Main track derailment

VIA Rail Canada Inc.

Train no. VIA 15

Mile 46.45, Bedford Subdivision

Stewiacke, Nova Scotia

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content.

Summary

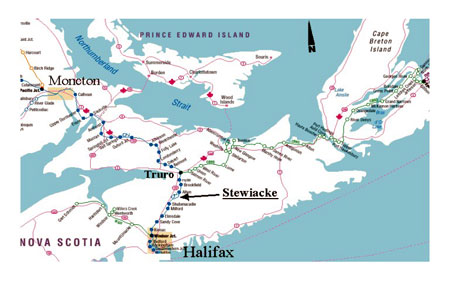

On 12 April 2001 at approximately 1424 Atlantic daylight time, a westward VIA Rail passenger train (VIA 15), consisting of two locomotives and 14 cars, travelling from Halifax, Nova Scotia, en route to Montreal, Quebec, derailed at a manually operated main track switch in Stewiacke, Nova Scotia (N.S.). A standard Canadian National (CN) switch lock used to secure the switch in correct position had been tampered with. The two locomotives and the first two cars continued on the main track, but the following cars took a diverging route onto an industrial track adjacent to the main track. Nine of the cars derailed and a farm supply building, as well as the industrial track were destroyed. Four occupants of the building escaped without injury prior to impact. There were 132 persons on board the train. Twenty-two persons were transported to hospital in either Truro or Halifax. Nine were seriously injured.

Ce rapport est également disponible en français.

1.0 Factual Information

1.1 The accident

On 12 April 2001 at approximately 1424 Atlantic daylight time (ADT)Footnote 1, a westward VIA Rail Canada Inc. (VIA) passenger train, VIA 15, consisting of two locomotives and 14 cars, derailed at Mile 46.45 of the Canadian National (CN) Bedford Subdivision. The derailment occurred at a manually operated main track switch, designated as TU-29 in the town of Stewiacke, Nova Scotia, located about 70 kilometres north of Halifax. Both locomotives and the first two cars of VIA 15 continued on the main track, but the following cars took a diverging route through the TU-29 industrial track. Nine cars, positioned 3rd to 11th in the train, derailed. The Skyline car struck the foundation of a farm supply building, severely damaging the car. The following car, a diner, collapsed in the mid-section area, bending around the building at approximately 90 degrees with the result that both the car and the building were totally destroyed (figures 2 and 3).Four occupants of the building escaped without injury prior to impact. There were 132 persons aboard the train.

1.2 Emergency response

At approximately 1426, a 911 call was placed by a Stewiacke resident, notifying emergency services that a VIA passenger train had derailed. Nine fire departments responded, with approximately 60 members. In addition, eight Emergency Health Services (EHS) ground ambulances, one EHS air ambulance and two EHS support units were dispatched. Royal Canadian Mounted Police and CN police also responded. Other responding agencies included VIA, CN, the Red Cross and the Bible Hill Hazmat (Hazardous Materials)Team.

When the first of the ground ambulances arrived at approximately 1440, ambulatory passengers were being helped from the wreckage by either VIA crew members or Stewiacke residents. A triage was established by EHS and a total of 100 persons were treated. The first patient was transported from the scene by ambulance at approximately 1529, with the last of the injured taken at 1722.

On evacuating the train, passengers who were not injured were directed to the town hall or the Legion, a short distance from the site, from where they were transported to the fire station/community centre by five buses provided by the local school board. By 1900 that evening, all VIA passengers had left the community centre and had either returned to Halifax, or were proceeding to their destinations as arranged by VIA.

1.3 Injuries

Twenty people were transported by ground ambulance to the Colchester Regional Hospital in TruroFootnote 2 and two were airlifted from the site by air ambulance and taken directly to the Halifax Infirmary - Queen Elizabeth II Hospital in Halifax. Nine of the twenty-two sustained serious injuries, including five on-train services (OTS) crew members. Several of the most severely injured persons were located in the heavily damaged Skyline and diner cars. A large piece of concrete from the foundation wall of the farm supply building was sheared off and projected into an occupied area of the Skyline car.

1.4 Damage to equipment

Of the nine derailed cars, one car was destroyed, two sustained serious damage and six had minor damage (Appendix A contains further information about the equipment as inspected post accident).

1.5 Other damage

Approximately 750 feet of main track and the entire industrial track were extensively damaged. A main track turnout was also slightly damaged.

1.6 Personnel information

The operating crew consisted of two locomotive engineers, and 13 OTS employees. They were qualified for their respective positions and met established fitness and rest standards.

1.7 Train information

VIA 15 was powered by two locomotives and consisted of one baggage car, four coach cars, a Skyline car, a diner car, six sleeper cars, and a park car. The train weighed approximately 1100 tons and was about 1250 feet in length.

1.8 Method of train control

Train operations from Mile 15.1 to Mile 61.5 are controlled by the Centralized Traffic Control (CTC) System authorized by the Canadian Rail Operating Rules and supervised by a rail traffic controller (RTC) located in Montreal.

