Main-track derailment and collision

Canadian Pacific Railway

Freight trains 200-19 and 465-19

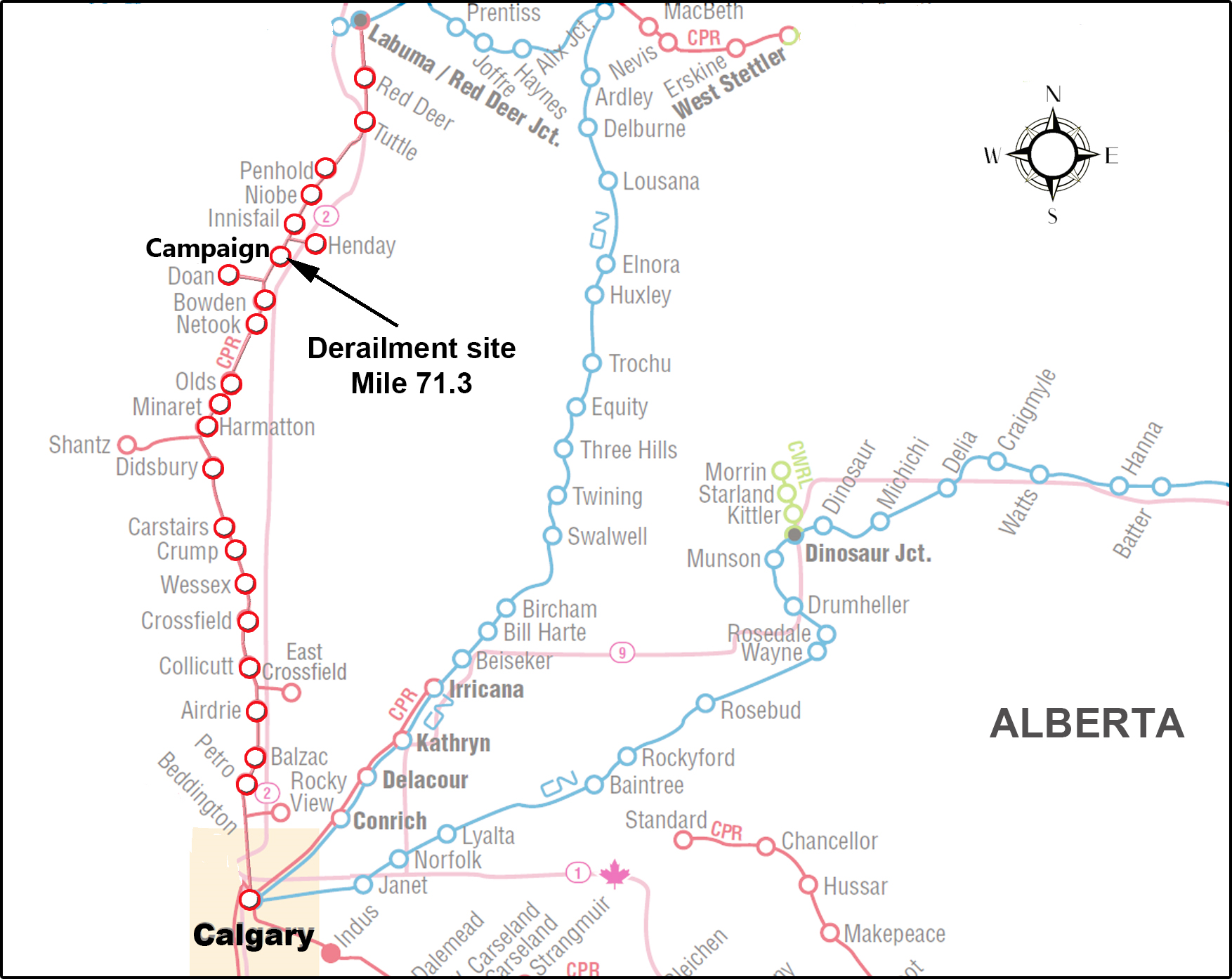

Mile 71.30, Red Deer Subdivision

Campaign, Alberta

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

At approximately 0127 Mountain Daylight Time on 21 April 2012, while proceeding northward on the Red Deer Subdivision, Canadian Pacific Railway freight train 200-19 entered the Campaign Siding at Mile 71.30 and derailed 10 empty tank cars. Two of the derailed tank cars contacted the lead locomotive on Canadian Pacific Railway freight train 465-19, which was stationary on the main track. One tank car leaked a small amount of glycol. There were no injuries.

