Explosion on board

Tug Risco Warrior

Near Mellersh Point in Bute Inlet, British Columbia

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content.

Table of contents

Summary

On 07 August 2020, while the tug Risco Warrior was holding the barge Western Carrier against the dock at Mellersh Point in Bute Inlet, British Columbia, an explosion occurred in the tug’s battery compartment, located in the lazarette. The vessel sustained structural damage, and 2 crew members on board sustained minor injuries.

1.0 Factual information

1.1 Particulars of the vessel

| Name of vessel | Risco Warrior |

|---|---|

| Official number | 313917 |

| Port of registry | New Westminster, BC |

| Registered owner | Glory Days Towing Ltd. |

| Flag | Canada |

| Type | Tug |

| Construction materials | Steel |

| Construction type | Carvel / flush |

| Gross tonnage | 14.27 |

| Length (registered) | 11.49 m |

| Moulded breadth | 3.51 m |

| Built | 1961 |

| Propulsion | 2 diesel engines of 340 kW (in total) |

| Crew | 3 |

1.2 Description of the vessel

The tug Risco Warrior (Figure 1) was built by Swiftsure Towing Co. Ltd. in New Westminster, British Columbia (BC). Glory Days Towing Ltd.,Footnote 1 the authorized representative (AR)Footnote 2 of the tug Risco Warrior, purchased it in 2008 and uses it for towing barges such as the Western Carrier.Footnote 3

The wheelhouse on the Risco Warrior is in the superstructure located on the main deck. The wheelhouse contains a steering wheel, 2 main engine controls, electrical and electronic switch panels, 2 ammeters, 1 magnetic compass, 1 GPS (global positioning system), 1 automatic identification system, 3 very high frequency radiotelephones (1 with digital selective calling), 1 echo sounder, and 1 radar plotter.

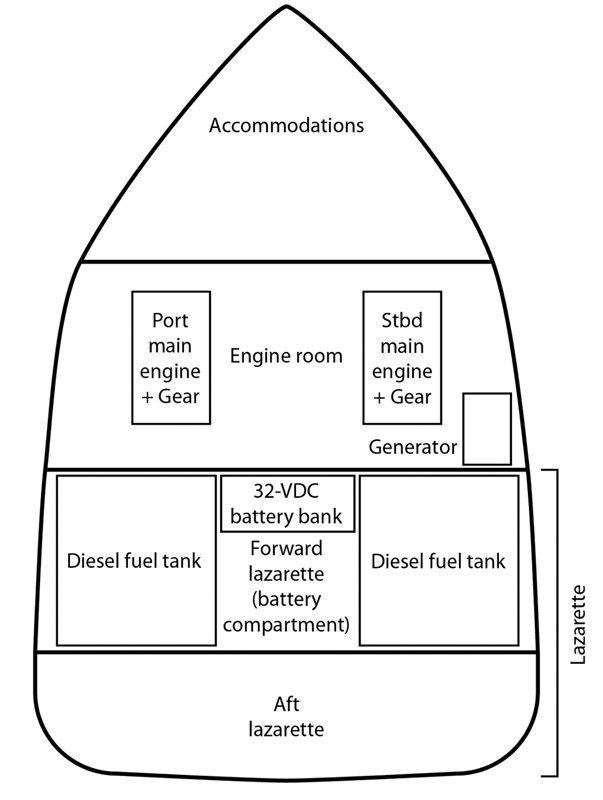

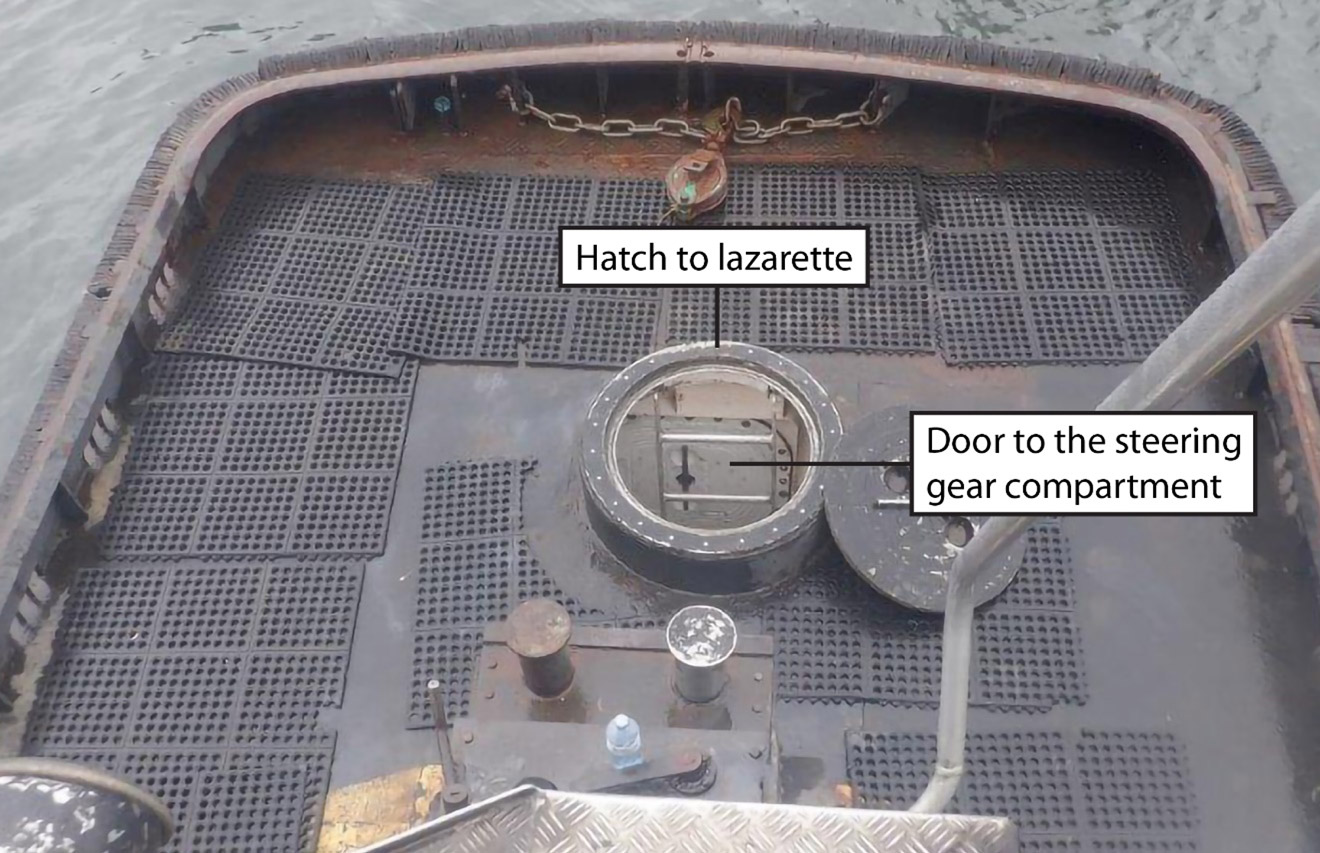

Below the main deck, the crew accommodation is located at the bow, the engine room is aft of the crew accommodation, and the lazarette is aft of the engine room (Figure 2). The lazarette has 1 access opening with a coaming on the main deck, which is made watertight by means of a dogged hatch cover (Figure 3). The tug has a flying bridge with machinery controls.

