Employee fatality

Total Track Railway Construction and Maintenance Services Inc.

(under contract to Canadian National Railway)

Nordco Grabber Model A Spike Puller

Mile 223.0, Kingston Subdivision

Moira, Ontario

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

On 11 November 2006 at 0210 eastern standard time, a spike puller operator was fatally injured while attempting to perform repairs to his machine at Mile 223.0 of the Canadian National (CN) Railway's Kingston subdivision. The operator was an employee of Total Track Railway Construction and Maintenance Services Inc. and was working on a tie gang under contract to CN.

Ce rapport est également disponible en français.

Factual information

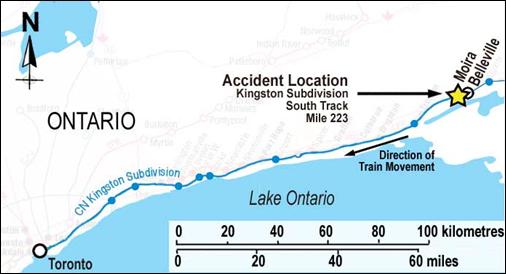

At approximately 0200 eastern standard timeFootnote 1 on 11 November 2006, two Total Track Railway Construction and Maintenance Services Inc. (Total Track) employees were operating a Nordco Model A spike pullerFootnote 2 in the vicinity of Mile 223.0, just west of Belleville, near Moira, Ontario (see Figure 1). They were part of a tie gangFootnote 3 under contract to Canadian National (CN) Railway and were replacing ties on the south main track of CN's Kingston subdivision. The temperature was about 4°C and the wind was from the north at 13 km/hFootnote 4

At 0200, the spike puller (see Photo 1). had advanced approximately 250 feet ahead of the following machine in the tie gang. The crew had just finished their work at this location and were preparing the spike puller to travel when its drive mechanism failed.

Both machine operators walked back to seek advice from the Kershaw tie ejector/injector machine operator (Kershaw operator). The Kershaw operator was conducting repairs on the hydraulics of his machine. He asked the spike puller operators to diagnose the problem and, if possible, make field repairs to the spike puller. One of the two spike puller operators (Operator 1), a 20 year-old male, went under the right side of the machine. The other machine operator (Operator 2) stood to the same side of the machine, handing him tools.

When the Kershaw Operator had finished his work, he walked over to the spike puller. As he approached the right side of the machine, the spike puller's roller frame assembly activated, lowered, and struck Operator 1. The Kershaw Operator called to Operator 2 to bring the roller frame assembly up, pulled Operator 1 out from under the machine, then ran back to his machine and radioed for medical assistance. It was approximately 0210.

Emergency personnel arrived shortly after the emergency call and confirmed that Operator 1 had been fatally injured. The Belleville Police Department and the Ontario Ministry of Labour (OMOL) also attended the accident site.

OMOL commenced a formal investigation. OMOL's examination of the spike puller determined that it was unsafe to operate. A lock-out tag was applied to the machine and the machine was deemed not to return to service until it was made safe, when the OMOL would inspect and remove the lock-out tag.

Employee Accident Data

This occurrence was the second accident involving tie gang activities on CN track within two weeks. On 01 November 2006, two CN tie gang employees had been injured, one seriously, when a spike puller machine became stuck in reverse and ran over them. This previous accident occurred at Mile 40.5 of CN's Togo subdivision in western Canada.

A review of TSB records from years 2000 to 2007 (see Table 1) indicates that, with the exception of 2003, the number of railway employee injuries has remained relatively constant over this period. However, while there were two employee fatalities in the four years from 2000 to 2003, there were twelve employee fatalities in the four years from 2004 to 2007.

| Year | All employee fatalities | CN employee fatalities | All employee injuries | CN employee injuries |

|---|---|---|---|---|

| 2000 | 1 | 0 | 8 | 6 |

| 2001 | 0 | 0 | 6 | 2 |

| 2002 | 0 | 0 | 7 | 6 |

| 2003 | 1 | 1 | 3 | 1 |

| 2004 | 5 | 1 | 7 | 5 |

| 2005 | 2 | 1 | 5 | 4 |

| 2006 | 3 | 3 | 6 | 4 |

| 2007 | 2 | 1 | 8 | 7 |

The contractor

Total Track was established in year 2000. Its head office is in Mallorytown, Ontario and its main shop and yard is located just west of Brockville, Ontario. Since inception, the company's core business has been track repair and maintenance services for industrial railway customers and short line railways. Given that track maintenance work is seasonal, Total Track operates with as few as six employees during the winter season. At the time of this occurrence, Total Track had 47 employees.

