Grounding

The bulk carrier Great Century

off Batiscan, St. Lawrence River, Quebec

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

On 26 February 2003, the Great Century was proceeding in fair weather down the St. Lawrence River, en route to Sept-Îles, Quebec. The vessel's progress was hindered by heavy ice concentration and, in the vicinity of Champlain, the diesel engine generators overheated. The ship's electrical power supply was affected and, therefore, the main propulsion system could not maintain its output and was eventually shut down. Shortly thereafter, the Great Century experienced a blackout. An officer was dispatched to the forecastle to let go the anchors, but they were frozen in the hawse pipes. The vessel drifted in the ice flow and grounded outside the channel some 2 nautical miles down river off Pointe à la Citrouille. During the up-coming tide, the vessel was refloated with tug assistance. There was no injury or pollution as a result of this occurrence.

Factual information

Particulars of the vessel

| Name | "GREAT CENTURY" |

|---|---|

| IMO / official number | 9206205 / HK-0458 |

| Port of registry | Hong Kong |

| Flag | Hong Kong, China |

| Type | Bulk carrier |

| Gross tonnage | 38 426 |

| LengthFootnote 1 | 225.00 m |

| DraughtFootnote 2 | Forward: 6.35 m Aft: 6.95 m |

| Built | 2000, Yokosuka, Japan |

| Propulsion | United Sulzer diesel engine, model 7RTA48T, 8384 kW |

| Cargo | Ballast water |

| Crew members | 22 |

| Owner | Great Century Shipping, Hong Kong, China |

Description of the vessel

The Panamax, Great Century, is a seven-hold bulk carrier with the crew accommodation arranged at the after end. The vessel was built at the Sumimoto Heavy Industries Ltd., Yokosuka Shipyard, in Japan, under the survey supervision of the American Bureau of Shipping classification society. The vessel was designed for the carriage of bulk cargo and strengthened for the carriage of heavy cargoes. The No. 4 hold was designed to be used as a deep ballast compartment. The Great Century was not built or classed for navigation in ice and, as such, does not have an ice class notation. However, it was given an "unrestricted service" designation by the American Bureau of Shipping. Its approximate mean draughts in light and heavy ballast conditions are 5.90 m and 7.90 m respectively.

The vessel is propelled by a slow speed diesel engine, which drives a single right-handed, fixed-pitch propeller. The four solid propeller blades are made of a nickel, aluminum and bronze alloy. All of the vessel's associated fuel, oil and cooling water pumps are driven electrically.

History of the voyage

On 14 January 2003, the bulk carrier Great Century departed Bunbury, Australia, loaded with 50 080 tonnes of alumina bound for Bécancour, Quebec. After calling at Durban, South Africa, for bunkers, the vessel resumed its trans-Atlantic voyage bound for Canada. In the mid-Atlantic, the master received a company telex advising him that, at this time of the year in Canada, the vessel would be subjected to navigation in ice-infested waters. This was the vessel's first encounter in ice, and most of the crew members' first introduction to ice navigation. The master held a safety meeting to remind the crew to follow company procedures and to take note of the various handbooks available on the subject, including engine room and bridge and deck procedures manuals.

On 15 February 2003, 48 hours prior to entering Canadian waters, the master forwarded to the Eastern Canada Vessel Traffic Services the standard required information to obtain traffic clearance.Footnote 3 The Great Century met the requirements and two days later entered the Vessel Traffic Services zone.

At 0110 on 20 February 2003, an ice advisor embarked the vessel off Port aux Basques, Newfoundland. The ice advisor informed the master of possible problems the crew and vessel may encounter while navigating in ice-infested waters and cold weather. The master told the ice advisor that the crew had been informed accordingly and that he was confident that the vessel could navigate in ice. At about 0915, the freshwater cooling-temperature alarm sounded, warning that the main engine cylinder head outlet temperature was higher than normal. The load on the main engine was reduced but, a few minutes later, two more alarms were heard. The air intake temperature was found to be above operating temperature and the sea water cooling pressure began to fluctuate. The engineers diagnosed the mechanical fault in the three-way valve in way of the cooling line outlet. Once the valve was freed, using an acetylene torch, the engineers positioned it to maximize the flow at the pump suction. Afterward, the cooling water temperature in the circuit was observed to be stable, at approximately 40°C. The main engine was then brought back to its operating full speed without further incident. On February 21 at 1815, the ice advisor disembarked at Les Escoumins pilot station and two river pilots boarded the vessel. On 22 February 2003, the Great Century berthed at Bécancour, Quebec, and the pilots disembarked.