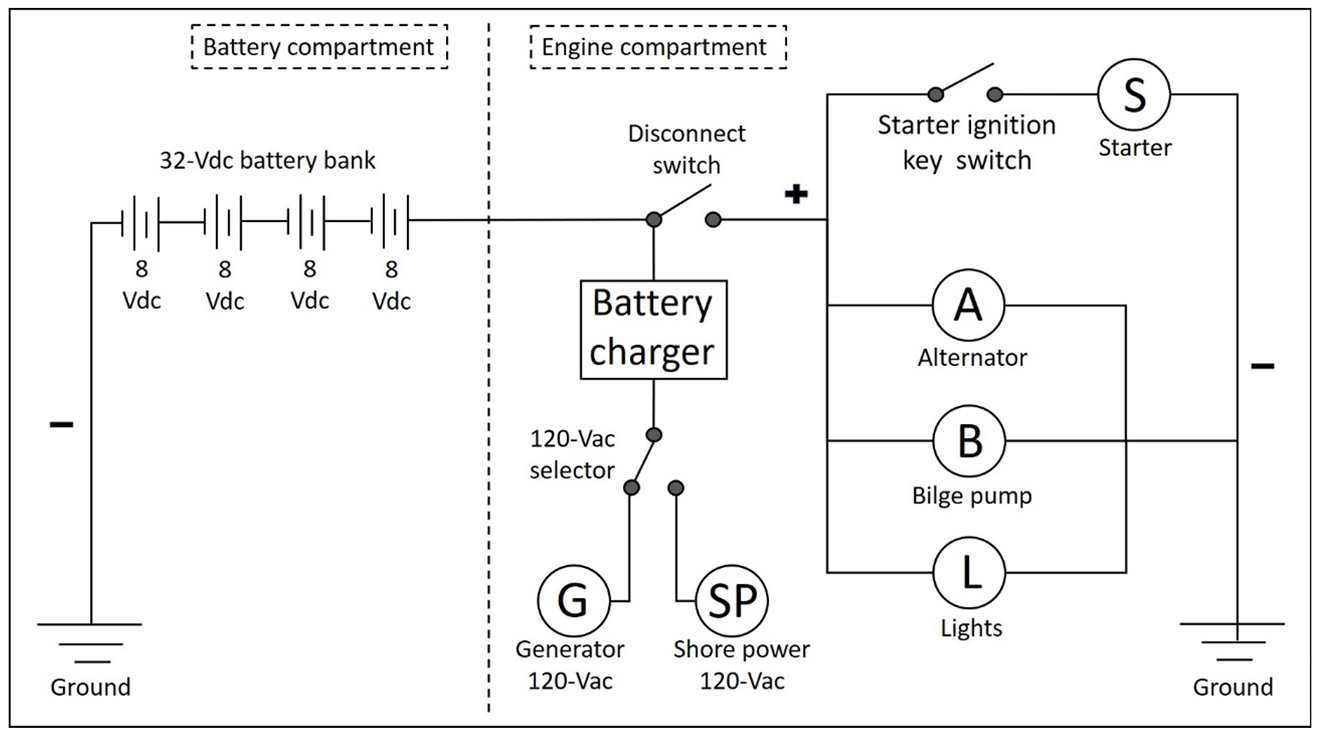

Internally, the lazarette is separated into 2 unventilated compartments, forward and aft, by a watertight bulkhead. The forward section of the lazarette (known on board as the battery compartment) contains 2 fuel tanks (port and starboard). The 32-volt direct current (VDC) battery bank, comprising four 8-VDC batteries, is located between the fuel tanks (Figure 4). A fresh water tank and the steering gear are located in the aft compartment of the lazarette. An opening in the bulkhead leading to the steering gear space is closed with a dogged steel watertight door (Figure 3).

1.3 History of the occurrence

On 04 August 2020 around 1500,Footnote 4 the master of the tug Risco Warrior completed some of the items in the pre-departure checklist, such as checking the fluid levels of the engines; however, the battery water level check was not completed.

At approximately 1925, the Risco Warrior departed Menzies Bay, BC, with the barge Western Carrier in tow. The vessel had 3 crew members on board: the master, a mate, and a deckhand.

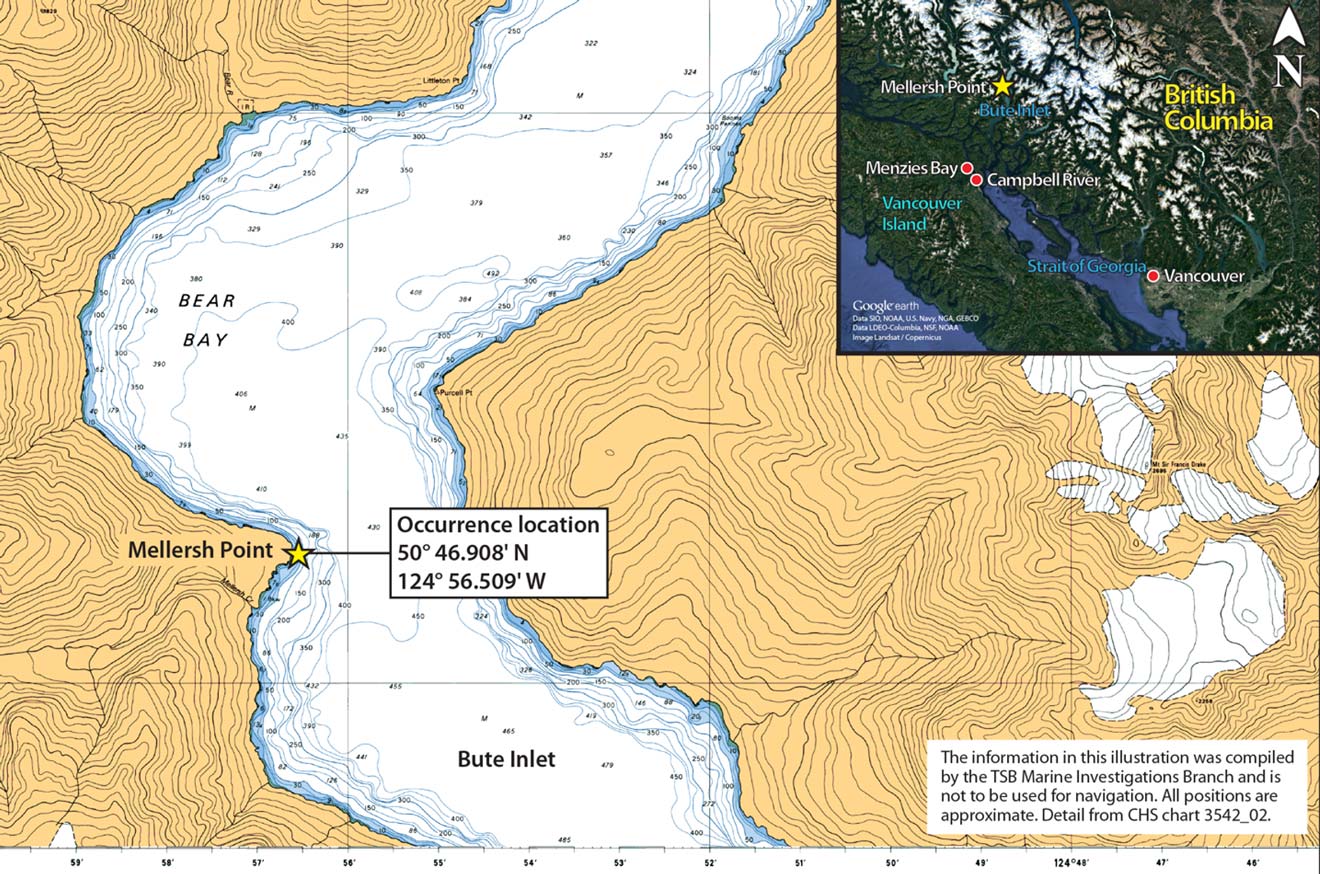

From 04 August to 07 August, the tug made stops to load and unload the barge. On 07 August at approximately 1215, the tug arrived at Mellersh Point, Bute Inlet, BC (Figure 5). At approximately 1230, the loading ramp of the barge was secured to the dock, while the tug held the barge against the dock. At this time, the master was in the wheelhouse, the deckhand was on the main deck of the tug, and the mate was on the dock discussing the loading plan of the barge with the client.

The crew on board heard an explosion and noticed that the lazarette hatch cover on the main deck had blown away, landing approximately 60 m away, in the sea. The master shut down all electrical power to the vessel.

The master sustained minor injuries from sound, and the deckhand sustained minor injuries from sound and debris. The master administered first aid to the deckhand on board.

The master identified the source of the explosion from the main deck and saw that the 32-VDC battery bank was exposed and damaged. The master and mate waited until vapours from the explosion had cleared. At about 1420, the mate sprayed a mixture of baking soda and fresh water into the battery compartment to neutralize acid that had been sprayed inside the compartment during the explosion.

Around 2000, the tug Midnight Drifter took the Risco Warrior and the barge Western Carrier in tow. At approximately 2315, the barge was unloaded at Campbell River, BC, and secured there on 08 August at approximately 0030. The tug Risco Warrior was later towed to Menzies Bay and secured for repairs.

1.4 Environmental conditions

At the time of the occurrence, the sky was clear and visibility was about 15 nautical miles (NM). The sea was calm. The air temperature was approximately 14 °C.

