Person overboard and subsequent loss of life

Fishing vessel Suvak

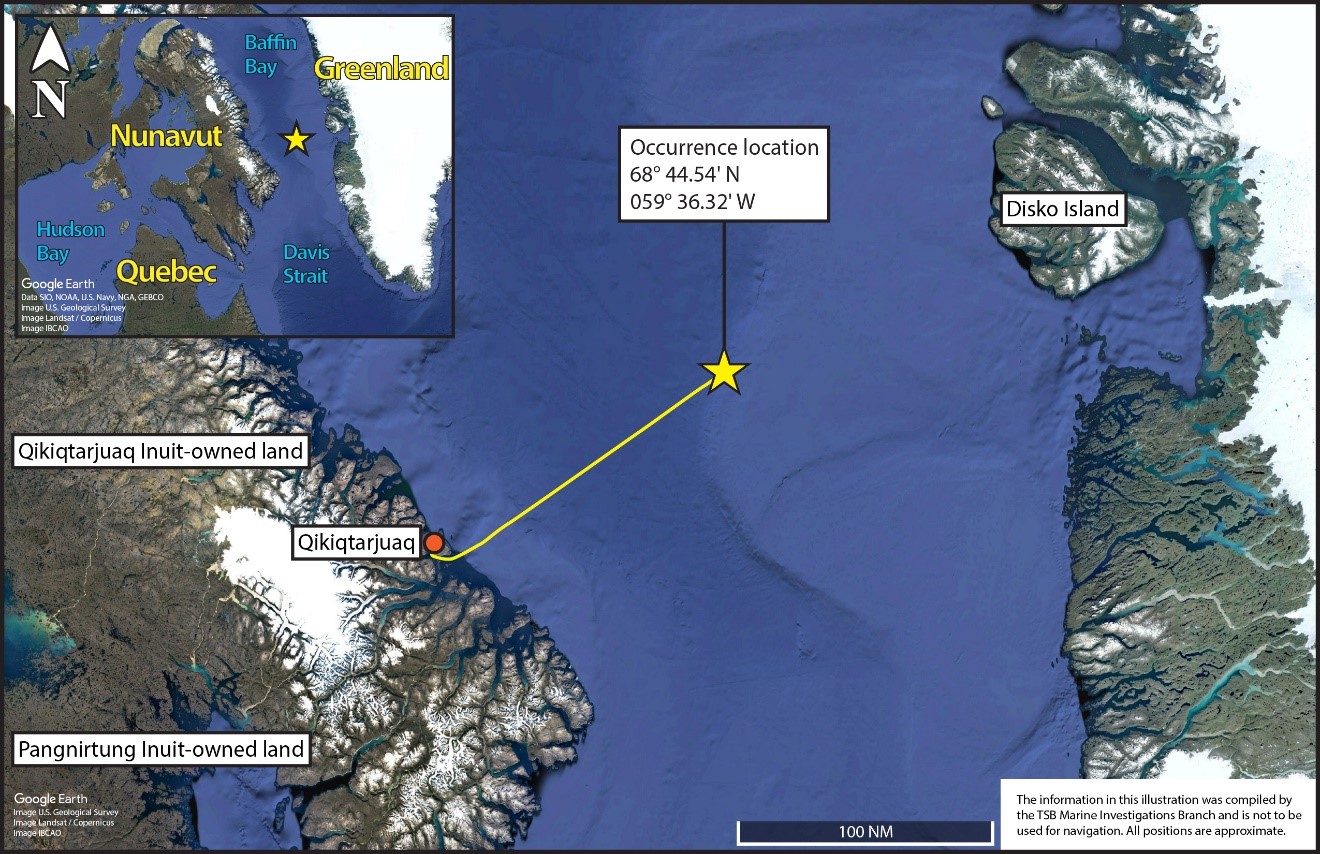

Davis Strait, approximately 120 NM northeast of Qikiqtarjuaq, Nunavut

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Executive summary

On 26 August 2021 at 0310 Newfoundland Daylight Time, a crew member on the fishing vessel Suvak went overboard while setting gillnets in Davis Strait, approximately 120 nautical miles northeast of Qikiqtarjuaq, Nunavut.

At the time, the Suvak was nearing the end of a 2-week fishing trip. Two crew members who were hauling and setting nets had been working long hours to complete all the fishing operation activities required before the vessel departed for port. They had set and hauled nets and completed other fishing operation activities throughout the day on 25 August and into the night, with 1 break of 1.75 hours. At the time of the occurrence, they had been awake for over 21 consecutive hours. The intention was for the crew members to have a rest period once the vessel departed. However, while setting nets in the early hours of the morning, one of the two crew members was pulled overboard after his arm became entangled in the buoy line. The crew member was recovered from the water and, despite significant lifesaving efforts, was later pronounced dead.

The investigation found that the 2 crew members who were setting the nets on the Suvak were experiencing sleep-related fatigue from a combination of acute and chronic sleep disruption, continuous wakefulness, and circadian rhythm disruptions, which reduced their cognitive abilities, including their ability to remain vigilant against risks. The crew member who went overboard had a smaller physical stature and had adapted the procedure for picking up the coils of buoy line to keep up the pace. In combination with mental and physical fatigue, this adaptation led to his arm becoming entangled in the buoy line.

The investigation identified risks related to the absence of fatigue management plans and risk assessments for operating procedures. It also identified a need for fishing allocation policies to take safety into account, and for emergency procedures, equipment, and drills for responding to entanglement situations to be implemented on board.

Oversight of occupational health and safety on fishing vessels registered in the Canadian territories

The investigation into this occurrence also found a gap in the oversight of occupational health and safety (OHS) on fishing vessels registered in the Canadian territories. Specifically, there had been no OHS inspections of the Suvak or of other fishing vessels registered in the territories. This was because the territories considered fishing vessels to be under Transport Canada’s jurisdiction, and Transport Canada considered OHS inspections of fishing vessels to be outside its jurisdiction. If there is no oversight of OHS on fishing vessels registered in the territories, there is a risk that crews of those vessels will be subject to OHS hazards in the workplace. Therefore, the Board recommends that

the Department of Transport, in collaboration with the Department of Employment and Social Development and the territorial governments, review the occupational health and safety oversight of fishing vessels registered in the territories to ensure effective workplace safety oversight.

TSB Recommendation M23-09

1.0 Factual information

1.1 Particulars of the vessel

| Vessel name | Suvak |

|---|---|

| Transport Canada official number | 808324 |

| International Maritime Organization number | 8710027 |

| Fisheries and Oceans Canada vessel registration number | 100646 |

| Flag | Canada |

| Port of registry | Iqaluit, NU |

| Type | Large fishing vessel |

| Gross tonnage | 346.03 |

| Length | 28.53 m |

| Breadth | 7.77 m |

| Depth | 5.30 m |

| Year built | 1987 |

| Propulsion | 1 diesel engine of 466 kW driving 1 controllable-pitch propeller |

| Crew complement | 16 |

| Registered owner and authorized representative | Masiliit Corporation |

| Managing company | Arctic Fishery Alliance |

| Recognized organization | Lloyd’s Register |

1.2 Description of the vessel

The Suvak (Figure 1) is a factory freezer fishing vessel of welded steel construction that is equipped for gillnet fishing of Greenland halibut. The vessel has 3 decks: the lower deck, the main deck, and the shelter deck (Figure 2). The fish hold and engine room are located on the lower deck. The factory is located on the main deck and includes a processing area and blast freezers. The primary net-setting area is also located on the main deck. The wheelhouse and top net house are located on the shelter deck.

The wheelhouse is fitted with navigation and communication equipment that includes medium and very high frequency digital selective calling radiotelephones and satellite telephones. The navigation console is located on the starboard side of the wheelhouse. A rigid inflatable boat that is used as a rescue boat is located on the shelter deck.

The vessel has an intercom system with speakers that allow for two-way communication at various locations throughout the vessel, including one in the top net house. The vessel also has a closed-circuit television system with cameras in various locations throughout the vessel. There is a camera in the top net house, but it was not working at the time of the occurrence.

1.3 Setting of gillnets

There are 2 areas of the vessel that are used for setting the gillnets: the primary net-setting area and the top net house. The nets are typically set from the primary net-setting area; however, when the vessel initially arrives on the fishing grounds and begins operations or departs them for port to offload, nets are also set from the top net house to provide more net-setting capacity. This additional capacity is needed because, on departure from the fishing grounds, the vessel typically sets multiple nets. The nets can be in the water for only a certain amount of time before the fish begin to spoil. When the vessel departs for port, multiple nets are set as close as possible to departure so that the fish will still be fresh when the vessel returns to haul them. On return to the fishing grounds, the vessel once again sets multiple nets. On the rest of the fishing days, the crew typically hauls, processes, and sets one net at a time using the primary net-setting area.