Factual information

Canadian Pacific Railway (CPR) freight train 200-19 (train 200) consisted of 3 head-end locomotives and 80 rail cars. Four of the rail cars were loaded and 76 were empty. The train, which was destined for Red Deer, Alberta, weighed 2717 tons and was 4615 feet in length. It had received a mechanical inspection and an air brake test at Alyth Yard in Calgary, Alberta, before departure. No defects were noted during these inspections.

At approximately 0127 Footnote 1 on 21 April 2012, while proceeding northward on the Red Deer Subdivision, the train began to enter the siding at Campaign (Figure 1) to meet southbound CPR freight train 465-19 (train 465), which was stationary on the main track just north of the south siding switch. Train 465 consisted of 3 locomotives and 86 loaded rail cars.

The conductor from train 465 was positioned on the east side of the south siding switch to perform a passing inspection on train 200 and then to re-align the switch once train 200 cleared. Train 465's locomotive engineer and locomotive engineer trainee were getting ready to exit the cab to inspect the west side of train 200. As the train passed the south siding switch, there was an unusual banging noise, followed by a number of derailing tank cars. The conductor radioed train 200 to stop immediately. During the derailment sequence, the 12th and 13th cars (CGTX 22219 and AOUX 5061) behind the locomotives on train 200 struck the lead locomotive of train 465 (CP 9807).

After making the necessary emergency broadcast and notifying the rail traffic controller (RTC), the site was inspected and it was determined that 10 empty tank cars had derailed. The tank cars last contained glycol, a non-regulated chemical used in the manufacture of polyester resins, de-icing and heat transfer fluids.

The temperature was 0°C and clear.

Crew information

The crew of train 200 consisted of a locomotive engineer and a conductor. The crew of train 465 consisted of a locomotive engineer, conductor and a locomotive engineer trainee.

Both crews were qualified for their respective positions, met rest and fitness standards and were familiar with the territory.

Recorded information for train 200

Information from the locomotive event recorder (LER) was reviewed and is summarized as follows:

| Event no. | Time | CPR adjusted distance (Mile) | Calibrated distance (Mile) | Speed (mph) | BP (psi) | BC (psi) | TE (kips) | EOT (psi) | THR | ACCL (mph/s) | DB |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 0109:36 | 66.869 | 66.902 | 0 | 90 | 74 | 0 | 75 | 0 | 0.002 | OUT |

| 2 | 0113:56 | 68.384 | 68.417 | 38.4 | 90 | 0 | 8 | 83 | 0 | 0.009 | 2.5 |

| 3 | 0114:58 | 69.044 | 69.077 | 38.4 | 90 | 0 | 16 | 84 | 0 | 0.009 | 2.9 |

| 4 | 0116:58 | 70.273 | 70.306 | 32.2 | 90 | 0 | 41 | 85 | 0 | -0.101 | 6.3 |

| 5 | 0119:13 | 71.085 | 71.118 | 11.5 | 90 | 0 | 25 | 86 | 0 | -0.068 | 2.9 |

| 6 | 0120:22 | 71.283 | 71.316 | 8.5 | 90 | 0 | 8 | 86 | 0 | -0.072 | 2.3 |

| 7 | 0120:51 | 71.352 | 71.385 | 8.5 | 90 | 0 | 0 | 87 | 2 | 0.024 | OUT |

| 8 | 0121:07 | 71.390 | 71.423 | 9.5 | 90 | 0 | 8 | 87 | 0 | -0.032 | OUT |

| 9 | 0121:34 | 71.459 | 71.492 | 9.5 | 87 | 0 | 0 | 87 | 0 | -0.032 | 6.1 |

| 10 | 0121:36 | 71.465 | 71.498 | 8.5 | 83 | 32 | 26 | 87 | 0 | -1.317 | 6.1 |

| 11 | 0121:37 | 71.469 | 71.502 | 7.2 | 22 | 16 | 43 | 87 | 0 | -1.317 | 2.6 |

| 12 | 0121:38 | 71.471 | 71.504 | 5.9 | 2 | 16 | 43 | 87 | 0 | -1.013 | 2.6 |

| 13 | 0121:43 | 71.475 | 71.508 | 0 | 0 | 72 | 0 | 5 | 0 | -0.405 | OUT |

| 14 | 0122:44 | 71.475 | 71.508 | 0 | 0 | 77 | 0 | 0 | 0 | 0 | OUT |

Note:

CPR adjusted distance and calibrated distance are the location of lead locomotive CP 9642.