1.5 Damage

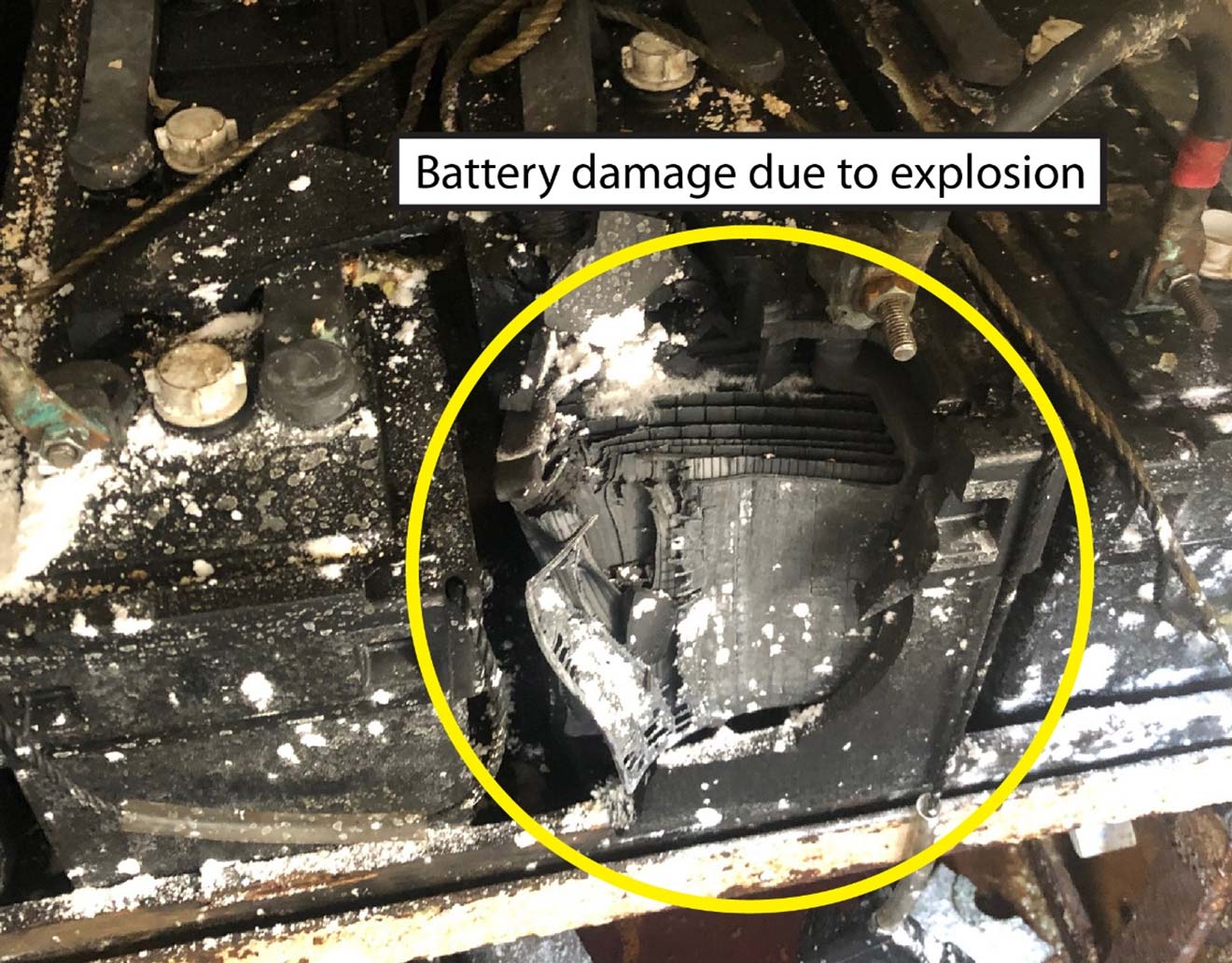

An explosion had occurred inside the second battery from the starboard side of the 32-VDC battery bank, and the battery was damaged as a result (Figure 6). The steel structural frames and bulkhead adjacent to the battery bank in the battery compartment were bent (Figure 7).

1.6 Personnel certification and experience

At the time of the occurrence, the master of the Risco Warrior held a certificate of Master, Limited for a Vessel of Less Than 60 Gross Tonnage, issued on 22 February 2016. The certificate was valid for tugs owned or operated by Marine Link Transportation Ltd., on inside passage, Victoria to Prince Rupert, in BC coastal waters not more than 10 NM from shore. He also held certificates for Small Vessel Operator Proficiency (SVOP), Radio Operator Certificate – Maritime Commercial (ROC-MC), and Marine Emergency Duties (MED) with respect to basic safety. The master started working as a deckhand in the fishing industry and on landing craft, tugs, and crane vessels. He had 24 years of seagoing experience. He joined Marine Link Transportation Ltd. as a master in August 2016.

The mate held a certificate of Master, Limited for a Vessel of Less Than 60 Gross Tonnage, issued on 26 September 2017. The certificate was valid for the towing vessels Aqua Totem, Paty S, River Brace, and Bash, and for the passenger vessel Squamish Relay, operating in Howe Sound and Quatsino Sound, in BC coastal waters not more than 25 NM from shore. The mate also held valid SVOP and MED certificates. He had 10 years of seagoing experience. The mate joined Marine Link Transportation Ltd. in April 2020.

The deckhand had 9 years of seagoing experience, 5 of which were on fishing vessels. The deckhand did not have any MED certificates. He joined Marine Link Transportation Ltd. in February 2020.

1.7 Vessel certification and inspection

As a commercially operated vessel with a gross tonnage (GT) of not more than 15, the Risco Warrior was required to be registered with Transport Canada (TC) but was not required to undergo periodic inspections by TC or to have a certificate of inspection to operate.Footnote 5 However, under section 106 of the Canada Shipping Act, 2001 (CSA 2001), a vessel’s AR is responsible for ensuring that the vessel complies with all applicable regulations.

Although periodic inspections are not required, TC can randomly inspect any vessel for compliance with the CSA 2001 and its regulations.Footnote 6

Following the investigation into the sinking of the tug Syringa off Sechelt, BC, in 2015, the Board issued a safety concernFootnote 7 that

without adequate oversight by the Department of Transport, shortcomings in the safety management and operations of tugs less than 15 GT may not be addressed.

The investigation determined that there was no record that TC had ever inspected the Risco Warrior.

1.8 Small Vessel Compliance Program

The Small Vessel Compliance Program (SVCP) is a voluntary TC program that provides tools to help ARs (or owners) meet their legal obligations.Footnote 8 As part of the SVCP, ARs are required to self-inspect their vessels. The program is available to ARs of non-pleasure vessels of less than 15 GT, passenger vessels of up to 15 GT carrying 12 passengers or less, and fishing vessels of up to 15 GT.

Before a vessel is enrolled in the SVCP, it must be registered with TC. To begin the SVCP process, and upon request, TC provides the AR with a report template and checklist, which offer a simplified explanation of applicable regulatory requirements, such as safety procedures, operations, equipment, maintenance, and emergency preparation. The AR completes this document to the best of their knowledge and understanding, although the AR can request the assistance of TC or an independent marine consultant in completing the document.

Once TC has reviewed the submitted package and concluded that its content is satisfactory, TC enrols the vessel in the SVCP and sends a confirmation letter to the AR. TC also issues a decal indicating compliance, which the AR must post visibly on the enrolled vessel.

TC does not routinely conduct inspections when a vessel enrols in the SVCP. Enrolment is valid for a 5-year period, during which the AR completes an annual report to demonstrate the vessel’s compliance with regulatory requirements. Every 5 years, the AR is required to submit a more detailed compliance report.

TC provided statistics to the TSB on 09 September 2020 indicating that a total of 28 728 registered commercial vessels of less than 15 GT are operating across Canada. Of these vessels, 12 742 are passenger vessels and workboats, and of these, 2047 vessels (about 16%) are enrolled in the SVCP. However, none of the vessels in this program are tugs. TC’s Marine Safety and Security Integrated National Oversight Plan recorded 950 small vessel compliance inspections under this plan in the 2019–20 fiscal year and 359 inspections in fiscal year 2020–21 (a lower number than planned because of restrictions in place during the COVID-19 pandemic).

A Small Vessel Compliance Program for Fishing Vessels of less than 15 GT (SVCP-F) was established in July 2017 to help owners meet the requirements of the new Fishing Vessel Safety Regulations.

TC has also developed an SVCP for tugs of less than 15 GT (SVCP-T). This program was not in effect at the time of the occurrence. A Ship Safety Bulletin announcing the addition of tugs to the SVCP was published on 13 January 2022.Footnote 9

1.9 Transport Canada Concentrated Inspection Campaigns

TC Marine Safety and Security conducts Concentrated Inspection Campaigns (CICs) at least every 2 years. A CIC addresses specific areas where inspectors have encountered high levels of deficiencies or where new regulatory or international convention requirements have recently entered into force. In the past, TC conducted CIC inspections only on international vessels, as part of the Paris and Tokyo Memoranda of Understanding on Port State Control. TC subsequently adopted the international approach and began conducting CICs on Canadian domestic vessels in 2014–15.

