out before the end of February 1998. It was also indicated to the owners that non-compliance by the due date could jeopardize classification standing and that suspension of class would lead to automatic invalidation of all Statutory Certificates issued by the Lloyd's Register.

It is the responsibility of the owners to ensure that all repairs necessary for the maintenance of class are carried out and to advise the regulatory authority of the proposed scheduled venue in order that a surveyor may attend for inspection and approval purposes. At the time of the occurrence, the Lloyd's Register of Shipping had received no formal request for the provision of such services.

1.11 International Safety Management (ISM) Code

In January 1998 the owners/operators of the "FLARE" were preparing to meet the requirements of the IMO International Safety Management Code (ISM Code), due to come into force in July 1998, although they had not completed the necessary procedures.

1.12 Personnel Information

The crew of the "FLARE" was made up of four nationalities. The master and 3 crew members were Greek nationals, 16 were Philippino, 2 were Romanian, and 3 were Yugoslav.

The master and 11 of the crew joined the ship in Rotterdam shortly before sailing. The senior officers and the remainder of the crew had joined the vessel at various times during 1997.

1.12.1 Master

This was the master's first voyage on the "FLARE" and this was his first command of a bulk carrier. His previous command experience was for a period of 10 months as master of a 1,598 gross registered tons general cargo vessel.

Since 1994 his bulk carrier service included service as first mate on three other bulk carriers with two periods on the "EVMAR", a vessel similar to the "FLARE" in both design and age.

Before joining the "FLARE" in Rotterdam on 22 December 1997, the master had been briefed extensively on details concerning the vessel while he was at the operators' office in Piraeus. The company was seeking ISM Code certification, and the master's briefing included one week of ISM Code familiarization.

In Rotterdam, the handover of command of the vessel took two days and reportedly included an inspection of the upper wing ballast tanks.

1.12.2 Ratings

The Philippino crew members aboard the "FLARE" were recruited through Bright Maritime Group, a licensed and ISO 9002-certified crewing agency in the Philippines. The owners of the "FLARE" employed the services of a Greek Port Captain in Manila.

Crewing practices at Bright Maritime Group include the interview of candidates by the Port Captain and the examination of their certification and experience to ensure compliance with STCW (1995). Once a group of candidates has been selected, if medically fit, their names are submitted to the Philippine Overseas Employment Administration. At this time, they are offered a contract that details rank, wages and other administrative details. Once a contract is signed, the company arranges for a visa and transportation as required.

Prior to departing the Philippines, the new crew members joining the "FLARE" were given some in-house training in accordance with STCW (1995). In particular, the crew was briefed on issues such as safety aboard, conduct and ISM Code requirements.

For those members of the crew who joined the vessel in Rotterdam, no boat drill was held due to the bad weather after sailing. However, the master held a half-hour briefing in the crew's mess on the use of the vessel's safety equipment.

1.13 Working Language

In compliance with STCW (1995), the official working language on board the vessel was English. The existing required vocabulary for navigational watchkeeping purposes is based upon IMO "Standard Marine Communication Phrases" and consists of approximately 50 phrases. These phrases have been chosen to facilitate communication: between ships, with coast stations, and among multilingual crews. While it is mandatory that officers of the navigation and engine-room watches have an adequate knowledge of English, there is no requirement for members of the crew other than officers to have such a level of understanding.

A more extensive IMO vocabulary has recently been introduced on a provisional basis and is being taught at some maritime colleges. This revised vocabulary could be introduced as early as 2000, following adoption by member states at IMO. As with the current IMO "Standard Marine Communication Phrases," the use of this vocabulary would not be mandatory for ratings.

1.13.1 Working-Language Proficiency on the "FLARE"

The three Philippino survivors were sufficiently proficient in English not to require a translator/interpreter when interviewed.

When the other survivor (the Yugoslav electrician) was interviewed after the occurrence, his limited knowledge of English was such that a translator/interpreter was required.

At lifeboat and emergency drills on a previous voyage, when the Greek master was explaining duties and functions in English, the chief engineer had translated for the benefit of the electrician.