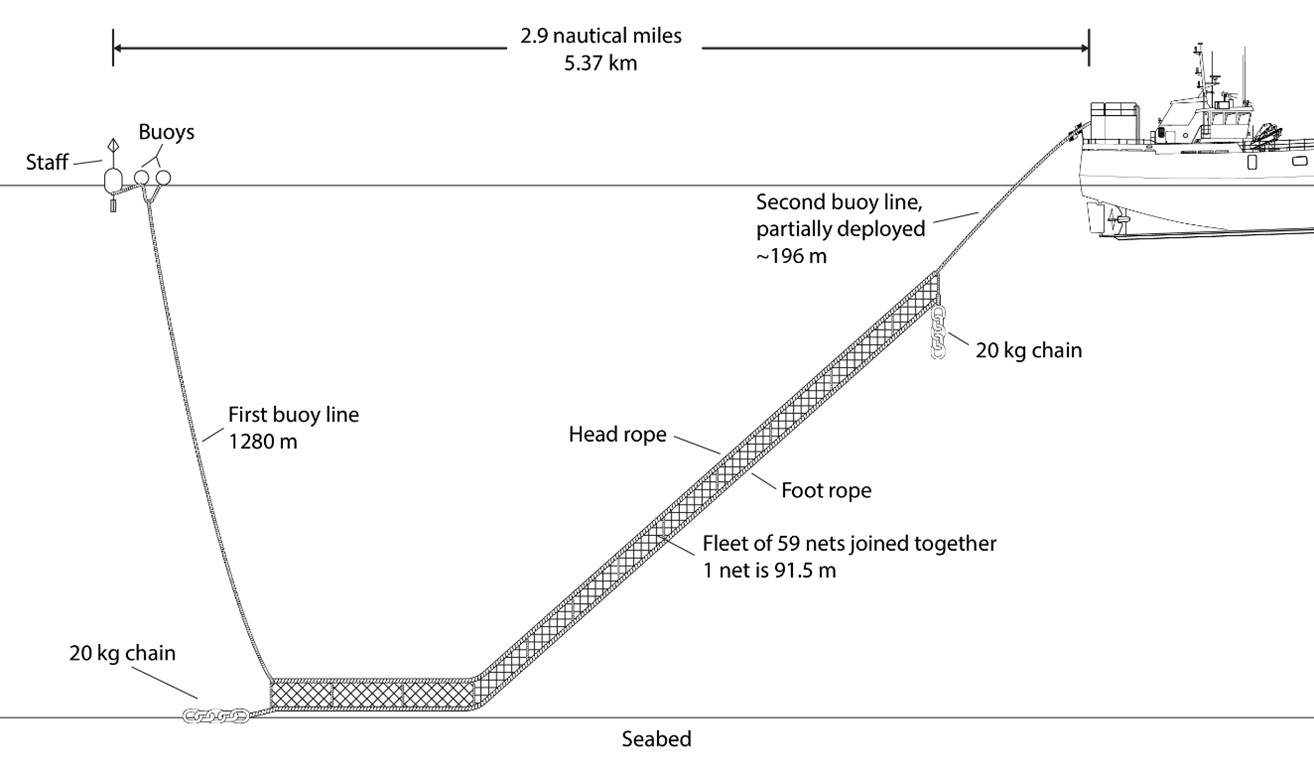

The Suvak operates with up to 10 fleets of nets. One fleet of nets consists of between 50 and 80 connected nets. A head rope runs along the top edge of the nets, and a foot rope runs along the bottom edge of the nets (Figure 3). On either end of the foot rope, there are detachable chains weighing 20 kg each. These anchor the bottom edge of the nets to the seabed. On both ends of the head rope, there is a buoy line of between 1000 m to 1500 m in length. The buoy line is connected to a set of buoys that provides an upward force on the head rope and keeps the net from collapsing in on itself. Depending on ice conditions, a staff may also be attached to the buoy line. A staff is a pole with a radar reflector that marks the ends of the nets.

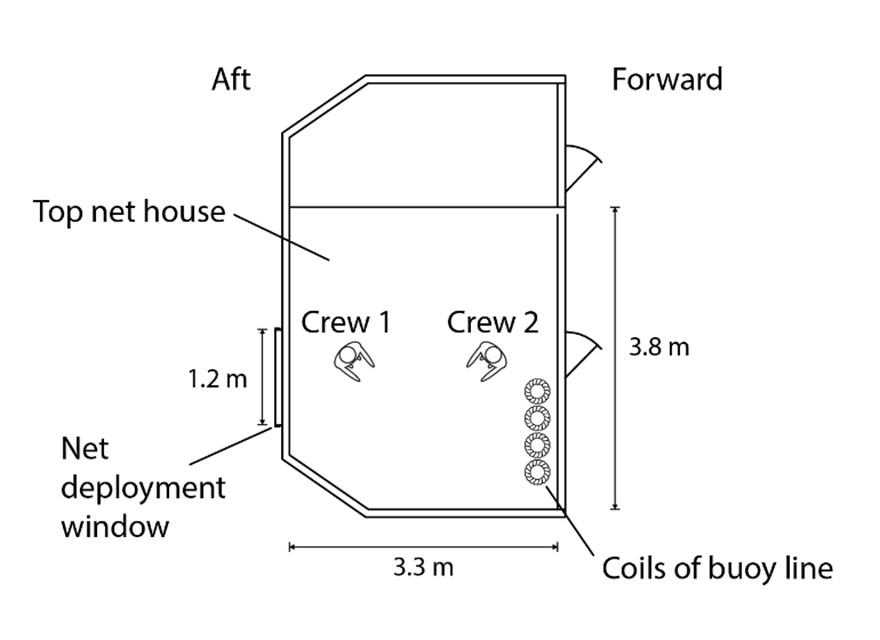

When setting nets from the top net house, there are 2 crew members in the top net house and another crew member, usually the first mate, on the starboard aft side of the shelter deck. The master remains in the wheelhouse and manoeuvres the vessel.

When the vessel arrives at the location where the nets are to be set, the master slows the vessel’s speed to 2.5 to 3 knots and uses the intercom system to tell the setting crew to begin setting the nets.

To begin this process, the first mate deploys the buoys into the water. The 2 crew members inside the top net house then begin throwing the buoy line into the water. The buoy line is stowed in the top net house in coils of approximately 200 m. One of the crew members stands near the coils and passes sections of them to the other crew member, who stands near a window in the aft bulkhead of the top net house and throws the sections of coil through the window into the water (Figure 4). The window is approximately 0.9 m high by 1.2 m wide (Figure 5).

As the crew in the top net house get to the end of the first buoy line, the first mate attaches one of the 20 kg chains to the foot rope. The first mate then throws the chain in the water and tells the crew in the top net house that the chain is away. The master increases the vessel’s speed to 6.5 to 7 knots. The 2 crew members leave the top net house, and the weight of the sinking chain and the forward movement of the vessel pull the nets into the water.

The 2 crew members wait near the top net house as the nets deploy, which usually takes around 20 to 30 minutes depending on the number of nets in the fleet. The 2 crew members periodically look into the top net house to check on the deploying nets during this time to ensure there are no snags and to gauge when they need to return to the top net house.

When there are approximately 3 to 6 nets left, the 2 crew members inform the master via the intercom system. The master reduces the vessel’s speed back to 2.5 to 3 knots. The 2 crew members return to the top net house and the same procedure is then performed in reverse: the second 20 kg chain is attached to the foot rope and the 2 crew members then throw the second buoy line with attached buoys into the water. Once the procedure is complete, the crew informs the master, who notes the location of the fleet of nets in the fishing log.

The procedure for setting the nets on board the Suvak had been developed to ensure the fishing gear was deployed quickly and to reduce the likelihood of the fishing gear coming into contact with any ice during setting. Contact with ice can cause the fishing gear to become entangled or move off location and be lost or damaged.

1.4 History of the voyage

On 14 August 2021, the Suvak departed from Sisimiut, Greenland, with a crew of 16, for a 2-week fishing trip in Davis Strait.Footnote 1 This was the Suvak’s 6th 2-week fishing trip of the 2021 season.

On 25 August, 12 days into the trip, 2 crew members (Crew 1 and Crew 2) who were assigned to the task of setting nets started work shortly after 0530. They worked throughout the day and into the night setting and hauling nets and completing other fishing operation activities. BecauseFootnote 2 the vessel was shortly going to depart the fishing grounds for port, the crew members were working long hours in order to complete all of the fishing operation activities. The intention was for the crew members to have a rest period once the vessel departed. Crew 1 and Crew 2 had a break of 1.75 hours between the time they awoke at 0530 on 25 August and the time of the occurrence at 0310 on 26 August.