BP: brake pipe pressure;

BC: brake cylinder pressure;

TE: traction effort;

EOT: end-of-train brake air pressure;

THR: throttle position;

ACCL: acceleration;

DB: dynamic brake position

At 0120:22, the head end of train 200 entered the siding at Campaign travelling at a speed of 8.5 mph. At 0120:51, to pull the train over a slight grade change at the south end of the siding, the dynamic brake (DB) was shut off and the throttle was increased to position 2.

After receiving the stop command from the conductor of train 465, the crew on train 200 applied DB and the train brakes. At 0121:37, a train-initiated emergency brake application occurred. The train stopped 6 seconds later, at 0121:43.

The 3 locomotives pulling train 200 were 6-axle, 4400 HP General Electric locomotives, each capable of generating nearly 100 000 pounds of DB force. Only the DB on the first 2 locomotives were on line. DB factorFootnote 2 was 20, in accordance with CPR's General Operating Instructions (GOI) Section 16, paragraph 7.1 (c).Footnote 3

Site examination

The accident occurred in a rural area approximately 7 km north of Bowden, Alberta. At this location, the track runs parallel to Highway No. 2.

During the site examination, it was observed that:

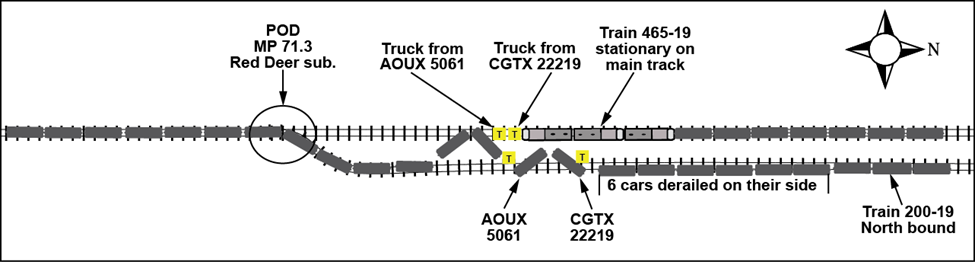

- The 3 locomotives and first 11 cars on train 200 had passed through the south siding switch.

- The 6th to the 11th cars were derailed on their sides to the east (Photo 1). These cars had remained connected through their double shelf couplers Footnote 4 (Photo 2).

- The leading truck of the 12th car, CGTX 22219, had separated and came to rest beside the tank car. The trailing truck of this car had travelled down the main track and came to rest after striking the lead locomotive on train 465 (Figure 2).

- The leading truck of the 13th car, AOUX 5061, had separated and came to rest beside the leading truck of the 12th car. The trailing truck of AOUX 5061 had separated, but continued along the siding and came to rest beside the tank car.

- The 12th and 13th cars came to rest in a jackknifed position on the siding track.

- The 14th and 15th cars came to rest in a jackknifed position.

- There was minor damage on the front of the lead locomotive of train 465 (Photo 3).

- Wheel marks were present on main-track ties, starting immediately north of the south siding switch (Photo 4).

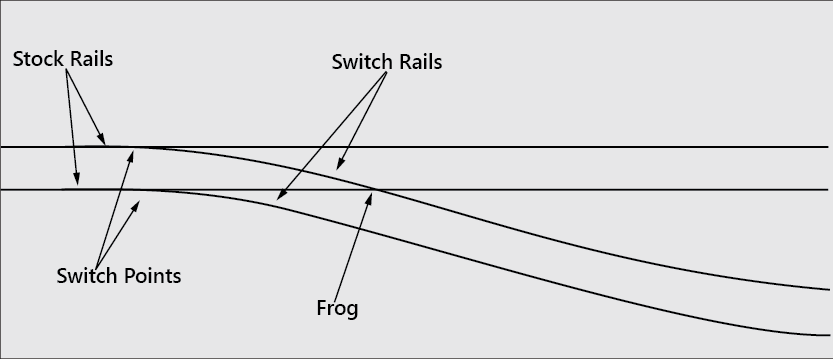

- There was no damage to the switch points (see figure 3 for schematic of switch and turnout components). However, the No. 3 rod was bent. There were wheel climb marks on the west face of the west switch point. Contact marks and shavings were present on the south face of the west switch heel block.

