Fatal Accident Fishing Vessel

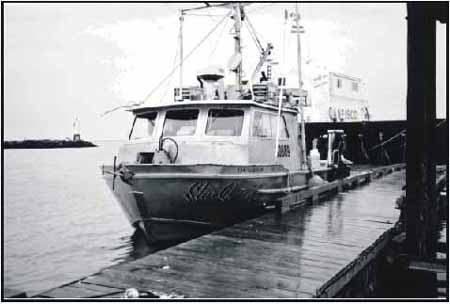

Trawler Star Queen

Fraser River, British Columbia

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

On 6 September 2000, the owner/operator of an aluminum trawler was fishing alone off the mouth of the Fraser River, British Columbia. During the daytime harvesting operation, it appears that elements of his protective clothing became entangled in the net, and he was drawn into the turning main net reel. He died as a result of his injuries.

Factual information

Particulars of the vessel

| "STAR QUEEN" | |

|---|---|

| Licence Number | 13K 108010 |

| Port of registry | Vancouver, British Columbia (B.C.) |

| Flag | Canada |

| Type | Fishing Vessel (Trawler) |

| Gross Tonnage1 | 4.5 |

| Length | 9.8 m |

| Built | 1995 |

| Propulsion | Single Screw |

| Number of Crew Members | 1 |

| Owner(s) | Quang Ngoc Dinh |

Description of the vessel

Built in 1995, the Star Queen is a commercial dragger-gillnetter. The hull and the superstructure are of all welded aluminum construction, and there is one fixed pitch propeller, driven by an inboard engine. The wheelhouse and cabin structure are arranged forward of midships, while the after hull section comprises the working area, with deck machinery and access covers to the cargo compartments, fish holds, and stowage lockers.

The vessel's deck is made of aluminum and includes flush deck diamond-patterned plates covering the cargo or bait compartments that provide non-skid properties. The deck beneath the trawl winch is about 0.75 metres lower than the main deck and extends to the after bulwark.

History of the voyage

On the morning of 6 September 2000, the owner/operator of the Star Queen set off to fish in the Sandheads area, around the mouth of the Fraser River. He wore bib-styled rain pants and rain jacket over his clothing. Though alone on his vessel, he sailed with a friend who was on board another trawler. As the two searched for ground fish, they remained within sight of each other until about 12002, after which they drifted apart. At around 1600, when the second operator had not seen or heard from the Star Queen for some time, he set out in search of the vessel. At about 1800, he located the Star Queen aground on a sand bank. The operator lay collapsed and supine on deck, with his left leg entangled in the winch drum and net. The trawl net itself was over-wound on the starboard side of the drum and had spilled over and wrapped itself around the sprocket gear and shaft. The winch drum was still turning at the time of the discovery.

The second operator raised the alarm by issuing a Mayday signal on VHF channel 16. The distress message was picked up by Marine Communication and Traffic Services (MCTS) and forwarded to the Rescue Co-ordination Centre in Victoria. MCTS made a Mayday relay of the situation and at 1820, a third craft which was in the vicinity found the Star Queen and the second fishing vessel rafted together and was able to confirm the distress position. At 1835 Canadian Coast Guard Search and Rescue was on the scene, and though resuscitative efforts were immediately initiated, the owner/operator succumbed to his injuries without regaining consciousness. He was taken to hospital where he was pronounced dead on arrival.

Description of the After (Working) Deck

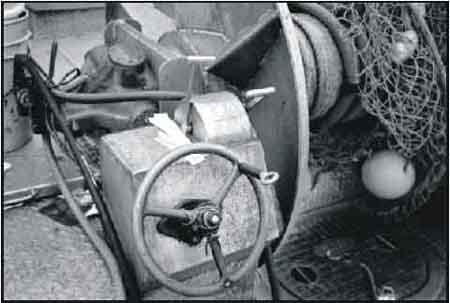

The working deck extends aft from the wheelhouse structure, to the stern of the trawler (see Figure 1). An hydraulically-operated boom is located abaft the wheelhouse, together with two hydraulic trawl winches, one on the port side and the other on starboard. A hatch for access to the main fish (cargo) hold, is located on the centre line, aft of the boom, and an open working space is aft of the hatch. The after deck area, part of which forms a well, is located under the drum of the main net storage winch. A second set of engine and rudder controls, used during fishing operations, are arranged on the port side, outboard of the winch. The control valve and handle to govern the speed and direction of rotation of the main winch motor is arranged under the bulwark on the port quarter.

