Striking of a public highway overpass

Iron Highway

Train No. CP 121-13 - Mile 102.9,

Winchester Subdivision

Bedell, Ontario

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

On 13 August 1997, a highway trailer loaded on a westbound Canadian Pacific Railway (CPR) freight train became loose and shifted over the side of the platform upon which it was loaded, beyond allowable railway clearance. While the train was proceeding under a public highway overpass for County Road No. 44, at Mile 102.9 of the Winchester Subdivision, the over-hanging trailer struck the bridge support columns. The trailer was extensively damaged, and the highway overpass was closed for several days. No dangerous goods were involved and there were no injuries.

The Board determined that the trailer became unsecured due to an improperly locked hitch that went unidentified during pre-departure inspections because employees did not possess the necessary information to recognize that a slightly protruding or damaged lock indicator pin could render a locking mechanism ineffective.

Contributing factors were the design of the hitch locking mechanism, and management's and employees' inexperience in working with the new technology.

1.0 Factual Information

1.1 The Occurrence

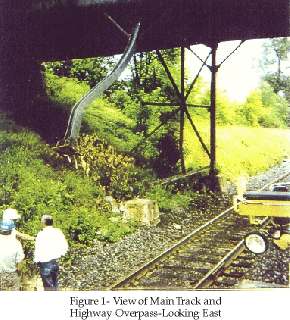

CPR freight train No. 121-13 (train 121) departed Côte St. Luc Yard in Montreal, Quebec, at 1030, and was proceeding westward on double main track near Bedell, Ontario, Mile 102.9 of the Winchester Subdivision. The crew of a rail grinding train, operating eastward on the adjacent south track, noticed that the last trailer on train 121 had shifted and, as they observed the train pass under an overpass for County Road No. 44, believed the shifted trailer may have struck part of the bridge support structure on the north side of the track. The crew of train 121 was immediately notified by radio of the possible problem and stopped the train. The conductor of train 121 confirmed that the last trailer was extensively damaged, and had shifted approximately 10 feet to the east end and 5 feet to the north side of the trailing platform. One of the four main support columns of the public highway overpass was ripped away from its pedestal, and several smaller diagonal steel braces were bent and twisted (see Figure 1).

1.2 Injuries

There were no injuries.

1.3 Damage

The bridge was closed to highway traffic for several days pending repairs. No railway equipment was derailed; however, there was minor damage to a steel A-frame on one car.

1.4 Personnel Information

The train crew consisted of a conductor and a locomotive engineer positioned in the lead locomotive. They were familiar with the physical characteristics of the subdivision and met mandatory fitness and rest standards.

1.5 Method of Train Control

Traffic on the Winchester Subdivision in the area of the occurrence is controlled by the Occupancy Control System authorized by the Canadian Rail Operating Rules and supervised by a rail traffic controller located in Toronto. The maximum authorized timetable speed is 60 mph for freight trains.

1.6 Train Information

1.6.1 Train 121

Train 121 was specially designed equipment commonly referred to as the Iron Highway. The train, powered by two locomotives, was approximately 1,400 feet long and weighed about 1,130 tons. There were 16 highway trailers on board, 9 of which were empty.

1.6.2 Iron Highway

Iron Highway is relatively new technology owned by CSX Intermodal Incorporated. In Canada, Iron Highway is a pilot project of CPR, which is operating the equipment under a 24-month lease on St. Lawrence & Hudson Railway trackage. The Iron Highway is a continuous platform on wheels (see Figure 2). Unlike conventional flat car technology, the Iron Highway is made up of forty 30-foot articulated platforms, two adapter platforms (one at each end of the train, both equipped with an A-frame) and a 'split ramp' at the centre of the train. Each 30-foot platform is designed with a hitch to carry a highway trailer. When standard-length trailers, 48 to 53 feet in length, are used, the trailer spans one of the points of articulation. The platforms are linked with slackless couplers. The wheels are mounted on independent axles and are positioned at the articulation joints. Forced steering is accomplished through the use of steering arms. The platforms are equipped with an elastomeric suspension system which is designed to provide a softer ride for the trailers as compared to the more traditional steel spring type.

The entire unit operates as only one car, called an 'Element'. The split ramp feature allows the Element to separate mid-length, creating two loading ramps. The Element can then be loaded without the use of cranes or other heavy-lifting equipment.

Before entering into service, a prototype model was extensively tested at the Association of American Railroads (AAR) test center in Pueblo, Colorado. Results showed that "the load bearing platforms provide a comparable or better ride than existing intermodal equipment with the exception of vertical bounce response." The Element was equipped with operative damping mechanisms during the tests, and ride performance was evaluated at track speeds up to 70 mph.

In design, several Elements may be coupled together in the same train should the extra platform length be required. CPR has been operating with one Element per train, and operates two such train sets. Both train sets have been operating in captive service between Montreal and Toronto since 15 November 1996. Each Element normally makes one 'round trip' per day, operating on similar arrival and departure schedules from each city.

The trains are exempted from certain requirements of Transport Canada's regulations due to their special design.

1.6.3 Terminal Operations

CPR contracts with a separate company, Rail Term, for the operation of its Côte St. Luc and West Toronto terminals. Rail Term employees have backgrounds primarily in either the rail or trucking industries. CPR has a representative based in Toronto who provides support for the overall project. Rail Term has a staff of 30-35 employees, including management and supervision. Rail Term staff load and unload the train, as well as inspect and perform much of the scheduled maintenance on the Iron Highway equipment.