- There were 3 wheel marks at the west heel block that crossed over the point to the gauge side but did not continue to the ground. A 4th wheel mark travelled approximately 7 feet before dropping between the east point and stock rail.

- Approximately 31 feet north of the switch point, wheel drop marks were observed to the field side of the curve closure rail and between the east point and stock rail.

- There were also wheel drop marks to the gauge side of the main-line rail and to the field side of the curve closure rail approximately 82 feet and 87 feet further northward respectively.

Subdivision information

The Red Deer Subdivision begins at CPR's Calgary Terminal (12th Street East, Mile 0.0) and runs north to Red Deer, Mile 95.6. Between Calgary Terminal and Airdrie (Mile 16.6), train movements are governed by the Centralized Traffic Control System (CTC). North of Airdrie, the remainder of the Red Deer Subdivision is governed by the Occupancy Control System (OCS). Both systems are authorized under the Canadian Rail Operating Rules and supervised by an RTC located in Calgary.

The maximum freight operating speed in the vicinity of the derailment is 45 mph. The maximum speed for trains through the Campaign Siding is 10 mph. The main track is Class 4, as defined by the Transport Canada–approved Railway Track Safety Rules. The siding track at Campaign is Class 1.

Track information

The rail in the area of the derailment was 115-pound continuous welded rail (CWR), manufactured by Algoma in 1983 (east rail) and 1984 (west rail) and installed in 1985. The rails were fastened to 14-inch double-shouldered tie plates with 3 spikes per plate on a mix of hardwood and softwood ties. The ballast was a mix of older local crushed rock and Grade 3 standard specification ballast. The drainage was good with no signs of fouling or mud pumping through the switch area.

The switch was a No. 13, 115-pound turnout with a high mast. It had 22-foot switch points, bolted guard rails (8 feet 3 inches in length) and adjustable braces. The frog Footnote 5 had been replaced on 02 April 2012 and had not received any welding or repairs since its installation. The turnout included a 4.3° right-hand curve reversing to a left-hand curve onto the siding. The siding track at Campaign was situated slightly lower than the adjacent main track. The transition from the main track to the lower siding track occurs in the vicinity of the turnout (Photo 5).

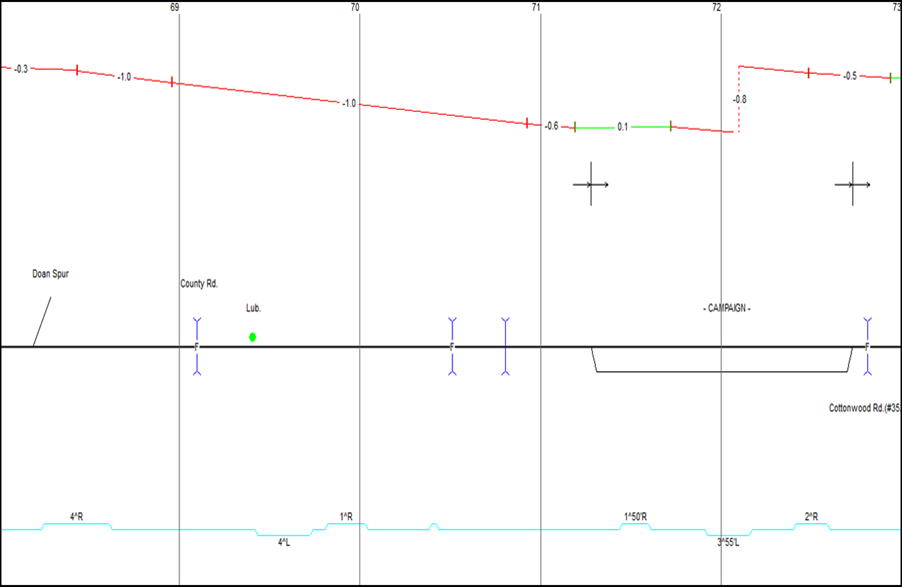

The track leading up to the south siding switch at Campaign is on a long descending grade (Figure 4). The steepest portion of the grade (that is, approximately 1.0%) occurs between Mile 68.43 and Mile 70.93. The south siding switch is located on tangent track at Mile 71.3, just north of the steepest part of the grade. In the vicinity of the switch, the grade changes from 0.6% (descending) to 0.1% (ascending) and then to 0.8% (descending).