At 0250 on 26 August, Crew 1 and Crew 2 began setting a fleet of 59 nets from the top net house. This was the last fleet of nets that needed to be set before the vessel returned to port. After the first buoy line and 20 kg chain were deployed, Crew 1 and Crew 2 left the top net house for about 20 minutes, during which time 56 nets went into the water. When there were 3 nets remaining, the crew members informed the master using the intercom system, and the master reduced the vessel’s speed to 2.5 knots. The 2 crew members then re-entered the top net house. One of the crew members passed the end of the foot rope through the top net house window to the first mate, who was standing by on the shelter deck. The first mate attached a 20 kg chain to it and deployed it while Crew 1 picked up a section of coil from the second buoy line and threw it into the water.

Crew 2 picked up a section of coil and passed it to Crew 1. Crew 1 took the coil from him and threw it into the water. When Crew 2 picked up the next section of coil, the line tightened around his arm and he was pulled toward the window in the top net house. Crew 1 tried to assist Crew 2 by attempting to physically pull him back from the window to prevent him from going overboard.

From his position on the shelter deck, the first mate saw Crew 2 come up against the window in the top net house and yelled to the master that one of the crew members was entangled in the buoy line. The master put the vessel astern and then the pitch to zero. At this time, Crew 2 was pulled through the window in the top net house and into the water. The first mate yelled that someone had gone overboard. The master proceeded to the top net house, where the first mate confirmed that a crew member had gone overboard. In the top net house, Crew 1 was trying to hold the buoy line in an attempt to assist Crew 2. The master instructed him to let go of the buoy line, and he did so. The first mate threw a life ring that was fitted with a light into the water and deployed more buoy line to provide slack.

The master returned to the wheelhouse, where he turned the vessel to starboard to begin circling back to where Crew 2 had gone into the water. He also used the intercom system to announce that there was a person overboard and used the vessel’s searchlights to help look for Crew 2 in the water. As the vessel was turning, Crew 2 was observed to have surfaced near the life ring, but he was unresponsive. Crew 2 was recovered from the water through the net retrieval opening on the main deck. The master and first mate performed cardiopulmonary resuscitation on Crew 2 for 2.5 hours, but he remained unresponsive.

At approximately 0500, the Suvak began proceeding toward Qikiqtarjuaq, Nunavut (Figure 6). At around 0550, the master contacted the vessel manager and notified him of the occurrence. After proceeding for approximately 17 hours, the Suvak arrived in Qikiqtarjuaq at around 2200, after which time Crew 2 was pronounced dead.

1.5 Vessel certification

The Suvak is a large fishing vesselFootnote 3 that was certified and equipped in accordance with existing regulations. The vessel held an inspection certificate for unlimited voyages for a vessel exceeding 150 gross tonnage (GT). Because the Suvak is a fishing vessel, it is not subject to the International Convention for the Safety of Life at Sea; that is, it is a non-Convention vessel. Inspections for certification, as required by the Large Fishing Vessel Inspection Regulations, were conducted annually. The Suvak is a delegated vessel under Transport Canada (TC)’s Delegated Statutory Inspection Program (DSIP), with Lloyd’s Register as the vessel’s recognized organization (RO).

1.6 Personnel certification and experience

The master held a Fishing Master, First Class certificate of competency. He had sailed as master on fishing vessels since 2005 and as master on the Suvak since 2011.

The first mate held a Fishing Master, First Class certificate of competency. He had sailed as first mate and master on fishing vessels since 2002 and as first mate on the Suvak since 2014. Since 2018, he also sometimes served as the relief master on the Suvak.

Both Crew 1 and Crew 2 had worked on board the Suvak for 3 years. Crew 1 held a Marine Emergency Duties certificate with respect to STCWFootnote 4 Basic Safety, and Crew 2 held a Domestic Vessel Safety certificate.

1.7 Environmental conditions

At the time of the occurrence, the wind was southerly from 17 to 21 knots, and there was a southerly swell of 0.6 to 1 m. The air temperature was 3 °C and the water temperature was 3.4 °C. Sunrise was at 0253 and sunset was at 1839, making for nearly 16 hours of daylight.

1.8 Operational context

The Suvak is owned by Masiliit Corporation, which purchased the vessel in 2010. Masiliit Corporation is a wholly-owned subsidiary of 4 Nunavut community hunters and trappers associations.Footnote 5 Masiliit Corporation manages the Arctic Fishery Alliance, which is responsible for operations on the Suvak and one other large fishing vessel.Footnote 6 The management of the day-to-day operations on the Suvak is supported from the Arctic Fishery Alliance administration office in St. John’s, Newfoundland and Labrador. The Suvak’s port of registry is Iqaluit, but in the off-season the Suvak secures in port in St. John’s.

The Suvak operates with a crew of 16, including the master, first mate, factory supervisor, a quality control person, a fisheries observer, and 11 other crew members. A number of the crew members have duties that relate to both the marine operations of the vessel (e.g., navigating and maintaining a lookout) and the fishing operations (e.g., assisting with setting and hauling nets or working in the factory).

The Suvak fishes for Greenland halibut in the northern Atlantic and Arctic oceansFootnote 7 from approximately mid-May to mid-November, but the fishing season is largely dependent on ice conditions. When ice conditions permit, the Suvak operates continuously throughout the fishing season on a 12- to 14-day schedule. The vessel normally departs Sisimiut and fishes for 10 to 12 days. Before returning to port, the crew typically works a long shift in order to set 3 to 4 fleets of nets so that these nets are ready to haul when the vessel arrives back on the fishing grounds. This last net-setting shift typically begins in the early morning (around 0500) and extends into the early hours of the next day.

Once the last fleet of nets is set, the vessel proceeds to port. The vessel times its arrival in port for 0700 to offload the catch. The crew then has 1 night of shore leave, with the exception of the master, first mate, and a crew member working in the engine room who remain on board. While in port, the vessel also takes on fuel, water, and provisions. The following morning, the vessel sails before noon.

Crew changes take place when the vessel is in port. During 2021, crew changes were affected by the COVID-19 pandemic. Because crew changes were being done in Greenland, with all crew flying in from different parts of Canada, the crew change lists had to be finalized 10 days in advance to meet Greenland’s COVID-19 protocols. This made it difficult to accommodate any crew changes arranged less than 10 days in advance and some crew members were asked and agreed to remain on the vessel for additional shifts when replacement crew members were not available.

1.9 Nunavut fisheries management

At the time of the occurrence, the Suvak was fishing in the offshore waters of Davis Strait, adjacent to Nunavut. Offshore commercial marine fisheries in Nunavut are managed by Fisheries and Oceans Canada (DFO) with special consideration given to advice provided by the Nunavut Wildlife Management Board (NWMB). Specifically, the NWMB provides advice to DFO about decisions regarding offshore quota allocation.Footnote 8 The primary mechanism that the NWMB uses to develop and provide offshore quota allocation advice to DFO is the NWMB allocation policy. The NWMB has a fisheries advisory committee that provides quota allocation advice to the NWMB. The committee is made up of 6 appointed members (2 from the Government of Nunavut, 2 from Nunavut Tunngavik Inc.,Footnote 9 and 2 from the NWMB).

The NWMB uses a points system to make quota allocation recommendations to DFO. The points system contains both mandatory criteria and other criteria against which commercial marine enterprises are scored. These applicants must meet all mandatory criteria and achieve a minimum of 60% on the other criteria.

Mandatory criteria relate to responsible stewardship and require applicants to comply with all DFO legislation and policies, with TC’s environmental stewardship requirements for fishing vessels, and with the Species at Risk Act. Failing to meet the mandatory criteria may result in enterprises not being recommended for quota allocation or being removed from the fishery.

The other criteria encompass a range of items related to good business governance, Inuit ownership and sponsorship, and reinvestment in local communities. As part of these other criteria, commercial marine enterprises are scored on being economically viable and profitable, as well as on consideration of past performance targets. If an enterprise fails to meet multiple performance targets, it is more likely to be subject to a reduction in quota.

On the Suvak, there was a focus on catching as much quota as possible in order to meet the criteria related to economic viability and profitability, and to meet performance targets in order to avoid the potential for a reduction in quota.

Applicants are not scored on compliance with TC regulations pertaining to vessel safety or territorial regulations regarding occupational health and safety, and there are no other criteria that encourage vessel or crew safety to be taken into account in applicants’ operations.

1.10 Familiarization, training, procedures, and drills

Under the Canada Shipping Act, 2001 (CSA 2001), a vessel’s authorized representative is required to develop procedures for the safe operation of a vessel and for dealing with emergencies. They must also ensure that crew receive safety training.Footnote 10 Under the Marine Personnel Regulations, crew members are also required to receive on-board familiarization and safety training, including familiarization with shipboard equipment and operational instructions specific to the vessel.Footnote 11 The master is responsible for ensuring that crew members’ knowledge is maintained up to date and that training records are kept on board. As the Suvak is a large fishing vessel, its master is also required to conduct drills under the Fire and Boat Drills Regulations.Footnote 12

The Suvak has a crew safety manual that was developed in 2013. The manual contains general guidance about familiarization of crew members, drills, safety when setting and hauling nets, and fish processing procedures, among other things. The manual also contains a checklist for crew familiarization, a drill record form, and emergency checklists for fire, abandon ship, person overboard, severe weather, steering gear or rudder failure, collision, blackout, and serious injury or death. The crew safety manual was available on the bridge but was not regularly referenced or discussed with the crew.