1.7 Occurrence Site Information

The track in the area of the occurrence is a curved double main track. The track structure consists of Algoma 130-pound continuous welded rail, laid on 14-inch double-shouldered tie plates and hardwood ties, and secured with six spikes per tie. CPR operated a track evaluation car westward over the Winchester Subdivision on 07 August 1997, six days before the occurrence. No serious track condition defects were noted. Although most of the curves on the Winchester Subdivision are less than two °, the amount of super-elevation is well in excess of what is required for the posted speed of 60 mph. The table in Appendix A provides some detailed information for the curves between Mile 22.0 and the accident site.

1.8 Training

A six-week training course was provided by CPR to Rail Term employees before the operation began. Employees were required to pass an open-book written exam and an operational test to obtain an Iron Highway Inspector Certificate. The scope of the training included duties associated with the loading and off-loading of trailers, as well as the inspection and maintenance of the Element and locomotives. All subsequent employees received informal on-the-job training from previously trained Rail Term workers. New employees performed only those duties for which they were trained, such as gate operation and 'spotter'. Spotters work from the ground and assist the hostler driver in the correct placement of trailers during loading and off-loading. They also provide the initial inspection of "locked" hitches.

In July 1997, the Canadian Auto Workers (CAW) secured the rights for its members to perform certain work which, up until that time, had been performed by the Rail Term employees. This work consists of the safety inspections, brake tests, and pull-by inspections. Rail Term employees continue to do repairs, such as wheel change-outs and hitch replacements. Safety inspections are performed to identify defects to critical mechanical parts, such as wheels, brakes, suspension components, and hitches. However, when the safety inspections are performed, the train is empty and the hitches are collapsed to the floor.

The CAW members are certified car inspectors and received training in accordance with CPR's regular Carman Certification Program. Little of this training program involved equipment identical to that of the Iron Highway; therefore, CPR provided a three-day training course on Iron Highway technology to employees who could potentially be working on the Iron Highway. These employees work out of the Côte St. Luc and West Toronto yards.

Rail Term supervisors are not required to have a mechanical (equipment) background, although some do. Before leasing the Iron Highway equipment, neither CPR nor Rail Term management had experience with this technology. Since then, all involved have acquired a better understanding of the equipment as they have worked their way through the day-to-day operating problems associated with the new operation and equipment.

1.9 Trailer Design

The highway trailer involved in the accident, unit No. CTC 36502, was owned by Canadian Tire Corporation. It was built in June 1995 by Manac Inc. in Orangeville, Ontario. It is a completely 'closed-in' style of trailer, of mainly aluminum construction, equipped with tandem axles, a rear roll-up door, and a fibreglass roof. The specified dimensions were 2.6 m by 4.0 m by 16.2 m, but the trailer was more commonly referred to as a 53-foot van-type trailer. The gross vehicle weight rating was 32,000 kilograms (70,400 pounds). It was last annually inspected in May 1997.

The trailer was connected to the hitch on the platform identified by the alpha designation 'AP'. The AP platform was the next-to-last (trailing) platform of the Element. As the train was proceeding westward, the hitch end of the trailer was leading. The trailer spanned two platforms, with the tandem wheels located on the last platform of the Element (see Figure 3). In transit, there is no air supply to the trailer resulting in full application of the spring-activated trailer parking brakes.

The trailer superstructure was extensively damaged in the accident. A small blunt impact mark was observed on the king pin, and the surrounding support plate had scrapes consistent with the direction of movement. The king pin on the trailer was gauged with a Holland King Pin Gauge for four different wear contours and all measurements were within acceptable wear limits. The trailer brakes were tested and found to be operative and properly adjusted. The trailer had no indication of being damaged before the accident.

In general, trailers of all designs are built with a smooth steel plate which is secured to the underframe and covers the area from the front of the trailer to approximately 14 inches behind the king pin. This plate reinforces the floor in a load bearing area, and transmits forces from the front of the trailer to either the suspension system of a tractor, or the hitch of a railway car. The plate also allows a smooth surface upon which the fifth wheel of a tractor can slide to position itself when picking up or dropping off trailers. Beyond this steel plate, the rest of the floor underframe system is usually exposed, revealing its structural components (i.e. cross members and stiffeners).

Many trailers, such as the one involved in this occurrence, are built to a capacity of 35 tons (32,000 kilograms). It is not known whether any trailers are being subjected to overloaded conditions as most trailers do not pass over weigh scales at either end of the delivery cycle.

1.10 Trinity LP-9 Hitches

The 16 trailers loaded on train 121 were secured by Trinity LP-9 hitches (see Figure 4). This type of hitch is known as a pull-up retractable, with automatic locking of both the trailer king pin rotor lock within the head assembly and the folding diagonal strut. The hitches are manufactured by Trinity Industries of Dallas, Texas, and are designed for a maximum king pin load of 30,000 pounds. Although they are not AAR-approved, they are similar to the AAR-approved LP-3 hitches (manufactured from 1968 to 1973) and the LP-8 hitches which have been used in marine service since 1971, with over 6,000 units in use today. The LP-9 hitch was specifically adapted for use on the Iron Highway project. There are no other known railway applications. When raised to the vertical position, the head of the hitch approaches the king pin of a trailer from the rear. This is the opposite direction than that of a fifth wheel on a normal highway tractor.

The applicable railway standard for rail car hitches is produced by the AAR Mechanical Division in the Manual of Standards and Recommended Practices, Book I. Specification

M-928-87, titled Highway Trailer Hitches for Freight Cars, states: "This specification covers the mechanical characteristics, structural adequacy and testing requirements of highway semi-trailer hitches of 65,000 pounds maximum gross vehicle weight capacity . . . ."

A 7,000-cycle test on a damped hitch configuration was completed in the prototype stage to verify wear on the pivot pins, and to ensure proper latching of the lock on the folding diagonal strut. The testing utilized a pair of pneumatic dampers in place of the single hydraulic damper that is used on all the hitches in Iron Highway service. The rate of fall with the pneumatic dampers was the same. Furthermore, the test involved a hostler raising and lowering a hitch which was bolted to the ground, rather than the deck of a loading platform. A highway trailer was not used during the cycle test; therefore, the interaction between the two was not studied.

