Main-track derailment

Canadian Pacific Railway

Freight train CP 353-267

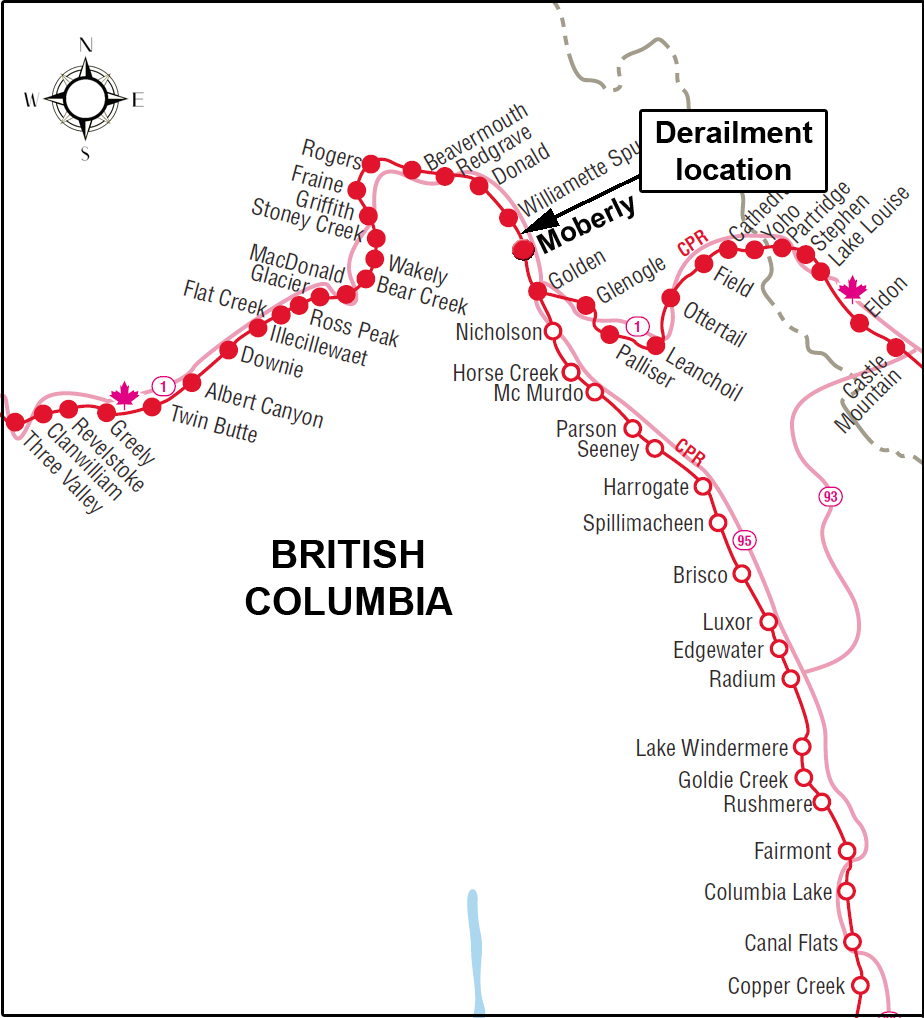

Mile 41.50, Mountain Subdivision

Moberly, British Columbia

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

On 27 December 2011, at 0855 Pacific Standard Time, Canadian Pacific Railway freight train 353-267, proceeding westward from Field, British Columbia, to Revelstoke, British Columbia, derailed 34 cars at Mile 41.5 on the Mountain Subdivision, near Moberly, British Columbia. Approximately 2900 feet of track was damaged, including portions of the north main track, south main track, and the back track. There were no injuries and no dangerous goods were released.

Ce rapport est également disponible en français.

Factual information

On 27 December 2011 at 0855Footnote 1 Canadian Pacific Railway (CP) freight train 353-267 (the train), proceeding westward at Mile 41.5 on the north main track of the Mountain Subdivision near Moberly, British Columbia, experienced an emergency brake application and derailed 34 cars (Figure 1). The train had originated in Lethbridge, Alberta, and was destined for Vancouver, British Columbia. It was a distributed power train, which was powered by three 6 axle, 4400 horsepower General Electric (GE) locomotives. Two of the locomotives were at the head-end of the train and one locomotive was at the rear. The train was handling 111 covered hopper railcars, of which 105 were loaded and 6 were empty. The train weighed 14 277 tons and was 6715 feet long.

The train crew consisted of a locomotive engineer, a conductor, and a locomotive engineer trainee. All 3 crew members were positioned in the cab of the lead locomotive. They were qualified for their respective positions, met rest and fitness standards, and were familiar with the subdivision.

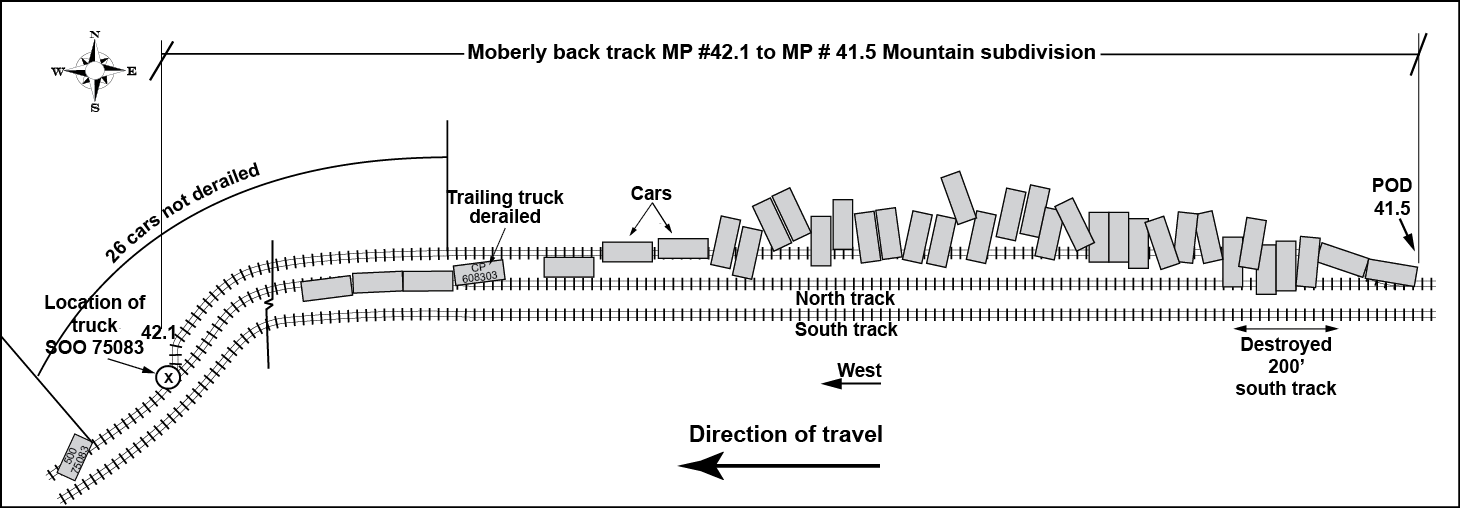

Just before the derailment, a train-initiated emergency brake application (emergency) occurred. After the crew made the necessary emergency broadcast and notified the rail traffic controller (RTC), the conductor then performed an inspection and determined that 33 loaded grain cars and 1 empty grain car had derailed. The first derailed car, which had stopped west of the west back-track switch, was empty grain car SOO75083 (i.e., the 33rd car behind the head-end locomotives). This car was followed by 26 cars that had not derailed. The next 33 cars (i.e., the 60th through 92nd cars behind the head-end locomotives) were derailed along the north main track and the back track. There were no injuries and no dangerous goods were released.

Recorded information

A review of the locomotive event recorder (LER) determined the following:

- An elevated in-train draft force was recorded at 0853:08.

- Two additional elevated draft force events occurred (at 0854:15 and at 0854:42).

- The train-initiated emergency brake application occurred at 0855:18.

- When the emergency application occurred, the train was travelling at 44 mph with the throttle in position 8.

- The dynamic brake was not applied and the independent brakes were released.

Weather

The weather at the time of the accident was -2 °C with snow showers.

Site examination

The derailment occurred in a rural area approximately 13 km west of Golden, BC. The track, which is situated alongside the Trans-Canada Highway in the vicinity of the accident, is comprised of double main track. There is also a back track situated north of the north main track between Mile 41.5 and Mile 42.1.

Brake assembly components were found along the track beginning at Mile 37.4. The main body of a No. 2 brake cylinderFootnote 2 was discovered at Mile 40.35. Additional brake assembly components were discovered along the railway right-of-way near Mile 40.40 and Mile 40.50. Drag marks in the snow were found beginning at Mile 40.90 (i.e., approximately 800 feet east of the east back-track switch).

The brake components found along the right-of-way had originated from railcar SOO75083. This car had come to rest approximately 250 feet west of the west back-track switch. SOO75083 was missing its B-end truck, which had come to rest in the vicinity of the west back-track switch. The B-end truck was missing its No. 2 brake cylinder, its No. 2 brake beam, and related brake assembly components.

The next 26 cars were not derailed. These cars were followed by 3 cars which derailed in a stringline fashion. The first of these 3 cars (CP608303) had derailed its trailing truck at the east back-track switch. The following 30 cars were derailed in an accordion manner on the north side of the north main track (Photo 1 and Figure 2).

As a result of the derailment, the east back-track switch was destroyed. A total of 2900 feet of track was damaged, including 900 feet of the back track, 1800 feet of the north main track, and 200 feet of the south main track.

Subdivision information

The Mountain Subdivision begins at Field, British Columbia, (Mile 0.0) and extends westward to Revelstoke, British Columbia, (Mile 125.7). Train movements on this subdivision are governed by the centralized traffic control (CTC) system, as authorized by the Canadian Rail Operating Rules (CROR), and supervised by a rail traffic controller located in Calgary, Alberta. The maximum operating speed for freight trains in the vicinity of the derailment is 50 mph, making it Class 4 track as defined in the Transport Canada–approved Railway Track Safety Rules.

Track information and track inspection

In the area of the derailment, the track was tangent track with a 0.5% descending grade in the direction of travel. The rail was 136-pound continuous welded rail (CWR) manufactured by Nippon in 2001 and 2002. Rail wear was determined to be within the limits specified by the Railway Track Safety Rules. Ties were 15-inch × 8 feet 6–inch treated No. 2 hardwood. The tie plates, which were in good condition, were 14-inch double shoulder plates with 3 spikes per plate. The east back-track turnout was a standard number 11 turnout equipped with a hand thrown switch.

The east back-track switch was last inspected in October 2011 and was found to be in fair condition. Rail flaw detection was last conducted on 13 December 2011, with no defects in the vicinity of the derailment. The last visual inspection by track maintenance forces was conducted on 26 December 2011, with no defects noted in the derailment area.

SOO75083 - The first derailed car

SOO75083 was a covered hopper railcar built in July 1978. It measured 60 feet long, 15 feet high and 10 feet 8 inches wide. The tare weight (empty) for this rail car was 60 100 pounds.

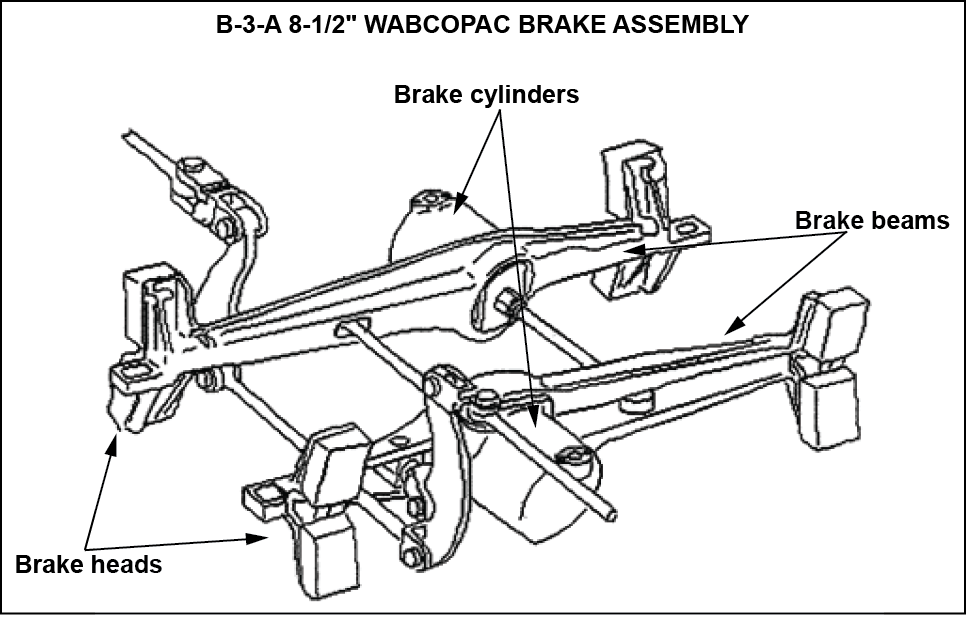

Truck-mounted brake assembly

SOO75083 was equipped with B-3-A 8-1/2" WABCOPAC brake assemblies manufactured by Wabtec (Figure 3). The brake assemblies were truck-mounted and each brake beam had a separate brake cylinder. In contrast, a standard brake assembly has a single brake cylinder mounted on the body of the car to operate the brake system.

The No. 2 brake beam (i.e., adjacent to the No. 2 wheel set) was manufactured in January 1978. This brake beam, along with the No. 2 wheel set and the side frames from the B-end truck of the car, was sent to the TSB Engineering Laboratory for detailed analysis.

Wheel impact load detector (WILD) history for the No. 2 wheel set

The wheel impact load detector (WILD) history for this wheel set indicated that there were no condemnable impact readings in the month prior to the derailment. This wheel set had registered a high value of 56.3 kips for the L2 wheel and 41.6 kips for the R2 wheel.

The AAR allows for the removal of a wheel when impact readings reach 90 kips.

TSB laboratory examination of the wheel set and brake assembly components (TSB Engineering Laboratory Report LP011/2012)

An examination of the No. 2 wheel set on SOO75083 determined the following:

- The wheel set consisted of a 6 ½-feet × 12-inch axle with two 36-inch freight wheels.

- The back-to-back dimension between the wheels measured 53 1/16 inches, which is within the allowable range of 52 15/16 inches to 53 3/16 inches.Footnote 3

- The identification marks on the wheels were as follows:

- Manufacturer: SW (i.e., Standard Steel LLC, Pennsylvania)

- Serial numbers: 13720 for the L2 wheel and 15866 for the R2 wheel

- Month and year of manufacture: 01/08

- Design: H-36Footnote 4

- Class: C

- The rim thickness measured 17/16 inches for both wheels. Freight car wheels are condemnable when the rim thickness is reduced to 7/8 of an inch.Footnote 5 Transport Canada–approved Railway Freight Car Inspection and Safety Rules condemns rim thickness at 11/16 of an inch.

- The wheels had multiple flat areas (i.e., slid flats) situated around most of the circumference of the wheel treads (Photo 2). The coloration and rounded edges of these slid flats and the fact that several slid flats blended into each other indicated that the slid flats were not fresh and pre-dated the occurrence.

- Brake applications through normal train operation brought the brake shoes in contact with the roughened wheel-tread surfaces (i.e., slid flats), resulting in accelerated wear of the brake shoes until they were completely worn away.

- RunoutFootnote 6 for the wheels on the No. 2 wheel set was measured. The 8 deepest runouts varied in depth from 0.118 inch to 0.280 inch. Rail wheels are condemnable by AAR rules when any run-out exceeds 0.070 inch.Footnote 7

- Slid flats are also condemnable by AAR rules when found to exceed 2 inches in length for a single slid flat or 1.5 inches for 2 or more adjoining spots.Footnote 8 On the L2 wheel, there were 9 condemnable slid flats ranging from 3 inches to 11 inches in length. On the R2 wheel, there were 8 condemnable slid flats ranging from 2 inches to 14 inches in length.

- Under Transport Canada rules, slid flats that exceed 2.5 inches for a single slid flat or 2 inches for 2 or more adjoining spots are condemnable.Footnote 9 There is no provision for condemning a wheel due to an out-of-round condition in the TC-approved Railway Freight Car Inspection and Safety Rules.

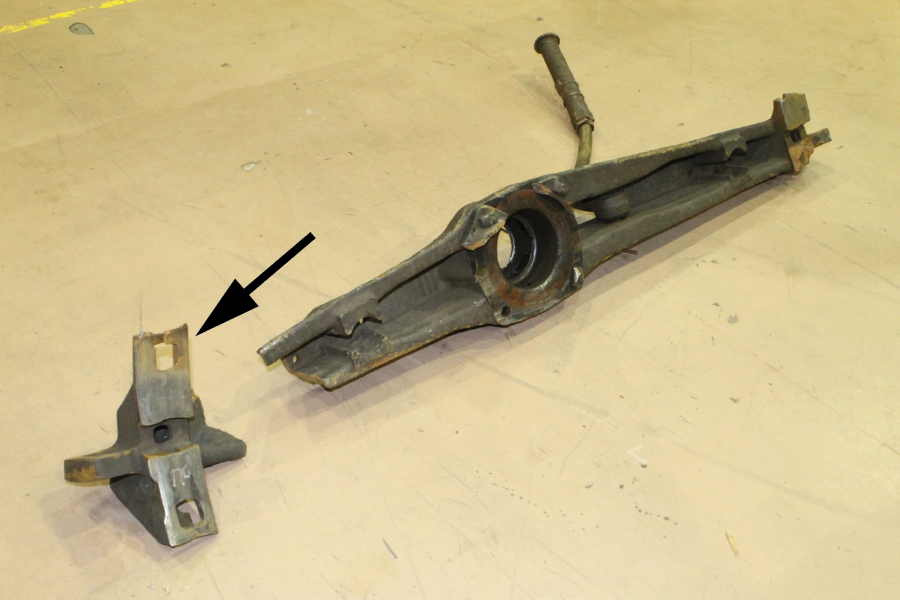

An examination of the No. 2 brake beam on SOO75083 determined the following:

- The brake beam failed due to an instantaneous overstress extension of a pre-existing fatigue crack.

- The fatigue cracking was likely caused by abnormal cyclic stresses due to interaction of the brake beam with an out-of-round wheel set.

- The fatigue cracking initiated at a casting surface irregularity located just inboard of the separated brake head (Photo 3).

- The brake beam material met the manufacturer's specification.

- The brake beam was in operation without brake shoes long enough for the brake heads to have taken on the profile of the respective wheel treads (Photo 4).

CP's train inspection policy

CP's train inspection policyFootnote 10 specifies that railway cars must be inspected to identify wear-related and/or safety-related defects and to take the necessary action to ensure the safety of train operations.

The train inspection policy is designed to protect against train accidents or personal injury caused by defective equipment while causing minimal interference with train operations. The policy is based on the following objectives:

- ensuring, by proper inspection, that cars are in a safe and satisfactory condition before being placed in a train; and

- ensuring that train systems are operating properly at the point where trains are assembled and at locations where a safety inspection is designated.

CP defines the certified car inspection (CCI, also called the safety and maintenance inspection) as follows:

an inspection of a standing train, or a block of cars, by a certified car inspector, for the maintenance of any condition that is hazardous and likely to cause accident, injury or damage to lading or property.

In addition, the mechanical pre-departure inspection is defined as follows:

an inspection of a standing train or block of cars, by certified car inspectors, for damage which may have been caused through switching and for conditions which include any apparent safety hazard likely to cause an accident or casualty before the train arrives at its destination.

Air brake testing

Air brake test requirements by the railwayFootnote 11 and by the regulatorFootnote 12 prescribe that a No. 1 air brake test shall verify

- the integrity and continuity of the brake pipe;

- piston travel and condition of the brake rigging on each car in the train; and

- the application and release of air brakes on each car in the train.

A No. 1 air brake test can only be conducted by a certified car inspector. The train service scheduleFootnote 13 for the occurrence train required that it receive its certified car inspections in Lethbridge, Alberta.

Inspection and air brake testing for S0075083

During December 2011, SOO75083 received 7 inspections (i.e., CCI, mechanical pre-departure or pull-by) (Table 1). These inspections were conducted at various CP car inspection locations. The last CCI for the car was performed in Keith Yard (Calgary, Alberta) on 12 December 2011.

Five No. 1 air brake tests were performed on SOO75083 during the month of December 2011. The last air brake test was performed in Lethbridge on 24 December 2011 (i.e., 3 days prior to the derailment).

| Inspection date | Description | Car number | Station |

|---|---|---|---|

| 12/1/2011 | Mechanical pre-departure inspection | SOO 0000075083 | Lethbridge |

| 12/1/2011 | No. 1 air brake test | SOO 0000075083 | Lethbridge |

| 12/6/2011 | Safety and maintenance inspection (CCI) | SOO 0000075083 | Coquitlam |

| 12/7/2011 | No. 1 air brake test | SOO 0000075083 | Coquitlam |

| 12/8/2011 | Pull-by inspection in/out | SOO 0000075083 | Coquitlam |

| 12/12/2011 | Safety and maintenance inspection (CCI) | SOO 0000075083 | Keith |

| 12/12/2011 | No. 1 air brake test | SOO 0000075083 | Keith |

| 12/18/2011 | Mechanical pre-departure inspection | SOO 0000075083 | Coquitlam |

| 12/18/2011 | No. 1 air brake test | SOO 0000075083 | Coquitlam |

| 12/18/2011 | Pull-by inspection in/out | SOO 0000075083 | Coquitlam |

| 12/24/2011 | Mechanical pre-departure inspection | SOO 0000075083 | Lethbridge |

| 12/24/2011 | No. 1 air brake test | SOO 0000075083 | Lethbridge |

Analysis

Neither track nor train handling was considered causal or contributory to the derailment. The analysis will focus on the broken brake beam and the slid flat wheels on SOO75083.

The accident

The presence of brake components from the B-end truck of SOO75083 along the right-of-way east of the derailment site indicates that the truck-mounted brake assembly had failed prior to the derailment. When the train reached the back track, the dragging brake components from the failed brake assembly contacted the east back-track switch, which damaged the switch and derailed the B-end truck of SOO75083. The derailment of the B-end truck likely coincided with the initial elevated draft force event at 0853:08. After 26 cars successfully passed the damaged switch, the trailing truck on CP 608303 derailed at the switch, resulting in further damage and precipitating the derailment of the following 32 cars.

No. 2 brake beam for SOO75083

The TSB laboratory examination of the No. 2 brake beam on SOO75083 determined that it had failed due to an instantaneous overstress extension of a pre-existing fatigue crack. The fatigue cracking had initiated at a casting surface irregularity located just inboard of the separated brake head. The fatigue cracking was likely caused by abnormal cyclic stresses due to the interaction of the brake beam and the out-of-round wheels on the No. 2 wheel set.

Brake applications through normal train operation had brought the brake shoes in contact with the slid flats and out of round wheels, resulting in accelerated wear of the brake shoes until they were completely worn away. The lab analysis determined that the brake beam had been in operation without brake shoes long enough for the brake heads to have taken on the profile of the respective wheel treads.

Inspection and air brake testing for SOO75083

The car inspection records for SOO75083 indicated that prior to the derailment the car had undergone 7 inspections and 5 No. 1 air brake tests during December 2011. On December 24 (i.e., 3 days prior to the derailment), a pre-departure mechanical inspection and a No. 1 air brake test had been performed. No exceptions were noted for this car. However, given the damage to the brake heads on the No. 2 brake beam from prolonged contact with the wheel treads, the brake assembly defects were likely present in the days prior to the derailment and had not been noticed.

Wheels and wheel impact load detector

The wheels on the No. 2 wheel set were found to have multiple condemnable slid flats and to be in condemnable out-of-round condition. The coloration and rounded edges of these slid flats, and the fact that several slid flats blended into each other, indicated that the slid flats were not fresh and pre-dated the occurrence. Although the slid flats and the out-of-round condition of the No. 2 wheel set on SOO75083 were condemnable, the WILD readings for this wheel set were below the 90-kip threshold set out by the AAR. When condemnable wheel defects are not identified and removed from service in a timely manner, there is an increased risk that the defective wheel will compromise the integrity of other car components, resulting in their failure.

Findings

Findings as to causes and contributing factors

- The presence of brake components from the B-end truck of SOO75083 along the right-of-way indicates that the brake assembly had failed prior to the derailment.

- When the train reached the back track, the dragging brake components from the failed brake assembly contacted the east back-track switch, which damaged the switch and derailed the B-end truck.

- After 26 cars successfully passed the damaged switch, the trailing truck on CP 608303 derailed at the switch, resulting in further damage and precipitating the derailment of the following 32 cars.

- The brake beam on SOO75083 had failed due to an instantaneous overstress extension of a pre-existing fatigue crack.

- Fatigue cracking had initiated at a casting surface irregularity located just inboard of the separated brake head.

- The fatigue cracking was likely caused by abnormal cyclic stresses due to the interaction between the brake beam and the out-of-round wheels on the No. 2 wheel set.

Findings as to risk

- When condemnable wheel defects are not identified and removed from service in a timely manner, there is an increased risk that the defective wheel will compromise the integrity of other car components, resulting in their failure.

Other findings

- Although the slid flats and the out-of-round conditions of the No. 2 wheel set on SOO75083 were condemnable, the WILD readings for this wheel set were below the 90-kip threshold set out by the AAR.

- Given the damage to the brake heads on the No. 2 brake beam from prolonged contact with the wheel treads, the brake assembly defects were likely present in the days prior to the derailment and had not been noticed during inspection.

This report concludes the Transportation Safety Board's investigation into this occurrence. Consequently, the Board authorized the release of this report on . It was officially released on 10 April 2013.