The Workplace Safety and Insurance Board (WSIB) classified Total Track as a construction company, a high-risk work category. Prior to the accident, Total Track had only one documented WSIB claim, dating back to 2003.

CN contract for tie replacement services

In August 2006, Total Track was hired by CN to conduct turnkey tie replacement services. This contract was for the replacement of 50 000 ties on CN's Caramat subdivision in the vicinity of Kowkash, Ontario. Kowkash is in a remote area of northern Ontario and access to the job site was by rail. For this work program, CN provided Total Track crews with near-site rail car bunkhouse accommodations. Work at this location started in August 2006 and was shut down due to cold weather in October 2006. Less than a third of the planned program was completed. The Caramat contract resulted in a rapid expansion of Total Track's business. It had to quickly hire, assemble, and deploy personnel and specialized railway maintenance equipment for this tie program. A month after work commenced on the Caramat project, Total Track hired a dedicated safety officer whose duties included the development of a new health and safety policy for the company.

The Total Track crew members were, for the most part, young and paid on an hourly basis. They were expected to learn on the job and demonstrate a "can do" attitude. Total Track did not employ dedicated on site trainers or qualified mechanics, however, on three occasions, outside contractors were hired to conduct electrical and mechanical repairs. Most new hires started as general labourers. New hires that demonstrated aptitude and a positive attitude were offered machine operator assignments when they became available. To retain the machine operator job, an employee had to quickly learn to operate the machine and be able to keep it operational.

During the Caramat work program, some difficulties arose between Total Track and CN. Specific work issues included:

- the level of work site protection and living conditions afforded to Total Track crews;

- the non-compliance of Total Track staff with CN's Personal Protective Equipment (PPE) policy;

- the non-compliance of Total Track staff with CN's alcohol and drug policy;

- the maintenance and condition of Total Track equipment; and

- the lack of a Total Track action plan to deal with past and current safety violations.

Following the Caramat work program, CN requested assistance from Total Track to provide tie maintenance support services to an ongoing tie program on its Kingston subdivision near Belleville. Both parties verbally agreed that the work would be completed under the terms of the Caramat contract, except that CN would not provide near-site accommodation. Total Track accepted the Caramat contract extension even though the contract to provide turnkey tie replacement work for CN was placing a strain on Total Track's operations.

Risk factors for workplace injuries

According to a 2005 OMOL analysis of WSIB statistics for high risk firms:Footnote 5

- new hires are five times more likely to be injured as compared to other employees;

- new hires are four times more likely to be seriously injured; and

- workers under the age of 25 are three times more likely to be injured as compared to other employees.

The analysis of WSIB data was used by OMOL to implement an inspection program targeting the top two per cent of these companies. The inspections focus on general health and safety culture, incident reporting structures, and health and safety training or knowledge.

In 2005, the Institute of Work and Health conducted a review of risk factors for work injuries among teenage and young adult workersFootnote 6. The review identified "occupation/work hazards" and "perceived work overload" as workplace factors that correlated with an elevated work injury rate.

In this occurrence, twenty three Total Track employees were assigned to the Belleville tie replacement work program. Fourteen of these, including the fatally injured employee, had been with Total Track for less than eight months. Five employees had been with Total Track for less than three months. Nine of these employees were males under the age of 25 who were initially hired to work on the Caramat work program.

Spike puller machine operators

Operator 1 had worked with the company for approximately eight months and had been a spike puller operator for approximately three-and-a-half months. He was hired as a general labourer. About a month into the Caramat work program, Total Track needed one more spike puller operator and Operator 1 was offered this position. His spike puller training consisted of two days of supervised on-the-job operation, followed by some instruction provided by his more experienced partner. Operator 2 had been with the company for a similar period of time and had been operating the spike puller for approximately four-and-a-half months.

