Capsizing and sinking with loss of life

Fishing vessel Ocean Tor

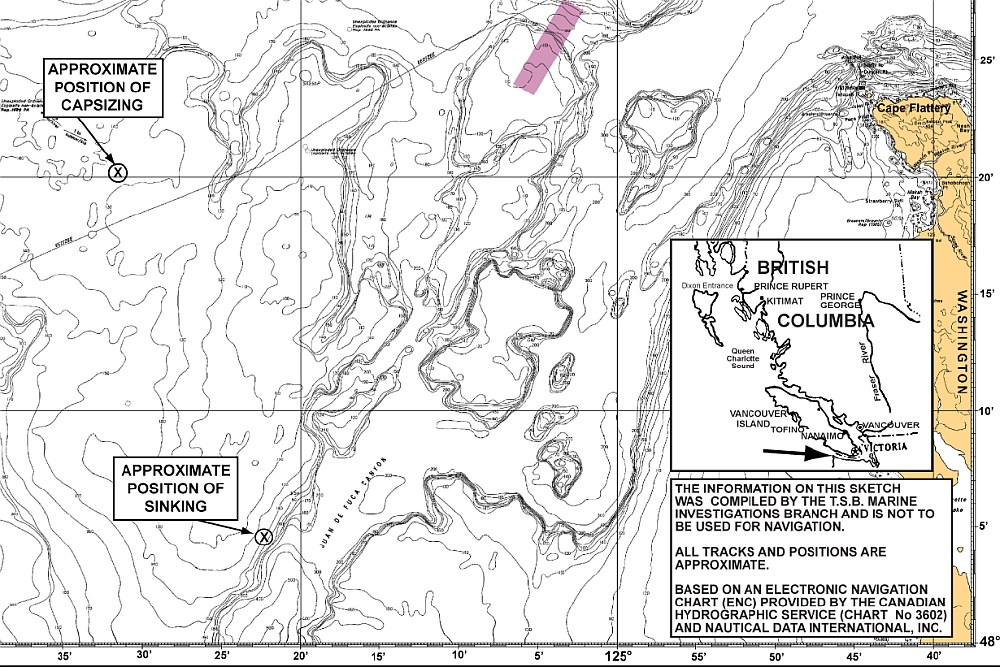

West of Cape Flattery, Washington, United States

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

On 26 July 2005, at approximately 0500, the fishing vessel Ocean Tor, with four persons on board, arrived at the fishing grounds in Canadian waters west of Cape Flattery, Washington, United States, and commenced fishing for turbot. At approximately 1700 Pacific daylight time, the crew was in the process of transferring a load of fish from the nets into the fish holds when the vessel suddenly listed heavily to port, rolled over, and subsequently capsized. A fishery observer and the master were rescued and transferred to the fishing vessel Osprey 1.

Two crew members lost their lives. The vessel is presumed to have sunk on 29 July 2005.

Factual information

Particulars of the vessel

| Name | Ocean Tor |

|---|---|

| Official number | 0369197 |

| Port of registry | Vancouver, British Columbia |

| Flag | Canada |

| Type | Fishing vessel |

| Gross tonsFootnote 1 | 99.70 |

| Length | 23.16 m |

| Built | 1974, John Manly Shipyard, Vancouver |

| Propulsion |

Caterpillar D 343, six-cylinder diesel engine; 317 kW; single propeller |

| Cargo |

Approximately 73 500 kg of fish (mainly turbot) |

| Crew members | 3, plus 1 fishery observer |

| Owner | Ocean Tor Holdings, Vancouver |

Description of the vessel

The Ocean Tor was a small fishing dragger of closed construction, having an all-welded steel double-chine hull with a raised forecastle. The hull below the main deck was subdivided by five watertight bulkheads, which divided the vessel into the forward crew accommodation, the engine room, forward fish holds (port and starboard), aft fish holds (port and starboard), ice holds (port and starboard), and the lazarette space comprising port and starboard fuel tanks with a centreline steering gear compartment. In addition to these tanks, the vessel had two fuel tanks in the engine room, and two freshwater tanks and a water-ballast tank forward of that (see Appendix A). The deckhouse housed the galley, sleeping quarters, engine-room entrance, and stairs leading to the wheelhouse. An inflatable liferaft fitted with a hydrostatic release was stowed on the open deck above the wheelhouse.

The vessel was built in 1974 with one large fish hold, an ice hold aft, two net drums on the stern and two trawl winches on deck. In 1979, it was lengthened by approximately 1.8 m in the midships area, the fish hold was subdivided into four, and the single hatch cover was replaced by four separate ones.