1.14 Weather Information as Recorded

"FLARE"

The record of the radio communications between the master and the operators was obtained and gives the weather reportedly experienced by the vessel between 30 December 1997 and 13 January 1998.

| Date | Wind direction and force, Beaufort Scale | Beaufort Sea State corresponding to reported wind speed |

|---|---|---|

| December 30 - January 1 | West Force 9 - 10 (44 - 55 knots) |

High/very high waves. Tumbling seas, become heavy and shock-like. Probable maximum wave height 10 to 12.5 m. |

| January 1 - 4 | WSW Force 10 - 11 (55 - 60 knots) |

Violent storm. Exceptionally high waves. Everywhere the edges of the wave crests are blown into froth. Probable maximum wave height 12.5 to 16 m. |

| January 4 - 7 | WSW Force 9 - 11 (44 - 60 knots) |

Violent storm. Exceptionally high waves. Everywhere the edges of the wave crests are blown into froth. Probable maximum wave height 10 to 16 m. |

| January 7 - 10 | WSW Force 8 - 9 - 10 (40 - 55 knots) |

High/very high waves. Tumbling seas, become heavy and shock-like. Probable maximum wave height 7.5 to 12.5 m. |

| January 10 - 13 | W Force 5 (17 - 21 knots) |

Moderate waves. Probable maximum wave height 2.5 m. |

| January 13 | SW Force 8 (34 - 40 knots) |

Moderately high waves of greater length. Edges of waves break into spindrift. Foam blown in well-marked streaks along direction of wind. Probable maximum wave height 7.5 m. |

Environment Canada

For the three-day period between January 14 and 16, information was obtained from Environment Canada, both forecast and actual weather as recorded by automatic weather reporting buoys positioned off the south coast of Newfoundland and near Banquereau Bank. For the areas in which the "FLARE" was on these dates, Environment Canada recorded the following weather information.

| Date | Wind direction and speed | Maximum sea state |

|---|---|---|

| January 14 | West 25 - 45 knots | 3 m - 5 m |

| January 15 | West 45 - 60 knots | 6 m - 9 m |

| January 16 | NW 30 - 45 knots | 5 m - 8 m |

In part, the plain language text forecast for Cabot Strait, issued at 1000, January 16, stated:

Gale and freezing spray warning continued. Winds Westerly 25 to gales 35 knots diminishing to Westerly winds 20 early afternoon.

The Gulf of St. Lawrence Marine Weather Guide, issued by Environment Canada, Atlantic Region, gives the following information for the Cabot Strait/Magdalen area:

Cabot Strait is exposed to very long open water fetches. From the northwest, it is open all the way to the Gaspé Passage (Detroit d'Honguedo), about 250 nautical miles. To the southeast, there is an unlimited fetch out into the Atlantic. The fetch from the northeast is actually limited in the Strait itself, but as you move out into the gulf towards the Magdalen Islands, this fetch also stretches to near 250 nautical miles. These long fetches can permit very large seas to form in the area. They also mean that waves will continue to roll for a long time after the wind dies down. These combined effects can make this one of the roughest areas in Atlantic Canadian waters.

Records show that the current in the area, on the date of the break-up of the "FLARE", would have been toward the west-northwest at approximately 0.5 knot, i.e., against the direction of the wind. The shallowing water at the edge of the Saint-Pierre Bank, in conjunction with the wind/current condition described above, can create conditions under which the established normal wave pattern is disturbed. This combination of factors leads to the creation of large, irregular waves.

"STOLT ASPIRATION"

The "STOLT ASPIRATION", a tanker of 12,219 gross registered tons, left Europe fully loaded for Montreal and followed a route similar to that of the "FLARE". Severe weather was experienced during the whole voyage. Winds were reported to be westerly, Beaufort force 8 to 9 most of the time and to have reached force 10 to 11 at times. During the night of January 15-16, the vessel was about 25 miles from the "FLARE", and was proceeding on a similar course at a reduced speed of 5 to 6 knots.

At 0400 (ship's time), the "STOLT ASPIRATION" was at 4650.5′ N, 05716.2′ W by global positioning system. Course was 295 and speed was six knots. The wind was west at force 8 and the sea state was about 7 Beaufort. The temperature of the air was -3C, and of the sea, 2C.

Although the "STOLT ASPIRATION" was loaded, the ship was labouring and making heavy going in the prevailing conditions. The master was woken several times when the ship ran into extraordinarily large swells/waves that caused heavy vibration and pounding.

1.15 Radio Equipment

The "FLARE" was equipped with short-, medium-, and long-wave transmitter/receivers, which were operated by a certificated radio operator in a dedicated radio room.

The vessel's radio equipment was surveyed in Cuba on 26 November 1997. At that time, the equipment was found to be in accordance with the requirements of SOLAS 1974, as amended. A Cargo Ship Safety Radio Certificate was issued in Havana, valid until 25 November 1998.