The hitch involved in this accident did not appear to have sustained any damage during the accident. When inspected, the hitch was upright with the diagonal strut in the locked position and the rotor in the hitch head in the unlocked position. The only abnormalities noted were a leaking hydraulic damper and a bent lock indicator pin on the hitch head.

While reviewing the general loading procedures, Rail Term employees stated that the hitches in the last few positions on the Element are the ones most frequently used. Wear on these hitches would therefore be greater than those in lesser used positions.

1.11 Loading Inspection Procedures

Written procedures for loading and off-loading the Iron Highway are provided to each employee and are available on site. With regard to inspection of the locking of the king pin, the Iron Highway Operator Manual states:

21. The ground crew should ensure the trailer is properly loaded on the trailer [note: should read "platform"] by the following:

. . .

B. Hitch's jams are locked around the trailer pin - look at the back of the hitch plate for a yellow tab which indicates an unlocked condition. If the hitch jams are not locked, the trailer must be positioned to enable the jams to lock. If necessary, the trailer must be removed and the hitch inspected. If the hitch jams will not lock, then the hitch must not be used to secure a trailer. If the hitch is defective, replace the hitch.

The Iron Highway Operator Training Guide, section 4.1.7 (King Pin Locking Plate), states:

- Check locking plate for cracks.

- Check all pin retainers.

- Check locking mechanism indicator flag.

1.12 Lock Indicator Pins

1.12.1 Lock Indicator Pin Design

Each lock indicator pin is custom fit to each hitch head, since it must take into consideration the tolerances from other related components. The system is designed so that the pin is flush to 1/16 inch below the outer surface of the surrounding plate when in the locked position. Figure 5 shows the illustration in the Iron Highway Operator Manual of an indicator pin in the locked and unlocked position. The pin in the locked position is shown to be inside the 1/4 inch flat plate, rather than flush to 1/16 inch below the outer surface of the flat plate as it is intended to be.

The normal engagement depth of the lock plunger is 7/8 inch when fully locked. The lock indicator pin is designed to protrude at least 3/4 inch to indicate an unlocked position.

The position of the indicator pins on locked hitches varied. Some pins considered to be in the 'locked' position were reported by employees to be inside the flat plate; others were flush, or even slightly protruding.

1.12.2 Indicator Pin Inspections

Rail Term employees described their process for inspecting the locked pins as the following:

- the "spotter" listens for the auditory "snap" that is heard as the plunger snaps into the rotor;

- the "spotter" looks to confirm that the coloured lock indicator pin has retracted; and

- the supervisor who performs the walk-around inspection after all trailers are loaded visually inspects each lock indicator pin to confirm that it is in the "locked" position.

CPR car inspectors do not perform walking inspections of the Element after the trailers are loaded. A pull-by inspection of the train on departure is performed by car inspectors positioned on either side of the train. However, during the pull-by inspection, the hitches on one half of the train are in the opposite orientation. This means that half of the indicator pins are not facing the inspector in the direction of train travel. The indicator pin of the subject hitch was facing the inspector during the pull-by inspection at Côte St. Luc Yard.

A perceivable change in pin position must occur in order for an employee to discriminate between locked and unlocked indicator pins. The difference between a fully locked pin and an unlocked pin is approximately 20 mm (3/4 inch) when all parts of the locking mechanism function as intended. During ground level inspections, employees are 7 to10 feet away from the indicator pin.

1.13 Other Information

1.13.1 TSB Engineering Branch

The hitch from the AP platform was removed from the Element and shipped to CPR's Weston Shops in Winnipeg, Manitoba, for tear down and analysis by CPR, CSX, Trinity, and TSB personnel. Subsequently, the hitch was shipped to the TSB Engineering Branch for further analysis.

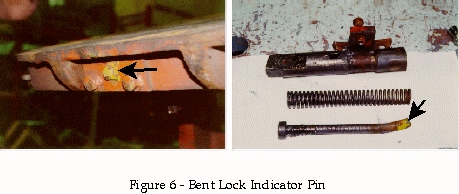

When placed in the 'locked' position, the lock indicator pin protruded 10 mm (3/8 inch) from the normal flush position. Tear down revealed that the indicator pin was bent upwards 11 mm at an angle of approximately 15 ° over a length of 48 mm (see Figure 6).

Because standard length trailers span an articulation point, the distance between the point where the trailer wheels contact the deck and the point where the king pin is mounted in the hitch varies during the curving action of the train. With the king pin restrained in the hitch and the trailer body a solid member, the variation in distance is handled by skidding of the trailer tires on the deck of the Element. Mathematically, using the dimensions of the subject trailer and the components of the Element, the change in distance was calculated to be minus 0.94 inches for the first curve encountered leaving Côte St. Luc Yard in Montreal. The change in distance was measured at the tire while traversing the same curve and found to be approximately one inch.

Laboratory examination showed that the king pin of the trailer must move forward 13 ½ inches to pass the front edge of the hitch head in either lateral direction. However, the king pin need only move 1 13/16 inches to be in a position where it can come out of the hitch vertically without interference with the top plate. It must raise 2 3/8 inches vertically to clear the hitch head.

The examination also showed that, if the forward acceleration of the hitch head is sufficient, the resultant inertia in the indicator pin causes over-compression of the spring, allowing the indicator pin to extend past the protective area of the hitch, where it is vulnerable to damage (see Figure 7).