On the-job instruction focused on how to operate the spike puller, pulling spikes, and travelling along the right of way. The machine operators were also provided with general instructions on how to work safely. For example, the operators were advised to "pin-up" the spike puller work heads to make the machine safe for travel. However, the operators were not given specific instructions on how to make the spike puller safe for repairs.

The Caramat work program began in a remote location where certified mechanical assistance was not available. There were no licensed mechanics assigned to the tie gang. At Total Track, it was normal practice to have machine operators perform routine field maintenance and repair activities on their machines.

CN's Employee Safety Standards for Maintenance of Way Activities

When maintenance of way work is performed by CN employees, it is conducted in a federally regulated environment. All CN employees in Canada are subject to minimum health and safety standards as set out in the Canada Labour Code. In addition, employee safety standards are set out in CN's Risk Management Policy and are included in its General Operating Instructions.

CN's Risk Management Policy specifies that:Footnote 7

- The policy applies to "all company employees, contractors, and other people granted access to CN property"; and

- The policy "provides a formal, organized process whereby people plan, perform, assess and improve all company activities to minimize risk and optimise loss control."

Use of contractors by CN for track work

Between January 2005 and December 2006, CN entered into 24 contracts with external companies for the performance of track construction or maintenance activities across Canada. The breakdown of contracts is summarized as follows:

| Contract Initiation Date | Number of Contracts |

|---|---|

| January 2005 to December 2005 | 6 |

| January 2006 to December 2006 | 18 |

All contractor employees are required to complete CN's contractor orientation training and to comply with CN's minimum health and safety standards. Failure to do so is considered grounds for contract termination. CN authorizes their "employee-in-charge" to take whatever actions are necessary to prevent injuries to any person, damage to railway property, or the disruption of railway operations. At the time of this occurrence, there was no process to ensure that, prior to entering into contracts, contractors have in place the resources and procedures to safely undertake the contracted activities.

However, during Total Track's tie replacement work on the Caramat and Kingston subdivisions, CN conducted regular "safety blitzes" and worker proficiency testing (including contract workers). Safety violations were communicated to the contractor's senior management. Prior to the accident, CN had alerted Total Track management to violations by its contract workers of CN's health and safety standards. CN expected that the contractor would take action to ensure its employees were brought into compliance.

On 12 October 2006, approximately one month before the accident, CN had met with Total Track management in Belleville. CN delivered a letter indicating that it was barring four Total Track employees from access to CN property. The fatally-injured employee was one of these employees. Total Track was aware that the employee was not permitted on CN property, but allowed him to continue to operate the spike puller on CN property.

Engineering branch examination of the spike puller

A detailed examination of the spike puller's condition and operation is summarized in TSB Engineering Laboratory report LP015/07. The spike puller was a Nordco Grabber Model A (serial no. 166), manufactured in 1989. It was specifically designed for the in situ removal of spikes from ties.

The spike puller was configured for two person operation, with one work station over each rail. A joystick at each work station operated various electronically-controlled hydraulic cylinders to position the spike removal claws, lower the roller frame assembly onto the rail head, align the claw mechanism, and articulate the claws to remove and release the spike.

The spike puller was designed to be self propelled at speeds reaching 25 mph in travel (non spike pulling) mode. A chain and sprocket drive mechanism connected the drive shaft to the drive axle and propelled the machine on the rails in a forward or reverse direction. Key observations from the TSB Engineering Laboratory report include:

- Before being placed into service on the Caramat tie program, Total Track undertook modifications and repairs to make the spike puller operational. However, the modifications were not in compliance with the manufacturer's specifications, nor were they conducted by a qualified mechanic.

- The modifications to the spike puller machine were not documented in the operator manual. Total Track did not maintain an equipment inspection, maintenance, and repair log book for any of its railway maintenance machines.

- The operators were unaware that pinning the roller assembly for travel did not prevent the roller assembly from lowering to a point where activation would likely cause a serious or fatal injury to a person positioned under the assembly.