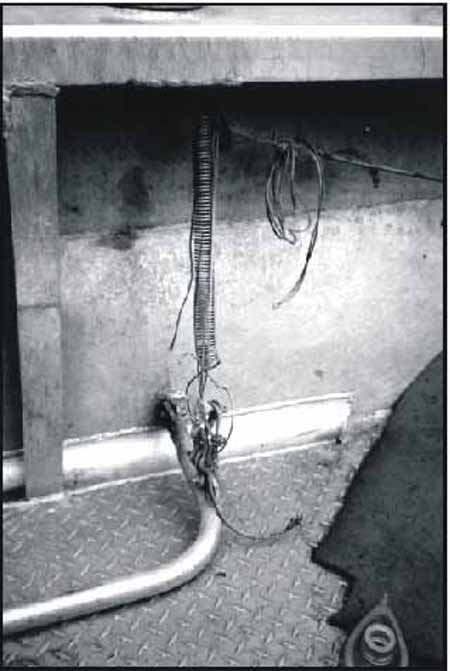

A remote start/stop device (hold-to-run control) to the hydraulic winch motor is fitted under the bulwark around the stern. All the controls are arranged ergonomically around the operator's stand.

Description of the Remote Stop Device

Also known as a hold-to-run-control, this is an emergency shut off device that is designed to automatically and immediately stop the main net winch in the event the winch operator becomes incapacitated. It seeks to prevent injury to the operator. It also finds frequent use, especially while hauling in the net, as a remote switch for starting and stopping the winch.

Essentially it consists of an horizontal, hinged lever, set up at deck level, so that it can be controlled by the operator's foot. Use of the foot-controlled lever leaves the operator's hands free to operate the various steering, engine, and winch controls. The lever is spring loaded and has a system of cables and linkages connecting it to the control valve of the winch motor. As long as the operator's foot keeps the lever depressed, the winch turns. As soon as foot pressure is released, the tension in the spring returns the remote stop device to the normal position, which returns the control valve to neutral and stops the winch motor.

Prior to the occurrence, the hold-to-run-control of the Star Queen had been disconnected from the winch control valve, leaving the emergency shut off device inoperative.

Description of the Hydraulic Motor and its Controls

An hydraulic motor provides the motive force that enables the trawl net reel to rotate. It is mounted on the port side of the drum and two fixed high pressure hoses supply it with high-pressure hydraulic oil via the control valve located on the port side bulwark. The speed and direction of rotation of the winch are primarily controlled by the control valve.

On the Star Queen an additional bypass valve was fitted between the high pressure and return lines, in such a way that when the open position is selected, the hydraulic oil is routed away from the motor and the winch does not rotate. When the bypass valve is closed, it allows pressurized oil into the motor which turns the winch. This valve is a second means of controlling the operation of the winch. The bypass-valve is used to quickly pay out the net. After disconnecting the hydraulic pump, the net drum can freewheel while the vessel is moving ahead.

The bypass valve is mounted directly on top of the hydraulic motor itself, on the port side of the drum, and its handle is located between the two hydraulic pipes. It can be reached from the operator's stand described above. In addition, it can also be accessed by a person standing at the centre of the winch drum, when the net is fully deployed by reaching over and across towards the port side. This however, is a relatively awkward and inconvenient way of reaching it. There is no guard or protective plate between the side of the drum and the bypass valve.

The general state of maintenance of the control valve was found to be poor; it was found to be leaking hydraulic oil. It is reasonable to assume that it had been malfunctioning for some time. The handle was hard to move and it did not automatically return to the central neutral position when released. Two external springs were found in the vicinity of the handle, one at the top and the other at the bottom, but disconnected from it. The working deck in the area of the control valve was covered with hydraulic oil and was quite slippery.

Vessel Certification, Training and Personnel History

Being a fishing vessel under 15 gross registered tons (GRT), the Star Queen is exempt from undergoing a quadrennial inspection and being issued a Ship Inspection Certificate by Transport Canada.