Familiarization and training of crew on the Suvak was done informally, with the master and other experienced crew members using a mentoring approach to demonstrate how tasks were completed. The master and experienced crew members then supervised crew members in their execution of these tasks. When crew members were proficient and met the expectations of the supervisors, the crew members were considered capable of performing the task independently.

With respect to the net-setting procedure, new crew members were trained by experienced crew members and were supervised while performing the task. Supervision was normally provided by the master, who used the camera in the top net house to check on the crew members working there. The net-setting procedure had been developed by experienced crew members and was communicated verbally to new crew members. There was no recurrent training for the net-setting procedure, but experienced crew members would verbally provide feedback if they witnessed actions that were considered unsafe.

The crew of the Suvak performed person overboard, abandon ship, and fire drills in accordance with regulatory requirements. During a person-overboard drill, the crew simulated recovering a person who was already in the water. The drills did not involve a person actually entering the water. The last person-overboard drill before the occurrence had been conducted on 03 May 2021.

1.11 Lifesaving equipment and distress alerting devices

The Suvak was fitted with the required lifesaving equipment.Footnote 13 The vessel had 2 life rafts and an inflatable boat that was used as a rescue boat. The vessel also carried the required standard lifejackets,Footnote 14 immersion suits, signalling equipment, and emergency communication equipment.

1.11.1 Use of personal flotation devices

The vessel carried TC–approved personal flotation devices (PFDs)Footnote 15 and the company had a policy requiring their use when on an exterior deck, which included the top net house. At the time of the occurrence, the crew in the top net house were not wearing PFDs. Crew members on the Suvak reported that the PFDs available on the vessel were bulky and uncomfortable to wear while working. From 2015 to 2020, the TSB has received reports of 14 occurrences where fish harvesters entered the water without wearing PFDs.Footnote 16 Fish harvesters have reported not wearing PFDs because they are uncomfortable and obstructive to wear while working,Footnote 17 and because of a perception that it is not practical or normal to wear a PFD.Footnote 18 PFD designs better suited for fishing operations may increase PFD use.Footnote 19

Finding: Other

Crew members are less likely to wear PFDs that are uncomfortable and obstructive to working. In most cases, wearing a PFD increases the likelihood of survival in the event a crew member goes overboard.

1.12 Risk assessment and operating procedures

The International Safety Management (ISM) Code, which sets an international standard for marine safety management, highlights the need for companies to assess all identified risks to vessels, personnel, and the environment and establish appropriate safeguards. It also states that there is a need for continuous improvement of the safety management skills of personnel ashore and those on board, including preparing for emergencies related to safety. The standard for safety management established by the ISM Code can be applied to non-Convention vessels like the Suvak, even if they are not subject to the Code.

When developing a workplace operating procedure, a comprehensive risk assessment is key to ensuring that all hazards and their associated risks are identified and that effective defences are implemented. It is important that the risk assessment consider all of the steps in the procedure. Both the risk assessment and the procedure should be documented. It is also important to include all relevant individuals in the risk assessment and the development of the procedure. This could include anyone who may perform or be involved with the procedure, or anyone who has a vested interest in it, from senior management ashore to crew members. The procedure should identify the requirements for it to be carried out safely, such as the minimum number of personnel required to carry it out, personal protective equipment required, fitness for duty (fatigue), and suitable weather windows. Once the procedure is developed and tested, it must be reviewed on a regular basis to ensure that it remains current, to identify any new hazards that may arise, and mitigate them as required.

The safety management process must also include an approval mechanism so that any identified risks and the proposed defences are approved at the appropriate level within the governance structure of the organization. This helps ensure that individuals at appropriate levels within the organization are aware of risks and proposed defences.

Another tool in the safe execution of a procedure is a pre-job assessment or toolbox talk. This involves a brief meeting of all those involved to discuss the procedure, the hazards and risks involved, and the existing defences. The meeting provides an opportunity for any new hazards to be identified and mitigated. If new hazards are identified and mitigated, then work can continue. However, if new hazards cannot be readily mitigated, then the work must be put on hold until defences can be put in place.

1.12.1 Net setting procedure

The procedure for setting nets on the Suvak was not documented and was developed without a documented risk assessment. The procedure required crew members to manually handle the staff, buoys, chains, buoy lines, and net ends. Handling of fishing gear creates a risk of entanglement.

The risk of crew entanglement with the fishing gear was recognized, and the defence implemented was to warn crew members not to put their arm through the side of the coil where the line was deploying. As well, the master normally supervised the crew members in the top net house using the camera when it was working.

There are various other strategies that can be used to mitigate entanglement risks. For example, knives or other engineered cutting devices can be placed at strategic positions around the vessel to permit lines to be cut quickly. Crew members can also carry knives on their person. Reels can be implemented to minimize the need for crew members to handle fishing gear. The vessel speed can also be reduced further so that the crew members in the top net house have more time to throw out the buoy line.

On the Suvak, there were no knives or cutting devices available in the top net house at the time of the occurrence, nor was it the practice for crew members to carry knives. There was no evidence of a regular review of the net-setting procedure. There were also no defined operating conditions for the procedure, nor were there emergency procedures or training for responding to entanglement situations.

1.13 Fatigue

Sleep-related fatigue is widely reported in the fishing industry. This type of fatigue results from insufficient good-quality sleep. Normal healthy adults need between 7 and 9 (with an average of 8) consecutive hours of sleep each night to feel well rested and to be able to maintain vigilance throughout the day.Footnote 20 For those who live or work in northern latitudes, there is a tendency to sleep less during the summer months.Footnote 21

An individual’s level of fatigue can be measured on a continuum that spans from being wide awake to being asleep. As an individual’s level of fatigue increases along the continuum, so does the likelihood of human performance impairments. With excessive levels of fatigue, almost all aspects of human performance are degraded, including those associated with vigilance, reaction time, and problem solving.

1.13.1 Vigilance

Vigilance is the action of maintaining one’s attention and remaining alert to stimuli over a prolonged period of time, with particular attention to stimuli that indicate possible danger or difficulties.Footnote 22 Vigilance is reliably impaired by fatigue.Footnote 23 This is especially the case with psychomotor vigilance, whereby people have to respond to a stimulus with some form of body movement.Footnote 24 Without frequent breaks, vigilance decreases over time as attentional and information processing resources are depleted and eventually exhausted.Footnote 25

1.13.2 Reaction time

An individual’s reaction time is determined by the time it takes them to perceive a stimulus, process any information associated with the stimulus, choose a course of action, and then perform the course of action. Many factors can impact reaction time. Fatigue, for example, can result in a reduced rate of information processing that affects the speed at which a person can identify, process, and react to important information.Footnote 26 Fatigued individuals will normally respond to stimuli more slowly than alert people and have significantly longer reaction times, known as “blocks”Footnote 27,Footnote 28 Blocks commonly occur in alert people when urgent or difficult decisions need to be made, such as during emergencies, and can be worse in people who are fatigued.Footnote 29

1.13.3 Problem solving

Problem solving involves considering different possible solutions and choosing the one that is the most appropriate.Footnote 30 This requires time and a large amount of cognitive resources. However, in an emergency situation, time is limited and a course of action must be chosen quickly. Fatigue can reduce a person’s ability to problem solve. Instead of being flexible in responding to a unique situation, a person who is fatigued may repeat previously ineffective responses (i.e., perseveration). Perseverating makes it difficult for a fatigued person to dedicate their attention to devising and trying a novel solution.Footnote 31

Fatigue may also increase risk-taking and reduce attention.Footnote 32,Footnote 33,Footnote 34 As well, in addition to impairing cognitive functioning, fatigue also reduces a person’s maximum muscle strength when performing physical activities.Footnote 35

1.13.4 Fatigue risk factors

Fatigue may result from a number of risk factors. The investigation determined that acute sleep disruptions, chronic sleep disruptions, continuous wakefulness, and circadian rhythm disruptions were fatigue risk factors that were present in this occurrence.

1.13.4.1 Acute sleep disruptions

Acute sleep disruptions are reductions in the quality or quantity of sleep that have occurred within the previous 72 hours. Acute disruptions in the quantity of sleep are normally considered remarkable when they are at least 30 minutes in duration.