- The button for selecting operation modes for the spike puller was missing. One of the positions for the missing selector button disabled the electronic joystick controls. Corrosion on the bottom post indicated that this selector had not been used by the operating crew for some time.

- The spike puller was not equipped with cab or control panel lighting, did not have a large shutdown button, and the drive chain guard was removed.

- At the time of the accident, the spike puller was not locked out to ensure the safety of the workers.

CN maintenance of way equipment maintenance practices

When CN maintenance of way equipment is repaired or serviced, work is performed by qualified mechanics. Inspections and maintenance of this equipment are completed on a predetermined schedule. CN machine operators do not repair their own equipment. A road maintenance crew is called out when equipment breaks down while in service. If it cannot be safely repaired, the equipment is taken out of service.

All maintenance and repairs are documented in a maintenance log that must be checked and signed-off by a supervisor. The equipment service log book and operator manual must stay with the machine and be readily accessible at all times.

Work site jurisdiction, inspection, and monitoring

CN is a federally-regulated company and is governed by the Canada Labour Code under the jurisdiction of Human Resources and Social Development Canada (HRSDC). Total Track is a provincially registered company that was being operated subject to the Ontario Occupational Health and Safety (OHS) Act under the jurisdiction of the Ontario Ministry of Labour.Footnote 8

In this accident, Total Track was operating under contract to a federally-regulated company. In addition, Total Track employees were working on the property of a federally-regulated company.

A Supreme Court of Canada decisionFootnote 9 clarified the responsibilities of a company when subcontracting work in Canada. This has led the Electrical Utilities Safety Association to implement new guidelines related to subcontracting utilities work. As part of these new guidelines, a formal due diligence process has been incorporated into tendering practice guidelines as a means of indemnifying the contracting company in the event of an accident or serious injury. This due diligence process extends to ensuring a contractor has the administrative structure and equipment in place to conduct the work safely. With respect to the condition of equipment to be used on a project, the Utilities Tendering Practices Guidelines stateFootnote 10:

The successful bidders shall submit prior to award a list of equipment to be used on the project. Substitutions or alterations to this list shall be approved by the Commission. The list, as per Appendix 'C', shall include a description of the equipment and the age, and shall be accompanied by MTO mechanical fitness certificates, and certification of aerial devices as per OHSA CAN/CSA 225 M88. All vehicles (automobiles excepted) shall contain pertinent rescue equipment, fire extinguishers, and safety kits. Test certificates of rubber gloves, insulating material, and other equipment must be made available to the Commission on demand, and shall be maintained current and up to date by the contractor.

Regardless of whether the contractor is a federal or provincial entity, CN applies the same contractor supervision, using its contractor safety process and its on-site "employee in charge". At the time of this accident, CN did not have a similar due diligence process to ensure a contractor had the administrative structure or equipment in place to work safely.

Contractor compliance with OHS regulations

In this occurrence, the spike puller was not being operated in compliance with OHS regulations. The spike puller was being operated at night without a light to illuminate the cab area and controls, without a conspicuously marked emergency stop control, and without all protective safety guards properly installed.

Analysis

When the fatal injury occurred, the machine operators were attempting to perform field repairs to the spike puller. The report will consider the condition of the machine at the time of the occurrence. It will also address the manner in which repairs were conducted and, in doing so, consider company training, equipment maintenance, and repair procedures. The report will also assess the influence of the contracting process on work site safety standards.

The accident

The spike puller engine was running with all primary electrical and pneumatic systems functioning. The operators were working as a team, with one operator under the machine and the other operator retrieving tools and equipment from the unlit, cluttered cab area. TSB Engineering Laboratory staff tested the equipment to determine what machine operation settings are necessary to replicate the accident sequence. Based on these tests, witness statements, and site photos, the accident likely occurred when the right side joystick controller of the spike puller was inadvertently activated, causing the right-hand roller frame assembly to drop rapidly onto the employee underneath the machine.

The machine operators had been operating the spike puller together for approximately three and a half months. Neither operator had experience in operating a spike puller prior to being assigned to this machine. They had been provided basic on-the-job training that was focused on the operation and maintenance of their machine as it had been configured. They had been operating the machine where a certified mechanic was not available. For employees hired by Total Track for the Caramat work program, this approach to equipment maintenance had become the de facto company operating practice. The spike puller operators, who were not qualified mechanics or mechanical technicians, were following normal Total Track operating practices when they attempted to perform field repairs on the spike puller.

During the field repairs, the spike puller had not been shut down and locked out, nor had the working heads been secured so that they could not lower from their raised position. Consequently, the roller frame assembly could be activated and lowered because the spike puller was not made safe prior to conducting repairs.

The spike puller operators had been provided with general workplace training related to making a work site safe. In addition, CN expected all contractors and their employees to comply with CN safety rules on the lockout of equipment. However, in this occurrence, the machine operators were not trained nor provided with procedural instructions on how to maintain or operate equipment in accordance with manufacturer instructions and minimum regulatory standards.

Total track operating culture

Total Track began operations as a provider of track maintenance and repair services to industrial and short-line customers. When its work activities rapidly expanded to include main line maintenance services for federally-regulated railways, it did not safely manage the transition. Hurried hiring and training resulted in a predominantly young and inexperienced male workforce, a group having a risk of a workplace injury from three to five times greater than the general working population.

In this occurrence, many of the newly-hired Total Track employees were immediately assigned to work in a remote location with minimal support or overview. During the Caramat work program, with Total Track falling behind production targets, employees who did not demonstrate a "can do" attitude did not thrive. When a "can do" work culture is applied to a young and inexperienced workforce, in an environment where formal training and supervision is limited, there is an elevated risk that unsafe operating procedures will be adopted.

Total track occupational health and safety practices

From the start of the Caramat work program, Total Track operating practices neglected or circumvented minimum occupational safety and health practices. Equipment was not being operated or maintained to the manufacturer's specifications and to the Ontario Occupational Health and Safety (OHS) Act minimum standards. Modifications, maintenance, and repairs to the equipment were not documented. The employees received minimal training and overview.

In addition, without qualified mechanical staff on site, the company became reliant on the machine operators to do whatever was necessary to keep the machines running, including performing field repairs. During these field repairs, machine operators could not, or did not, consistently apply safety lockout procedures when working on their machines. Consequently, the de facto practice of requiring unqualified operating staff to conduct heavy equipment repair and maintenance increased the risk of workplace accidents.

This approach to equipment maintenance is in contrast to CN company operations. At CN, maintenance and repairs to equipment are performed using approved parts and qualified mechanical staff. All equipment maintenance work is recorded in log books and signed-off by supervisors. Equipment manuals and log books stay with the machine at all times. As a federally-registered company, CN job sites are maintained in compliance with minimum Canada Labour Code standards and with CN's safety rules.

CN safety inspections had documented non-compliance situations involving Total Track employees and equipment. However, Total Track's response to CN's safety concerns was slow and operations were allowed to continue. A month into the Caramat contract, Total Track was in the process of hiring a dedicated safety officer and developing a new health and safety policy.

The lack of a robust health and safety culture and a lack of health and safety training or knowledge are factors that the Ontario Ministry of Labour has found to be characteristic of high risk companies. In the absence of adherence to established occupational health and safety protocols, companies are likely to operate in a manner that is not consistent with minimum safety standards, thus leading to an increased risk of serious workplace accidents.

Due diligence and job site safety

CN requires all contractors to take and pass a contractor orientation course. The contract required Total Track to comply with CN's minimum operating standards while working on the Caramat and Kingston programs. During the execution of the work, CN's "employee in charge" is authorized to take whatever actions are necessary to prevent injuries to any person, damage to railway property, or disruption of railway operations. CN contracts clearly state that failure to comply with its safety policy is grounds for contract termination. These steps ensure that the contractor is made aware of the minimum expectations for companies contracted to do work for CN.

When the Caramat contract was signed, Total Track was not operating its business in compliance with provincial or federal safety standards. As the company did not have a Workplace Safety and Insurance Board safety record that would draw attention warranting a targeted inspection, Total Track was not audited for OHS compliance.