The owner/operator was not required to hold a Transport Canada certificate to command a fishing vessel of this size and type. He was well experienced in the fishing trade both in Canada and abroad, before immigrating to Canada. He had been a fisher in Vancouver for over ten years, five of which were as joint owner of another fishing vessel and five as sole owner of the Star Queen, which he had purchased new.

Analysis

Hydraulic Winch, the Remote Stop Device, and Associated Control Valves

The flow of pressurized hydraulic oil in and out of the hydraulic motor is controlled via a control valve. It has three positions: up and down which control direction of winch rotation (i.e. paying out or hauling in); and a central, neutral position. In the neutral position, no oil flows into the hydraulic motor and because of an hydraulic lock, it is not allowed to turn. The control valve has an internal spring which automatically returns it to the neutral position when the handle of the valve is released.

The winch control valve on the Star Queen was found to be in a substandard condition. The valve had become sticky and hard to move; its internal resetting spring did not have sufficient tension to return the valve to neutral. Two external springs had been fitted in a makeshift arrangement to increase the resetting force, but these too had eventually become ineffective. In the end, since the hold-to-run-control could not have been used to regulate the valve, it had been disconnected.

The hydraulic winch controls were also controlled by a by-pass valve on top of the motor. This valve appears to have been installed to assist single-handed operation of the net launch and it cannot be considered a remote control device similar to the hold-to-run-control. When utilizing this by-pass valve, there is no hydraulic lock, and the winch can freewheel in either direction.

The hold-to-run-control is a spring loaded, remote means of regulating the control valve. When it is pressed down by the operator's foot, it pulls the handle of the control valve into the up position and turns the winch in the hauling in direction. When pressure is taken off the hold-to-run-control (i.e. the operator removing his foot), an internal spring in the control valve returns it to the neutral position, and the winch stops turning.

During the hauling in process, the fisher is required to have his hands free to remove fish caught in various sections of the net and to arrange the stow and net evenly on the drum. Towards this end, fishing vessels like the Star Queen are fitted with the hold-to-run lever - a remote, foot-controlled device - that permits intermittent, start and stop process. In the event of an accident or an unforeseen occurrence, releasing the hold-to-run control will immediately stop the winch, thereby preventing injury. This is particularly important in one-person operated fishing vessels, which are common in the West Coast fishing industry.

Paying out a fishing net into the water is done most often by allowing the winch to freewheel. To accomplish this, the control valve is set to neutral and the bypass valve turned to open. The weight of the net and water friction force the winch to turn and quickly pay out. Paying out can also be carried out under load by putting the control valve on stroke and closing the bypass valve. The winch now turns under the influence of the hydraulic pressure; however, this is much slower than the freewheeling mode.

Protective Clothing

According to the Occupational Health and Safety Regulations of the B.C. Workers' Compensation Board, paragraph 8.10 (2) (a), "If there is a danger of contact with moving parts of machinery, the clothing of the worker must fit closely about the body".

The owner of the vessel was wearing bib style rain pants and a rain jacket over a tee shirt and sweat pants. This protective rain gear was loose fitting, and there is no indication of the open sleeves or flaps of his jacket having been tightly secured to his body. He was working in very close proximity to rotating machinery, where wire rope, nylon rope, and fish net were in the process of being stowed. In all probability his loose clothing became entangled in the net, ropes, or machinery and he was drawn into the turning winch drum.

Checkered Aluminum Deck

Fishers in the local industry prefer to wear rubber deck boots which have flat, flexible soles. The efficacy of diamond-patterned decks in increasing the amount of grip between an operator's boot and the deck surface on fishing vessels is questionable because the checkered surface actually reduces the amount of contact area between the sole of the boot and the deck. There are anti-skid mats available which offer better traction when placed over potentially slippery surfaces. The Star Queen had no such anti-skid mats fitted over its working deck area.

Maintenance Standards for Deck Equipment on Fishing Vessels

Though the Star Queen was relatively new (having been purchased in 1995), some of the deck machinery had not been well maintained, and some elements had fallen into a state of disrepair. There were examples of jury-rigged and makeshift gear; the emergency stop/hold-to-run control had been disconnected, and hydraulic oil had leaked from machinery, on deck.