Further modifications to the stern were made in 1990 to incorporate a centreline fish-hauling ramp. The ice hold was divided in two. The four fish holds were reduced in volume and insulated to allow the fish to be stowed in ice/water slush. A berthing winch was mounted on the deckhouse top to pull nets up the ramp. At the time of the occurrence, the vessel was rigged for bottom-trawling operations with nets wound on each of the drums.

Navigation and communication equipment in the wheelhouse included two very high frequency (VHF) radiotelephones, one of which was equipped with digital selective calling (DSC), and an emergency position-indicating radio beacon (EPIRB).

History of the voyage

The Ocean Tor departed Ucluelet, British Columbia, at approximately 2130Footnote 2 on 25 July 2005, with full freshwater tanks, full fuel tanks forward, and approximately 10 000 litres of fuel in the aft tanks. Ice had been loaded and distributed primarily among the four fish holds, with a small amount loaded in the two ice holds. The intent was to fish for approximately 81 650 kg of turbot. On board were the master, an engineer, a deckhand/cook, and a fishery observer.

The vessel headed for fishing grounds on the continental shelf, approximately 30 miles west of Cape Flattery, on the Canadian side of fishery zone limits. While en route, the fish holds were filled with water to form a slush mixture in preparation for loading fish, and the starboard freshwater tank was emptied to improve the vessel's behaviour in the seaway and to compensate for the heavier net on the port drum.

The vessel arrived at the fishing grounds at approximately 0500 on July 26 and commenced its first tow shortly afterwards. Fishing was good, and five tows and eight hours later, there were almost 60 000 kg of turbot on board. As the fish were loaded into the holds, the water level was lowered; once loading was complete, the holds were topped up with water so that free surface was minimized. Throughout this process, the hatch covers of holds that were being used to load fish were left unsecured to facilitate the visual inspection of the holds and to transfer the slushy water between holds.

When hauling the nets on board, the master would leave the wheelhouse unattended while he helped the engineer and deckhand. The engineer was also responsible for transferring water to and from the holds while fish were loaded, and for transferring fuel and water as necessary to compensate for vessel list induced during towing operations. Besides the fishery observer, whose primary duty while on board was to record the catch, both the master and engineer kept records of the quantity of fish loaded into each hold.

After the fifth tow, the vessel seemed lower in the water than usual for the amount of fish on board. A possible leak in the lazarette was considered, but the engineer assumed that, because the space had been pumped out previously on the trip, the bilge pump was functioning normally. Being lower in the water was thought to be a result of being heavy with fuel in the aft tanks. No visual inspection of the lazarette was made because the master was reluctant to open the flush deck hatch while underway.

The sixth tow was hauled on board and the net was dragged on to the deck via the aft ramp; the first section of the net was suspended from the middle of the boom, and emptied. As the next section was being lifted, the deck became awash on the port side aft. Concerned for the vessel's stability, the master ran from the deck towards the wheelhouse, intending to speed up the vessel to drain the accumulated water.

Before the master reached the wheelhouse, the vessel began listing to port, sinking further by the stern. It shortly began downflooding through the open engine-room door, vents, and other deck openings, until the Ocean Tor lay over on its port beam ends at about 1700 and subsequently capsized in position 48°20.2′ N, 125°31.6′ W (see Appendix B).

The fishery observer retrieved his immersion suit from the accommodation and exited via the galley door. He was followed by the engineer, who had been in the engine room pumping slush from the ice hold. The engineer had no time to grab his immersion suit from the forecastle, and for protection, had only the rain gear he already wore. The deckhand, also wearing rain gear, deployed the liferaft, which inflated but became trapped under the rigging. On reaching the wheelhouse, the master activated the DSC alarm, then attempted to get into his immersion suit. He exited without his immersion suit via a galley window after his attempts to exit via the galley door were unsuccessful due to water pouring in over the top half of the door.

Distress signals from both the float-free 406 EPIRB and the VHF/DSC were received by the Victoria and Seattle Joint Rescue Coordination Centres (JRCCs). Search and rescue (SAR) resources were deployed, including a United States Coast Guard (USCG) helicopter that was on scene at 1845.

On exiting the vessel and swimming to the surface, the master, with the deckhand's help, tried unsucessfully to dislodge the raft from under the vessel.

The master then held onto the trailing liferaft sea anchor line and climbed aboard the overturned hull. He stayed there until he was picked up at about 1903 by the zodiac from the fishing vessel Osprey 1, which had responded to the distress broadcast.

The fishery observer managed to don his immersion suit, although he was wet and cold from the exposure to water. He was also picked up by the zodiac and taken to the Osprey 1.

The deckhand was last seen near the liferaft. The engineer, who could not swim, was never sighted.