CN's contractor selection process did not include a due diligence element to ensure that contractors are fit to operate safely. CN allowed the contractor to bring poorly-maintained equipment and personnel not trained to minimum CN standards onto their property.

Once the contract work had begun, CN gradually became aware of the degree to which Total Track behaviour was non-compliant. CN took steps to hold Total Track management accountable for taking and enforcing corrective action, and had gone as far as barring some Total Track workers from the company property. However, had a thorough review of the contractor's health and safety structure and operating practices been undertaken, the absence of a designated safety officer, for example, should have raised serious concerns. In the absence of a procedure which ensures contractors have resources and processes in place to safely undertake activities, there is an increased risk that contracted work will not be completed in a safe manner.

Restricting movement of the roller frame assembly

The right-hand roller frame assembly travel pin was not inserted at the time of the accident. The travel pins are designed to prevent the roller frame assembly from lowering onto the track structure during travel between work locations. However, when inserted, the travel pin does not completely restrict the downward movement of the roller frame assembly, nor does it affect the speed at which the assembly deploys. Testing of the machine determined that with the travel pin in place, the bottom of the alignment guide on the roller frame assembly lowers to within five inches of the rail head. Therefore, had the travel pin that limits the downward movement of the right-hand roller frame assembly been inserted prior to commencing the repairs, downward movement of the assembly would still have been sufficient to cause serious or fatal injury.

Findings

Findings as to causes and contributing factors

- The accident occurred when the right side joystick controller of the spike puller was inadvertently activated, causing the right-hand roller frame assembly to drop rapidly onto the machine operator underneath the machine.

- The spike puller operators, who were not qualified mechanics or mechanical technicians, were following normal Total Track operating practices when they attempted to perform field repairs on the spike puller machine.

- The roller frame assembly was able to activate and lower because the spike puller machine had not been made safe prior to conducting repairs.

- The machine operators had not been trained on how to make their equipment safe.

- Contrary to current Ontario Occupational Health and Safety (OHS) Act requirements, the spike puller was being operated at night without a light to illuminate the cab area and controls and without a conspicuously marked emergency stop control.

Findings as to risk

- When a "can do" work culture is applied to a young and inexperienced workforce in an environment where overview and formal training is limited, there is an elevated risk that unsafe operating procedures will be adopted.

- The practice of requiring unqualified operating staff to conduct heavy equipment repair and maintenance increases the risk of workplace accidents.

- Companies operating without established occupational health and safety protocols are likely to operate machinery in a manner that is not consistent with minimum safety standards, leading to more frequent workplace accidents.

- In the absence of a due diligence process which ensures contractors have the resources and procedures in place to safely undertake activities, there is an increased risk that contracted work will not be completed in a safe manner.

Other finding

- Had the travel pin that limits the downward movement of the right-hand roller frame assembly been inserted prior to commencing equipment repairs, downward movement of the assembly would still have been sufficient to cause serious or fatal injury.

Safety action taken

Canadian National (CN)

Following this accident, CN terminated its contract with Total Track and banned the contractor from further work with CN. In addition, CN conducted an audit of other existing contracts and cancelled another contract where the contractor's safety practices were not in compliance with CN requirements.

CN also conducted awareness sessions with its supervisors explaining how to deal with contractors when they are working with CN.

Total Track

In March 2008, Total Track held a health and safety orientation training day for all its returning and new employees, prior to starting work on a recently awarded contract.

Transport Canada

Transport Canada initiated a review of CN policy regarding contractor safety and the adequacy of contractor overview as part of its review of CN's safety management system.

Ontario Ministry of Labour

The Ontario Ministry of Labour (OMOL) conducted a formal investigation under the terms of the Ontario Occupational Health and Safety Act. OMOL's examination of the spike puller determined that it was unsafe to operate. A lock-out tag was applied to the machine and the machine was deemed not to return to service until it was made safe.

OMOL charged Total Track for a number of regulatory infractions. A recent Ontario court decision (subject to appeal) determined that Total Track's operations fall under federal jurisdiction.

This report concludes the Transportation Safety Board's investigation into this occurrence. Consequently, the Board authorized the release of this report on .