In the CIC conducted between January and March 2017, 30 tugs of less than 15 GT and 30 tugs of 15 GT or greater were inspected. TC concluded that tugs of less than 15 GT had significantly more instances of regulatory non-compliance than tugs of 15 GT or greater.Footnote 10

The 2018–19 CIC was the fourth conducted on domestic vessels. According to the report on the 2018–19 CIC,Footnote 11 83 vessels were inspected nationwide, 49 of which were inspected under the annual inspection category and 34 through quadrennial inspections per the Hull Inspection Regulations.Footnote 12 None of these vessels was less than 15 GT; 19 were tugs. The data showed that vessels inspected every 4 years had more deficiencies than those inspected annually.

1.10 Regulations governing the inspection of towing vessels in other countries

Given the high rate of incidents involving U.S.-flagged towing vessels, the U.S. Congress reclassified them in 2004 to make them subject to inspection. As a result, towing vessels and tows are now subject to a specific rule developed by the U.S. Coast Guard that is aimed at reducing the incident rates. In June 2016, new towing vessel regulations were published that included previously uninspected tugs of 26 feet (7.9 m) or more in length and some towing vessels less than 26 feet in length when towing a barge carrying oil or other dangerous goods. RegulationsFootnote 13 are now in place that require these vessels to be inspected by the U.S. Coast Guard or other third-party organizations (such as classification societies).

In Australia, tugs are considered domestic commercial vessels and are required to have a certificate of survey unless they are exempted (for example, small vessels in sheltered waters, small sailing vessels, and existing vessels that did not need a survey before 2013).Footnote 14 Domestic commercial vessels are regulated under the Marine Safety (Domestic Commercial Vessel) National Law Act 2012, which underpins the National System for Domestic Commercial Vessel Safety.

1.11 Independent survey report

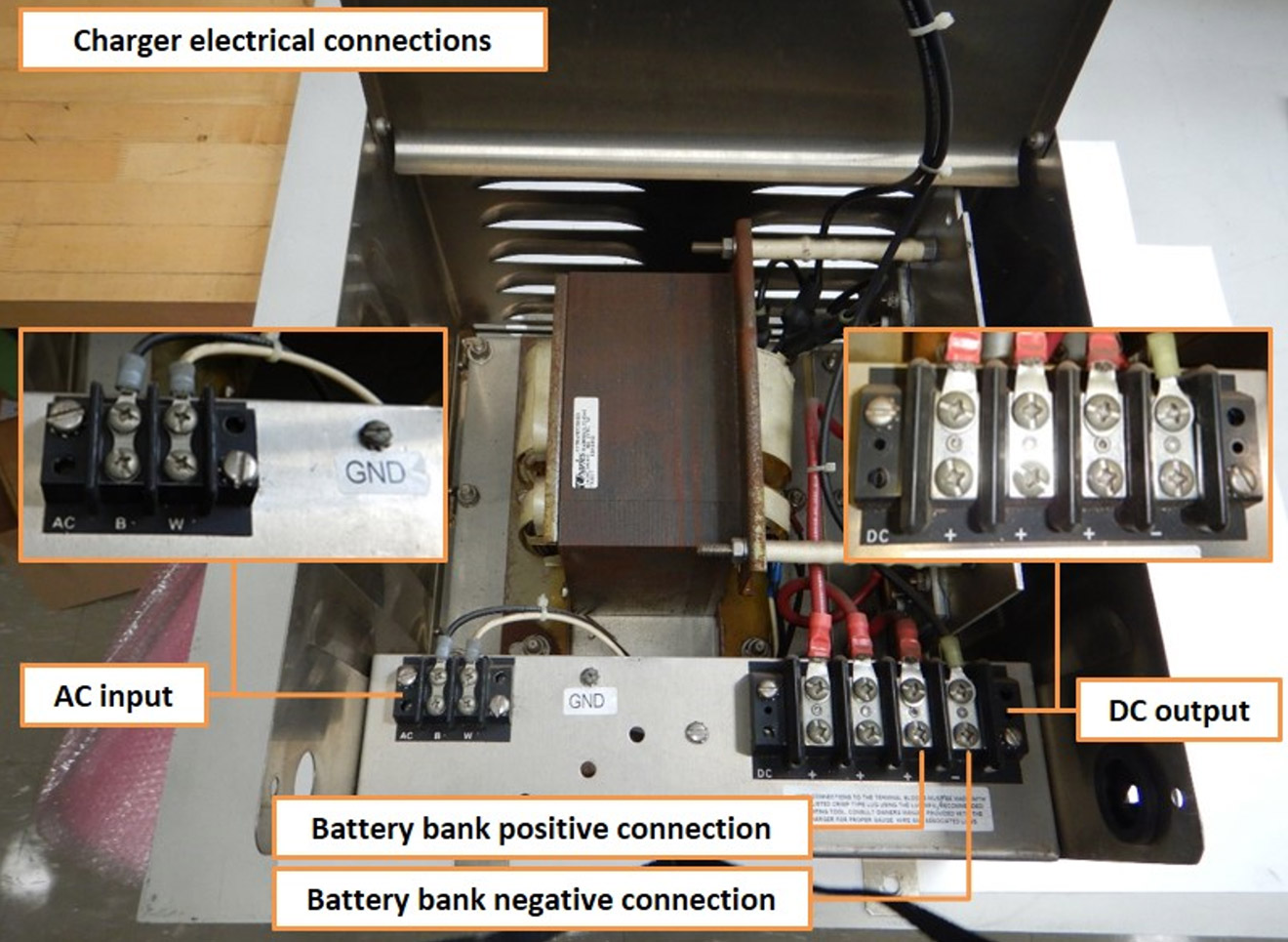

In June 2020, an independent survey of the Risco Warrior was carried out for Glory Days Towing Ltd. to ascertain the vessel’s condition and to make an appraisal for insurance purposes. The survey identified a number of areas with deficiencies. Those related to the electrical system were the following (Figure 4):

- Protective covers were missing from the starting and ship power batteries.

- Ship power batteries were not secured.

- Protection against chafing for wires and cables was missing.

- The electrical system was not properly sized in relation to the rated overcurrent circuit protection.

- Waterproofing was recommended for all electrical wiring connections that may be exposed to moisture.

- The alternating current (AC) shore power input connector needed to be replaced with a proper plug.

The report also advised the owners to comply with TC regulations, WorkSafeBC regulations, and other applicable rules and safety regulations.

1.12 Electrical load distribution

The 32-VDC battery bank powered the port and starboard main engine starters, the bilge pumps for the battery compartment and engine room, 2 spotlights, and all of the engine room lights (Figure 8).

Note: “VAC” means “volts alternating current.”

When the vessel engines were not running and the disconnect switch was engaged, the 32-VDC battery bank provided voltage to the engine room lights, bilge pumps, and the starboard engine starter, when required. The 32-VDC battery bank was charged through a direct connection from a 120-volt alternating current (VAC) battery charger, which provided a steady 32-VDC output to the battery bank. The charger was powered either by an on-board generator or by shore power, as described above.

When the starboard engine was running and the disconnect switch was engaged, the starboard engine alternator provided a 32-VDC recharging voltage to the battery bank. The voltage output from the alternator was 34 to 36 VDC. Therefore, the voltage coming from the starboard alternator was stronger than the voltage coming from the battery charger.

When the starboard engine was powered down, the battery charger took over to recharge the 32-VDC battery bank.

The output from the 12-VDC battery was converted to 110 VAC by an inverter and was used as a backup power supply for navigation and communication equipment.

The company changed the 32-VDC battery bank, which required regular maintenance, approximately once every 3 years. In February 2019, the company technician replaced the 32-VDC battery bank with a new battery bank of the same kind and configuration.

In May 2019, the company installed a new 7-kW diesel generator in the engine room to supply 120 VAC to power all hotel services, including the cooktop and the refrigerator, and all navigational and communication equipment on board.

1.13 Battery installation and ventilation

The lazarette, where the batteries were installed, did not have any means of ventilation. The crew reported that, when they needed to access the compartment, they left the hatch open for a few hours to air the compartment out naturally. The battery compartment was a confined space according to WorkSafeBC regulationsFootnote 15 and Part 14 of the Maritime Occupational Health and Safety Regulations.Footnote 16

Finding: Other

The 32-VDC battery bank was kept in an unventilated compartment, which was a confined space. WorkSafeBC requires the employer to provide written procedures that guide crew members in minimizing or eliminating hazards when entering a confined space; however, no such written procedures were available on board the Risco Warrior.