1.13.4.2 Chronic sleep disruptions

Chronic sleep disruptions are reductions in the quality or quantity of sleep that are sustained for periods of longer than 72 hours. These disruptions may be less remarkable than acute sleep disruptions. Successive episodes of sleep loss—as little as 15 minutes per night—can accumulate and result in a sleep debt.Footnote 36

1.13.4.3 Continuous wakefulness

Continuous wakefulness, or prolonged wakefulness, is associated with being awake for too long. Twenty-two hours of continuous wakefulness is the limit which almost all aspects of human performance decline due to fatigue. One research finding identified that 17 hours of wakefulness produces impairments in psychomotor functioning equivalent to a blood alcohol concentration of 0.05%.Footnote 37 The effects of continuous wakefulness are also influenced by the time at which it occurs, with higher levels of fatigue resulting from continuous wakefulness that occurs at night rather than during the day.

1.13.4.4 Circadian rhythm disruptions

Circadian rhythm disruptions refer to disruptions to natural human sleep–wake cycles. Human sleep propensity (the inclination to sleep) follows circadian rhythms; it increases dramatically at night and moderately in the middle of the afternoon.Footnote 38 A circadian trough occurs between 2230 and 0430,Footnote 39 during which time an individual’s core body temperature drops and overall performance and cognitive functioning are at their lowest. A post-lunch dip also occurs around 1400.Footnote 40

Optimal human performance occurs when circadian rhythms are synchronized to each other as well as to external time cues. Changing sleep–wake patterns too quickly can cause circadian rhythms to desynchronize, which can lead to performance impairments. For example, circadian rhythm desynchronization can result in sleep-related fatigue, daytime sleepiness, reduced cognitive skills, impairment of psychomotor functioning, anxiety, depression, moodiness, general malaise, impairment of well-being, physical fatigue, insomnia and other sleep disturbances, as well as gastrointestinal disorders.Footnote 41 Contrary to popular belief, people who have worked shift work for many years do not become immune to circadian rhythm desynchronization and its effects.Footnote 42 Irregular shift patterns increase the risk of fatigue due to circadian rhythm desynchronization.

1.14 Crew fatigue

Using data collected during the investigation, the TSB was able to estimate the hours of sleep for Crew 1 and Crew 2, who were on the same schedule and worked the same hours. When the time between work periods was 10 hours or more, the TSB assumed that Crew 1 and Crew 2 slept for 8 hours. When the time between work periods did not allow for 8 hours of sleep, the duration of sleep was estimated by allowing for 0.5 hours of wakefulness after each night shift and 1.5 hours of wakefulness after day and evening shifts to account for eating, showering, and other personal activities.

The TSB’s estimation of the crew members’ hours of sleep did not account for the possibility of sleep loss resulting from the accommodations on the Suvak not being conducive to restorative sleep and other factors. On the Suvak, cabins were shared by at least 2 crew members. The cabin shared by Crew 1 and Crew 2 was beside the galley, where other crew members gathered for meals and breaks. The presence of high waves and engine noise also sometimes disrupted the sleep of the crew.

1.14.1 Crew 1 and Crew 2

At the time of the occurrence, Crew 1 and Crew 2 had been on board for 6 weeks. They had originally joined the vessel for a 2-week shift, but had been asked to and agreed to stay on for 2 extra 2-week shifts. On the evening of 24 August into the morning of 25 August, they had a rest period of 6.5 to 7 hours. They then began 21.5 hours of work, with a 1.75-hour break during which they did not nap. At the time of the occurrence, they had been awake for over 21 consecutive hours. Based on the data gathered during the investigation, it was estimated that Crew 1 and Crew 2 were subject to the following fatigue risk factors:

- An acute sleep disruption of 8.5 hours over a period of 72 hours.

- A chronic sleep disruption of 29.5 hours over a period of 144 hours.

- Continuous wakefulness totalling 21.5 hours.

- Circadian rhythm desynchronization as a result of frequent changes to sleep onset time. These changes sometimes exceeded 3 hours, without sufficient time for their circadian rhythms to adjust to the changes.

- A circadian rhythm low, given that the accident happened at 0300, which is during the circadian rhythm trough.

1.15 Fatigue management

A fatigue management plan is a recognized way to proactively manage fatigue. It may include appropriate work and rest scheduling, fatigue awareness training, and use of alertness strategies and fatigue-reporting mechanisms to monitor actual levels of fatigue.

In the marine industry, fatigue is linked to the intensive nature of the business: long and irregular hours of work over extended periods, brief or interrupted sleep, rapidly rotating shifts, high workload, and social isolation. Enforcement of hours-of-work regulations on domestic vessels has been problematic. A strong work ethic, labour shortages, and economic imperatives in the marine industry may also encourage individuals to work while fatigued because of a real or perceived obligation to do so. This makes it more difficult for fatigue to be recognized as a problem and for appropriate action to be taken.

Fatigue has been identified in previous TSB reports as a contributing factor to accidents, and fish harvesters have confirmed that fatigue risk factors are widespread in the commercial fishing industry. The presence of fatigue risk factors demonstrates that fatigue persists as an issue within the commercial fishing industry. The TSB previously investigated another occurrence involving the fishing vessel Arctic Fox IIFootnote 43 where fatigue was identified as an issue.

There is currently no requirement in the Marine Personnel Regulations for comprehensive fatigue awareness training or fatigue management plans, and the Suvak had neither. The work and rest schedules of most of the crew members on the Suvak, including the master, were based on the fishing operations. These work and rest schedules were conducive to fatigue.

1.15.1 Hours of work and rest

Under the Marine Personnel Regulations, masters on fishing vessels of 100 GT and greater that are engaged on unlimited voyages, like the Suvak on the occurrence voyage, are required to ensure that crew members do not work more than 14 hours in any 24-hour period or more than 72 hours in any 7-day period. Crew members must also have at least 10 hours of rest in every 24-hour period and 77 hours of rest in every 7-day period. The hours of rest cannot be divided into any more than 2 periods, 1 of which is at least 6 hours in length, and the interval between 2 consecutive rest periods cannot exceed 14 hours.Footnote 44,Footnote 45

The master is also responsible for ensuring “that the danger posed by the fatigue of crew members, especially those whose duties involve navigational safety and the safe and secure operation of the vessel, is taken into account when determining the scheduled hours of work and rest.”Footnote 46 The master must “keep a record of every crew member’s daily hours of work or hours of rest.”Footnote 47 Finally, the master must post a table with the shipboard working arrangements in a conspicuous place on board the vessel.Footnote 48

The master on the Suvak had not received any fatigue management training. The master ensured that, before heading to port, the first mate and the crew member in the engine room were given a rest period so that they could keep a watch on the voyage. As well, to encourage the crew to put away their personal electronic devices and sleep during rest periods, the master would sometimes cut off the crew’s access to the internet at around 2200.

To increase the likelihood of the Suvak reaching its quota, the crew’s work and rest schedules were based around optimizing fishing operations. Work hours were largely dependent on fishing activities (e.g., hauling the nets on time to get them out of the water in order to maintain the quality of the catch, setting the nets before the vessel sailed to offload so that there would be catch to haul when they got back, and timing the blast freezing of the fish). Work on board took place during the day and sometimes part of the night. The investigation determined that the crew’s hours of work and rest were not documented and that fatigue was accepted as part of the job.

The investigation also determined that Nunavummiut and Inuit crew members who had been scheduled for 2-week shifts were being asked to stay on the vessel for extended periods of time due to the effect of COVID-19 protocols on the availability of replacement crew members. Because the NWMB’s quota allocation scoring system provided points for encouraging employment of Nunavummiut and Inuit crew members, these crew members were being asked to remain on board past their scheduled crew change dates. Without appropriate fatigue management, extended shifts increase the risk of fatigue.

1.16 Adaptation of net-setting procedure

An adaptation to a procedure occurs when an unofficial change is made to an existing procedure. Adaptations are usually made because they are perceived to improve efficiency. They are also made when the procedure is impractical or when crew members are unable to follow it for various reasons. Procedures that are not documented are more likely to be adapted because there is no formal approval process for changes, which may make it seem acceptable for crew members to make adaptations. An absence of training and familiarization on a procedure can increase the likelihood of adaptations because the importance of adhering to the procedure may not be well understood or reinforced. The longer that crew members use an adaptation without a negative outcome, the more confident they become in the adaptation. Over time, the adaptation becomes the norm and can be passed along to other crew members. However, adaptations can erode safety margins.

On the Suvak, the procedure for setting the nets involved 1 crew member picking up coils of buoy line and passing them to a second crew member, who then threw them into the water through the top net house window. When the first buoy line was being thrown into the water, there was minimal tension on the line because only the buoys and the deployed line were in the water. However, when the second buoy line was being thrown into the water, the nets and the 20 kg chains had been deployed, and the weight of this fishing gear in the water created a downward force on the buoy line. The crew members had to work quickly and throw out enough buoy line so that there was slack in the water to keep ahead of the downward force being exerted on the line.