Both the master and the fishery observer were transported to Ucluelet and treated for hypothermia. The engineer's body was recovered two weeks later by a vessel fishing in the area of the occurrence. The deckhand's body was found a few weeks later off the coast of Oregon, United States.

On 27 July 2005, a tug with a diver on board was dispatched to the site to assess salvage possibilities. The vessel was not located, although an oil sheen and debris were sighted. The Ocean Tor was last seen from the air, barely afloat and stern up, on 29 July 2005, in position 48°05′ N, 125°22′ W, and it was later presumed sunk.

Weather

Area weather at the time of the occurrence was reported as winds from west-northwest at 20 to 25 knots, with 2 m swells.

Crew certification and experience

The master had 18 years of experience in the fishing industry, 12 of them trawl fishing. He held a fishing master, fourth-class certificate of competency that was issued by Transport Canada (TC) in 2001. He had recently completed Marine Emergency Duties (MED) courses B1 and B2. He had been master on the Ocean Tor for three months before the occurrence; prior to this, he had relieved as a master on other fishing vessels.

The engineer had 20 years' experience in the fishing industry and had previously worked as skipper in the black cod fishery. He held a commercial fishing vessel, Class 3 certificate and a watchkeeping mate certificate. Both were issued in 1982. In 1998, he completed the MED A1 course.

The deckhand had no certification, nor did regulations require him to have any. He had been involved in the fishing industry for some six years, but had no MED training.

Vessel certification

The Ocean Tor was last inspected by TC on 12 September 2003. An inspection certificate (SIC 29) was issued for operation as a home-trade, Class II vessel with a crew of five; it was to expire on 11 September 2007.

Vessel stability

On 06 December 1982, an inclining experimentFootnote 3 was carried out on the vessel. In 1987, two stability booklets were submitted to TC, one for herring packer and the other for bottom-dragger operations. The herring packer booklet was approved. Because TC regulations require only those small fishing vessels carrying herring or capelin to have approved stability, the stability booklet for bottom-dragger operations was reviewed and stamped "noted." Calculations in these booklets indicated that, to meet the TC standard for fishing vessel stability (STAB 4),Footnote 4 both aft fuel tanks and the ice holds were to be kept empty when the other holds were loaded with fish.

During modifications in 1990, a naval architect estimated the changes to the vessel's stability characteristics, based on the work being done. The capacity of the fish holds was to be reduced to meet STAB 4 criteria; accordingly, foam insulation was added to lower the deckhead in the aft holds by 45 cm. The shipyard's work order also stated that an inclining experiment was to be carried out after the modifications were completed; there is no record that this was performed.

Occurrence stability

Based on the 1990 stability estimates, the TSB carried out post-occurrence calculationsFootnote 5 to assess the transverse stability of the vessel around the time of capsizing. Once the sixth and final tow had been brought on board, the total weight of fish in the holds and on deck was estimated at 73 500 kg, and the combined weight of fish with water on board was approximately 84 845 kg. This was less than the maximum loaded condition described in the vessel's stability booklets—roughly 90 745 kg of fish and water—a figure the master used as guidance when loading the vessel.

TSB calculations indicate that, with the vessel's watertight integrity intact and before taking the sixth tow on board, the vessel met or exceeded TC's standard for fishing vessel stability and had 1.0 m of freeboard aft. With the final tow on deck, stability was somewhat reduced, but the vessel only marginally missed the STAB 4 standard, with approximately 0.85 m of freeboard aft. Once the net was lifted, righting ability was significantly reduced; freeboard aft, however, was approximately 0.88 m.

At the time of capsizing, the vessel was loaded within typical limits; crew members, however, felt that they were very low in the water and that the vessel's behaviour was unusual. Therefore, further calculations were conducted to examine possible explanations for the reported loss of freeboard. The results indicated that seawater ingress into the lazarette (via the deck hatch or rudder stock penetration) alone would be insufficient; however, there was a history of leaking via the stuffing box. It was also noted that water ingress into the shaft tunnel could pass into the engine space once the level of the transverse floors had been reached.

Bilge monitoring and pumping system

The bilge pumping system on the Ocean Tor consisted of three separate pumps—two hydraulic and one driven by the main engine—each of which could pump out any compartment on the vessel. The lazarette space could be pumped out by any one of these pumps and had its own float switch alarm with wheelhouse monitoring light and buzzer.

The shaft tunnel was completely overhauled in the mid 1990s. A small dam was installed in front of the stuffing box gland to eliminate the constant presence of a small amount of water lying along the rest of the tunnel floor to reduce corrosion. A small float and electric pump were installed inside this dam to pump away any water that the stuffing box was producing.