On 24 February 2003, the engine room staff switched from low to high sea suction. Unloading operations were completed at approximately 0930Footnote 4 on 26 February 2003. As the ballast tanks were being filled (or partially filled) in preparation for departure, including the No. 4 cargo hold, the second and fourth engineers carried out routine tests on the machinery. The vessel was downbound in the St. Lawrence River, bound to Sept-Îles, Quebec.

Generators Nos. 2 and 3 were both put on line and, at about 0910, in order to test the main engine, the main sea water cooling pump was started. However, some three minutes later an alarm sounded. The duty engineer acknowledged the alarm and informed the second engineer that the pressure in the sea water cooling line leading to the generators was low, however, no remedial action was taken nor was the situation closely monitored. At 0932, a second alarm went off; the lube oil temperature in both generators was found to be abnormally high. Shortly thereafter, the sea water pressure and the lube oil temperature returned to normal operating conditions.

Two river pilots boarded the vessel at approximately 1000. The bridge called the engine room and gave them a half-hour notice prior to departure. The vessel's departure mean draught was approximately 6.65 m. At 1030, following the normal routine, the engine's control was transferred to the bridge; engine room personnel remained on stand-by. Tugs were made fast, fore and aft, at 1045, and around 1100 the vessel commenced the unberthing manoeuvre.

The first telegraph order was given at 1108, and the main engine responded accordingly. Some seven minutes later, the pressure in the generator sea water cooling line started to drop and fluctuate. The departure manoeuvring continued until the vessel was in the channel. At approximately 1145, the tugs were cast off and by 1200 the vessel was proceeding down the St. Lawrence at a speed of approximately 9 knots in 6/10 slush ice concentration.

Notwithstanding the fact that the main engine was operating normally, the generators were experiencing cooling problems. In order to cool down the system, the engine room personnel performed the following:

- generator No. 1 was started and put on line;

- the sea suction was transferred to the low suction;

- steam was applied to the high sea suction chest; and

- the generator cooling pump was replaced by the stand-by pump.

Up until this time, the vessel had continued to use the high sea suction for cooling water. The cooling circuit water pressure, nevertheless, continued to fluctuate and sometimes the flow stopped. The generators were, in succession, brought off line and once cooled, were reconnected in order to maintain the electrical supply. At 1213, a generator alarm sounded; both lube oil and water jacket temperature readings on the three generators were observed to be abnormally high. Four minutes later, the main engine sea water cooling pressure began to fluctuate. Notwithstanding efforts deployed to resolve the cooling problem, the situation continued to worsen and the chief engineer advised the bridge team that a blackout could occur.

At 1221, generator No. 2 tripped off the main switchboard, as well as the preferential switchboard. About four minutes later, the vessel experienced a short-term blackout, which stopped the propulsion system. Electrical power was regained shortly thereafter, but not sufficiently in time to restart the main engine. Meanwhile, the master ordered a deck officer to the forecastle anchor station. As both anchors were frozen in ice, they could not be released and the vessel commenced drifting with the ice flow. The generators, which had all been brought on line, continued to sustain cooling problems; eventually they shut down. A second blackout occurred and, at 1241, the emergency generator started automatically.

With neither propulsion nor the use of anchors, at approximately 1255, the Great Century was driven onto the Battures Perron (reef). The vessel grounded in position 46°28.392′ N and 072°14.862′ W, some 1.5 nautical miles upriver from Batiscan, Quebec.

As the vessel lay athwartships to the ice flow on a 245°G heading, the ice, which had accumulated on the starboard side of the vessel, drifted down stream. The open water condition was favourable to restarting a generator. As the sea water suction pressure built up, essential systems were restarted, and, at 1303, the main engine was operational. A sounding of the tanks revealed that the vessel had not sustained an ingress of water. At 1418, with the assistance of two tugs, the Great Century was refloated on the rising tide.