The procedure for setting nets was originally developed by individuals with a stature that allowed for picking up coils of 35 to 45 m of buoy line using only their 2 hands. From an ergonomics perspective, picking up this amount of buoy line using only 2 hands is more difficult for those with statures smaller than those who originally developed the procedure. Crew 2 had a smaller stature and, as he was picking up the last coil before the occurrence, he inserted his right arm into the coil in order to pick up enough buoy line to maintain the required pace (Figure 7).

In the past, the crew members working in the top net house had sometimes adapted the procedure by inserting their arm into the coil in order to pick up enough buoy line to maintain the required pace. Whenever supervising crew members noticed this adaptation being used, they would verbally warn the crew members.

1.17 Fishing safety

The commercial fishing industry in Canada is complex and diverse, with economic and market conditions, crew availability issues, and regulatory systems influencing operational decisions and safety. In 2012, the TSB conducted a comprehensive national review of safety issues in the fishing industry and published the Safety Issues Investigation into Fishing Safety in Canada (SII).Footnote 49 The SII identified 10 safety-significant issues that are interconnected, and it revealed a complex relationship and interdependency among these issues. While the SII did not look at large fishing vessels, many of the safety-significant issues identified with respect to small fishing vessels also apply to large fishing vessels.

Of the 10 safety-significant issues identified in the SII, 5 were analyzed and found to have a role in this occurrence:

- Fatigue

- Safe work practices

- Training

- Fisheries resource management

- Regulatory oversight

The SII also identified that the safety of fish harvesters will continue to be compromised until the complex relationship and interdependency among safety issues is recognized and addressed by the fishing community.

1.17.1 Post-occurrence drug and alcohol testing

It was reported during the investigation that there had been cannabis use on board the Suvak. The use of drugs and alcohol on board fishing vessels has been identified as a growing concern by members of the fishing industry. Arctic Fishery Alliance has a zero-tolerance policy for use of drugs and alcohol on board. Ship’s officers were responsible for enforcing the policy on the Suvak. Arctic Fishery Alliance had installed an additional camera in the vessel’s forepeak compartment to ensure all working areas of the vessel could be viewed in order to deter the use of prohibited substances.

Detection of drug and alcohol use on board vessels can be difficult because these substances are usually consumed in private and because, with drugs in particular, there are different methods of using them that can make them especially hard to detect (e.g., edibles).

Current Canadian law does not require systematic drug and alcohol testing following a marine accident or incident. Without systematic testing, accident investigators may have only eyewitness reports of drug and alcohol use, which can be unreliable.

Finding: Other

There is no mandatory post-occurrence drug and alcohol testing in the marine industry for Canadian crews involved in occurrences, limiting the ability to determine if drugs and alcohol were a factor in an occurrence.

1.18 Regulatory surveillance

1.18.1 Transport Canada

As the federal department responsible for transportation, TC has a significant regulatory role when it comes to commercial fishing safety and provides a national regulatory framework that applies to many aspects of fishing vessels.Footnote 50 For matters falling under federal jurisdiction, occupational health and safety (OHS) is regulated by the Canada Labour Code, Part II. Although Employment and Social Development Canada is responsible for the application of the Canada Labour Code, Part II, TC is delegated the responsibility to apply and enforce the related Maritime Occupational Health and Safety Regulations.Footnote 51

The territories have jurisdiction over property and civil rights matters under their enabling legislation.Footnote 52,Footnote 53,Footnote 54 Therefore OHS for fishing vessels, as an element of labour relations, falls under their jurisdiction. Although the Suvak was registered in Nunavut, tied up in Newfoundland during the off-season, and crossed international borders to offload its catch in Greenland, it was not considered by TC to be subject to federal OHS regulations, because it was a fishing vessel.

The Suvak was enrolled in the DSIP, a program through which TC delegates authority to ROs to complete inspections required under section 16 of the CSA 2001 and to deliver certain Canadian maritime documents to vessels enrolled in the program. Many other flag states have similar programs. The DSIP is mandatory for all Canadian vessels of 24 m in length and above.

As a delegated large fishing vessel, the Suvak was required to undergo annual inspections conducted by the RO to verify compliance with the CSA 2001 and specified regulations. These inspections typically involve checking the vessel’s documentation, hull and machinery, lifesaving equipment, firefighting equipment, and crew certification. The Suvak underwent annual inspections by the RO as required. During the last inspection conducted before the occurrence, on 03 May 2021, the RO identified no deficiencies.

The Maritime Occupational Health and Safety Regulations and the Marine Personnel Regulations are excluded from the DSIPFootnote 55 which means that ROs do not verify compliance with these regulations.

1.18.2 Occupational health and safety on fishing vessels in Nunavut

Provincial and territorial OHS regulations vary across the country. The Suvak was registered in Nunavut and had workplace insurance coverage with the Workers’ Safety and Compensation Commission of the Northwest Territories and Nunavut (WSCC), the agency responsible for administering Nunavut’s Safety Act and Occupational Health and Safety Regulations. WSCC has OHS inspectors who conduct inspections in northern workplaces to ensure that Nunavut’s safe workplace laws are being followed.

WSCC provided insurance coverage for the crew on board the Suvak but considered the activities of large fishing vessels like the Suvak, which harvest catch off the coast of Nunavut, to be under TC’s jurisdiction. As a result, WSCC had not conducted any OHS inspections of the vessel. The same was true for the 9 other fishing vessels registered in Nunavut.

The investigation identified similar situations in the other Canadian territories. WSCC is also the agency responsible for workplace health and safety in the Northwest Territories. There are 24 fishing vessels registered in the Northwest Territories. As in Nunavut, WSCC considers fishing vessels to be under TC’s jurisdiction and does not conduct OHS inspections on these vessels. In the Yukon, the agency responsible for workplace health and safety is the Workers’ Safety and Compensation Board – Yukon (WSCB). There are 4 fishing vessels registered in the Yukon. Similar to the WSCC, the WSCB does not perform OHS inspections on fishing vessels registered in the Yukon.

1.19 Similar occurrences

Between 1999 and 2021, the TSB received 81 reports of fatalities as a result of people falling overboard from fishing vessels. Since 2011, the TSB has also received reports of 6 occurrences involving crew members going overboard specifically as a result of entanglement with fishing gear (Appendix A). The TSB completed investigation reports on 2 of these occurrences, involving the fishing vessels Cock-a-Wit Lady and Diane Louise.

1.20 Active recommendations

1.20.1 Fatigue

Following an occurrence on 13 October 2016, in which the tug Nathan E. Stewart and the tank barge DBL 55 went aground after the watchkeeper on the bridge, who was fatigued, fell asleep, the Board made 2 recommendations related to fatigue. In the first recommendation, the Board recommended that

the Department of Transport require that watchkeepers whose work and rest periods are regulated by the Marine Personnel Regulations receive practical fatigue education and awareness training in order to help identify and prevent the risks of fatigue.

TSB Recommendation M18-01

In the second recommendation, the Board recommended that

the Department of Transport require vessel owners whose watchkeepers’ work and rest periods are regulated by the Marine Personnel Regulations to implement a comprehensive fatigue management plan tailored specifically for their operation, to reduce the risk of fatigue.

TSB Recommendation M18-02

In response to these recommendations, TC implemented a 5-year Fatigue Action Plan to address fatigue among seafarers. TC also proposed amendments to the Marine Personnel Regulations that would require fatigue management training for seafarers seeking to obtain certain STCW certificates. However, there have been a number of delays in the publication of the Marine Personnel Regulations. As well, the Board notes that TC’s December 2022 response does not provide a new approach to fatigue management plans. It thus appears that training will still be aimed at masters and crew members; these individuals do not establish crewing levels and vessel schedules and, as a result, may not be able to apply the training that they receive. The Board continues to underline that training is not a substitute for a fatigue management plan established by the owner of a vessel.

TC’s response to Recommendation M18-01 was assessed as Satisfactory Intent.Footnote 56 TC’s response to Recommendation M18-02 was assessed as Unsatisfactory.Footnote 57

Given the importance of the watchkeeper to the navigational safety of the vessels involved in this occurrence in 2016, both recommendations were aimed at watchkeepers. However, as demonstrated in the occurrence involving the Suvak, there is a need to ensure that effective fatigue management extends to all crew members so that they are properly rested in order to prevent fatigue-related accidents.

1.20.2 Workplace safety on fishing vessels

Following an occurrence on 08 October 1996, in which a deckhand on the fishing vessel S.S. Brothers was seriously injured during fishing operations, the Board made 2 recommendations relating to provincial workplace safety legislation. In the first recommendation, the Board recommended that

the Department of Transport coordinate with appropriate provincial authorities to conduct a review of existing safety regulations administered by both levels of government to help ensure that the regulatory provisions pertaining to workplace safety on fishing vessels and overall operational safety are harmonized and enforced to achieve their intended objectives.