1.9 Occurrence site information

The derailment occurred between a highway overpass located at Mile 46.35 and a public crossing (equipped with flashing light signals and bell) located at Mile 46.75 (Figure 6). Although the train movement was designated as westward, in this location the track infrastructure was oriented north/south. The track was tangent on a 0.35 per cent descending grade. At Mile 46.45, there was a switch for an industrial track (TU-29). The industrial track was equipped with a derail which protected the main track from unintentional movements of rolling stock. There was a fenced park area to the west side of the tracks, and a mix of commercial and residential properties to the east side of the main track. The last intermediate signal (identified as H443) before the TU-29 switch was located at Mile 44.3. At that location, there was also a wayside inspection system (WIS).

When the derailed train came to rest, the TU-29 switch stand handle was observed to be raised and sitting on top of the switch stand table and the switch points were open.

1.10 Track information

1.10.1 Bedford Subdivision

The Bedford Subdivision is single main track. The authorized timetable speed is 75 miles per hour (mph) for passenger trains and 60 mph for freight trains. A temporary slow order restricted speed to 50 mph over a public crossing (Main Street) at Mile 46.75 in the town of Stewiacke.

Through the derailment area, the track consisted of 115 pound continuous-welded rail, rolled and laid in 1989. The ties were No. 1 hardwood. The rail was secured with four to six spikes per tie on 14-inch double-shouldered tie plates and anchored every tie. The crushed rock ballast was in good condition.

1.10.2 Turnout details

Track TU-29 was connected to the main track with a No. 10 turnout with a rated design speed of 15 mph. The distance from the tip of the switch point to the heel was 16.5 feet (Figure 7). It was noted that the tip ofthe switch point closest to the switch stand had some fresh markings and was slightly battered. It was also noted that the end of the switch point, by the heel block, had a slight bend. The guard rail on the main track opposite the frog was damaged by wheel impact and was bent towards the industrial spur track. There were marks noted on the base of the rail, on the ties, and in the ballast from the turnout location up to the first derailed cars. There was no track damage prior to the turnout location.

The switch stand was a standard 31B model equipped with a switch target and tip assembly (Figure 8). Due to the presence of a derail on the industrial spur track, the switch stand lever was painted yellow in accordance with CN Standard Practice Circular (SPC) 3603.

The switch stand was equipped with a standard CN switch lock (Figure 9). The clasp mechanism was broken and the switch lock was hanging loosely, suspended by the chain that affixes the lock to the switch stand. The lock had numerous dents and deformations (Figure 10).

The industrial track had last been used approximately six months before the accident by maintenance-of-way personnel. The turnout for track TU-29 was inspected and serviced on 10 April 2001. The track had not been in use for commercial purposes for several years.

There were two hi-rail inspections performed on the Bedford Subdivision on the day of the occurrence and no track defects were found in the area of the derailment. The switch was inspected by a signal maintainer at 1030 on the day of the accident. The second hi-rail inspection was conducted by a track supervisor approximately 2.5 hours later. Both the switch and the railway traffic signal system were functioning as intended at that time, and the switch lock was noted to be in place.

The switch and signal systems were examined after the accident and found to be in normal working order.

1.11 Weather

The weather was calm and clear with a temperature of plus 10 degrees Celsius.

1.12 Recorded information

Prior to the emergency brake application, the locomotive event recorder data showed that train speed was being reduced from 73 mph to approximately 50 mph. As the train approached the derailment area, the recorded train speed was down to 48 mph. The brakes on both the locomotives and the cars were applied and the locomotive horn was in use. At 1424 and at a recorded speed of approximately 46 mph, with the throttle in the idle position, a train-initiated emergency brake application occurred.

Rail traffic control

The locomotive engineer at the controls called the RTC before the train arrived at Signal H443 to obtain an occupancy control system clearance, which was required for the train to enter the non-CTC portion of the Bedford Subdivision near Truro. The conversation was conducted on a cellular telephone. The background noise of both the RTC Centre and the locomotive cab (e.g. locomotive engine sounds, locomotive whistle and bell, and in-cab voice sounds including radio transmissions heard in the cab) were recorded on the RTC tape recording; thereby, providing investigators with the equivalent of a cab voice recording. RTC tape recording systems are installed at the railway's initiative; there is no regulatory requirement to record RTC conversations. This audio recording was compared to the recorded data from the WIS and the locomotive event recorder allowing accurate time and location references to be determined.

Previous Railway Transport Committee Orders requiring the installation of locomotive event recorders in locomotives in Canada (R-39922; R39915; R-40340 R-40339; R-40614) required that recorders register time, speed, distance, brake pipe pressure, throttle position, emergency brake application, independent brake cylinder pressure, and whistle. At present, there is no requirement for a cab voice recorder on locomotives similar to those for commercial aircraft. Cab voice recorder contents are used solely by TSB for investigative purposes, they are protected by law, and may not be used as evidence for disciplinary purposes or prosecution by the carrier or the regulator.

Signal activity and WIS information

From the time of the departure of VIA 15 from the previous controlled location (Milford, Mile 38.4) until the train derailed, there were no records of any block occupancy conditions in the signal log data which were unaccounted for by railway activity (i.e. there was no record of a block showing an open main track switch but no train in the block.) The signal log indicates clear signal indications throughout, which is consistent with the train crew's recollection of events.

All of the train control, signal, and wayside inspection systems in use were functioning as intendedFootnote 3.