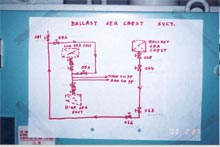

Shortly thereafter, the vessel was anchored for inspection of its cooling system. A Transport Canada (TC) inspector, who had boarded the vessel prior to the refloating operation, began the inspection by examining both sea suction strainers; they were both found filled with ice. Using the ship's plans, the inspector informed the engine room personnel of the different means available to them to cool the onboard machinery while navigating in ice-infested waters. Hand-drawn diagrams were posted in way of the main and auxiliary cooling pumps starter panel to better inform the personnel (see photos 2 and 3).

Thereafter, the vessel returned to the port of Bécancour. An underwater survey of the hull revealed scratch and scuff marks on the paint, and the propeller sustained damage in way of the tips.

Environmental conditions

At the time of departure, visibility was clear with northwesterly winds at some 10 knots. Ice reconnaissance information available to the pilots and master, valid for the period 16:35Z to 17:45Z, indicated that the ice concentration was approximately 6/10 of brash ice between the port of Bécancour and Batiscan.

Inspection of the cooling system

The vessel had three sea chests that were vented and each was fitted with a flanged vent valve on top. However, there was no permanent steam or air line connected to them. The two sea chests on the starboard side were used as a sea-water inlet to cool the main engine and generators (see Figure 2). The high sea suction inlet was located on the ship's side, while the low suction was found on the ship's bottom in way of the centre line. Both are fitted with strainers and isolating valves and linked to a common pipe. The third sea chest is located on the port side and is used mainly for the ballast operations. The circuit allowed interconnection between the three suctions.

The cooling system of the main engine is separate from the generators. To protect the generators from overheating, built-in protection devices would automatically shut down the engines. The vessel was not designed to re-circulate the cooling sea water for the main engine and generators when navigating in ice-infested waters. However, a connection is available between the aft peak, ballast tanks and No. 4 cargo hold and the suction side of the main sea-water cooling system, but it was not considered as a recirculating internal cooling system. It is only usable as long as there is water in the tank from which water is being drawn, or as long as the tank can be refilled. In the vessel's ballasted condition at the time of the occurrence, these tanks contained a total of 24 247 metric tons of ballast water available for emergency cooling of the main engine and generators.

The temperature of the main engine sea-water circulating system is controlled by a three-way valve installed on the outlet side of the coolers, enabling part of the water to return to the pump suction. The three-way valve is controlled by a thermo-pneumatic device that is linked to a probe at the outlet end of the air cooler, with a set point of 25°C.

According to the company's procedures manual, before arrival in the cold climate zone, the internal cooling system was to be tested by the duty engineer using the Ice Navigation Checklist form, No. CL-E09, and an entry is to be made in the bridge and engine room logs. The checklist includes the following items:

- Engine department is fully conversant with the vessel's internal cooling system

- Cross-over valve checked: open/closed

- All engine room valves of the internal cooling system checked: open/closed

- Bridge is informed that the vessel is operating using the internal cooling system

- All engine room heaters on

- Steering gear heaters on

- Engine room pressurized

- Internal cooling tanks filled to working level

- Fuel oil tanks' heaters on

Four CL-E09 forms were completed and signed by the second engineer and were dated 19, 20, 21/22 and 26 February 2003. The four documents showed that items Nos. 5 and 6, concerning the heaters, were not checked and that item No. 8, on the 19 and 21/22 forms concerning the internal cooling tanks, was not checked. None of the forms indicated that a deficiency had been identified.

Past occurrences

| 1997/98 | 1998/99 | 1999/00 | 2000/01 | 2001/02 | 2002/03 ** | |

|---|---|---|---|---|---|---|

| Cooling problem - not resulting in an accident | 18 | 19 | 15 | 27 | 12 | 22 |

| Electrical and/or propulsion loss | 1 | - | - | - | 1 | - |

| Grounding | - | - | 1 | 1 | - | 1 |

| Totals | 19 | 19 | 16 | 28 | 13 | 23 |

* Period from November 1 to April 30.