TSB Recommendation M99-01

In response to this recommendation, TC arranged a series of meetings with the provinces and territories on this issue in order to clarify the respective roles and obligations. By 2000, TC had met with all the provinces and territories.

As a result of Recommendation M99-01, British Columbia’s Worker’s Compensation Board entered into a memorandum of understanding with TC that clarified their respective roles, responsibilities, and obligations. No other memorandums of understanding were negotiated between TC and the other provinces and territories.

In 2004, given that TC had coordinated meetings with the provinces and territories to raise awareness about OHS, the response to the recommendation was rated as Fully Satisfactory and was closed. The TSB notes that, even when the response to a recommendation is rated as Fully Satisfactory, there may continue to be residual risk.

In the second recommendation, the Board recommended that

the provinces review their workplace legislation with a view to presenting it in a manner that will be readily understood by those to whom it applies, to help ensure that the enforcement mechanism and the regulatory regime complement each other.

TSB Recommendation M99-02

Each of the provinces responded individually to this recommendation. As of August 2023, all of the provinces had taken action to resolve the safety deficiency identified in the recommendation and had had their responses assessed as Fully Satisfactory.Footnote 58 As a result of this investigation, the Board notes that there is a residual risk remaining for the Canadian territories, whose workplace legislation has not undergone a review.

1.21 TSB Watchlist

The TSB Watchlist identifies the key safety issues that need to be addressed to make Canada’s transportation system even safer.

Commercial fishing safety is a Watchlist 2022 issue. The Board placed commercial fishing safety on the Watchlist in 2010. Every year, the same safety deficiencies on board fishing vessels continue to put at risk the lives of thousands of Canadian fish harvesters and the livelihoods of their families and communities. This occurrence demonstrates the continued need for coordinated regulatory oversight, fatigue management plans, and effective safety management.

ACTION REQUIRED Commercial fishing safety will remain on the Watchlist until there are sufficient indications that a sound safety culture has taken root throughout the industry and in fishing communities across the country, namely:

|

Fatigue management in rail, marine, and air transportation is a Watchlist 2022 issue. As this occurrence demonstrates, some marine companies are not managing the risk of fatigue in their operations effectively, and many are not required to have fatigue management plans in place. The problem will persist until vessel owners are required to have fatigue management plans and mariners receive fatigue training.

ACTION REQUIRED Fatigue management in marine transportation will remain on the Watchlist until the following actions are taken:

|

Regulatory surveillance is a Watchlist 2022 issue. In this occurrence, inspections by the RO did not identify that the vessel was not meeting the minimum hours of work and rest set out in the Marine Personnel Regulations. As well, the investigation identified that a jurisdictional gap between TC and Nunavut has resulted in an absence of OHS oversight for fishing vessels in Nunavut.

ACTION REQUIRED Regulatory surveillance in marine transportation will remain on the Watchlist until TC provides more oversight of the commercial vessel inspection process by demonstrating that its surveillance and monitoring are effective in ensuring that authorized representatives and recognized organizations are ensuring vessel compliance with regulatory requirements. Additionally, TC must demonstrate an increase in proactive surveillance. |

2.0 Analysis

One of the crew members on the Suvak was pulled overboard after becoming entangled in the buoy line while setting gillnets. The analysis will focus on fatigue, adaptation of procedures, management of risk, fishing allocation policy, and regulatory surveillance.

2.1 Development of the entanglement situation

On the Suvak, when the second buoy line is deployed in the water, the submerged fishing gear, in combination with the vessel moving forward at 2.5 to 3 knots, exerts a downward force on the buoy line that can cause the line to become taut and pose a risk of entanglement for the crew members. This same risk is not present when the first buoy line is deployed, as there is minimal weight applying a downward force on the line. The crew have to perform physical work quickly to ensure there is enough slack buoy line in the water to keep ahead of the downward force being exerted by the submerged fishing gear. The primary defence against entanglement relies on the crew members remaining vigilant regarding the technique and speed used to pass the coils of buoy line.

Sleep-related fatigue can reduce an individual’s cognitive abilities, including the ability to remain vigilant against risks, and affect overall performance. At the time of the occurrence, the 2 crew members setting the nets from the top net house were fatigued. The investigation determined that 4 fatigue risk factors (continuous wakefulness, acute sleep disruption, chronic sleep disruption, and circadian rhythm disruptions) were present for the 2 crew members. They had been working for 6 weeks, rather than the typical 2 weeks, because there were no replacement crew members available to relieve them. During these 6 weeks, they had worked long hours and their work and rest periods had varied, with their sleep onset time changing frequently, sometimes by more than 3 hours. When the occurrence took place at 0310, both crew members had been awake for over 21 hours and they were working during the circadian trough, which is when a person’s overall performance and cognitive functioning are at their lowest.

Finding as to causes and contributing factors

The 2 crew members who were setting the nets on the Suvak were experiencing sleep-related fatigue from a combination of acute and chronic sleep disruption, continuous wakefulness, and circadian rhythm disruptions, which reduced their cognitive abilities, including their ability to remain vigilant against risks.

As the crew in the top net house were deploying the second buoy line, Crew 2 picked up a section of coil to pass it to Crew 1. When he picked up the section of coil, he inserted his right arm inside the coil to lift a larger portion. Because Crew 2 was fatigued, his ability to remain vigilant to prevent entanglement was compromised and likely made maintaining the pace required to keep ahead of the downward force on the buoy line more difficult. Muscular fatigue resulting from a long period of work also likely increased the difficulty of picking up a sufficient amount of the coil to maintain the pace. The smaller physical stature of Crew 2 would have made it more difficult for him to pick up large sections of coil using only his hands, which left him with limited options: pick up a smaller amount of line using both hands and potentially slow the pace, or use his arm as a support and maintain the pace. When Crew 2 inserted his arm into the coil to lift a larger portion of coil, the buoy line quickly became taut around his arm and he became entangled with no way to free himself.

Finding as to causes and contributing factors

Crew 2, who had a smaller physical stature, adapted the procedure for picking up the coils of buoy line to keep up the pace. In combination with mental and physical fatigue, this adaptation led to his arm becoming entangled in the buoy line and caused him to go overboard, resulting in his death.

2.2 Fatigue management

Given the many performance decrements that occur when a person is fatigued, it is critical that organizations manage fatigue effectively. One way to do so is through the implementation of fatigue management plans and fatigue awareness training to ensure that both employers and employees understand how to mitigate fatigue in the workplace and prioritize doing so.

At the time of the occurrence, the Arctic Fishery Alliance did not have a fatigue management plan, nor was there a regulation requiring it to have one. The scheduling of the crew was left to the master, who had not received any fatigue management training, and crew members’ work and rest schedules were largely dictated by the fishing operations. There was a focus on optimizing fishing operations to meet performance targets related to economic viability and profitability to avoid the possibility of the vessel’s quota being reduced or not renewed. However, this focus prioritized the fishing operations over fatigue management and meant that crew members worked long hours with varied schedules that put them at risk of not being sufficiently rested to safely perform their duties.

The issue of inadequate fatigue management is not specific to the Suvak. The TSB Watchlist 2022 has identified that there is currently no mandatory requirement in the Marine Personnel Regulations for comprehensive fatigue awareness training or fatigue management plans. Given the long hours and high levels of physical and mental exertion involved in commercial fishing, there needs to be greater awareness of the risks associated with fatigue and effective strategies to mitigate its risks.

Finding as to risk

If marine operators are not required to implement fatigue management plans, there is a continued risk that crew members will work while fatigued, increasing the risk of accidents.

2.3 Safety management

To ensure the safety of crew, the vessel, and the environment, it is imperative that regulators and operators recognize the critical nature of safety management and take steps to ensure it is implemented effectively at all levels of an organization.

In this occurrence, the net-setting procedure had been developed by experienced individuals, but there had been no comprehensive risk assessment to ensure that all hazards and risks associated with the procedure had been identified and effective defences had been implemented. The risk of entanglement with fishing gear was recognized, and the primary defence in place for the 2 crew members in the top net house relied on the crew members remaining vigilant concerning the speed and technique used to pass the coils. However, in this case, the crew members’ ability to remain vigilant was compromised by fatigue, and there were no other defences in place to mitigate the risk of entanglement. Additionally, reliance on human vigilance without any other defences poses risks because humans are prone to fatigue, distraction, and other factors that can impact vigilance. Without a comprehensive risk assessment of the procedure, the effectiveness of the defences to prevent entanglement were not evaluated, which resulted in a missed opportunity to put additional safeguards in place.

Finding as to risk

If a comprehensive risk assessment is not completed prior to the development of a workplace operating procedure and the procedure is not regularly reviewed, then unsafe work practices that can lead to injury or death may result.

2.3.1 Emergency procedures, equipment, and drills for responding to entanglement situations

Entanglement situations often develop rapidly, meaning that there is little time for crew members to problem solve and react. Emergency procedures and drills can provide crew members with opportunities to identify risks that can lead to entanglement situations, as well as guide their response to these types of emergencies. With regular practice through drills and the availability of the appropriate equipment, the chances of survival in these situations is increased.