In addition to regulations, TC publishes standards, safe practices, and guidelines that govern the construction and operation of vessels. TP 127 Ships Electrical StandardsFootnote 17 states in detail how batteries must be stored, installed, and arranged on board. The standard identifies the hazards associated with charging batteries on board and details the necessary ventilation requirements to prevent the accumulation of hazardous gases. The standard also defines the requirements for securing batteries, protecting battery connectors, and testing.

Information regarding the battery installation was also provided in the battery manufacturer’s safety data sheet (SDS).Footnote 18 The SDS mentions that highly flammable hydrogenFootnote 19 gas is generated during charging and operation of batteries. It also states that batteries must be stored under roof in cool, dry, well-ventilated areas separated from incompatible materials and from activities that may create flames, spark, or heat.

In 2016, the master had noticed that the battery bank was in an enclosed compartment with no ventilation and had advised the owner and maintenance supervisor in writing about possible dangers due to lack of ventilation. The investigation could not determine if any action had been taken in response.

1.13.1 Battery charging system

The battery charger for the 32-VDC battery bank was an original installation that came with the vessel when the company purchased the tug.

The 32-VDC battery bank had 2 means of charging. The 1st was via a charging selector panel, where output from either a diesel generator, while at sea, or from shore power while docked, was selected as needed.

The 2nd means of charging was through the starboard engine 32-VDC alternator, which fed directly through a disconnect switch to the battery bank (Figure 8). The disconnect switch was used to electrically disconnect the path between the alternator and other equipment to the battery bank for maintenance purposes. Unless the tug was on shore power, the on-board diesel generator was always in service.

The 32-VDC battery charger did not have any overcharge circuitry protection system.Footnote 20 At the time of occurrence, both main engines were in operation, and the 32-VDC battery bank was being charged simultaneously by the starboard engine alternator and the battery charger.

1.13.2 Alternator charging the 32-VDC battery bank

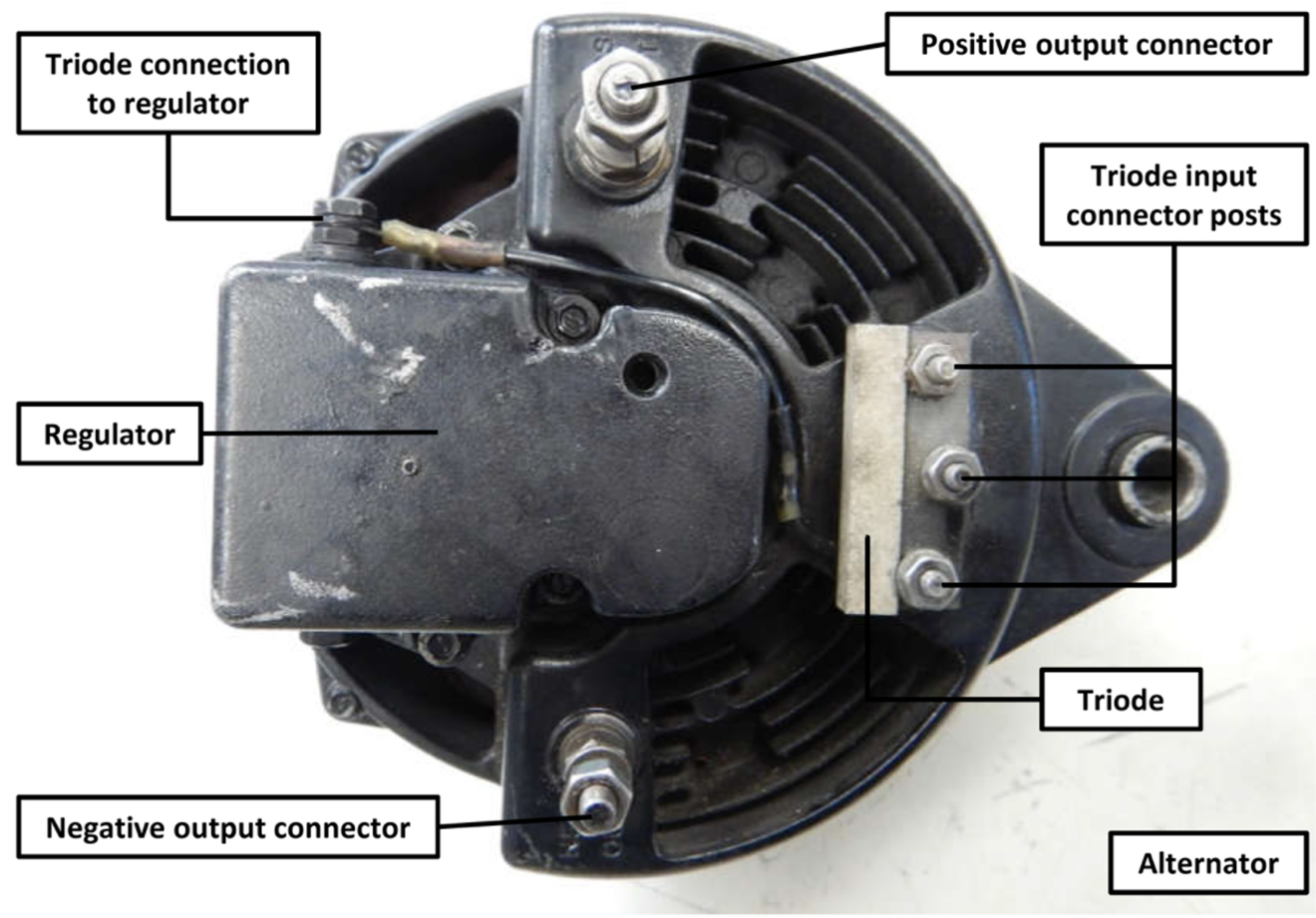

The alternator had no marking other than a sticker indicating “32 volts” and some handwritten markings. The investigation could not identify the manufacturer, date, model, or serial number of the alternator. The components of the alternator (the regulator, triode, and connectors) are shown in Figure 9.

1.14 Lead–acid battery and its maintenance

The four 8-VDC lead–acid batteries were constructed of several single cells connected in series. The distributor of the batteries was Canadian Energy, and the model number was S827. The battery cable was an arc welding cable, size 2/0 American wire gauge (AWG). The charger output cables were rated at 600 V and size 6 AWG.

Each 8-VDC battery on the Risco Warrior was composed of four 2-VDC cells. Within each cell, plates made of lead were immersed in the electrolyte, a highly corrosive sulphuric acid solution. Specifically, each cell was composed of 12 negative plates made from sponge lead and 11 positive plates made from lead dioxide, positioned alternately, side by side, and immersed in the electrolyte. The positive plates were individually encased in porous polymer envelopes to prevent short circuits. Each cell had a water filler cap in which there was a mechanical valve to release internal pressure due to gas buildup inside the battery while charging.

Oxygen in the active material (lead dioxide) reacts with the hydrogen ions to form water, and the lead reacts with the sulphate ions to form lead sulphate. Lead sulphate can build up when the solution level drops and plates are exposed. This leads to damage to the plates, reduced capacity, and lower performance. The electrolyte solution should cover the plates at all times, and the batteries must be regularly topped up with distilled or de-ionized water to compensate for losses due to boiling and evaporation.

A 2-page battery leafletFootnote 21 is available when the batteries are purchased. In one of the safety precautions, the leaflet states that plates should be covered before the batteries are charged and that electrolyte levels should be checked and topped up with distilled water as needed after charging is complete. The frequency of adding water depends on usage, charge method, and operating temperature. A new battery should be checked every few weeks to determine the requirements.