Being under 15 GRT, the Star Queen was exempted from quadrennial inspections by Transport Canada, Marine Safety (TCMS). However, it had to comply with all applicable conditions and regulations of the Canada Shipping Act and was subject to spot checks and random inspections by TCMS. These inspections, however, did not include occupational health and safety issues, which are under provincial jurisdiction.

In B.C., the Workers' Compensation Board has jurisdiction over work places and equipment aboard vessels engaged in the business of fishing. Towards that objective, WCB conducts random inspections on fishing vessels, gives educational presentations, and issues Hazard Alerts to educate fishing vessel operators of dangers. Potentially hazardous and unsafe conditions are effectively targeted for corrective action.

Accident

The fishing gear consisted of a trawl net attached to a wire warp, which was in turn fixed securely to the winch drum. The condition of the wire warp was sub-standard because the lay of the wire had opened and loose strands were protruding. The fishing net had been paid out until the drum was most probably completely empty. The operator was wearing loose-fitting protective rain gear, and it is possible that he was standing in between the sides of the drum, preparing to guide the net as it was being hauled in. As the drum was turning, the sharp strands of wire probably caught his loose sleeve or jacket, and pulled him in.

Torn portions of his jacket were found entwined in between the turns of wire rope and the drum. Boots, hat, and the remainder of the jacket were found at various locations on the after deck.

The control valve was observed to be leaking and the working deck was found to be covered with hydraulic oil and was quite slippery. The operator was not wearing boots when he was found and it is possible that he had slipped on this oily surface and become entangled in the fish net as it was being reeled in. Since the hold-to-run-control had been disconnected (and also because he was working alone), once he had lost his footing, there was no way of stopping the winch.

Findings

Findings as to causes and contributing factors

- The hold-to-run-control had been disconnected. There was thus, no automatic remote means of stopping the winch in the event of the operator becoming incapacitated.

- The control valve for the hydraulic winch did not move freely and it did not automatically return to the neutral or stop position.

- With no automatic resetting action available, the control valve would remain where it was positioned, and the winch would continue to turn until the control valve would be brought back manually to the neutral position. The winch continued to turn unchecked, once the owner/operator left the control stand to work the deck.

- It is probable that the owner/operator's loose clothing became entangled in the net or warp and that he was drawn into the turning winch drum.

Findings as to risk

- The control valve was leaking, and the spreading of hydraulic oil over a large area of the after deck made it slippery.

- No anti-skid matting was laid out over the working deck behind the operator's stand.

- The owner/operator was working alone and after the accident, had no means of raising the alarm or calling for help.

- At some time, external springs had been fitted to aid the control valve internal resetting spring; however, these were disconnected at the time of the accident.

Safety action

Action Taken by Transport Canada

As a result of the numerous accidents on board fishing vessels many of which have been the subject of TSB investigations and recommendations Transport Canada has appointed Small Vessel Inspectors in its offices to inspect this class of vessel. Further, it is in the process of forming a Small Vessels Group, which will carry out spot checks and random inspections on all vessels below 60 GRT.

Action Taken by the Workers' Compensation Board of British Columbia

The Workers' Compensation Board (WCB) of British Columbia entered into a Memorandum of Understanding (MOU) with Transport Canada Marine Safety, in May 2001. The MOU demarcates areas of jurisdiction and also establishes areas of joint responsibility, as well as the sharing and mutual exchange of acquired information on a continuous basis.

The WCB is also actively involved in disseminating safety information to and educating the fishing community of British Columbia. The goal is to educate all industry participants on long-term economic advantages of good maintenance; requirements for safe working practices; and the need to comply with appropriate provincial and federal regulations.

This report concludes the Transportation Safety Board's investigation into this occurrence. Consequently, the Board authorized the release of this report on .

Appendix A - Photographs

Photo 1. Star Queen alongside.

Photo 2. Manoeuvring stand showing by-pass valve.

Photo 3. View of the after deck.

Photo 4. Disconnected remote stop device(hold-to-run control).

1. Units of measurement in this report conform to International Maritime Organisation (IMO) standards or, where there is no such standard, are expressed in the International System of Units.

2. All times are Pacific daylight time (Coordinated Universal Time minus seven hours).