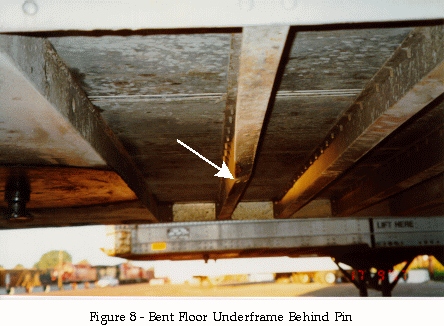

Both CPR and Rail Term employees, including management, reported that indicator pins have been known to occasionally get caught on the underside of the floor structure of some trailers during the hitch knock-down sequence (see Figure 8).

Testing demonstrated that several noises occur as the king pin engages with the hitch. These include the king pin contacting the end of the slot in the hitch head, the rotor contacting the stop block and the plunger contacting its end of travel.

The TSB Engineering Branch report (LP 150/97) included the following conclusions:

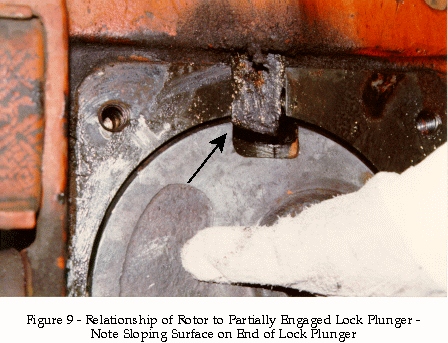

- The rotor in the subject hitch was not properly locked in the closed position.

- The rotor lock indicator pin was bent, restraining the plunger lock spring.

- The rotor lock plunger was free to "float" in its guide.

- The end of the rotor lock plunger is angled in such a way as to make the rotor self-unlock if the plunger is not fully engaged (see Figure 9).

- The rotor lock indicator pin was bent due to contact with the trailer floor ribs as a result of hyper-extension during the knock-down sequence.

- There is no secondary locking mechanism on the hitch to retain the trailer king pin in the event the primary lock fails or is not fully engaged.

- An unlocked trailer hitch can allow a trailer to creep forward during articulating movements of the two platforms upon which it is resting.

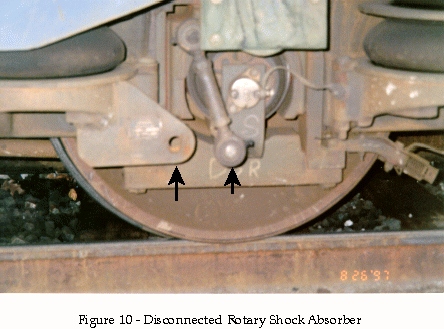

- The missing rotary shock absorbers on the Element would have a negative impact on its damping characteristics and could contribute to higher-than-normal vertical bounce.

- Trailers are not designed to receive railway hitches in the reverse position than that of the normal 'over the road' highway transport.

- Railway hitches are not designed to work with highway trailers in the same manner as which they were designed for 'over the road' highway transport.

The hitch is designed so that the rotor lock plunger should not self-unlock when the engagement depth of the lock plunger exceeds approximately 1/8 inch.

1.13.2 Maintenance

1.13.2.1 Train

The Element was examined in West Toronto and was noted to have the following mechanical defects:

| Component | Total |

|---|---|

| Broken/Missing Braided Bond Wire | 9 |

| Missing/Disconnected Rotary Shock Absorber | 25 |

| Missing/Disconnected Brake Sensor | 5 |

| Missing/Defective Hydraulic Damper (Hitch) | 6 |

The rotary shock absorber (Vibratech) on the Iron Highway equipment is used extensively in the passenger/commuter industry. It is designed to improve the ride characteristics of the equipment by controlling vertical bounce and to improve critical damping by 20 to 27 per cent. There are 84 shock absorbers on each Element. At nine locations, the shock absorbers were missing or disconnected on one side only, and at eight other locations, they were missing or disconnected on both sides. The latter situation applied to both the hitch end of the AP platform (where the trailer was connected) and the platform immediately ahead of the AP platform. The 25 missing or disconnected shock absorbers represent approximately 30 per cent of the total damping mechanisms on the entire Element.

The Railway Freight Car Inspection and Safety Rules state that:

A railway company may not place or continue a car in service if: . . . (b) a truck is equipped with an ineffective damping mechanism as indicated by : . . . iii. truck springs or hydraulic snubber units that show evidence of not maintaining travel or load.

Section 4.18 of the Iron Highway Operator Manual states, "Inspect rotary shock. They must not be loose or damaged."

1.13.2.2 Hitch

Thirteen of the original 40 hitch locations did not have a hitch. The hitches had been removed and used as replacements for others as they were in locations where they were not being used (for 20-foot trailers). Of the remaining 27 hitch locations, 5 hitches did not have the hydraulic damper used to control the impact of the hitch to the deck of the flat car when being lowered. On 3 others, the hydraulic dampers, although present, were not functioning properly. On 2 recently rebuilt hitch heads, the bolts for the lock indicator 'keeper plate' were not welded in place. CPR employees reported replacing broken or missing 'C clips' used to retain the pins that attach the entire hitch assembly to the car. Periodic inspection and lubrication dates stencilled on most hitches had expired. Iron Highway employees did state that they occasionally would use the longer terminal time on Saturdays to do hitch inspections, during which time they would operate and grease the hitches as required.

Maintenance records indicate that bent lock indicator pins on hitches were being identified during train inspections. Repair records show such pins as having been repaired by heating using an oxyacetylene torch and then straightening. Further inspection of a number of hitches removed for repairs in the West Toronto Terminal showed that 6 out of 19 hitches had bent lock indicator pins. The outboard end of several lock indicator pins were observed to be generally dirty or chipped, with little or none of the paint used to enhance visibility apparent. The end surface of the pin is painted the same colour as the cylindrical portion of the pin. Over-sprayed paint was visible around the end of the rotor lock indicator pin on a number of hitches. Other hitch heads were noted to have the lock indicator pins painted green, rather than yellow.