** To date of occurrence, 26 February 2003.

Before 1997, vessels experiencing cooling problems due to a blockage of the sea suction inlet by ice (in Canadian waters) were not systematically compiled in the TSB database. Nevertheless, the database revealed that, prior this date, 22 significant occurrences were captured due to this recurring problem. During this period, there was an average of 2170 movements per year between the months of December and March.

Eastern Canada Vessel Traffic Services Zone

The Canadian waters north of 60°N latitude are considered as Arctic ice-covered waters and, as such, the Arctic Shipping Pollution Prevention Regulations apply in this region. In 1996, TC made an extensive revision to these regulations by introducing the Arctic Ice Regime Shipping System, with the aim of reducing the risk of damage to vessels and the environment. The system is based on a calculated Ice Numeral (IN), which is a function of the quantity of hazardous ice present and the vessel's ability to navigate in ice. The IN determines whether or not a ship may proceed, i.e. if the IN is negative, clearance is not given.

In contrast, traffic in eastern Canadian waters south of 60°N latitude is regulated by the Eastern Canada Vessel Traffic Services Zone Regulations (ECAREG). Every ship of 500 or more in gross tonnage shall provide, 24 hours before entering the ECAREG zone, a report to a Canadian Coast Guard (CCG) Marine Communications and Traffic Services centre.Footnote 5 The regulations, however, do not assess a vessel's ability to navigate in ice, nor is there a requirement for the vessel to report whether or not it carries an ice classification, including, inter alia, whether there is an available internal recirculation/cooling system for the machinery.

Previous safety action

It is not uncommon for a TC inspector to board a vessel and find that the engine room personnel is unaware of the fact that the ship may not be fitted with an internal re-circulating system and that when fitted with one, the crew may not have the required knowledge to activate the system. As a result of previous occurrences involving the blockage of sea inlets by ice, TC Marine Safety published two Ship Safety Bulletins (SSBs), (08/1989 and 09/1996), to serve as a reminder of some of the problems that may be encountered when operating in winter conditions.

Additionally, to raise awareness of the issue, TC's Quebec Region, through a CCG notice, informed ships of the risks associated with ice navigation. The notice was issued before the commencement of 2002-2003 winter season and was to be repeated in subsequent winter navigation seasons. The International Maritime Organization (IMO) recognizes that vessels that do not have an ice class notation are prone to sea suction problems and, as such, are more than likely to be involved in an accident. Consequently, IMO issued Circular 504, Guidance on Design and Construction of Sea Inlets under Slush Ice Conditions, in 1989, which provides guidance on the design and construction of sea suction inlets for vessels that navigate under slush ice conditions (see Figure 3).

On 02 March 1991, the Bahia de la Habana, a 10 572 gross tons general cargo vessel under the Cuban flag, was under way in the St. Lawrence River when the sea-inlet strainers became blocked with ice. While trying to clear the strainers, the engine room began to flood and the vessel blacked out. As a result of this occurrence, the TSB sent a Marine Safety AdvisoryFootnote 6 to the vessel's owners, informing them of the problems associated with slush ice blocking sea suctions, as well as a copy of TC SSB 08/1989 and IMO Circular 504.

On 27 December 2000, the Canmar Force, a container ship of 28 176 gross tons, sailing under the Panamanian flag, was under way in the St. Lawrence River, under the conduct of a pilot, bound for the Port of Montreal. At 1959 local time, near Cap Levrard, the vessel experienced a power blackout and subsequently went aground. The vessel was refloated the next day with tug assistance. There was no apparent damage to the vessel or the environment.

The vessel was equipped with an internal recirculating system and a steam line connected to the sea chest to reduce the risk of loss of pressure while operating in slush ice conditions, but they were not used. Engine room personnel were unaware that slush ice could block sea inlets and that the vessel was equipped with an internal recirculating system for use in such instances. As a result of this occurrence, the TSB sent a Marine Safety InformationFootnote 7 letter to the vessel's owners, informing them of the problems associated with slush ice blocking sea suctions.