1.15 TSB laboratory reports

The TSB completed the following laboratory reports in support of this investigation:

- LP140/2020 – Battery explosion

- LP095/2021 – Alternator examination and testing

1.16 Examination of the 32-VDC battery bank and charging system

1.16.1 32-VDC battery bank

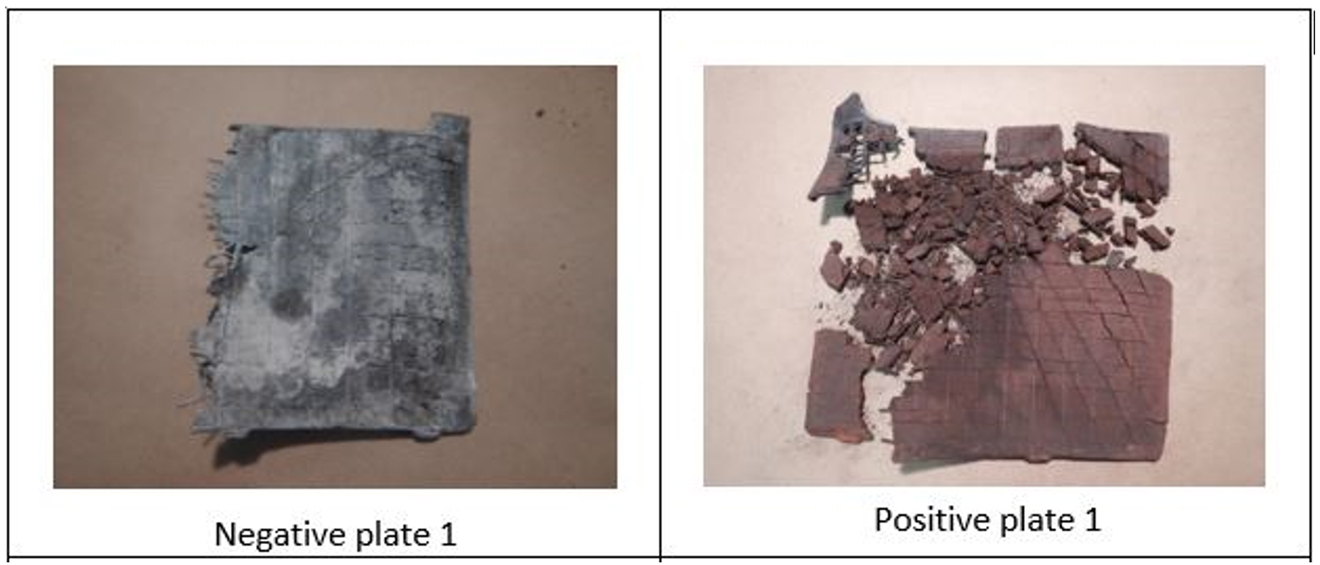

Following this occurrence, the TSB Engineering Laboratory examined the 32-VDC battery bank, its charger, the alternator attached to the battery bank through the disconnect switch, and the disconnect switch itself. In the damaged battery, cell 4 had exploded and cell 3 was damaged. Electrolyte levels in the damaged battery were at 50% in cell 1, 90% in cell 2, 25% in cell 3, and nil in cell 4. Electrolyte levels in the remaining 3 batteries were between 90% and 100% of the required level.

The state of charge (SoC) of the battery cells was also estimated using the method described in the Battery Council International’s Battery Technical Manual. The SoC is the level of charge of an electric battery relative to its capacity and is rated in percentage. The SoC was shown as 0% in some of the cells, indicating the beginning of damage to the internal plates and degradation of electrolyte, which was likely caused by overcharging.

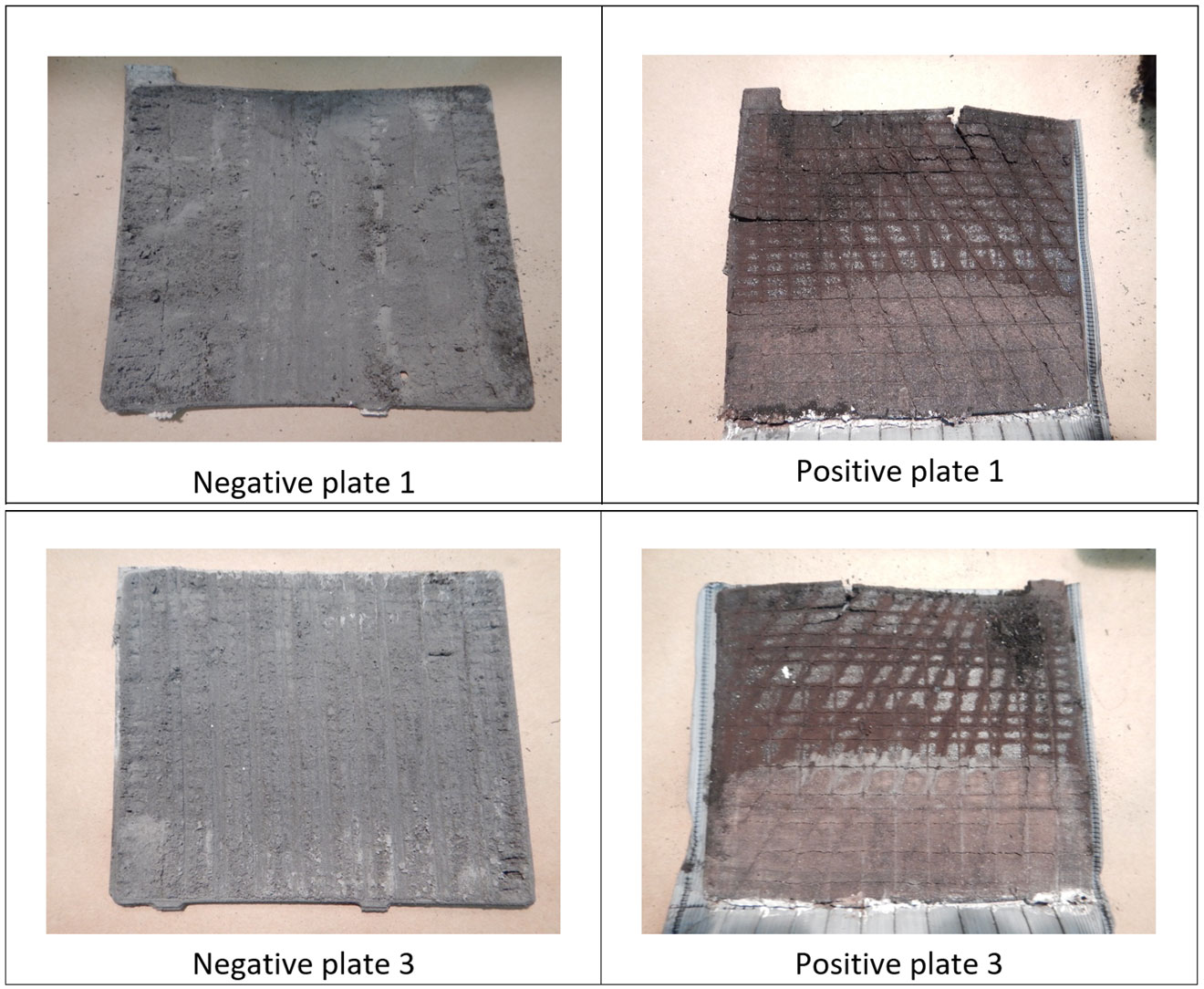

All battery cells were examined to detect any lead sulphate deposits on the top and visible portion of the plates. The examination revealed the following:

- Every cell of the 1st battery from the starboard side showed lead sulphate buildup on top of the visible negative plates. Buildup in cells 2 and 4 was more pronounced.

- Every cell of the 3rd battery from the starboard side showed lead sulphate buildup on top of the visible negative plates. Buildup in cell 3 was more pronounced.

- Every cell of the 4th battery from the starboard side showed lead sulphate buildup on top of the visible negative plates. Cell 2 showed a cracked positive plate and cell 3 showed a more pronounced buildup of lead sulphate.

- Lead sulphate buildup and crystallization were seen in cell 3 of the damaged battery (Figure 10).

- The negative plates of cell 4 in the damaged battery showed signs of lead sulphate buildup, stratification,Footnote 22 and deterioration of plate material. The 1st positive plate had disintegrated (Figure 11).

- The water filler cap on cell 4 of the damaged battery was missing. The investigation could not determine whether the filler cap was missing before the explosion or due to the explosion.

- All of the mechanical pressure-relief valves for the filler cap on the 3 undamaged batteries were found to be functional.

1.16.2 32-VDC battery charger

The vessel’s 32-VDC battery charger had been discontinued by the manufacturer. The charger had 3 separate outputs that could charge 3 battery banks simultaneously. At the time of the occurrence, only one output of the charger was used to charge the 32-VDC battery bank. Upon visual inspection by the TSB Engineering Laboratory, the charger’s internal circuitry appeared to be clean, with no signs of overheating (Figure 12).

1.16.3 Alternator

The regulator of the alternator was removed, and carbon dust was found inside the brush assembly housing. The brush assembly was composed of 2 brushes in good condition.

The triode was removed for inspection. The post holes of the triode input connector had been altered to fit the alternator connector posts, indicating that this triode was not approved for use in this alternator (not an original equipment manufacturer part). The triode was disconnected from the alternator and tested for electrical leakage. The triode was in good operational condition.

The regulator was removed for testing and was found to be in good operational condition. The alternator was tested with the regulator connected, and it produced a steady 32-VDC output. It was found to be fully functional.