Person overboard drills typically simulate recovering a crew member in the water but do not take into account the events leading up to this situation, such as entanglement. On fishing vessels where crew are required to handle fishing gear on a regular basis and there is a known risk of entanglement, a person overboard drill that also simulates an entanglement situation can help raise awareness of this risk among crew members and provide for an opportunity to practise responding to these situations.

Drills can provide a consequence-free environment with time for crew members to determine how entanglement occurs and explore the outcome of different actions. Over time, drills can help crew members react automatically to emergency situations. Drills also provide an opportunity to consider equipment to assist in preventing and responding to entanglement situations, such as knives or other cutting devices, and where they should be placed to maximize their effectiveness. Finally, drills provide an opportunity for senior management to authorize the crew to take measures in an emergency that are not normally acceptable, such as cutting a net loose.

In this occurrence, the 2 crew members in the top net house were faced with this novel emergency situation for which there was no obvious solution. Because the Suvak’s person overboard drills typically simulated recovering a person from the water, the crew members had not had an opportunity to practise responding to an entanglement situation. They also did not have access to equipment like knives. Their problem-solving abilities and reaction time were also likely compromised by fatigue.

Finding as to risk

If emergency procedures, equipment, and drills for responding to entanglement situations on board a vessel are not in place, the likelihood of survival in this situation is reduced.

2.4 Fishing allocation policy

The way that fishing resources are allocated can have significant implications for the safety of fishing operations. For this reason, it is important that allocation policies take safety into account and encourage operators to prioritize safety in their fishing operations.

At the time of the occurrence, the Suvak was allocated quota based on a points system established by the Nunavut Wildlife Management Board. The points system scored commercial marine enterprises on various criteria, including economic viability and profitability, but did not take safety into account. This posed a risk of the balance between operations and safety shifting toward a priority on operations, and of certain risks being accepted as a cost of doing business, such as the risk of fatigue.

Finding as to risk

If fishing allocation policies do not take safety into account, there is a risk that operators will prioritize fishing operations over safety and that unsafe practices will develop or persist.

2.5 Regulatory surveillance

2.5.1 Occupational health and safety oversight

Effective and regular oversight of occupational health and safety (OHS) on fishing vessels is a key component of keeping crew members safe at work. With respect to the Suvak and the 9 other fishing vessels registered in Nunavut, the Workers’ Safety and Compensation Commission of the Northwest Territories and Nunavut (WSCC) provided insurance coverage for the workers on board these vessels, but it considered the activities on board these fishing vessels to be under Transport Canada’s (TC) jurisdiction. Similar to the WSCC, the Workers’ Safety and Compensation Board – Yukon does not perform OHS inspections on the 4 fishing vessels registered in the Yukon. TC also does not conduct OHS inspections of fishing vessels, including those registered in the territories, as it considers this activity to be outside its jurisdiction. As a result, there had been no OHS inspections of the Suvak.

TC is responsible for the application of the Maritime Occupational Health and Safety Regulations made under the Canada Labour Code, and Nunavut, under its territorial act, is responsible for property and civil rights, which encompasses OHS on fishing vessels. However, a lack of recognition around jurisdiction created a gap that resulted in no OHS oversight of the Suvak or of other fishing vessels registered in the territories.

Finding as to risk

If there is no oversight of OHS on fishing vessels registered in the territories, there is a risk that crews of those vessels will be subject to OHS hazards in the workplace.

2.5.2 Transport Canada oversight

As a delegated vessel, the Suvak underwent annual inspections performed by the recognized organization (RO). Although the RO is required to verify compliance with the Canada Shipping Act, 2001, the Marine Personnel Regulations are not delegated, and so the RO did not verify compliance with these regulations. TC also does not routinely verify compliance with these regulations. This meant that there was no oversight to identify that the Suvak’s crew work and rest periods were undocumented and were not meeting the minimum requirements set out by the Marine Personnel Regulations.

Past TSB investigations have also identified that even compliance with the minimum requirements set out by the Marine Personnel Regulations can lead to fatigue over time, underscoring the need for effective fatigue management plans and fatigue training.

Finding as to risk

If oversight of delegated vessels by TC and ROs does not lead to the identification and timely resolution of unsafe conditions and regulatory contraventions, there is a risk to the safety of the vessel and its crew.

3.0 Findings

3.1 Findings as to causes and contributing factors

These are conditions, acts or safety deficiencies that were found to have caused or contributed to this occurrence.

- The 2 crew members who were setting the nets on the Suvak were experiencing sleep-related fatigue from a combination of acute and chronic sleep disruption, continuous wakefulness, and circadian rhythm disruptions, which reduced their cognitive abilities, including their ability to remain vigilant against risks.

- Crew 2, who had a smaller physical stature, adapted the procedure for picking up the coils of buoy line to keep up the pace. In combination with mental and physical fatigue, this adaptation led to his arm becoming entangled in the buoy line and caused him to go overboard, resulting in his death.

3.2 Findings as to risk

These are conditions, unsafe acts or safety deficiencies that were found not to be a factor in this occurrence but could have adverse consequences in future occurrences.

- If marine operators are not required to implement fatigue management plans, there is a continued risk that crew members will work while fatigued, increasing the risk of accidents.

- If a comprehensive risk assessment is not completed prior to the development of a workplace operating procedure and the procedure is not regularly reviewed, then unsafe work practices that can lead to injury or death may result.

- If emergency procedures, equipment, and drills for responding to entanglement situations on board a vessel are not in place, the likelihood of survival in this situation is reduced.

- If fishing allocation policies do not take safety into account, there is a risk that operators will prioritize fishing operations over safety and that unsafe practices will develop or persist.

- If there is no oversight of occupational health and safety on fishing vessels registered in the territories, there is a risk that crews of those vessels will be subject to occupational health and safety hazards in the workplace.

- If oversight of delegated vessels by Transport Canada and recognized organizations does not lead to the identification and timely resolution of unsafe conditions and regulatory contraventions, there is a risk to the safety of the vessel and its crew.

3.3 Other findings

These items could enhance safety, resolve an issue of controversy, or provide a data point for future safety studies.

- Crew members are less likely to wear personal flotation devices (PFD) that are uncomfortable and obstructive to working. In most cases, wearing a PFD increases the likelihood of survival in the event a crew member goes overboard.

- There is no mandatory post-occurrence drug and alcohol testing in the marine industry for Canadian crews involved in occurrences, limiting the ability to determine if drugs and alcohol were a factor in an occurrence.

4.0 Safety action

4.1 Safety action taken

4.1.1 Arctic Fishery Alliance

Following the occurrence, Arctic Fishery Alliance took the following safety action:

- It purchased a different style of personal flotation devices with lights for the crew members involved in setting the nets.

- It provided crew members with specialized rope-cutting knives to be worn on their belts during setting and hauling of the nets. Rope-cutting knives were also placed in areas where nets are hauled and set. The knives are of a different color and design from general-use knives to avoid confusion.

- It added metal containers in the top net house and main deck setting areas to hold the 20 kg chains so that the chains can be pre-rigged to the buoy line, allowing for hands-free deployment of the chains.

- It added a requirement for 1 supervisor and 2 crew members to be involved in setting the nets from the top net house.

- It updated the Arctic Fishery Alliance crew safety manual to reflect the safety action taken after the occurrence and provided crew members with copies of the manual.

- It required each crew member to sign off to confirm that they had completed an orientation.

- It installed a new closed-circuit television system with a 30-day recording capability.

- It added a new camera and redundant wiring in the top net house, as well as a new camera in the forepeak compartment.

- It installed a redundant wiring system for all cameras and loud hailers in areas where nets are set and hauled.

4.2 Safety action required

4.2.1 Oversight of occupational health and safety on fishing vessels registered in the Canadian territories

On 26 August 2021, at 0310 Newfoundland Daylight Time, a crew member on the fishing vessel Suvak went overboard while setting gillnets in Davis Strait, approximately 120 nautical miles northeast of Qikiqtarjuaq, Nunavut. The crew member was recovered from the water and later pronounced dead.

The investigation into this occurrence determined that the Suvak’s port of registry was Iqaluit, Nunavut, and that the vessel had workplace insurance coverage with the Workers’ Safety and Compensation Commission of the Northwest Territories and Nunavut (WSCC), the agency responsible for administering legislation on workers’ compensation and workplace health and safety in Nunavut. WSCC has occupational health and safety (OHS) inspectors who conduct inspections in northern workplaces to ensure that Nunavut’s safe workplace laws are being followed. However, WSCC considered fishing vessels to be under the jurisdiction of Transport Canada (TC), and there had been no OHS inspections of the vessel by WSCC. The same was true for the 9 other fishing vessels registered in Nunavut.