1.13.3 Communications

Some Rail Term and CPR employees expressed uncertainty about the scope of their responsibilities. For example, several Rail Term employees were not sure who was responsible for the maintenance of the hitch.

CPR car inspectors expressed concern about the lack of clear procedures regarding their inspection duties. Some felt that they were not provided with a specific list of items to be inspected, nor explicit instructions regarding which items on the Element were 'safety critical'. Inspection and repair records frequently showed broken or missing parts on the Element identified as "not in stock".

CPR car inspectors were often faced with inspecting the same deficiencies on the same train, day after day because of:

- the relatively high number of missing or broken parts on the Element;

- the lack of availability of replacement parts;

- the repetitive nature of the Element's train schedule; and

- the practice of scheduling some non-critical maintenance for future dates (e.g. Saturdays).

Deficiencies, missing parts, and required maintenance were identified on paper by CPR car inspectors and sent to the Rail Term supervisor. CPR car inspectors seldom received feedback from Rail Term regarding what repairs were done, or scheduled to be done. Also, the CPR car inspectors work for supervisors remote to the Rail Term terminal. Supervision of CPR car inspectors' repair work is indirectly applied by Rail Term and CPR supervisors.

A lack of standardized terminology for parts and maintenance procedures was an area of concern for some CPR employees. In particular, a lack of familiarity with the technical names of certain parts of the Element led to the use of non-standardized terms, thereby creating uncertainty in written and verbal communication.

1.13.4 Intermodal - Car Loading and Securement

Subsection 15(j) of the Railway Freight Car Inspection and Safety Rules indicates that a railway company may not place or continue a car in service if the car is a loaded flat car with lading restraining devices worn or damaged to the extent that these devices will not restrain the load.

The U.S. Federal Railroad Administration (FRA) prepared a report in 1994 on Trailer-on-Flat Car and Container-on-Flat Car Loading and Securement Safety (TOFC/COFC). The report determined that, in the United States, between 1983 and 1993, there were 108 accidents or incidents caused by TOFC/COFC loading problems, 60 per cent of which were caused by the load securement, 30 per cent by the lading or cargo, and the remaining 10 per cent by 'other' causes.

The main safety concern identified in the report was the need for a thorough post-loading, pre-departure inspection of the securement system by a knowledgeable inspector.

In response to the safety weaknesses identified in TOFC/COFC loading operations, the FRA proposed that both the FRA and industry promote a number of safety actions which are listed in Appendix B.

2.0 Analysis

The trailer was seen displaced on the Element by the crew of the rail grinding train immediately before the steel bridge near Bedell, Ontario. Train handling was not found to be a factor in the occurrence. The analysis will focus on the manner in which the trailer became unsecured from the Element, and the design and operation of the Iron Highway equipment.

2.1 The Occurrence

Post-accident tear down analysis showed that the rotor lock indicator pin was bent. The trailer involved in the accident is not considered to have bent the lock indicator pin for the following reasons: 1) there were no unusual marks on the trailer floor underframe; 2) there were no bent floor cross members; and 3) testing has shown that the hyper-extension of the lock indicator pin occurs during the off-loading process, during the hitch knock-down sequence, rather than when the trailers are being loaded. Therefore, the lock indicator pin was damaged before the last loading sequence.

During the loading sequence on 13 August 1997, the hitch lock likely activated; however, because a bent lock indicator pin restrained the spring, the lock plunger was not forced to fully engage with the rotor, and was therefore 'free-floating'. The free movement that this provided the lock plunger, in combination with its angled design, resulted in the hitch head unlocking itself as the trailer travelled between Côte St. Luc and Bedell. Because there is no auxiliary locking mechanism, once the primary lock failed, the trailer was no longer secured to the hitch.

For the king pin to have cleared the hitch plate entirely, the trailer had to move in a forward direction. Possible sources for this forward movement include the in-train forces associated with normal train movement, and the forward creep due to the articulating action of the Element with the trailer sitting on two separate platforms. Laboratory examination showed that less than two inches of forward movement was required for the king pin to clear the hitch head assembly. The normal accumulation of grease on both the hitch plate and the steel plate around the king pin of the trailer would facilitate further uncontrolled forward or sideways movement.

The ride control characteristics of the Element would have been adversely affected by the missing or disconnected rotary shock absorbers (approximately 30 per cent). In some cases, these shock absorbers were functioning on only one side of a platform. Both the hitch end of the AP platform, where this trailer was located, and the platform immediately in front of it did not have a functioning damping mechanism on either side of the platform (left or right). The combination of ineffective damping mechanisms and the increased lateral forces created by the excess super-elevation on the curves on the Winchester Subdivision would also have contributed to the propensity for the unrestrained trailer to lift and/or shift sideways.

Once the train reached the restricted clearance limits imposed by the steel bridge support at

Mile 102.9, the trailer came in contact with the bridge support structure, and forward movement of the train drove the trailer rearward until it struck the A-frame on the following adapter car. The resistance provided by the A-frame would have caused the steel bridge support beam to yield, and the trailer to be severely damaged.

2.2 Hitch Design and Testing

The design of the hitch locking mechanism played a key role in this occurrence. Figure 11 illustrates the major components of the hitch locking mechanism within the hitch head.

Post-accident tear down analysis showed that, when a rotor lock indicator pin is bent, it restrains the plunger lock spring, thereby allowing the rotor lock plunger to 'float' in its guide. Furthermore, the end of the rotor lock plunger is angled in such a way as to allow the rotor to self-unlock if the plunger is not fully engaged, rather than to prevent unlocking. Given the fit and the total allowable tolerances on the lock plunger, the rotor and the hitch head, combined with normal 'wear and tear' on these same parts, the possibility exists that self-unlocking may occur for any lock plunger engagement that is less than 1/2 inch.