Analysis

Loss of propulsion and subsequent grounding

While the Great Century was assigned an "unrestricted" service by the American Bureau of Shipping, the vessel was not assigned an ice class or built for navigation in ice; specifically, it was not equipped with a means of recirculating warm cooling water back to the sea chests, or with an internal ballast water recirculation system as recommended in the IMO's Circular 504. Consequently, after the grounding, both the upper and lower sea strainers were found blocked by ice, which had reduced the flow of cooling water. Protection devices installed on generators to prevent mechanical failures automatically shut down the diesel engine before overheating, hence the ship's ability to provide electrical power was reduced to a level that was insufficient to operate the main propulsion system. The main engine stopped, thereby leaving the vessel adrift. Since the vessel's anchors were not cleared of ice before the departure, the crew was unable to let them go and, consequently, the vessel drifted northeasterly and grounded.

Winter Navigation in Eastern Canada Traffic Zone and St. Lawrence River

In order for a vessel to be considered seaworthy, it must be sufficient in its materials, construction, equipment and crew for the trade in which it is employed.Footnote 8 Vessels without ice class notations, such as the Great Century, are suitable for most worldwide trades. However, the extreme environmental ice conditions encountered during the winter in higher latitudes create conditions that have the potential to compromise the safety of the vessel and the crew, and place the environment at risk.

During winter 2003, a mass of cold Arctic air remained stationary over the St. Lawrence River, worsening the ice condition on the river. TSB statistics show that, during this period, the number of vessels experiencing sea suction problems was higher than that observed in the previous six years (except for one other year), reflecting the harsh winter conditions on the river at the time of the accident.

For vessels operating in Arctic ice conditions, the Arctic Ice Regime Shipping System was introduced to mitigate risks posed to vessels and the environment. Notwithstanding the harsh winter conditions present, vessels entering the Gulf of St. Lawrence and St. Lawrence River are not subject to an assessment to determine the vessel's ability to navigate safely in ice.

Additionally, during the winter season, with the exception of oil tankers and chemical bulk carriers, vessels entering Canadian waters south of 60°N latitude are not assessed for their ability (or lack thereof) to safely navigate in ice-infested waters. The risks associated with operating vessels in certain waters off the East Coast of Canada during the winter and spring months have been recognized by the industry and regulators. The publication Joint Industry-Coast Guard Guidelines for the Control of Oil Tankers and Bulk Chemical Carriers in Ice Control Zones of Eastern Canada specifically addresses the risks, but limits its application to high-risk vessels such as tankers and chemical carriers. While the risk associated with these vessels is higher than that associated with other types of vessels, the hazards posed in each case are essentially the same. Furthermore, although navigation in ice requires specific knowledge and experience, there is no prerequisite for masters of any vessel to have such experience. Given these shortcomings, the mandate of the Eastern Canada Vessel Traffic Services Zone Regulations (ECAREG), to safeguard Canadian waters against pollution and damage to the environment, is compromised.

Statistics show that vessels proceeding on the St. Lawrence River in winter do experience severe ice conditions. Based on the TSB database, since 1997 an average of 19 vessels per year experience sea suction problems during the winter season on the St. Lawrence River. Moreover, since 1999, three vessels have experienced electrical blackouts that resulted in groundings.

The Great Century is typical of the vessels that have experienced difficulties, in that it was not built for navigation in ice. In fact, the ability of any vessel to proceed in ice is not taken into consideration by the present Eastern Canada Vessel Traffic Services Zone Regulations, nor are vessels required to report if they are ice classed or if they are equipped with an internal recirculation system. The current regulatory regime in the Eastern Canada Traffic Zones and the St. Lawrence River does not adequately address the risks associated with vessels operating in ice-infested waters.

International Safety Management Code compliance

The majority of ice-related occurrences reported to the TSB in the Eastern Canada Vessel Traffic Services Zone involve problems with sea suction blockages and loss of electrical power or propulsion. While ice pilotage expertise is available to all vessels entering Canadian waters, the expertise is limited to nautical aspects; machinery-related aspects are not addressed. While the nautical staff benefit from the advice of the ice advisor or a pilot, the engine room crew do not receive any guidance and are left to operate on their own knowledge and experience. Consequently, engine room crew who are unfamiliar with the precautions to be taken when vessels operate in ice conditions may not fully appreciate the risks and may not be adequately prepared.