Track inspection and maintenance

The last ultrasonic rail test before the derailment had taken place on 08 March 2012. During this test, no rail defects were noted on the main track in the vicinity of the Campaign Siding. The last track inspection by hi-rail had taken place on 19 April 2012. No defects were noted in the vicinity of the south siding switch and turnout.

The track geometry in the Campaign Siding had been tested using CPR's track evaluation car (TEC) on 14 December 2011. During this test, the following priority defects were noted:

- Defect 128 - Priority SPXLVFootnote 6 in begin spiral – 2 feet long, 1 ⅜-inch maximum value.

- Defect 129 - Priority SPXLV in begin spiral – 2 feet long, 1 ½-inch maximum value.

- Defect 130 - Priority AL/62Footnote 7 in end spiral – 3 feet long, 1 ⅞-inch maximum value.

The 3 defects did not exceed CPR's urgent threshold levelFootnote 8 for Class 1 track. Following the track geometry test, no immediate repairs were performed at the diverging route of the south siding switch. These defect locations were added to CPR's Spring 2012 surfacing work list.

In collaboration with Transport Canada, CPR has been sponsoring research that uses an instrumented tank car to look for combinations of track geometry priority defects that are, by themselves, below safety limit thresholds. For example, a combined alignment/twist defect has been developed, which allows the railway to place a higher urgency on these types of defects.

Turnout inspection

The turnout at the south siding switch (Campaign) was last inspected on 12 April 2012. During this inspection, the turnout was found to be in good condition.

Mechanical inspection of derailed tank cars

Cars CGTX 22219 and AOUX 5061 (the 12th and 13th cars behind the locomotives on train 200) were taken to CPR's Alyth car repair facility in Calgary. Teardown inspections were performed.

For car CGTX 22219, it was determined that:

- The side bearing clearances on the leading B endFootnote 9 of the car were ⅛-inch below the Association of American Railroads (AAR) condemning limit,Footnote 10 a condemnable defect.

- The coupler height on the trailing A end of the car was ½-inch lower than the AAR standard.Footnote 11 Although considered a non-condemnable defect, maintenance was required to be performed the next time the car was on a repair track.

- The centre plate was dry and rusty with no lubrication present.

- The last time this car was on a repair track was 07 December 2011.

For car AOUX 5061, it was determined that:

- The coupler height on the trailing B end of the car was ½-inch lower than the AAR standard. Although considered a non-condemnable defect, maintenance was required to be performed the next time the car was on a repair track.

- There was a non-condemnable height difference of 1 ¼ inches between the couplers connecting the leading A end of car AOUX 5061 with the trailing A end of car CGTX 22219.Footnote 12

- The B-end side bearings had some wear and were at the extreme lower limit of the AAR condemning limit for constant contact side bearings (CCSB), but were not condemnable.

- The centre plate was dry and rusty with no lubrication present.

- The last time this car was on a repair track was 11 May 2010.

The railway had no prior knowledge of existing condemnable and non-condemnable defects on either of the 2 cars inspected. The coupler height measurements were taken after the derailment. These mechanical defects would not have been readily identifiable through normal inspection processes.

Torsional rigidity of tank cars

Stub sill tank cars, similar to the tank cars that derailed in this occurrence, utilize the tank itself as a centre sill and are more rigid than traditional rail cars. A consequence of this is that, as one corner of the car travels over a track irregularity (for example, a turnout or entrance/exit spiral to a curve), the diagonally opposite corner of the car may experience some degree of wheel unloading as a result of the rigidity of the car body.

For other types of rolling stock, which can twist more readily as they negotiate varying track structure, vertical unloading at the diagonally opposite corner will not occur to the same extent. In this case, the forces at one end of the car will not necessarily affect the truck at the opposite end.