The vessel's Record of Approved Cargo Ship Radio Installation Certificate indicates that there were two VHF radios on the bridge. One of these radios was used to broadcast the MAYDAY call on channel 16.

The vessel's INMARSAT C was not integrated with the vessel's satellite navigation system, nor was there a regulatory requirement for the vessel to be so fitted before 01 February 1999.

1.16 Emergency Position Indicating Radio Beacon (EPIRB) and Search and Rescue Transponder (SART)

1.16.1 EPIRB

The vessel's class 1 EPIRB had been tested and certificated by a radio inspector accredited by the Cuban Government and accepted as satisfactory by a Lloyd's Register surveyor.

This unit was reportedly mounted on the starboard wing of the navigation bridge, near the gyro repeater. The mounting arrangement was designed to allow the unit to float free of the ship without human intervention, in the event of the ship sinking.

The battery-operated distress radio beacon transmits a coded digital signal on 406 MHz when automatically or manually activated. The radio signal is received by a satellite, which relays the information to one of many receiving stations on land. The signal is decoded to identify the owner, the name of the vessel and the location of the EPIRB. This information is used to determine the area to which a SAR response is directed.

A previous master stated that, in order to prevent the theft of the EPIRB while the vessel was in port, he usually removed it from its mounting and stowed it in the accommodation or in the secured wheel-house.

No EPIRB signal was ever received from the "FLARE" nor was the EPIRB recovered. It is not known if the EPIRB was in its dedicated mounting on the starboard wing of the bridge. It is also unknown whether the unit floated free or not.

1.16.2 SART

The purpose of a SART is to indicate the position of persons or vessels in distress. It is easily portable and should be taken into the liferaft or lifeboat when abandoning ship. It generates a series of response signals when "interrogated" by shipborne or suitable airborne radar. IMO standards call for a range of up to five miles for a SART that is unobstructed and one metre above sea level.

The "FLARE" was equipped with two SARTs, which were stowed on the bridge deck; however, in the event, no SART response was received by SAR equipment.

1.17 Life-saving Equipment

The Record of Equipment for the Cargo Ship Safety Equipment Certificate (Form E), issued by the Lloyd's Register, lists the following equipment for a complement of 30 persons:

- a 30-person capacity (No. 1) motor open lifeboat on the starboard side;

- a 30-person capacity (No. 2) open lifeboat on the port side;

- a 20-person capacity inflatable liferaft (stowed aft);

- a 10-person capacity inflatable liferaft (stowed aft);

- a 6-person capacity inflatable liferaft (stowed on the main deck forward of the No. 1 hatch);

- 8 lifebuoys;

- 35 lifejackets;

- 6 immersion suits; and

- 27 thermal protective aids.

The documentation indicated that the life-saving equipment was in compliance with SOLAS 1974 and its Protocol of 1978, articles, annexes and amendments.

1.18 Recovery of Life-saving Appliances

1.18.1 Lifeboats

Overturned lifeboat No. 2, with four persons on top, was seen near the position of the floating bow section of the "FLARE", which was first sighted in position 4628.46′ N, 05712.82′ W. The survivors were recovered from the capsized lifeboat by helicopter at 1434 and a body was later recovered from underneath the boat. The lifeboat was subsequently recovered and taken to the CCG base at St. John's.

When the "STOLT ASPIRATION" arrived on the scene about an hour and a half later, attempts were made to recover some floating debris and equipment believed to have come from the lifeboat. These attempts were abandoned due to the prevailing weather conditions.

The motor lifeboat (No. 1) from the "FLARE" was found washed ashore at Lamaline, on the south coast of Newfoundland, on 17 July 1998, and taken to the CCG base at St. John's. The inside was heavily encrusted with mussels, indicating that the boat had been in a capsized position for a considerable time.

As all loose equipment from both lifeboats was missing and their fibreglass hulls were extensively damaged, the condition of the boats at the time of the occurrence could not be determined.

1.18.2 Liferafts

During the SAR operation, both liferafts stowed aft were discovered inflated, near the position of the floating bow section of the "FLARE". Each was checked for survivors, but there was no one aboard. To eliminate duplication of SAR efforts, both liferafts were intentionally sunk after examination. Consequently, the condition of these liferafts at the time of the occurrence could not be verified. The six-person liferaft was not sighted or recovered after the bow section of the "FLARE" sank.

1.18.3 Lifejackets

The vessel's documentation showed that a sufficient number of lifejackets (35) was carried for the number of persons aboard (25). Lifejackets were recovered from all the survivors and from all the bodies of the victims.