The International Safety Management (ISM) Code is intended to address risks associated with ship operations and establish well-documented vessel-specific procedures and practices.Footnote 9 Additionally, the crew members designated to the vessel are required to possess skills and knowledge essential for the safe execution of the tasks they are expected to perform in normal operations and during emergencies.Footnote 10 Given that the Great Century was scheduled to ply in.Canadian waters during the winter months, the onus was on the ship's owner and the ship's senior staff to ensure that the infrastructure in place for an internal cooling system was functional. However, in this instance:

- the Safety Management System (SMS) documentation was not vessel-specific and did not provide the engine crew with effective procedures to operate in ice-infested waters;

- the vessel was not designed to operate in ice conditions; and

- the crew was unfamiliar with the precautions that needed to be taken when the vessel was operating in ice conditions.

The application of the ISM Code and the provision of adequate policies and procedures provide the ship's complement with necessary information to make sound decisions in any operating condition. Consequently, it is essential that the manuals, procedures and practices be complete and vessel-specific.

The crew members on the Great Century were experienced seafarers but had not acquired experience on vessels operating in a cold climate or ice-infested waters. Subsequent to entering the ice in the Gulf of St. Lawrence, when the sea water flow to the engine room began to fail, the crew did not recognize that the sea suction strainer was probably becoming blocked with ice. The engineers assumed the three-way valve at the outlet of the machinery cooling system was the cross-over valve referred to on the CL-E09 form.Footnote 11

Given the cooling problems, they concluded that it was defective and by readjusting it, assumed that the recirculation system had been re-activated. A change from low to high sea suction was carried out in Bécancour. This runs contrary to the accepted practice to use the lower suction, which is less likely to be affected by loose ice. This situation continued until the vessel had departed Bécancour, when the crew finally recognized that the sea suctions were becoming blocked with ice. Additionally, the vessel's crew was unaware that the aft peak, double bottom ballast tanks and No. 4 cargo hold could be used to supply water for short-term emergency cooling.

The crew was inexperienced in ice navigation and, without adequate training and vessel-specific documented procedures/directives in the SMS manual, the crew was unable to recognize and prevent the blockage of the sea suctions, resulting in the loss of propulsion followed by grounding.

Findings

Findings as to causes and contributing factors

- Ice blocking the main sea suction strainers caused the vessel's generators to overheat and shut down, resulting in a loss of electrical and propulsion power.

- The crew was unable to let go the anchors, which were frozen in the hawse pipes and, without propulsion power, the vessel drifted with the ice flow and grounded outside the channel.

- The cooling system in the Great Century was not designed for efficient navigation in ice.

- The crew was inexperienced in ice navigation, and without adequate training and vessel-specific documented procedures/directives in the Safety Management System manual, the crew was unable to readily recognize and prevent the blockage of the sea suctions.

Findings as to risk

- The current information required to provide clearance to vessels entering ECAREG waters does not allow the regulator to sufficiently evaluate the risk profile of a vessel. As such, the mandate of the Eastern Canada Vessel Traffic Services Zone Regulations (ECAREG), to safeguard Canadian waters against pollution and damage to the environment, is compromised.

Safety action

Action taken

Transport Canada (TC)

TC required the master of the Great Century to obtain proper winter clothing for the crew to work outside. The company was also required to install a temporary pipe connection to the sea water cooling outlet and the strainer of the high sea suction inlet. The latter installation allows water to return to the sea chest instead of the suction end of the main engine sea water pump (see Photo 4).

Department of Fisheries and Oceans Canada (DFO)

As a result of the investigation, DFO reviewed the annual edition of the Notices to Mariners 1 to 46, and determined that it did not contain a warning to keep sea suction inlets clear in ice-infested waters. A warning concerning this safety issue will be included in the next publication. TSB will monitor the proposed amendment to the publication.

Safety concern

Seaworthiness is defined as the sufficiency of a vessel in materials, construction, equipment, crew and outfit for the trade or service in which it is employed.Footnote 12 For a vessel to safely navigate in ice conditions, the ship's cooling water system must be designed so that a continuous flow of water is supplied to all machinery. Furthermore, given the unique operational demands placed on the vessel, the crew must be trained accordingly.