Track/train dynamics

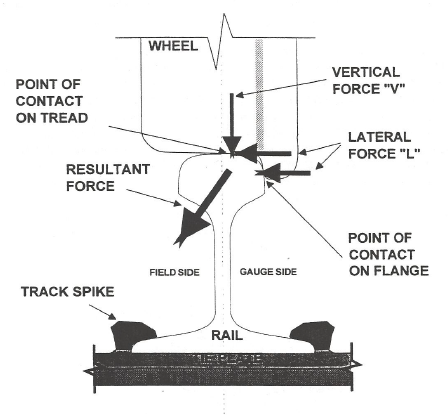

The wheel/rail interface sees a combination of lateral (L) and vertical (V) forces when a car is moving (Figure 5). The ratio of lateral-to-vertical (L/V) forces provides an indicator of the likelihood of a derailment. The tendency toward derailment increases as the L/V ratio increases. A high lateral and low vertical force (for example, empty cars travelling on a curve) could result in the wheel flange being pushed up and over the gauge face of the rail or result in

the rail being pushed outward (that is, rail cant) and possibly rolling over. The highest L/V ratios will typically occur when there is a sudden reduction in vertical load. A wheel L/V ratio of between 0.80 and 0.90 of sufficient duration is known to cause wheel climb.Footnote 13

Longitudinal train forces are transmitted through the train between the coupler pivot points. When a train is being pulled on tangent track, the train is typically experiencing draft forces (that is, tensile forces acting along the centre line of the track). When a train is operating on curved track, the longitudinal forces, whether compressive (that is, pushing) or tensile (that is, pulling) and related coupler angles, result in lateral forces at the vehicle centre plates and at the car wheels. These lateral forces are transmitted by the wheels to the rails. The magnitude of the lateral forces at the rail will vary based on the magnitude of the longitudinal force, the coupler angle, the grade and the degree of curvature.

Dynamic analysis of the derailment

The TSB Laboratory conducted a dynamic analysis of the derailment. It was determined that:

- The west wheels of the trailing truck of the 12th car, CGTX 22219, and the leading truck of the 13th car, AOUX 5061, climbed over the west point rail of the south switch at the Campaign Siding and started the accident.

- The wheel climb over the west point rail was likely caused by a combination of factors, including in-train buff force, jackknifing position of the cars and couplers (Figure 6), track geometry conditions, car conditions, point rail profile and coupler height difference. Each of these factors alone would not have led to the derailment.

- A medium longitudinal in-train force (that is, approximately 95 kips) was produced while the head end of the train transitioned from the descending grade to the slight ascending grade in the vicinity of the south siding switch.

- Although non-condemnable, low and different coupler heights between the first derailed cars may have created a vertical loading/unloading effect in transmitting the longitudinal force.

- The jackknifing position of the first 2 derailed tank cars (that is, CGTX 22219 and AOUX 5061) transformed the in-train buff force laterally, resulting in a higher L/V ratio.

- Track geometry irregularities, side bearing clearance and dry centre plate conditions of the rigid tank cars generated a transient dynamic response, contributing to the final dynamic L/V ratio.

- The point rail profile is easier for wheels to climb over as compared to the standard rail profile, especially for impeded or jackknifed cars.

- The west wheels (that is, trailing truck of 12th car and leading truck of 13th car) aligned with the stock rail. Instead of catching the east gauge face of the west point rail and travelling along the curve closure rail, the west wheels travelled over the point rail in the straight direction of the stock rail.

Analysis

Despite having no apparent track exceptions or issues with train handling, a derailment occurred. The analysis will consider how rolling stock conditions, track geometry conditions and track/train dynamics can affect the lateral and vertical forces at the wheel/rail interface and lead to a derailment.

The accident

The derailment occurred at the south siding switch at Campaign when wheels on the 12th and 13th cars climbed the rail in the turnout. As the train was entering the Campaign Siding, a medium longitudinal in-train buff force was produced when the head end of the train transitioned from the descending grade to the slight ascending grade in the vicinity of the south siding switch. With a non-condemnable coupler height mismatch (that is, 1 ¼ inches) between the 12th and 13th cars, a vertical loading-unloading effect on the adjacent trucks may have occurred.

With the train navigating the turnout, the cars were in the jackknifing position, which transformed the in-train buff force laterally against the rail, resulting in a higher L/V ratio. The track geometry irregularities in the vicinity of the turnout and the mechanical condition of the 12th and 13th cars (that is, side bearing clearance and dry centre plate conditions) also contributed to the higher L/V ratio.

During the wheel climb event,Footnote 14 the west wheels on the trailing truck of the 12th car and on the leading truck of the 13th car aligned with the stock rail. Instead of catching the east gauge face of the west point rail and travelling along the curve closure rail, the west wheels travelled over the point rail in the straight direction of the stock rail, leading to the derailment.

A combination of non-actionable track geometry defects, non-condemnable car defects, and train action due to track grade had produced an L/V ratio that was sufficient for the wheels on the light, empty tank cars to climb the rail. Each of these factors alone would not have resulted in the derailment.