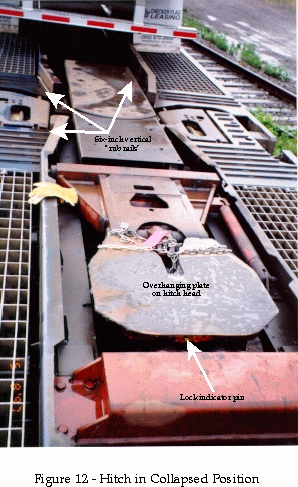

The cause of the bend in the indicator pin, as identified in TSB Engineering Branch report LP 150/97, was as follows: the rotor lock indicator pin hyper-extended during knock-down of the hitch, and then bent due to contact with the floor ribs of a trailer. Employees' past experience with pins getting caught on floor underframes, and the number of bent pins examined by TSB investigators or referenced in inspection and repair records, suggest that this type of problem is not infrequent. During the off-loading sequence, a spotter may not be aware that an indicator pin has contacted a floor underframe, unless the hitch head actually remains jammed under the trailer. Because subsequent safety inspections of the Element are performed when the train is empty and the hitches are collapsed to the floor, the view of the lock indicator pin is obscured by the geometry of the hitch head and the framework of the platform (see Figure 12). Because the damaged pin went unrepaired, the conditions existed for the accident to occur.

The initial design and testing of the hitch did not simulate the actual loading and off-loading conditions because:

- a hitch with two pneumatic dampers rather than a single hydraulic damper was used;

- the test hitch was bolted to the floor rather than secured to an actual platform; and

- no trailer was used with the hostler during the 7,000-cycle test.

Therefore, all areas of potential incompatibility between their designs (such as hyper-extension of the lock indicator pins during accelerated knock-downs) were not identified.

Although the Iron Highway was equipped with non-AAR-approved rail car hitches, the adequacy of the AAR standard (AAR M-928-87) is questionable. Many highway trailers have a gross vehicle weight of 70,000 pounds, which is in excess of the 65,000-pound 'maximum gross vehicle weight capacity' stated in the standard.

2.3 Operator Knowledge and Inspection

The reasons why a trailer could be improperly locked in place and be allowed to proceed after being inspected by trained personnel were explored.

In general, inspection tasks are a two-step process: first, an item must be inspected using the senses (visual, auditory, tactile, olfactory), and then one must make a decision regarding whether the item meets specifications. The initial inspection process used by Rail Term employees places heavy reliance on the auditory 'snap' that is heard as the plunger snaps into place in the rotor. However, testing demonstrated that several noises occur as the king pin engages with the hitch. If the indicator pin is bent, the plunger does not snap into place, yet the other noises still occur. Thus, the auditory 'snap' guarantees only that the rotor is in place, not that the entire locking mechanism is properly deployed.

Subsequent inspection of the hitch locking mechanism involves the visual sense. Although the coloured indicator pins may be useful for helping the operator to identify the general location of the pin, the colour is less useful for identifying whether the pin is properly engaged, since some colour is seen in both the locked and unlocked positions (the only difference being how much colour is seen, and this quantity is inconsistent across the different hitches). Also, different colours were used (green and yellow), and the paint was often chipped away, obscured by dirt and oil, or discoloured by the heating of bent pins with oxyacetylene torches.

The fully unlocked pin extends past the surrounding plate by approximately 20 mm (3/4 inch). While this distance may be acceptable under optimum viewing conditions, there are a number of factors (such as poor lighting, distance of observer from the pin, snow and ice in winter, similarity in shape of the pin with the adjacent bolt heads) that could create conditions where the observer is no longer able to discriminate accurately. Furthermore, in the locked position, there is some variability in the distance of the end of the pin from the protecting plate. Even a protrusion of only 2 mm, as observed on some CPR inspection sheets, represents fully 10 per cent of the unlocked indicator pin position. Without precise measures of "acceptable" versus "unacceptable" protrusion limits, the decision-making aspect of the inspection is open to subjective judgements. Because of the small size, location, and appearance of the indicator pins, final inspections performed at ground level may mistake a partially unlocked hitch for a locked hitch with a slightly protruding pin.

The inspections performed by the Rail Term employees, who load the train, are critical to ensuring the safe movement of the trailers. Subsequent pull-by inspections by CPR car inspectors are designed to identify more general problems with any part of the train; therefore, these inspections cannot focus on only the locking mechanisms. Also, because the Element is moving and one half the trailer hitches are in the opposite orientation to the direction of travel, it is more difficult to differentiate small changes in lock indicator pin positions during pull-by inspections.

The frequently dirty condition of the visual indicator pins, the number of bent pins, and employees' experience with occasionally seeing pins slightly protruding suggest a general lack of awareness of the significance of the lock indicator pin to the proper operation of the lock plunger. The information in both the Iron Highway Operator Training Guide and the Iron Highway Operator Manual for employees involved in the inspection and maintenance of the Iron Highway equipment revealed the following shortcomings regarding hitch lock inspections:

- there were no appropriate photographs or descriptions of precisely what specifications to inspect--this can allow a drift in standards over time;

- there was little technical information on the design and operation of the lock--this hinders employees' ability to fully understand the inner workings of the locking mechanism, and therefore may interfere with their decision-making process (such as not recognizing the significance of a protruding lock indicator pin); and

- terminology was not consistent between the manuals (for example, the word "jam" was used in one manual, while "rotor" was used in another; and the use of the word "flag" instead of "indicator pin"). All employees require a good understanding of these parts as they are critical to the safe operation of the locking mechanism, and terminology should be consistent.