1.13 Switch Securement

1.13.1 Regulatory Requirements

The use of high-security switch locks (Figure 11) was one outcome of The VIA Passenger Train Speed Inquiry (Railway Transport Committee, 1985). This inquiry was prompted by an act of vandalism to a main track switch in June of 1984 on the Smith Falls (Ontario) Subdivision of CN which caused a derailment of a VIA passenger train. Subsequent to the accident, and a show causeFootnote 4 order (Order No. R-39612) issued 25 July 1986, CN implemented the widespread use of high-security switch locks in non-signalled territory, and on signalled territories that were historically prone to switch vandalism. In 1986, Order No. R-39910 governing high-security switch locks was issued to Canadian Pacific Railway Company Ltd. (CP). This order required high-security switch locks be installed on manually operated main track switches on:

- Non-signalled passenger train routes;

- Non-signalled established passenger train detour routes;

- Non-signalled freight train routes where speed exceeds 30 mph; and

- Sidings where cars containing dangerous goods are frequently placed.

As CN had previously informed the Railway Transport Committee of its planned safety measures in these similar areas, Order No. R-39910 was only issued to CP.

Although CP stated that it was their intention to change over existing switch locks with high-security locks on all main track territories within 36 months, signalled tracks were not included in the scope of Order No. R-39910. At that time, a signalling system was considered to be capable of providing an advance warning to an operating crew of a pending hazard in sufficient time.

1.13.2 Industry practice

In addition to installing high-security switch locks in the areas referenced in Order No. R-39910, CP specified that high-security switch locks also be used on all manually operated main track switches in signalled territory. Other than areas historically prone to vandalism, CN did not initially extend the use of high-security switch locks to signalled territory.Footnote 5

Notwithstanding that the requirements for CP under Order No. R-39910 were not applicable to other railways, some railways instituted programs to equip their manually operated main track switches with high-security switch locks. For example, the Quebec North Shore and Labrador railway has been using high-security locks on manually operated main track switches in non-signalled territory on the Menihek Subdivision since 1987.

With the creation of significant regional and short line systems, not all of the smaller railways are using high-security switch locks on those subdivisions formerly owned by CN and CP. Subsequent to the accident, the TSB requested information from the Railway Association of Canada (RAC) on the practices of its member railways with regard to the use of high-security switch locks. The information revealed that a variety of strategies and types of locks were being used by the smaller railways. Of the twenty railways which responded, three indicated that they were not using high-security switch locks on manually operated main track switches.

Also, many railways selectively identify switches that are located near grade level crossings (that are prone to acts of vandalism, or risk of damage due to a crossing accident) for the added protection afforded by switch point locksFootnote 6.

1.13.3 Testing of switch locks and handle

A sample of new and used switch locks from several manufacturers commonly used by the railways were forwarded to the TSB Engineering Laboratory for further analysis (TSB Report LP 046/01,Appendix B):

- A tensile test machine with adapters was used to measure the ultimate strength of the locks. The average failure load obtained during the tensile test was 2500 lbs for standard switch locks similar to the type involved in this accident versus 10 000 lbs for high-security locks;

- Impact resistance was compared by counting the number of hammer strikes to open the lock when installed on a switch stand test apparatus. The same 16 ounce hammer and user were utilized for all of the impact tests in order to minimize the variability of the energy in the hammer blows. The impact test results averaged 25 hammer strikes for standard switch locks versus over 100 hammer strikes for high-security locks;

- Bolt cutters were used on the eye of the switch handleFootnote 7 to assess its resistance to tampering. The lock is not in a concealed location, therefore the eye of the switch handle, the hasp and the lock can be easily accessed. The 12-inch handled bolt cutters easily cut through the eye above and below the lock, bypassing the lock in 20 seconds.

1.13.4 Risks associated with an unlocked switch handle

Maintenance personnel adjust switch points so that they are tight to the stock rail when set in the normal (closed) position. When the switch handle is fully rotated then lowered into its retaining slot and locked (Figure 12), the switch points apply a compressive force against the stock rail. Because the switch points are sitting on lubricated flat steel plates, as soon as the switch handle is unlocked and raised out of the slot, the force is released and the switch point generally moves away from the stock rail, opening the switch a slight amount. An examination of the occurrence switch stand revealed that the sole action of raising the switch handle in its slot vertically to the level of the table (Figure 13) was enough to cause the switch points to open approximately 1/4 inch.

Even in a condition where a hand throw switch handle is down in its retaining slot but left unlocked, over time, vibration and dynamic forces imposed on the switch under the weight of passing trains can cause the points to flex and open. Unless the points are held tight to the stock rail by the connecting rod and secured by the stand and lock or a switch point lock, the points can open sufficiently to allow a wheel flange to take a diverging route.

Other than a visual inspection of the switch lock or handle, there is no indication when a manually operated switch is left unlocked. However, when the switch handle is in the raised and open position, a red target will be displayed. If the switch is located within CTC, then a restrictive signal (light) is displayed as an advance warning.

1.13.5 Switch stand and targets

The switch target and tip assembly is directly affixed to the switch stand mast. The switch stand mast is linked to a spindle and switch handle (Figure 14). Therefore, there is a direct relationship

between the lateral movement of the switch handle and the change in aspect of the switch target and mast. As the mast is rotated 90 degrees to move the switch points from the normal to the reverse position, the target attached to the mast and spindle moves to the same degree. The design of the switch stands and their associated targets dates from the early 1930s.

1.13.6 CTC signal system

CTC allows movement of trains over routes and through blocks on a designated section of track or tracks as directed by signals controlled by an RTC. Train crews are provided with signal indications that reflect conditions as sensed by the system. The system can identify occupancies within a block created by trains, or disruptions to the track circuit continuity created by such things as a broken rail, or an open switch point.

In normal operation, signal indications change to display more restrictive signals in both directions if a switch point moves away from the stock rail by a distance of 1/4 inch or more. The signal system will continue to reflect a normal condition when that distance is less than 1/4 inch. The system is not designed to detect an unlocked switch, nor a switch point that is not properly restrained by the design mechanism of the manually operated switch.

1.13.7 New Technologies for Indicating Position of Manually Operated Main Track Switches

The Transportation Development Centre, on behalf of Transport Canada (TC) Rail Safety, retained the Transportation Group at the University of New Brunswick to conduct a review of technologies capable of indicating the position of hand-operated switches on non-signalled rail linesFootnote 8. The review included surveys directed to universities, research and/or development centres and suppliers/manufacturers of signalling equipment around the world. In addition, visits and interviews were held with representatives of TC, RAC, CN, CP, the Brotherhood of Locomotive Engineers, and selected companies and institutions.

An initial cost-benefit analysis was undertaken to assess the savings from reduction in property damage, personal injuries and fatalities on main-track lines if a system were installed to provide advance warning to train crews on the position of a manually operated switch on non-signalled rail lines. Passenger travel time and cargo savings were also used in the cost-benefit analysis. An estimate of future accidents related to improper position of manually operated switches was made.

The review identified 10 technologies having the potential for application to the issue. Of these, five were considered to have the highest probability of successful application. None of the technologies could be justified financially from a safety perspective only. However, the study noted that they should be economically viable if certain travel time savings were includedFootnote 9.

Between October 2000 and January 2002, CN field-tested a self-developed switch point indicator signal system for use in non-signalled territory. The system was installed in the Toronto area on the CN Uxbridge Subdivision and used spread-spectrum radio technology to convey the switch position to the crew of an approaching train. CN indicated that, although the test confirmed that the technology was sound, it was not deemed to be cost effective. The equipment was removed from the site on 15 January 2002. The estimated cost of the system per individual site was $25 000. CN stated that the railway would continue to keep abreast of developments using alternative technologies which may be more cost effective.

1.14 Trespass/Vandalism

TSB data indicate that in Canada, over a five-year period (1996-2001), broken switch locks or switch tampering due to vandalism were considered contributory in 40 railway occurrences; none involved high-security switch locks. Four of these occurrences resulted in derailments of passenger trains.

A review of CN reports on trespassing and vandalism specific to the Bedford Subdivision for years 1997-2000 revealed that there was one reported incident of vandalism that involved switch pointsFootnote 10. VIA operating and OTS crews, CN transportation and engineering employees, as well as CN police personnel, stated that the CTC portions of the CN Bedford Subdivision, including the Stewiacke area, were not locations considered to be prone to acts of vandalism.

An examination of the site revealed that there were well-worn footpaths adjacent to the railway right-of-way between the area of the highway overpass and the downtown. Immediately under the highway overpass, physical signs of trespassing were noted (e.g. an extensive amount of graffiti, litter, and pieces of broken glass). All-terrain vehicle trails were also noted in the region. There were no signs warning local persons to stay off the railway right-of-way in these areas. The only fencing that existed was constructed by the town of Stewiacke along the park area to the west of the main track.

Operation Lifesaver is a joint industry/government program used to increase public awareness of the danger of trespassing on railway rights-of-way and also to advocate for level crossing safety. Between 01 January 2000 and 16 October 2002, 104 safety presentations were made at 47 locations within Nova Scotia by Operation Lifesaver volunteers. Approximately 9600 students attended these presentations, the vast majority of which were elementary age.

1.15 Passenger Safety

A detailed inspection of the rolling stock, crew and passenger interviews, and a subsequent mail-in passenger survey, led to the identification of a number of passenger safety issues.

Access to one emergency exit window was noted to be partially obstructed by the location of a box used for wheelchair storage. An examination of the VIA fleet of 37 HEP 1 (head-end power) stainless steel coaches revealed that a similar condition existed in eight of the coaches. In other instances, the location of the wheelchair box obstructed access to the hammer used to break the glass of the emergency exit windowFootnote 11.

The impact of the collision caused two of the beds in the roomettes of one sleeping car (VIA 8225) and one in another car (VIA 8228) to fall from their stowed position in the wall above the passenger seat, resulting in one passenger being struck on the head. An examination of the latching mechanism revealed that the release of the beds was most likely due to the beds not being correctly secured in position when they were last stowed.

Three OTS employees were trapped inside the kitchen area of the diner car. The emergency egress provisions for employees required to work in the diner car was the subject of a subsequent Occupational Health and Safety (OHS) investigation conducted by TC under Part II of the Canada Labour Code (Appendix C).

Other issues identified in this investigation, i.e. unrestrained items (carry-on baggage, heavy items such as chairs and tables moving about in the cars, dinnerware, cooking utensils); broken glass; and contact with other sharp objects were common to other passenger train occurrences investigated by the TSB between July 1999 and April 2001 (TSB occurrence nos. R99T0298, R99S0100, R99H0009, and R00M0007). A separate examination encompassing all five accidents was undertaken to provide a better understanding of the passenger safety data, and provide a more complete picture of the safety issues identified. As a result, in July 2001, Railway Safety Advisory 05/01 was sent to TC and VIA outlining passenger safety issues as identified from the investigations. The advisory appended a report with observations on common, relatively minor safety issues which, when aggregated, gave some indication of a possible risk to the travelling public.

2.0 Analysis

The cause of the accident was not a matter of dispute as the damages to the switch lock and chain were a clear indication that the switch was unsecured due to tampering. The Royal Canadian Mounted Police (RCMP) conducted a criminal investigation that led to a local youth pleading guilty to ‘mischief endangering life'. As it is not the function of the TSB to assign fault or determine civil or criminal liability, the TSB investigation concentrated on all other aspects of the occurrence that would allow the further advancement of transportation safety.

There were no deficiencies identified with respect to the operation and mechanical condition of the train. There were no defects noted with the track infrastructure. The signal system functioned as designed, and no restrictive signal indication was displayed or communicated to the crew of VIA 15 while approaching the switch at Mile 46.45. The analysis will focus on those issues relating to trespassing, the securement of main track switches, the warning provided to the operating crew, passenger safety issues, and the emergency response.

2.1 The accident

Dynamic forces generated by the equipment passing over the unsecured TU-29 switch resulted in the switch points moving under the train. The marks on the track infrastructure and an examination of the derailed equipment indicate that the leading truck of the fourth car took the diverging route resulting in further switch point movement and the derailment of the other cars.

2.2 Trespassing

The town of Stewiacke, Nova Scotia, like many other Canadian municipalities, has developed over time such that it is now built up on each side of the track. People living in such communities can seldom avoid the railway tracks and the railway right-of-way frequently provides a convenient shortcut to their destination. Despite the presence of well-worn footpaths and other physical signs of trespass activity (e.g. graffiti, all-terrain vehicle trails), there was a limited amount of fencing and signage in the area to deter such activity. Efforts by the railway police, the RCMP, and the town (such as Operation Lifesaver, fines under the Contraventions Act, and fencing), although positive, were not part of a comprehensive risk management approach. Without a structured approach to trespassing by all stakeholders, including comprehensive risk assessment and risk management principles, the ability to identify and address safety issues related to trespassing, such as vandalism, was limited.

2.3 Switch securement

A person intent on vandalism could undermine the security of a switch mechanism in a number of ways. In this accident, the more visible aspects of the mechanism, that being the switch stand handle and the associated lock, were targeted. The impact and tensile tests conducted by the TSB indicated that a high-security switch lock is significantly more difficult to break than a standard switch lock, which is supported by the TSB occurrence dataFootnote 12. However, the bolt cutter test clearly demonstrated that whatever lock is used, the eye of the switch handle which is in plain view can be quickly and easily cut leaving the switch unsecured.

The regulatory framework pertaining to manually operated main track switches does not mandate the installation of high-security switch locks on railways other than CP. Therefore, there are a variety of switch securement strategies in use, as indicated in the response from Railway Association of Canada (RAC) members. Some railways are not using high-security switch locks in areas that they perceive to be low risk. However, when standard locks are used on manually operated switches, the risks associated with switch tampering due to vandalism are increased.

Furthermore, by limiting the mandatory use of more tamper-proof, high-security switch locks mainly to non-signalled tracks, and by not requiring extended use of the extra protection afforded by switch point locks, the risk of switch misalignment due to tampering in signalled territories was higher than what it otherwise would have been. The reasons for focussing on non-signalled territories back in the mid 1980s were obvious; until this accident, the risk of switch tampering within signalled territories was deemed to be low, given the perceived capability of the system to alert a train crew of a pending hazard.

2.4 Advance warning

In CTC territory there are devices, such as the railway signal system and the switch targets themselves, which can provide train crews with advance warning of an unsafe main track switch position. However, this investigation has revealed that there are limitations in the level of safety provided by these devices.

When the securement of a switch has been compromised, but the points have not moved 1/4 inch or more, the railway signal system continues to indicate to the crew of an approaching train that the switch condition is lined as intended. Also, should manually operated switch points be moved after a train has passed the last signal display location, the signal system does not communicate this change to the train crew. In such situations, an approaching train crew would be unaware of the unsafe switch position in front of them, as happened in this accident.

Lateral movement of the interconnected switch points, switch rod, and switch handle is required in order to rotate the switch stand mast and thereby display a red target and red tip assembly to an approaching crew, indicating that the switch is lined for the diverging route. However, when a switch stand handle is unlocked, or the switch points are even slightly open, the switch target will remain displaying a normal (e.g. green) indication, providing false information to an approaching train (figures 15 and 16).

Although the risk of switch tampering in signalled territory is low, the inability of either the railway signal system, or switch targets, to provide reliable warning that a main track switch is not properly locked puts train crews and the public at risk.

Operating crews need information which reflects the actual switch conditions that they will encounter. Neither the signal system nor the switch target was capable of providing the crew of VIA 15 with information that the TU-29 switch was not properly lined and securely locked. As a result, the approaching train did not receive an advance warning on the change of the switch position.

The lack of concordance between the information provided to the crew and the actual switch position resulted in the crew not being able to react to the unsafe condition (Figure 17).

Figure 17. First two photographs show switch points open 3/16 inch yet a green CTC signal is displayed to a train crew. Last two photographs show an unlocked and partially raised switch handle, yet a green switch target.

Other risk control measures, such as semi-permanent switch point securement (by spiking the switch points in the normal position) or the provision of additional protection by securing it with switch point locks, could have also reduced the consequences associated with a vandalized switch handle lock.

2.5 Passenger safety

The location of the wheelchair boxes in some of the HEP 1 coaches presented a potential risk to passengers needing ready access to the emergency exits in an emergency. In the event of an evacuation, the safety benefit afforded by an emergency exit window may be effectively lost if the window or the hammer to break the window is obstructed by the location of the wheelchair box.

The investigation also revealed that the beds in some of the sleeper cars can be stowed and appear secured when they are not. Although in this case no injury was sustained by the passenger, under other circumstances this situation could lead to serious injury for the occupant.

2.6 Emergency response

The emergency response to the derailment was the largest in the province of Nova Scotia since the Swissair (Flight SR111) accident in 1998, and involved a number of agencies at both the municipal and provincial levels. Following the occurrence, the agencies involved met under the auspices of the provincial emergency measures organization to review and evaluate the response activities. It was concluded that the emergency response was well coordinated and no significant deficiencies were identified that would have impacted on the handling of the passengers.

2.7 On-board voice recorders

Since the mid 1990's, TSB has been advocating the need for on-board voice recorders to supplement information captured by the locomotive event recorders. Recorded sounds can play an important role in the investigation process and identification of safety deficiencies. Although rail traffic controller (RTC) tapes are in widespread use, not all railways possess RTC tape recording facilities, nor are they required. The sound environment in the locomotive cab will only be recorded during open-ended telephone conversations with the locomotive engineers in the cab, or when the locomotive engineer is transmitting when the locomotive radio is being used to communicate with the RTC, where an RTC tape capability exists. No other conversations or background sound record will be available for analysis, as there is no on-board continuous recording of sound.

Too often, TSB investigators are unable to conduct a complete analysis of the events preceding an occurrence because there is not enough information available. While rail operations depend heavily on voice communications, at present, there is no means for recording and subsequently evaluating all audio sounds preceding an accident which can hinder the identification of risks to safety. In this accident, the existence of an audio recording with the locomotive operating environment noise and speech recorded on the RTC tape permitted TSB to make a positive identification of train location during a safety-critical communication (obtaining an occupancy control system clearance) for the duration of the conversation which occurred prior to the accident and materially assisted the investigation.

3.0 Findings

3.1 Findings as to causes and contributing factors

- Damage to the switch lock and chain were a clear indication that the TU-29 main track switch was unsecured due to tampering.

- The train derailed when cars took a diverging route at the unsecured switch.

- The presence of a standard switch lock on the TU-29 switch increased the risks associated with switch tampering due to vandalism.

3.2 Findings as to risk

- As neither the railway signal system nor the switch target was capable of providing the crew of VIA 15 with information that the switch was not properly lined and securely locked, the approaching train did not receive an advance warning of the actual switch position.

- Without a structured approach to trespassing by all stakeholders, including comprehensive risk assessment and risk management principles, the ability to identify and address safety issues related to trespassing, such as vandalism, was limited.

- The location of the wheelchair box in some coach cars obstructed access to the emergency exit windows, which could impede the emergency egress of passengers.

- When the beds in some of the sleeper cars are stowed, they can appear secured when they are not, thereby posing a risk to the occupants.

3.3 Other findings

- The emergency response was well coordinated and conducted in a prompt and professional manner.

- The existence of an audio recording which included locomotive operating environment sounds, as well as speech, permitted a better understanding of crew activities and materially assisted the investigation.

4.0 Safety action

4.1 Action taken

4.1.1 Stewiacke - Industrial spur

In May 2001, VIA Rail Canada representatives made Operation Lifesaver presentations at two Stewiacke, Nova Scotia, area schools; additionally, other schools in the area were also visited.

In August 2001, Canadian National Railway (CN) removed the TU-29 switch and associated track from the Bedford Subdivision and installed additional trespass prevention signage in the Stewiacke area.

Transport Canada's Atlantic Region office targeted Stewiacke and the surrounding municipalities for a presentation to introduce the Community Trespass Prevention Guide. The guide was developed as part of the Direction 2006 program and offers detailed instructions on how railways, communities, police services, and other groups can best work together to implement trespass prevention activities.

4.1.2 Protection of manually operated main track switches

Testing conducted by TSB indicated that a high-security switch lock would have been significantly less prone to damage or vandalism than the standard switch lock. To enhance safety and reduce the risk of vandalism, both CN and Canadian Pacific Railway reviewed their policies and practices regarding the installation of high-security switch locks. As a result, several thousand high-security switch locks were installed on all manually operated main track switches for both signalled and non-signalled territories. Priority was given to those locations with passenger train operations and those prone to vandalism. The applicable sections of the respective railway Standard Practice Circulars were revised accordingly to reflect the more stringent locking requirements.

Not all railway companies have taken such action. Programs relating to the use of high-security switch locks and switch point locks vary, and not all railways have programs in place. Given the safety risks posed by vandalism to switches, in August 2001, the TSB issued Rail Safety Advisory - 06/01 titled Switch Locks on Hand Operated Main Track Switches which concluded that:

...in consideration of the safety risks posed to railway operations by vandalism to switches, Transport Canada may wish to review the differences between railways concerning the use of high security switch locks, and the use of switch point locks, on hand-operated main track switches, paying particular attention to those railways over which passenger trains operate.

TC advised that a cursory scan of the short line railways indicated that most meet the requirements of Order No. R-39910, or are upgrading to these requirements. TC advised that it conducted a survey of all other railways on the usage of high-security switch locks and switch point locks. Assessment of the survey indicated that federally regulated railways have equipped main track switches with proper high-security locking devices.

4.1.3 Passenger safety

In April and May 2001, joint Railway Association of Canada (RAC) and TC workshops were delivered at strategic locations across the country to educate railways, railway labour unions and both federal and provincial regulators in the requirements of the recently introduced Railway Passenger Handling Safety Rules, and the companion Circular No. 6 - Passenger Train Handling Safety and Emergency Procedures. VIA training material was shared with and circulated to other passenger carrying railway companies. The extensive training modules and videos developed by VIA were voluntarily provided to interested Railway Association of Canada (RAC) members.

On 20 July 2001, TSB issued detailed Rail Safety Advisory - 05/01 to TC entitled Observations of Railway Passenger Safety in Canada. The safety advisory letter concluded that many relatively minor issues relating to passenger safety remain unaddressed, which on their own do not pose a significant risk but, when taken in combination, indicate a possible systemic risk situation. It stated that:

Transport Canada and industry may wish to examine these issues and in view of the potential combined risk, evaluate the adequacy of their existing regulatory and safety management approaches in these areas.

On 10 September 2001, TC responded advising that Departmental staff met with representatives of VIA on 13 August 2001. In addition, TC provided the RAC with a copy of the Rail Safety Advisory in order that its other passenger-carrying railway companies could be apprised of these issues. TSB contacted TC in January 2003 to assess the status of these initiatives; corrective action is being implemented and is monitored by TC.

In July 2001, TSB issued Rail Safety Advisory - 03/01 to TC entitled Wheelchair Box on VIA HEP 1 Passenger Cars Obstructing Access to Emergency Exit Window and Hammer. The safety advisory letter concluded that:

... in view of the safety risk this condition poses to both on-board railway staff and passengers during an evacuation, Transport Canada, in conjunction with VIA Rail, may wish to re-evaluate the current wheelchair box installations in all HEP1 coaches.

On 08 August 2001, TC advised that to correct the situation the department recommended to VIA that the hammers on all HEP 1 coaches be relocated. VIA subsequently relocated the hammers and in addition, relocated the wheel chair storage boxes on all HEP 1 coaches.

In July 2001, TSB issued Rail Safety Advisory - 04/01 to TC entitled Securement of Beds in VIA Sleeping Cars. The safety advisory letter concluded that:

Transport Canada may wish to advise VIA to review the locking procedures and have on-train service (OTS) employees ensure that all beds are correctly secured when in the stowed position.

On 08 August 2001, TC advised that a VIA Maintenance Procedure (No. C604/003, issued in April 1992) applied to this topic, and OTS employees were reminded of the importance of ensuring that the maintenance procedure was followed. VIA also instructed OTS employees to listen for the locking mechanism to ‘click' when securing beds in sleeping cars. TC also advised that, following this derailment, VIA inspected (and where required, repaired) the locking mechanisms of all beds in its sleeping cars.

4.1.4 Emergency egress, securement of items, communications, and lighting

As a result of the OHS investigation that was conducted under Part II of the Canada Labour Code, TC issued a Direction to VIA to address the question of emergency egress for the kitchen area of the car (Appendix C). In response, VIA initiated a program to equip the kitchen area windows with breakout glass.

As part of its final OHS investigation report, it also stated:

- That portable radios and radio monitors be securely attached to on-train services employees at all times;

- That glassware, dinnerware, kitchen utensils and cooking utensils be safely and securely stowed when not in use;

- That flashlights carried by employees be securely and permanently attached to their person at all times, in a case that would prevent the flashlights from being dislodged from the case; and

- That the satellite phone be relocated in the last car of the train and that the employees be trained and qualified to use it.

VIA agreed with and has taken action to address the first three items. As to the fourth, VIA found that relocating the satellite phone would not be practicable, however, a training program was initiated to qualify on-train services employees in its use.

4.1.5 Review of operating rules

The Railway Association of Canada has tasked the Operating Rules Committee to review and possibly revise the Canadian Rail Operating Rules to incorporate the principles of Order No. R-39910, with respect to high-security switch locks. Should any amendments to the operating rules be deemed necessary, the changes would apply to virtually the entire railway industry in Canada.

This report concludes the Transportation Safety Board's investigation into this occurrence. Consequently, the Board authorized the release of this report on .

Appendices

Appendix A - Position of eEquipment post accident

An inspection of the derailment site revealed the following:

- VIA 6405 and VIA 6455 (locomotives) had remained coupled and upright on the main track. They were not derailed.

- VIA 8619 (baggage car) and VIA 8119 (coach car) had remained coupled and upright on the main track. They were not derailed and were coupled to the two locomotives.

- VIA 8134, 8130, 8136 (coach cars) and VIA 8503 (Skyline car) were derailed to the right of the main track in the direction of train travel. They all remained coupled and upright. The brake pipe was separated between the fifth and sixth cars.

- The leading end of VIA 8503 (Skyline car) had struck the foundation wall of the farm supply building resulting in severe damage to the car. A piece of the foundation wall had been dislodged and entered the occupied compartment area of the car.

- VIA 8417 (diner car named "Wascana") had collapsed in the mid-section area. The bent car struck the upper structure of the farm supply building, resulting in both the car and building being destroyed.

- VIA 8225 (sleeper car) came to rest upright with its forward end within the damaged building. The car was roughly parallel to the main track.

- VIA 8206 (sleeper car) derailed and came to rest upright about 45 degrees to the main track.

- VIA 8212 (sleeper car) derailed and came to rest upright and roughly parallel to the main track.

- VIA 8228 (sleeper car) derailed and came to rest upright on an angle to the main track.

- VIA 8205 (sleeper car) did not derail, but the leading truck was positioned on the industrial spur track switch points. The trailing truck was positioned on the main track.

- VIA 8311 (sleeper car) and VIA 8709 (park car) were not derailed and were on the main track.

Appendix B - List of Supporting Reports

TSB Engineering Branch Report(s) LP 046/01 - Switch Lock/Stand Tests was completed 26 October 2001. The results obtained are shown in the following table.

| Lock | Max Load (Lbs) |

Comments | |

|---|---|---|---|

| Std. New 1 | 2950 | internal failure | |

| Std. New 2 | 3450 | shackle failure | |

| Std. New 3 | 3150 | internal failure | |

| Average | 3183 | ||

| Std. Used 1 | 1900 | internal failure | |

| Std. Used 2 | 2050 | internal failure | |

| Std. Used 3 | 1850 | internal failure | |

| Average | 1933 | ||

| High Security 1 | 10500 | shackle failure | |

| High Security 1 | 11580 | shackle failure | |

| Average | 11040 | ||

| High Security 2 | 10500 | internal failure | |

| High Security 2 | 8880 | internal failure, shackle failure | |

| Average | 9690 |

| Lock | Hammer strikes (16 oz.) |

Time (m.s.) |

Comments | ||

|---|---|---|---|---|---|

| Std. New 1 | 23 | 1:14 | shackle failure | ||

| Std. New 2 | 35 | 1:28 | internal failure | ||

| Std. New 3 | 42 | 1:16 | internal failure | ||

| Average | 33 | Average | 1:19 | ||

| Std. Used 1 | 11 | 0:20 | shackle failure | ||

| Std. Used 2 | 16 | 0:27 | internal failure | ||

| Std. Used 3 | 41 | 1:18 | internal failure | ||

| Average | 22 | Average | 0:42 | ||

| High Security 1 | 105+ | 3:15+ | no signs of failure | ||

| High Security 2 | 105/133 | 3:56 | signs of failure after 105 hits, internal failure after 28 additional hits |

BOLT CUTTERS

The eye of the switch stand handle was easily cut open with 12-inch handled bolt cutters, by-passing the lock entirely. This took 20 seconds to accomplish.

Appendix C -Canada Labour Code Part II - Direction to Employer

IN THE MATTER OF THE CANADA LABOUR CODE PART II OCCUPATIONAL HEALTH AND SAFETY

DIRECTION TO THE EMPLOYER UNDER SECTION 145(1)

The undersigned health and safety Officer inquired into the serious and disabling injuries of VIA Rail employees in the work place operated by VIA Rail Canada , being an employer , subject to the Canada Labour Code , Part II, at mile 46.6 Canadian National Railway's Bedford Subdivision , Stewiacke , Nova Scotia , April 12th, 2001.

The said officer is of the opinion that the following section of the Canada Labour Code, Part II, is being contravened:

Paragraph 124 of the Canada Labour Code, Part II.

VIA Rail did not provide protection to employees trapped in the kitchen/pantry area of the Dining Car, ensuring that there was an alternate access for first responders to enter and for the employees to exit from the car through the window in the kitchen.

Therefore, you are HEREBY DIRECTED, pursuant to section 145(1) of the Canada Labour Code, Part II , to terminate the contravention no later than November 19th, 2001.

Issued at Moncton, this 21st day of June, 2001.

Appendix D - Glossary

- ADT

- Atlantic daylight time

- ATV

- all-terrain vehicle

- CN

- Canadian National

- CP

- Canadian Pacific Railway

- CTC

- Centralized Traffic control

- EHS

- Emergency Health Services

- hazmat

- hazardous materials

- HEP

- head-end power

- km

- kilometre

- mph

- mile per hour

- OTS

- on-train service

- RAC

- Railway Association of Canada

- RCMP

- Royal Canadian Mounted Police

- RTC

- rail traffic controller

- SPC

- Standard Practice Circular

- TC

- Transport Canada

- TSB

- Transportation Safety Board of Canada

- TTM

- train traffic management

- UTC

- Coordinated Universal Time

- VIA

- VIA Rail Canada Inc.

- WIS

- wayside inspection system