Mechanical condition of the tank cars

The centre plates on the first 2 derailed tank cars (that is, CGTX 22219 and AOUX 5061) were dry and unlubricated. The side bearing clearances on car CGTX 22219 were just beyond the AAR condemning limit and the side bearing clearances on car AOUX 5061 were just under the AAR condemning limit.Footnote 15 However, neither mechanical defect was considered critical nor would they have been readily identified through the normal inspection process. These types of mechanical defects can affect car body movement on curved track and lead to increased lateral forces. When the mechanical condition of a torsionally rigid tank car does not allow for unimpeded movement of the truck on curved track, there will be an increase in lateral forces at the wheel/rail interface, increasing the risk of wheel climb derailments.

Non-actionable track conditions combined with condemnable car defects

The priority track geometry defects detected in the vicinity of the turnout during the December 2011 TEC test did not exceed CPR’s urgent threshold level for Class 1 track. No immediate track repairs were performed at this location. These defects alone would not have directly resulted in the derailment.

In this occurrence, the 12th and 13th cars (CGTX 22219 and AOUX 5061) each had a number of condemnable and non-condemnable mechanical defects that may have had an impact on the cars’ ability to negotiate curved track. When non-actionable track geometry defects are combined with condemnable and non-condemnable car defects, the full impact of the defects in combination may produce higher L/V conditions, increasing the risk of derailments.

Wheel/rail forces at a turnout

Lateral forces at the turnout point rail can be substantial, even under normal train handling conditions. The point rail, a section of straight rail planed to a fine tip, represents an abrupt change in direction. Wheel sets encountering a point rail when negotiating a turnout take a more aggressive angle of attack, resulting in higher flange forces.

In addition, any reduction in vertical force at this point will result in a higher L/V ratio with an increased chance of wheel climb. This situation may occur when the train is entering a siding track that is situated slightly lower than the adjacent main track (as was the case at the Campaign Siding). When tank cars with high torsional rigidity negotiate turnouts where the siding track is situated lower than the adjacent main track, the rear trucks may experience a momentary loss of vertical load, resulting in a higher L/V ratio and an increased risk of derailment.

Double shelf couplers

Double shelf couplers are designed to prevent unintended detachment of coupled cars. They are used primarily on tank cars to reduce the likelihood of disconnected couplers puncturing tank heads in the aftermath of a derailment. In this occurrence, 6 empty tank cars, the 6th through 11th, were dragged off the rails by the derailed 12th car due to their double shelf couplers.

Findings

Findings as to causes and contributing factors

- The derailment occurred at the south siding switch at Campaign when wheels on the 12th and 13th cars climbed the rail in the turnout.

- As the train was entering the Campaign Siding, a longitudinal in-train buff force was produced when the head end of the train transitioned from the descending grade to the slight ascending grade in the vicinity of the south siding switch.

- With a non-condemnable coupler height mismatch between the 12th and 13th cars, a vertical loading/unloading effect on the adjacent trucks may have occurred.

- With the train navigating the turnout, the 12th and 13th cars were in the jackknifing position, which transformed the in-train buff force laterally against the rail, resulting in a higher lateral/vertical (L/V) ratio.

- The track geometry irregularities in the vicinity of the turnout and the mechanical condition of the 12th and 13th cars (that is, low side bearing clearance and dry centre plate conditions) also contributed to the higher L/V ratio.

- Instead of catching the east gauge face of the west point rail and travelling along the curve closure rail, the west wheels on the trailing truck of the 12th car and the leading truck of the 13th car travelled over the point rail in the straight direction of the stock rail, leading to the derailment.

Findings as to risk

- When the mechanical condition of a torsionally rigid tank car does not allow for unimpeded movement of the truck on curved track, there will be an increase in lateral forces at the wheel/rail interface, increasing the risk of wheel climb derailments.

- When non-actionable track geometry defects are combined with condemnable and non‑condemnable car defects, the full impact of the defects in combination may produce higher L/V conditions, increasing the risk of derailments.

- When tank cars with high torsional rigidity negotiate turnouts where the siding track is situated lower than the adjacent main track, the rear trucks may experience a momentary loss of vertical load, resulting in a higher L/V ratio and an increased risk of derailment.

Other findings

- Six empty tank cars, the 6th through the 11th, were dragged off the rails by the derailed 12th car due to their double shelf couplers.