Higher-quality training aids and a more detailed understanding of the inner workings of the hitch lock components would enhance the quality of the inspections.

2.4 Feedback and Communication

Neither Rail Term nor CPR employees had a clear understanding of which group was responsible for the inspection and maintenance of the hitches. Some employees attributed this oversight to the transition period incurred by the July 1997 ruling enabling CPR car inspectors to take over certain aspects of the inspection and maintenance work. The working relationship between employees of the two companies can be characterized as agreeable. All involved appeared motivated and committed to the success of the project.

Given the distribution of responsibilities between Rail Term and CPR, a formalized procedure for delivering and acknowledging communications is more likely to enhance accountability of both parties. The lack of such a procedure with respect to planned or taken action on deficiencies and required maintenance allowed responsibility to diffuse between the two groups. The situation was somewhat compounded by the lack of familiarity of some employees with the technical names of certain parts of the Element. This led to the use of non-standardized terms, thereby creating uncertainty in written and verbal communication between the CPR and Rail Term employees.

Because some CPR car inspectors did not know which parts of the Element were safety critical, they did not know when to "stop" the train on the basis of a particular part being non-functional. In any event, final safety decisions were made by the Rail Term supervisors, largely eliminating the relevance and importance of the safety inspection procedure. More importantly, the lack of clearly defined criteria regarding whether the train was safe to depart posed a daily potential threat to the safe operation of the train. It would also appear, based on the number of problems noted with the trailer inspections, that some of the findings of the FRA report on TOFC/COFC operations are also relevant to the Iron Highway operations.

3.0 Findings

- Train handling was not considered causal to the accident.

- Due to a lack of experience with the unique design of the Iron Highway, CPR and Rail Term management and employees did not possess in-depth knowledge of all safety-critical components.

- The hitch securement system has no auxiliary locking mechanism.

- The angle of the rotor lock plunger is designed to facilitate, rather than prevent, the unlocking process.

- During the release cycle, the hitch lock indicator pin may hyper-extend beyond the protection afforded by the hitch head casting, contacting the exposed floor underframes of some trailers.

- The contact of the indicator pins to trailer underframes was damaging the pins, and the significance of this damage was not readily recognized by all employees.

- The lock indicator pin on the AP platform hitch was bent before the loading of trailer CTC 36502.

- Slightly protruding indicator pins were considered to be locked by some Rail Term and CPR employees.

- Employees inspecting the hitches during loading, the walk-around, and the pull-by did not identify the AP platform hitch as unlocked.

- Visual conspicuity of the lock indicator pin is limited due to its size, location, state of cleanliness, and similarity in shape with the adjacent bolt heads.

- The applicable AAR standard for all rail car hitches (AAR M-928-87) is for highway semi-trailer hitches of 65,000-pound maximum gross vehicle weight capacity. This is less than the gross vehicle weight rating of many highway trailers.

3.1 Causes

The trailer became unsecured due to an improperly locked hitch that went unidentified during pre-departure inspections because employees did not possess the necessary information to recognize that a slightly protruding or damaged lock indicator pin could render a locking mechanism ineffective.

Contributing factors were the design of the hitch locking mechanism, and management's and employees' inexperience in working with the new technology.

4.0 Safety Action

4.1 Action Taken

4.1.1 Railway

Subsequent to this occurrence, heightened awareness of the mechanical condition of the relatively new equipment has resulted in a number of safety initiatives and maintenance improvements to the Elements:

- all defective hitches and dampers have been repaired or replaced;

- all missing or defective rotary shock absorbers have been changed, and a scheduled replacement program has been put in place;

- electronic brake sensors have been replaced with a mechanical style of brake indicator that is less vulnerable to damage or failure;

- braided bond wires and shoes have been replaced with solid bar shunting devices;

- all indicator pins have been repainted yellow, with the background area painted a contrasting black to heighten the visibility of the lock indicator pins;

- periodic inspection and lubrication of the hitches have been scheduled for every six months;

- inspection procedures now include: a securement inspection by the ground person member of the Rail Term loading crew, a second securement inspection by another Rail Term employee or supervisor, and a pre-departure securement inspection by CPR car inspectors before a final outbound pull-by inspection;

- employees at Iron Highway have been provided with a training course on the operation, inspection, lubrication and rebuilding of the LP-9 hitch by Trinity Industries;

- a revision to the loading and unloading procedures manuals has been completed by Educom Technologies;

- retraining, according to the revised procedures, and competency assessment of all employees have been completed;

- operating instructions now require that the hostler fifth wheel be raised an additional 2 inches to prevent the hitch head from contacting the trailer during hitch knock-down;

- the hostler is restricted to a speed of 1 mph while backing under the trailer to unload;

- it is required that the landing gear of the trailers be lowered before unloading; and

- all actions taken by CPR, including new procedures, training, standards and manuals, are being shared with the industry.

4.1.2 Transport Canada

Transport Canada (TC) inspectors will monitor the inspection of hitch locking mechanisms closely in the course of future inspections. TC will also include the safety actions identified in Appendix B and related issues in their ongoing discussions with the Railway Association of Canada and the Federal Railroad Administration.

4.1.3 Association of American Railroads

The Association of American Railroads (AAR) Safety and Operations Management Committee approved the "Standard Operating Procedures for Intermodal Securement" (SOP) which are effective 01 August 1998. The new procedures require post-loading/pre-departure inspections by a securement verifier and the establishment of certification criteria and qualification testing of loading personnel. Section 3, Definitions for Purposes of this Document, of the SOP defines 'Securement Defect' as:

An equipment condition or problem which prevents proper securement of a trailer or container to an intermodal railcar, or which poses a risk that proper securement may be compromised.