The power supply to the small pump inside the stuffing box dam was operated by a switch located in the alleyway leading to the engine room. There was no guard in place to prevent it from being inadvertently moved to the OFF position by anyone brushing past. On one previous occasion, the engine space flooded while the vessel was alongside the owner's dock for maintenance, due to the leaking stuffing box, with the pump switch for the stuffing box dam inadvertently off.

Crew complement

According to TC's inspection certificate, the vessel was to have a crew of five to meet safe crewing requirements. At the time of the occurrence, there were three crew members on board—a typical number.

Analysis

Vessel capsizing

The Ocean Tor was likely experiencing water ingress via the shaft tunnel, which may also have progressed into the engine room. The resulting loss of freeboard and reserve buoyancy significantly diminished the vessel's righting ability. The situation was exacerbated by the fluctuation in buoyancy forces as the vessel moved through wave crests and troughs, and the rise in centre of gravity as a result of lifting the net with the cargo boom. At this point, the vessel was unable to overcome the heeling forces. When it capsized, seawater downflooded through the hatches, and via open doorways to other spaces until, approximately two days later, the vessel lost all reserve buoyancy and sank.

Bilge monitoring and pumping

The shaft tunnel was vulnerable to water ingress via the propulsion shaft stuffing box. Water collecting there would not be noticeable to anyone in the engine room until, once the level of the transverse floors was reached, it eventually spilled over.

In addition, the system in place to protect from water ingress into the space was itself vulnerable. Without a guard in place, the location of the switch meant the power to the small stuffing box pump could be inadvertently shut off by someone brushing past. If, in addition, the alarms were not functioning or were not heard, it is likely that no one would recognize the problem, as had happened on a previous occasion.

Decision to fish

The Ocean Tor was operating with a crew of three, rather than the minimum of five stipulated on the inspection certificate. This meant the master had to leave the wheelhouse—the vantage position from which to supervise and ensure vessel safety—unattended to help with operations on deck. Similarly, rather than focussing on the safe operation of the engine room and related machinery, the engineer was also busy performing tasks related to the fishing operations. The result was that both senior supervisory personnel were distracted from their main duty, that of ensuring vessel safety, and were busy dealing with the stowage of the catch.

Following the fifth tow, crew members, including the master, noticed that the vessel was unusually low in the water despite having only some 61 000 kg of fish on board. However, the risk was not fully appreciated and fishing continued with compromised safety margins.

Stowage of liferafts

In this occurrence, the liferaft became trapped when it was deployed, its painter caught in the rigging. As is the case on most fishing vessels, the Ocean Tor's liferaft had been placed on top of the wheelhouse due to a combination of space limitations on deck and the need to have an unobstructed work area for fishing operations.

Although practical from an operational point of view, storing liferafts this way—close to booms, rigging and/or railings—may impede their safe launch and, consequently, evacuation during emergency abandonment. Should a raft or its painter become entangled, there is increased risk of damage to the liferaft and injury to the crew. This issue has been raised in several other TSB reports involving small fishing vessels.Footnote 6

TC has issued Ship Safety Bulletins (SSBs) 09/1993 and 03/2001. Both of these SSBs address recommendations on the stowage of inflatable liferafts. A new SSB, 07/2007, was issued in August 2007. It reiterates TC's recommendations regarding the optimum stowage of liferafts and advises owners of TC's intention to amend requirements concerning float-free arrangements.

Findings

Findings as to causes and contributing factors

- The Ocean Tor likely experienced ingress of water into the shaft tunnel, which progressed into the engine room. The resulting loss of reserve buoyancy, exacerbated by the rise in centre of gravity when the net was lifted, left the vessel unable to overcome the heeling forces of the seaway, culminating in the capsizing.

- Once the vessel capsized, seawater downflooded via open doorways, vents, and other deck openings until the vessel eventually sank.

- The vessel had insufficient crew, and both senior supervisory personnel were busy dealing with the stowage of the catch rather than ensuring vessel safety.

- The risk to the vessel's stability was not fully appreciated, and fishing continued with compromised safety margins.

Findings as to risk

- Placing liferafts near booms and rigging can impede their safe launch, as well as the subsequent evacuation of crew during an emergency abandonment.

Other findings

- The power to the independent stuffing box pump on board the vessel was vulnerable to being inadvertently shut off when people brushed past the switch.

Safety action

Action taken

Transport Canada (TC) issued a new Ship Safety Bulletin (SSB), 07/2007, in August 2007. It reiterates TC's recommendations made in SSBs 09/1993 and 03/2001 regarding the optimum stowage of liferafts and advises owners of TC's intention to amend requirements concerning float-free arrangements.

This report concludes the Transportation Safety Board's investigation into this occurrence. Consequently, the Board authorized the release of this report on .