1.17 Authorized representative responsibilities

The CSA 2001and its regulations and standards set out certain responsibilities for owners and operators of small commercial vessels. Regardless of whether the vessel is inspected or not, the AR is required to provide:

- procedures both for the safe operation of the vessel and for dealing with emergencies; Footnote 23 and

- written instructions to the master that, at a minimum, define the procedures and, if applicable, the policies Footnote 24 to be followed to ensure that each member of the complement, before being assigned any duty, is familiar with the shipboard equipment and their duties. Footnote 25

The AR is responsible for ensuring that the vessel and its machinery and equipment meet regulatory requirements and that the crew members receive safety training. Footnote 26 The master, along with the AR, is responsible for using all reasonable means to make sure the vessel is seaworthy before and during each voyage, to protect the vessel and the people on board from hazards, and to operate within legal limits. Footnote 27

In this occurrence, on-board documentation and record-keeping to support crew members on aspects such as training, familiarization, drills, and maintenance were limited. For example, the battery manual was not on board the vessel.

The company was unable to provide any maintenance documentation for the vessel.

1.18 Safety culture and safety management systems

Safety culture refers to how safety is addressed and communicated in the workplace.

Safety culture is the way that safety is perceived, valued, prioritized, and managed throughout all levels of a company. It encompasses the attitudes, beliefs, perceptions, and values of all employees in an organization in relation to safety. One of the most important factors affecting safety culture is the company management’s degree of commitment to safety. It is vital that owners and operators actively demonstrate their commitment by providing leadership and resources to manage safety. For example, management should support employees in ensuring safe operations and reporting of safety-related issues, and provide documented procedures.

One way to encourage a good safety culture is to use a formal safety management system (SMS). The principal objective of an SMS on board a vessel is to ensure safety at sea, prevent human injury or loss of life, and avoid damage to property and the environment. Safety management involves individuals at all levels of an organization and requires that a systematic approach be taken to identify hazards and mitigate risks.

Some elements of an effective SMS include the following:

- Operating procedures for the vessel and the use of associated checklists

- Maintenance procedures for the vessel and its associated equipment

- Documentation and record-keeping procedures

- Procedures for identifying hazards and managing risks

- Procedures to prepare for, and respond to, emergency situations

- Drills, training, and familiarization for the vessel’s crew

Currently, only Canadian vessels that operate on international voyages and are subject to Chapter IX of the International Convention for the Safety of Life at Sea must comply with the existing Safety Management Regulations. These regulations do not apply to the majority of domestic vessels (referred to as “non-convention” vessels).

In 2010, TC began formal consultations on a regulatory proposal to introduce safety management regulations to Canadian non-convention vessels, including those of less than 15 GT. At that time, industry expressed concerns, primarily concerning costs and feasibility, that the new regulations would be too onerous for small companies that operate small vessels. In response to stakeholder concerns, TC amended its regulatory proposal in 2012 to include only vessels greater than 24 m in length and those carrying more than 50 passengers.

However, TC has recently proposed to expand the application of the regulations further. TC held consultationsFootnote 28 during the fall 2020 meeting of the Canadian Marine Advisory Council and also discussed this regulatory proposal with industry groups in 2020.

TC will pre-publish the proposed regulationsFootnote 29 in the Canada Gazette, Part I in the spring of 2022. They are expected to be published in the Canada Gazette, Part II in 2023.

Under the proposed Marine Safety Management System Regulations, 2021, Class 4 vessels (such as tugs like the Risco Warrior) would be required to have a documented SMS that names a ship manager.Footnote 30 This documented SMS would include written instructions and procedures for equipment inspection, maintenance, and testing. It would also include a defined level of authority and lines of communication between shore and vessel personnel and procedures for internal reviews of the SMS.

In this occurrence, although the company did not have any written safety procedure, there was an informal practice that, before the first trip of every month, the master of the Risco Warrior was required to check the batteries for visible damage, check the battery electrolyte levels, top up with distilled water when needed, and record the action in a checklist. The certification required for the master to operate the vessel did not require knowledge of batteries or battery maintenance. The company had not provided the master with training, familiarization, or procedures related to battery maintenance. This checklist was the only written document that, once checked by the master, would go to the shore staff. However, the investigation could not determine whether the management conducted any active monitoring of the checklist items.

The investigation determined that the batteries were not checked in July 2020 or before or during the occurrence voyage. The company had no record of when the 32-VDC battery bank was last inspected by the company or ship staff, nor of when the water level of the battery bank was last topped up.

1.19 TSB Watchlist

The TSB Watchlist identifies the key safety issues that need to be addressed to make Canada’s transportation system even safer.

Safety management is a Watchlist 2020 issue. The Risco Warrior did not have a formal SMS nor procedures for the safe operation of the vessel or procedures for dealing with emergencies, as required by the CSA 2001.

|

ACTIONS REQUIRED Safety management will remain on the Watchlist for the marine transportation sector until:

|

Regulatory surveillance is a Watchlist 2020 issue. The Risco Warrior was not subject to periodic inspection by TC because it was less than 15 GT, and it had not been subjected to a random compliance inspection. The Board has also previously identified the lack of regulatory oversight for these types of vessels as a safety concern.Footnote 31

|

ACTIONS REQUIRED Regulatory surveillance will remain on the Watchlist for the marine transportation sector until

|

1.20 Previous occurrences

Previous occurrences with battery fires and explosions reported to the TSB since 1987 are as follows:

M19A0419 – On 19 October 2019, the passenger vessel Kawartha Spirit reported that the starting battery exploded when the captain attempted to start the engine. No injuries were reported.

M16P0052 – On 02 February 2016, the Canadian Coast Guard (CCG) vessel W.E. Ricker reported that its starting battery for the emergency generator exploded while a crew member was starting the emergency generator at Sydney, BC. The affected battery unit was replaced.

M11L0146 – On 19 October 2011, the fishing vessel Jean Philippe had 2 battery explosions, caught on fire, and sank alongside the wharf in Forillon, Quebec. The captain was treated at the hospital for smoke inhalation. Minor oil pollution was reported.

M11L0058 – On 31 May 2011, the CCG vessel F.C.G. Smith had an explosion of the starting battery for its generator while berthed in Sorel-Tracy, Quebec. No injuries or pollution were reported.

M10C0034 – On 22 May 2010, while on maritime security, the CCG vessel Isle Rouge had a battery explosion in the engine room. The ignition source was undetermined.

M09C0030 – On 31 July 2009, while preparing to get underway from CCG Prescott Base, the CCG vessel Cove Isle had a battery explosion in the engine room, causing minor damage.

M08L0074 – On 14 June 2008, the CCG vessel Louis M Lauzier reported a battery explosion.

M06M0075 – On 04 August 2006, the Atlantic Odyssey reported that it was without power and disabled due to a battery fire. The CCG towed the vessel toward Shelburne, Nova Scotia.

973-21-938 – On 12 March 1987, the tug Seaspan Discovery reported that an explosion had occurred in its battery compartment while it was docked at Roberts Bank, BC. The battery bank consisted of six 12-VDC batteries, arranged 2 batteries in a plate with 3 plates connected in a series. The battery bank was kept in a locker room on the aft main deck. The ventilation in the battery room was inadequate, and the accumulation of the explosive hydrogen gas was ignited by an unknown source of spark. Structural damage to the battery compartment was reported.

2.0 Analysis

The investigation determined that maintenance, familiarity with regulatory requirements, the safety culture, and Transport Canada (TC) regulatory oversight were factors in this occurrence.

2.1 Battery explosion

Hydrogen gas is a normal by-product of battery charging. The hydrogen gas concentration in the unventilated compartment had likely reached its lower explosive limit such that a spark within the compartment caused it to explode.

The batteries were not regularly topped up with water; as a result, while the batteries were being charged, the increased resistivity of the exposed top portion of the plates caused overheating. This amplified the following problems: overheating of the electrolyte, evaporation, gas buildup, increasing internal pressure in the compartment, and conversion of the water portion of the electrolyte into hydrogen and oxygen. Consequently, the risk of explosion of the gases increased.

Finding as to causes and contributing factors

Without ventilation in the battery compartment, hydrogen gas accumulated, causing a hazardous condition.

The extent of lead sulphate buildup, crystallization, and stratification seen in all 4 batteries indicated that electrolyte levels had been low for some time before the occurrence and therefore had not been maintained in accordance with the manufacturer’s standards. In addition, the investigation revealed that water had not been added to the battery bank in July and August (before the occurrence), and it could not be determined when the electrolyte was last topped up with water. However, the remaining 3 batteries had electrolyte levels of 90% to 100% at the time of the occurrence, which was not consistent with the condition of the batteries.

The batteries were connected to a charger that had no overcharge circuitry protection system. Therefore, it could be surmised, from the lead sulphate buildup on the negative plates of these batteries, that constant charging had depleted the water, resulting in low electrolyte levels and electrolyte degradation and raising the temperature, which caused cracking of the positive plates of cell 3 of the damaged battery.

Low water levels caused stratification of the plates, cracks and disintegration of the positive plates, as well as lead sulphate buildup on the plates, which increased the internal resistivity of the damaged battery. In addition, the 3 negative plates of cell 4 of this battery showed reduced surface material and sulphation, which also indicates overheating of the plates caused by overcharging and low electrolyte levels.

Finding as to causes and contributing factors

Continuous unregulated charging of the damaged battery caused the water in the electrolyte to break down into hydrogen and oxygen and evaporate. The resulting low electrolyte levels combined with a lack of maintenance caused overheating and internal damage to the battery plates.

The June 2020 report on the independent survey of the Risco Warrior, which was conducted to ascertain its condition and make an appraisal of the vessel, indicated that the batteries (Figure 4) were kept without protective covers and were not secured, which did not meet the standards defined in TP 127 Ships Electrical Standards. Also, wires and cables were not waterproofed or protected against chafing. The company did not attempt to rectify any of those issues prior to the occurrence. Any damaged wiring, such as the bilge pump wiring or grounding wires, could have generated a spark inside the battery compartment.

Finding as to causes and contributing factors

A spark from an unknown source ignited the accumulated hydrogen gas in the unventilated battery compartment, causing the explosion.

2.2 Regulatory surveillance

Vessel owners and operators have the primary responsibility to manage safety. However, it is vital that TC provide effective oversight and proactively intervene to ensure that vessel owners and operators comply with regulations and standards and can manage the safety of their operations effectively.

Effective oversight is required to ensure that all authorized representatives (ARs), including ARs for tugs of less than 15 gross tonnage (GT), comply with all applicable regulations and standards. Unlike larger tugs, tugs of less than 15 GT are not required to be certified under the current Vessel Safety Certificates Regulations. Consequently, TC is often unaware of the conditions of the tugs in regard to the level of regulatory compliance. Although TC has the authority to conduct random inspections of tugs of less than 15 GT, these inspections are not conducted regularly.

TC conducted its first official Concentrated Inspection Campaign (CIC) for domestic vessels in 2014–15. TC has also worked to expand the voluntary Small Vessel Compliance Program to include tugs of less than 15 GT and thus help ARs make their vessels compliant with regulations. This specific program for tugs of this class was not in operation at the time of the occurrence; it began enrolling vessels on 13 January 2022.

Tugs of less than 15 GT are not required to have inspection certificates and therefore TC does not have structured regulatory oversight over these vessels. However, the consequences of not managing risks may be similar to those of tugs of 15 GT or greater. The results of the 2017 CIC show that a sampling of tugs of less than 15 GT had more deficiencies than a sampling of those of 15 GT or greater. It is therefore important that tugs of less than 15 GT be subject to a level of oversight similar to that for larger tugs to ensure that they are operated safely.

A TC inspection includes an examination of the batteries; the securing arrangements; the space where the batteries are located; the condition of the batteries, wiring and cabling; and other points defined in TP 127 Ships Electrical Standards.

Finding as to risk

In the absence of comprehensive regulatory surveillance and enforcement, there is a risk that tugs of less than 15 GT will continue to be operated with unsafe equipment and operating practices.

2.3 Authorized representative responsibilities

TC oversees vessels to ensure that they are being operated in accordance with the Canada Shipping Act, 2001 (CSA 2001) and its associated regulations. However, under this legislation, an AR is the person responsible for acting with respect to all matters related to a vessel that are not otherwise assigned to any other person. For the Risco Warrior, the AR was the owner.

The AR, along with the master, is responsible for using all reasonable means to make sure the vessel is safe and seaworthy before and during each voyage in order to protect the vessel and the people on board from hazards. In this occurrence, the master, who had joined the company 4 years before the occurrence, noticed that the batteries were kept in an unventilated compartment, which did not meet TP 127, and had notified the AR in writing. However, the battery bank was still in the compartment, which remained unventilated, at the time of the occurrence. In addition, the AR continued to operate the tug knowing that the 32 volts direct current (VDC) battery bank was kept in an unventilated compartment, which created a hazardous situation.

Finding as to risk

If tug operators do not implement applicable standards and comply with regulations, there is a risk that hazards will not be identified and managed safely.

The master had no training on lead–acid batteries or knowledge of how they function; however, he was required to carry out all general maintenance of the batteries and to top up water. The shore maintenance staff did not verify the checklist completed by the master and checked the batteries only when the master informed them of any visible issue. As a result, deficiencies with the batteries, for example low electrolyte levels, were not identified and corrected.

Finding as to causes and contributing factors

An informal division of responsibilities between shore maintenance staff and the master, as well as a lack of detailed instructions for battery maintenance, contributed to poor maintenance of the batteries, creating a hazardous condition on board.

2.4 Safety management systems and safety culture

A safety management system (SMS) is widely recognized as an effective method for assessing risk in the marine sector, although not all organizations are required to have a formal SMS in place. The Risco Warrior did not operate under an SMS, nor was it required to under SMS regulations in effect at the time of the occurrence. However, procedures for the safe operation of the vessel and for dealing with emergencies were still required for the vessel by the CSA 2001.

If a company does not have a strong safety culture, commercial pressures can lead to unsafe practices and the company may operate at the minimum level of safety required by regulations or may not comply with regulations. Over time, unsafe practices can become normalized as part of operations, so that they are no longer considered risks. For example, in this occurrence, as the vessel had been operating without any incidents related to the batteries since it was built, the master accepted the placement of the batteries in the unventilated battery compartment. Masters may be placed in a challenging position if they receive little support to make operational decisions that prioritize safety.

The safety issues identified in the Risco Warrior occurrence suggest potential shortcomings in the company’s safety culture. For example, the crew of the Risco Warrior did not mitigate the risks associated with the unventilated battery compartment when it was raised by the master in 2016. As well, the company did not provide detailed instructions about when to top up the battery water level and how much water was required, nor did it have any procedure for the shore staff to physically monitor battery conditions, which contributed to the poor condition of the batteries.

An SMS can assist owners and masters involved in towing operations to identify hazards and mitigate risks through education and the implementation of procedures.

Finding as to risk

If companies do not provide formal safety management processes, then there is an increased likelihood that hazards will not be identified and their associated risks will not be mitigated.

3.0 Findings

3.1 Findings as to causes and contributing factors

These are conditions, acts or safety deficiencies that were found to have caused or contributed to this occurrence.

- Without ventilation in the battery compartment, hydrogen gas accumulated, causing a hazardous condition.

- Continuous unregulated charging of the damaged battery caused the water in the electrolyte to break down into hydrogen and oxygen and evaporate. The resulting low electrolyte levels combined with a lack of maintenance caused overheating and internal damage to the battery plates.

- A spark from an unknown source ignited the accumulated hydrogen gas in the unventilated battery compartment, causing the explosion.

- An informal division of responsibilities between shore maintenance staff and the master, as well as a lack of detailed instructions for battery maintenance, contributed to poor maintenance of the batteries, creating a hazardous condition on board.

3.2 Findings as to risk

These are conditions, unsafe acts or safety deficiencies that were found not to be a factor in this occurrence but could have adverse consequences in future occurrences.

- In the absence of comprehensive regulatory surveillance and enforcement, there is a risk that tugs of less than 15 GT will continue to be operated with unsafe equipment and operating practices.

- If tug operators do not implement applicable standards and comply with regulations, there is a risk that hazards will not be identified and managed safely.

- If companies do not provide formal safety management processes, then there is an increased likelihood that hazards will not be identified and their associated risks will not be mitigated.

3.3 Other findings

These items could enhance safety, resolve an issue of controversy, or provide a data point for future safety studies.

- The 32-VDC battery bank was kept in an unventilated compartment, which was a confined space. WorkSafeBC requires the employer to provide written procedures that guide crew members in minimizing or eliminating hazards when entering a confined space; however, no such written procedures were available on board the Risco Warrior.

4.0 Safety action

4.1 Safety action taken

4.1.1 Glory Days Towing Ltd.

In response to the occurrence the company has completed the following safety actions:

- Forced air ventilation has been introduced into the battery compartment.

- New batteries, both 32 volts direct current (VDC) and 12 VDC, have been installed, including new cables and clamps.

- The 32-VDC alternator has been replaced with a new one.

- New charging systems with overcharging circuitry protection systems for all the batteries have been installed.

- Battery boxes, including liners and lids, have been replaced to ensure a secure and safe electrical system.

- Written policies and procedures for conducting safe operations and dealing with emergency situations have been developed.

This report concludes the Transportation Safety Board of Canada’s investigation into this occurrence. The Board authorized the release of this report on It was officially released on