Vessels of 500 gross tonnage or more, vessels engaged in towing or pushing a vessel, and vessels carrying a pollutant or dangerous goods entering Canadian waters must comply with the 24 Hour Notification, as per the Eastern Canada Vessel Traffic Services Zone Regulations. Since July 2004, vessels must report 96 hours before entering Canadian waters, as described in the new Marine Transportation Security Regulations. The present reporting scheme provides general vessel information, but it does not require a vessel to indicate its capability to navigate in ice. As indicated by this investigation and previous occurrences reported, often the first indication of a vessel's lack of suitability for ice navigation occurs when the vessel reports a cooling water problem; more often than not, the vessel has already lost propulsion.

It is acknowledged that the Joint Industry-Coast Guard Guidelines for the Control of Oil Tankers and Bulk Chemical Carriers in Ice Control Zones of Eastern Canada addresses certain risks to these types of vessels and recommends the carriage of an ice advisor. However, the guidelines do not apply to the majority of vessels navigating in the zone. Also, the ice advisor is a qualified navigating officer, not necessarily an experienced engineer, familiar with internal machinery cooling systems. Nor is it a requirement that all ships should carry an ice advisor; it is a service provided when a vessel owner requests it. As such, many vessels navigating in the zone without experienced ice navigators and officers remain at risk if the proper precautionary measures are not taken to address such conditions.

Although a warning will be placed in the annual edition of Notices to Mariners, to keep sea suctions clear while navigating in ice, a vessel is currently not required to report its ice class (or lack thereof), or the suitability of its on-board cooling-water system for ice navigation, along with the 20 items required to be reported to ECAREG (see Appendix A). As a result, the Board is concerned that some vessels entering Canadian waters during the ice navigation season will continue to pose a risk to life, property and the environment.

This report concludes the Transportation Safety Board's investigation into this occurrence. Consequently, the Board authorized the release of this report on .

Appendices

Appendix A

Report required under the Eastern Canada Vessel Traffic Services Zone Regulations shall specify :

- the name of the ship;

- the radio call sign of the ship;

- the name of the master of the ship;

- the position of the ship;

- the time the ship arrived at the position;

- the course of the ship, if any;

- the speed of the ship, if any;

- the prevailing weather conditions (including ice if applicable);

- the estimated time that the ship will enter the Eastern Canada Vessel Traffic Services (VTS) Zone;

- the destination of the ship;

- the estimated time of arrival of the ship at the destination;

- the route of the ship intends to take through the Eastern Canada VTS Zone to arrive at the destination;

- the name of the last port of call of the ship;

- the draught of the ship;

- any dangerous goods, listed by class, or pollutant that is carried on board the ship or the vessel being towed or pushed by the ship;

- revoked;

- any defect in the ship's hull, main propulsion systems or steering systems, radars, compasses, radio equipment, anchors or cables;

- any discharge, or threat of discharge, of a pollutant from the ship into the water, and any damage to the ship that may result in the discharge of a pollutant from the ship into the water;

- the name of the Canadian or United States agent of the ship; and

- the date of expiration of a certificate referred to in Article VII of the International Convention on Civil Liability for Oil Pollution Damage, 1969/1992, the International Oil Pollution Prevention Certificate for the Carriage of Noxious Liquid Substances in Bulk, the Certificate of Fitness and the Certificate of Compliance, the International Safety Management (ISM) Certificate and the ISM document of compliance, if any, issued to the ship.

Appendix B - Glossary

- ECAREG

- Eastern Canada Vessel Traffic Services Zone Regulations

- CCG

- Canadian Coast Guard

- DFO

- Department of Fisheries and Oceans Canada

- ed.

- edition

- G

- gyro (compass course, heading or bearing)

- IMO

- International Maritime Organization

- IN

- Ice Numeral

- ISM Code

- International Safety Management Code

- kW

- kilowatt

- m

- metre

- M/B

- main ballast

- M/E

- main engine

- N

- north

- SSB

- Ship Safety Bulletin

- SMS

- Safety Management System

- Stbd

- starboard

- TC

- Transport Canada

- TSB

- Transportation Safety Board of Canada

- UTC

- Coordinated Universal Time

- W

- west

- Z

- Zulu [time] (equivalent to UTC)

- °

- degree

- ′

- minute