The inspection criteria for the trailer hitch 'Top Plates' include a missing auxiliary lock as one of the defective conditions to be identified during inspections.

4.2 Action Required

The Board acknowledges the safety actions and initiatives taken by the industry and TC in response to this occurrence and believes that these measures will improve the safety performance of the Iron Highway operation. These areas include training as well as enhanced procedures and inspections. However, inspection of the visible portion of the lock indicator pin, a small protrusion, is impaired by two adjacent bolt heads and two reinforcing webs of the hitch head, thereby making the identification of an improperly locked hitch difficult to detect during these inspection processes.

The Iron Highway is a prototype which has required an exemption from some requirements of TC's regulations to operate in Canada. The Iron Highway does not meet all the requirements of the AAR interchange rules. Although similar lock mechanisms are used on other types of hitches (AAR-approved LP-3), the vast majority are used in combination with a secondary locking mechanism. The industry's "Standard Operating Procedures for Intermodal Securement" (SOP) as defined by the AAR, effective 01 August 1998, and accepted by the railway industry, consider that a hitch missing a secondary locking mechanism is to be considered a securement defect.

The automatic hitch is designed to self-unlock through movement of the plunger, spring, and lock indicator pin assembly. Unintentional operation of the self-unlocking mechanism can occur if the plunger is not fully engaged, the spring is broken, or the pin is bent. Notwithstanding the initiatives undertaken to reduce the associated risks of this equipment, these deficiencies may remain undetected during the inspection processes. The risk of a highway trailer becoming disengaged en route, through undesired operation of the automatic unlocking mechanism, is therefore not eliminated. Considering the high speed at which the Iron Highway operates and the potential weight of the equipment, proper securement of the highway trailers is critical to safe operation. Consequently, the Board recommends that:

The Department of Transport assess the trailer securement system and related safety inspections of the Iron Highway to ensure that the risks associated with the securement of highway trailers are appropriately addressed.

Transportation Safety Recommendation R98-02

This report concludes the Transportation Safety Board's investigation into this occurrence. Consequently, the Board, consisting of Chairperson Benoît Bouchard, and members Maurice Harquail, Charles Simpson and W.A. Tadros, authorized the release of this report on .

Appendices

Appendix A - Track Evaluation Car - 07 August 1997

This table provides the detailed information for the curves between Mile 22.0 and the accident site.

| Track Evaluation Report for Curves - Winchester Subdivision | |||||||

|---|---|---|---|---|---|---|---|

| Begins Mile |

Average Curve (°) |

Length (feet) |

Average Elevation (inches) |

Maximum Elevation (inches) |

Design Speed (mph) |

Minimum Design Speed (mph) |

Posted Speed (mph) |

| 22.0 | 0o 29' | 3453 | 2 3/8 | 3 | 114 | 77 | 60 |

| 43.2 | 0o 28' | 545 | 2 3/4 | 3 3/4 | 120 | 73 | 60 |

| 50.3 | 0o 29' | 2119 | 2 1/4 | 2 7/8 | 112 | 71 | 60 |

| 52.3 | 0o 29' | 3581 | 2 7/8 | 4 1/4 | 119 | 75 | 60 |

| 64.2 | 0o 23' | 865 | 2 5/8 | 3 | 130 | 93 | 60 |

| 73.1 | 0o 27' | 2598 | 2 3/4 | 3 1/2 | 122 | 88 | 60 |

| 77.5 | 0o 30' | 3801 | 2 7/8 | 3 3/4 | 117 | 71 | 60 |

| 84.9 | 0o 28' | 2136 | 1 3/8 | 2 1/8 | 101 | 70 | 60 |

| 96.2 | 0o 27' | 1879 | 1 7/8 | 2 1/4 | 109 | 81 | 60 |

| 97.4 | 1o 2' | 843 | 2 1/2 | 2 3/4 | 78 | 67 | 60 |

| 98.7 | 1o 29' | 3671 | 3 3/8 | 4 1/8 | 72 | 60 | 60 |

| 100.0 | 2o 10' | 1415 | 3 7/8 | 4 5/8 | 64 | 61 | 60 |

| 101.4 | 0o 56' | 1993 | 2 | 2 1/2 | 77 | 59 | 60 |

| 102.8 | 0o 26' | 1320 | 3 1/4 | 4 1/8 | 127 | 91 | 60 |

Appendix B - TOFC/COFC Car Loading and Securement

The U.S. Federal Railroad Administration (FRA) prepared a report in 1994 on Trailer-on-Flat Car and Container-on-Flat Car Loading and Securement Safety . In response to the safety weaknesses identified in TOFC/COFC loading operations, the FRA proposed that both the FRA and industry promote the following safety actions:

- Require post-loading, pre-departure inspections of all loaded TOFC/COFC equipment by personnel other than the loading crew such as loading crew supervisors or carmen;

- Establish a uniform minimum set of training requirements to qualify TOFC/COFC loading crews throughout the industry;

- Establish required preventative maintenance intervals for TOFC/COFC securement systems that include cleaning and re-lubrication of critical moving parts;

- Develop written standard operating procedures for safely loading TOFC/COFC equipment at each loading site;

- Discontinue the practice of collapsing defective hitches into the floor of the flat car and loading the car with containers without providing a means of positively preventing the defective hitch from being raised and used after it is unloaded;

- Review design standards of trailers and containers to be loaded on TOFC/COFC equipment to ensure they are compatible with the various lifting modes while loaded to capacity; and

- Provide railroad oversight of the work of contractors performing TOFC/COFC loading work to ensure the contractors follow all the established safety procedures.

In conjunction with the FRA findings, the Brotherhood of Railway Carmen (BRC) conducted a loading site survey and reported, among others, the following findings: