Main-track train derailment

Canadian National Railway Company

Freight train U70451-02

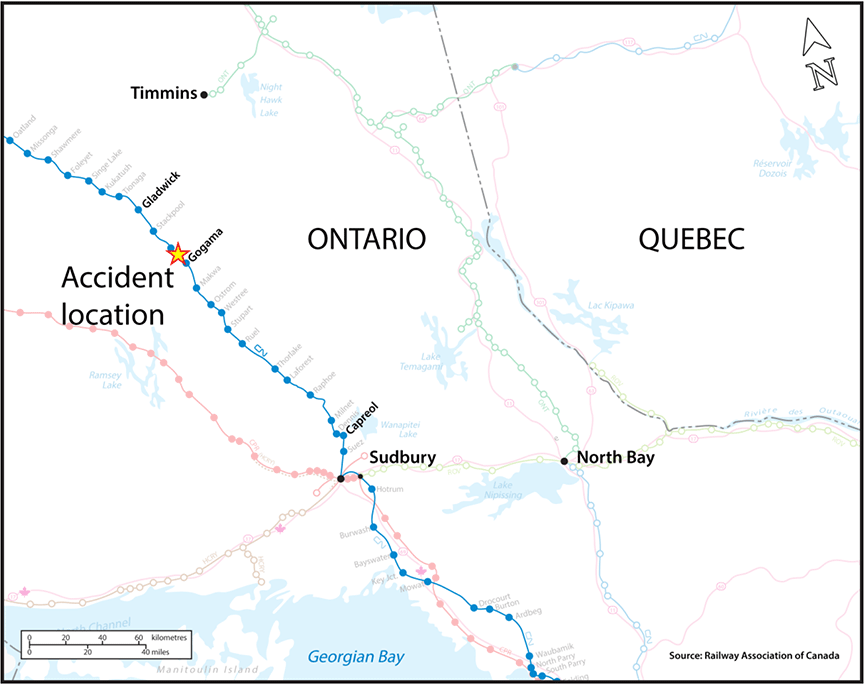

Mile 88.75, Ruel Subdivision

Gogama, Ontario

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

On 07 March 2015, at 0242 Eastern Standard Time, Canadian National Railway Company (CN) crude oil unit train U70451-02 was proceeding eastward at about 43 mph on CN's Ruel Subdivision when it experienced a train-initiated emergency brake application at Mile 88.70, near Gogama, Ontario. A subsequent inspection determined that the 6th to the 44th cars (39 cars in total) had derailed. As a result of the derailment, about 2.6 million litres of petroleum crude oil (UN1267) was released to atmosphere, water, or surface. The released product ignited and caused explosions, and some product entered the nearby Makami River. A CN bridge over the Makami River (at Mile 88.70) and about 1000 feet of track were destroyed. There was no evacuation, and there were no injuries.

Le présent rapport est également disponible en français.

1.0 Factual information

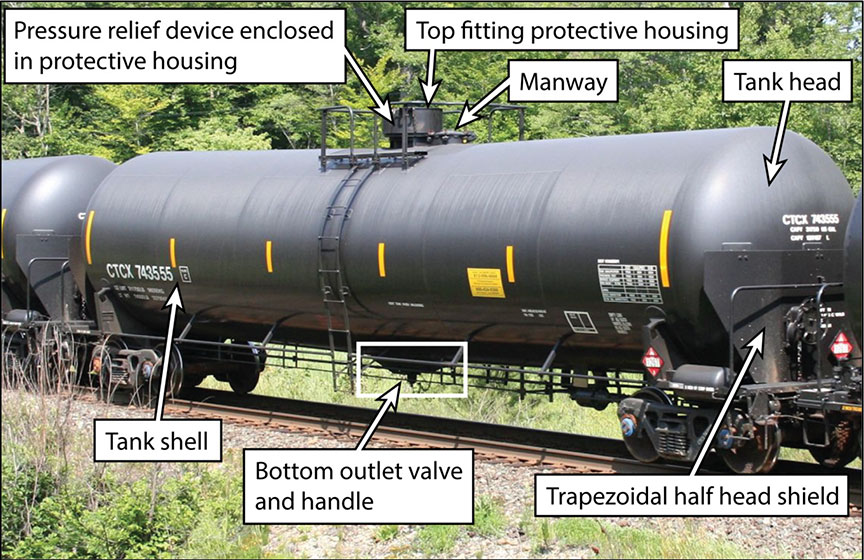

On 02 March 2015, Canadian National Railway Company (CN) crude oil unit train U70451-02 (the train) departed eastward from Redwater, Alberta, destined for the Valero Energy Incorporated (Valero) refinery located at Lévis, Quebec. The train consisted of 2 head-end locomotives and 94 tank cars loaded with petroleum crude oil (UN1267). It weighed 13 497 tons and was 5733 feet long. The train was designated as a key trainFootnote 1 operating on a key route.Footnote 2

On 06 March 2015, a regular crew change was made at Hornepayne, Ontario, located at Mile 296.2 of CN's Ruel Subdivision.Footnote 3 The outbound train crew consisted of a locomotive engineer, a trainee, and a conductor. All crew members met fitness and rest standards and were qualified for their respective positions. The train departed eastward on the subdivision at about 2230.Footnote 4

The Makami River flows southward towards the town of Gogama, Ontario (Mile 86.60), and into Minisinakwa Lake. The river then flows around Gogama, turns northeast and flows towards Timmins and the Mattagami First Nation. A CN mainline rail bridge spans the river at Mile 88.70.

1.1 The accident

At about 0242 on 07 March 2015, while the train was proceeding at about 43 mph, the locomotive forward- facing video recorded a slight dip just before a train-initiated emergency brake application occurred at Mile 88.70 near Gogama (Figure 1). The train crew looked back and observed a large explosion and ensuing fire. They followed the emergency procedures and made the necessary radio broadcast. After the train came to rest, the crew inspected the train and determined that tank cars behind the 5th car from the head end had derailed and were on fire. The crew disconnected the locomotives and the first 5 cars from the train and travelled to a safe location east of the fire. There were no injuries and there was no evacuation.

Just west of the derailment area, the tail end of the train was blocking the crossing at Highway 144 (Mile 88.98). The crossing was subsequently cleared when the tail end of the train was pulled westward by locomotives from eastbound CN train 112, and the tank cars were left at Stackpool, Ontario (Mile 105.4).

The temperature at the time of accident was −9 °C, and there was an 11 km/h wind from the northwest. For the 7 days following the derailment, the weather was similar and close to seasonal norms.

1.2 Site examination

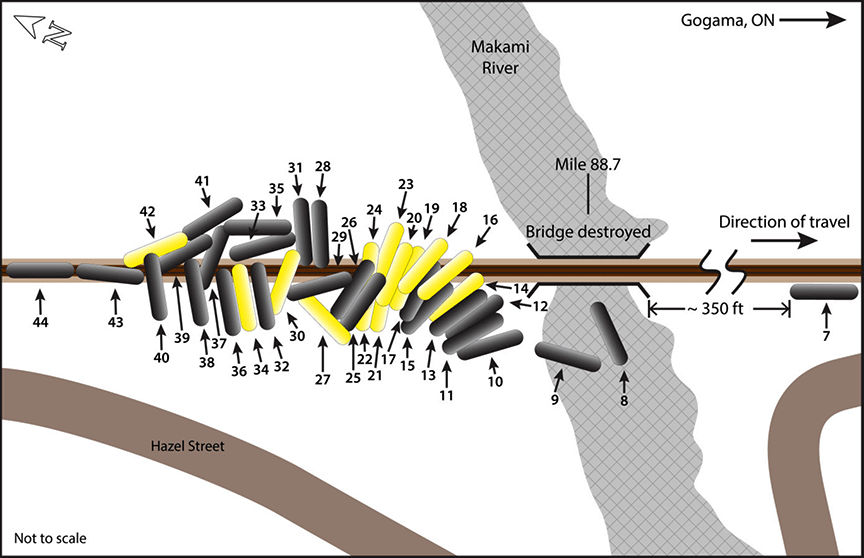

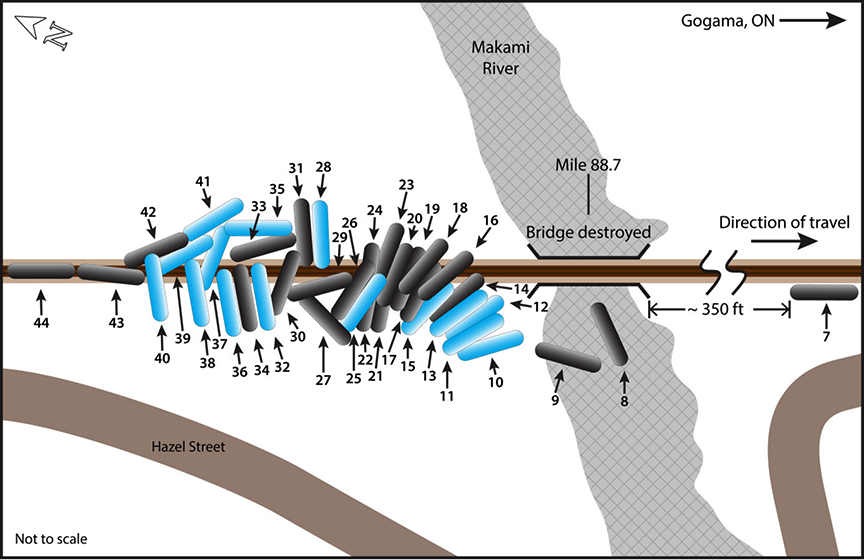

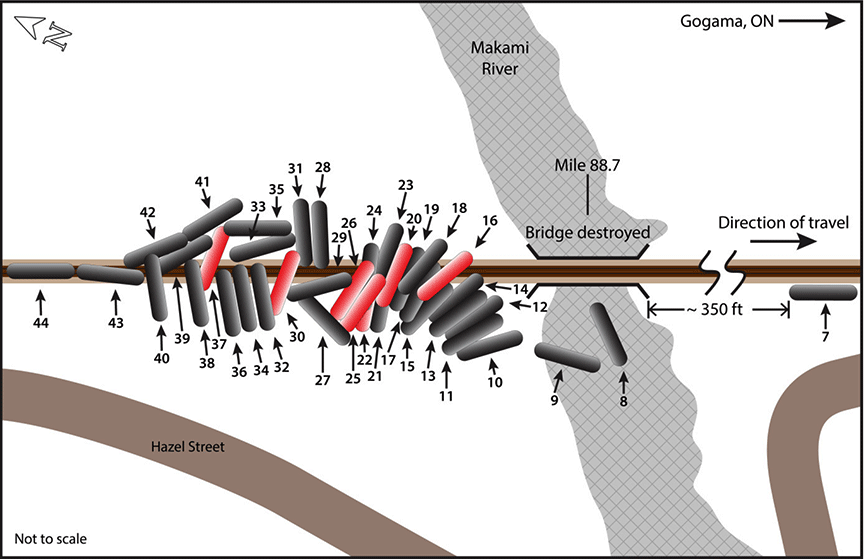

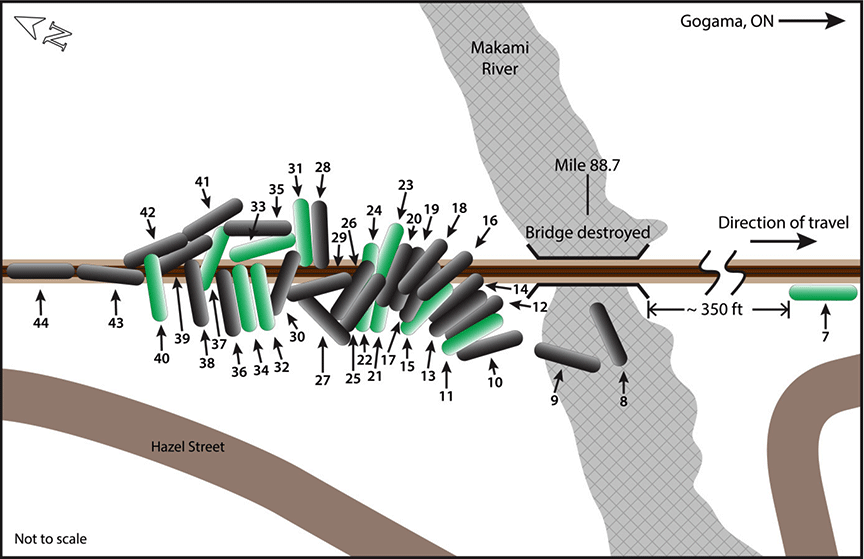

The 6th to the 44th cars from the head end (39 tank cars) had derailed (Figure 2). The 6th car (VMSX 310431) had travelled across the rail bridge over the river and derailed upright to the south of the track. The 6th car was subsequently re-railed and removed from the site. The trailing end of the 7th car (VMSX 310442) had struck the south side of the bridge structure and rolled down the south side embankment about 350 feet east of the bridge. Its bottom outlet valve was damaged and product was released. The 8th car (VMSX 311916) struck the bridge heavily and came to rest in the river south of the bridge, along with parts from 5 other cars. Most of the remaining derailed cars had jackknifed on the west approach to the bridge and travelled down the south embankment. The last two derailed cars, the 43rd and 44th cars (VMSX 310060 and VMSX 311681), derailed upright and came to rest near Mile 88.75.

Of the 39 derailed tank cars, 33 had been breached and released product, fuelling the fire, and some product entered the river. The fire occupied an area about 300 yards in diameter and was centred near the west end of the rail bridge (Figure 3). The bridge and about 1000 feet of track were destroyed (Figure 4).

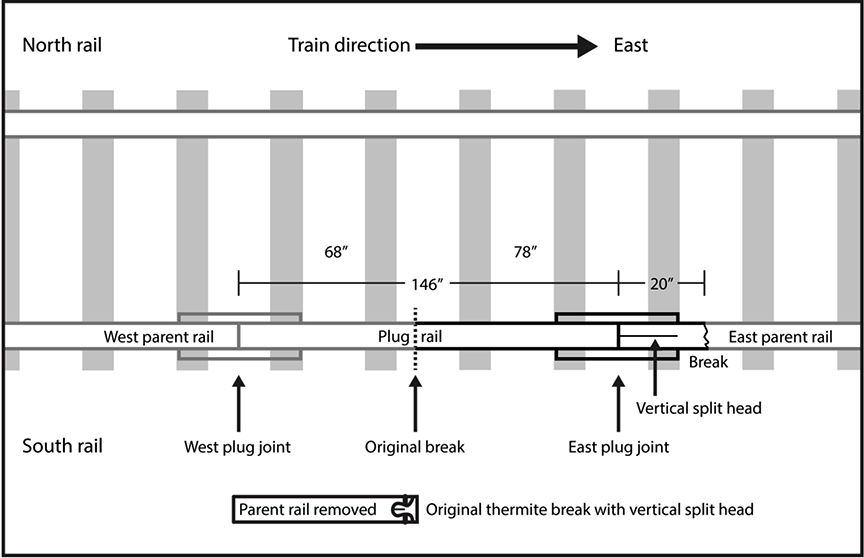

Approaching the derailment site from the west, there were no impact marks observed on the track infrastructure. At the west end of the derailment site, a number of broken pieces of the south rail were observed in the vicinity of Mile 88.75, as follows:

- Sitting beside the track were 2 sections of rail, one measuring 68 inches long and one measuring 78 inches long, which contained a defective field weld (DWF) that had been removed from the south rail 3 days before the accident, during the repair of a broken rail (Figure 5).

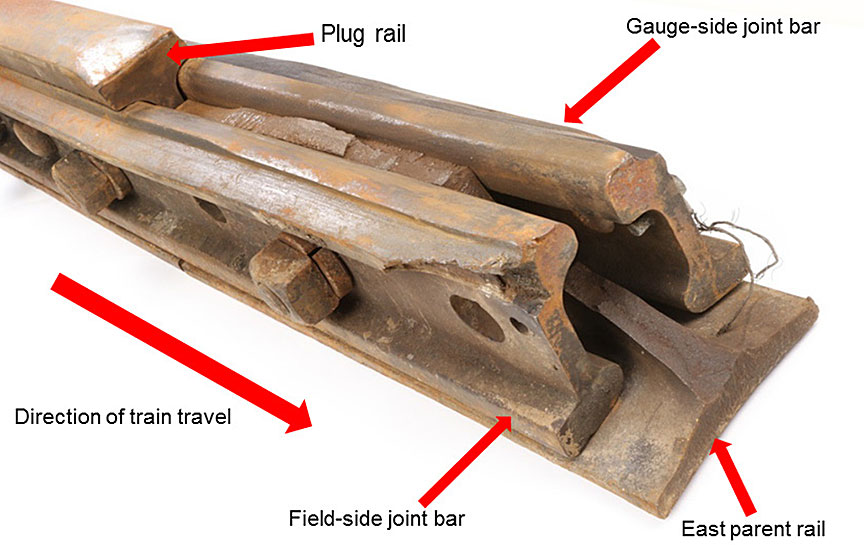

- The east joint of the plug rail, with joint bars still holding together an intact 53-inch-long section of plug rail and a fractured 20-inch-long section of parent south rail, was recovered about 265 feet west of the west bridge abutment (Figure 6).

- Most of the rail head of the 20-inch section had broken off (Figure 7). Only a 4-inch-long piece of the rail head was recovered.

- The 4-inch-long piece of the rail head that was recovered exhibited a vertical split head (VSH) rail defect (Figure 8).

- The west joint of the plug rail connected 28 inches of plug rail and 72 inches of parent rail.

The recovered rail components were sent to the TSB Engineering Laboratory for analysis.

During site cleanup, the first derailed car was re-railed and taken to Capreol, Ontario (Mile 0.0), on the Ruel Subdivision. The 7th to 43rd cars were destroyed. The 44th car was re-railed and sent to destination at Lévis, Quebec, on 13 March 2015.

1.3 Locomotive video recorder

The lead locomotive, CN2913, was equipped with a forward-facing camera that provided a video and audio recording with date, time, and speed information. Based on the camera's recording, it was determined that an impact sound and a vibration in the locomotive cab occurred 4 seconds before the train encountered the west end of the bridge. Three seconds later, a train-initiated emergency brake application occurred.

1.4 Dangerous goods

The transportation of dangerous goods (DGs)Footnote 5 is governed by federal regulations in CanadaFootnote 6 and in the United States.Footnote 7 These regulations are based on the United Nations Recommendations on the Transport of Dangerous Goods.

In this occurrence, petroleum crude oil (UN1267) was being transported in each tank car. The product was listed as Class 3 flammable liquid, Packing Group (PG) I, which is the most hazardous group in this class.

1.4.1 Class 3 flammable liquids

Class 3 flammable liquids are DGs whose vapours can form an ignitable mixture with air at or below a temperature of 60 °C. These flammable liquids can pose serious hazards due to their volatility and flammability, which are determined by the initial boiling pointFootnote 8 and the flash point, respectively.Footnote 9

Because the volatility and flammability vary widely, products in this class are grouped together based on these characteristics so that different requirements, including packaging, storage, handling, and transportation, can be established. According to the Transportation of Dangerous Goods Regulations, Class 3 flammable liquids are divided into 3 packing groups, ranging from PG I (highest hazard) to PG III (lowest hazard). The specific criteria for these packing groups are:

- PG I, if the flammable liquid has an initial boiling point of 35 °C or less at an absolute pressure of 101.3 kPa and any flash point.

- PG II, if the flammable liquid has an initial boiling point greater than 35 °C at an absolute pressure of 101.3 kPa and a flash point less than 23 °C.

- PG III, if the criteria for inclusion in PG I or PG II are not met.

1.4.2 Petroleum crude oil

Petroleum crude oil has a wide range of flammability and volatility characteristics. The product is usually qualified in terms of sulphur content (low sulphur being "sweet" and high sulphur being "sour") and density (light to heavy). The density of petroleum crude oil is described in terms of its American Petroleum Institute (API) gravityFootnote 10 (expressed in degrees), where a higher number indicates lower density. The thresholds defining "light," "medium," and "heavy" crude oil vary depending on the product's region of origin and the organization making the determination.Footnote 11

Petroleum crude oil can also vary in viscosity, which is often referred to as the thickness of a fluid. Products with low viscosity (e.g., water) flow freely, while products with high viscosity (e.g., molasses) are thicker and do not flow freely.

1.4.3 Emergency response procedures for petroleum crude oil

Guide 128 of the Emergency Response Guidebook.Footnote 12 identifies the potential hazards of petroleum crude oil products, including petroleum distillates. Guidance is provided for emergency response and for ensuring public safety.

Under the heading "Potential Hazards,"Footnote 13 the guide indicates:

- These products are lighter than water, are highly flammable, and will be easily ignited by heat, sparks or flames.

- The product vapours are heavier than air; they will spread along the ground and collect in low or confined areas (e.g., sewers, basements, or tanks). These vapours may form explosive mixtures with air, and may travel to source of ignition and flash back.

- These products are associated with a vapour explosion hazard indoors, outdoors or in sewers, and containers may explode when heated.

Under the headings "Emergency Response"Footnote 14 and "Public Safety,"Footnote 15 the guide states that

- Water spray, fog or regular foam should be used to fight fire, but not straight streams of water. Because these products have a very low flash point, water spray may be inefficient; it may be necessary to use vapour-suppressing foam to reduce vapours.

- An initial downwind evacuation for at least 300 metres (1000 feet) should be considered.

- All ignition sources must be eliminated.

- All equipment used when handling the product must be grounded.

- Responders must not touch or walk through spilled material.

- The leak should be stopped if it can be done without risk.

- Entry into waterways, sewers, basements or confined areas should be prevented.

- Spilled product should be absorbed or covered with dry earth, sand or other non-combustible material, and transferred to containers.

- Clean, non-sparking tools should be used to collect absorbed material.

1.5 Emergency response

The accident occurred about 2 miles west of the town of Gogama and 0.25 miles east of Highway 144. There was good access to the site, which facilitated mitigation activities.

CN and the Gogama fire service immediately implemented a unified incident command system. With cooperation from the local municipality, the Gogama town hall, located approximately 2 miles northeast of the derailment site, was established as the incident command center (ICC). The ICC served as the location for internal and external responders to provide updates on remediation plans, site mitigation progress, operational recovery plans, and other safety concerns.

CN's remediation plans were shared with all responders and local stakeholders at regular pre-planned times. Other response agencies established work centres within the ICC to coordinate activities. The ICC also provided relief to responders from the weather, and hot meals were available to responders and support personnel around the clock.

Sign-in and sign-out control procedures for all response personnel were established and monitored 24 hours a day from the ICC. CN police and security personnel controlled derailment access at checkpoints surrounding the perimeter of the site.

All responders who required access to the site were issued either a half- or a full-face respirator complete with supporting "fit test" documentation and proper filter canisters. CN dangerous goods officers performed regular air testing throughout the derailment site, monitoring for hydrogen sulfide (H2S) and hydrocarbon explosive level thresholds. Drager tube testing for airborne benzene was conducted at half-hour intervals. Wind socks were erected at strategic locations to provide responders with advance warning when changing wind conditions increased the potential risk of inhalation hazards.

Water samples and water testing results from nearby Minisinakwa Lake and its tributaries were on display in the ICC as derailment mitigation and environmental remediation progressed. Photographs and topographical maps were posted, regularly updated, and consistently made available to residents and the general public. Ongoing environmental impact assessments were conducted and discussed among all stakeholders. Future remediation commitments were shared with the local community.

CN mobile command posts were positioned at the east end and the west end of the site perimeter. Each command post was equipped with food, water, first aid equipment, and replacement safety equipment for distribution to personnel as necessary, and was used to provide relief to responders from the weather. Secondary job briefings and directions regarding remediation plans were also coordinated and communicated from these mobile command posts.

A detailed information session involving provincial and municipal officials, First Nations Chiefs and elders, response agencies, and Gogama residents, was chaired by CN 4 days into the derailment cleanup. A follow-up town hall meeting took place in Gogama in November 2015 to reassure the stakeholders of CN's continued involvement with the environmental cleanup.

1.6 Track restoration and bridge replacement

Because the accident resulted in a lengthy track outage and impacted rail operations, CN constructed a 1482-foot-long diversion track to the south of the accident site (Figure 9).

The diversion bridged the Makami River with 5 culverts (Figure 10) and was in service from 10 March to 18 March. About 130 trains were routed over the diversion track during that period.

The destroyed bridge was replaced with 2 previously used beam spans, each measuring 49 feet long, and a steel tray ballast deck. The replacement bridge was supported on the existing bridge abutments. A new centre pier was built out of 4 steel casings filled with concrete and a new precast concrete cap. The first train went over the new bridge on 18 March 2015. Once the new bridge (Figure 11) was operational, the diversion track over the Makami River was removed and the riverbed restored.

1.7 Environmental impact

1.7.1 Site description

Along the north shore of the river, there is a low-lying wetland area. Along the south shore of the river, there is a low-lying wetland area and an upland dense forested area.

Old Gogama Road (also known as Hazel Street) is located south of the track and generally runs parallel to the mainline track and the river. Old Gogama Road crosses the river at the Bailey Bridge, located about 250 m downstream (south) of the mainline rail bridge.

The majority of the tank cars derailed along the north shore of the river just east and west of the north abutment of the rail bridge. Two tank cars came to rest in the river. Initially, there was visual evidence of released product in the river and along the north shore, east and west of the mainline.

Of the more than 4 million litres of petroleum crude oil transported in the derailed cars, approximately

- 1.6 million litres of product burned to atmosphere;

- 1 million litres of product was lost to surface or water; and

- 1.4 million litres of product was recovered and transferred from the tank cars.

1.7.2 Surface water monitoring program

Following the initial site containment and booming strategies, a surface water sampling program was initiated within the river and Minisinakwa Lake. A total of 14 sample stations were established upstream of the derailment site and downstream of the river extending into Minisinakwa Lake. Samples were collected daily for several weeks until the test results stabilized. Sampling frequency was reduced to twice weekly following several consecutive rounds of sampling which showed no detection of petroleum products, as verified with the Ontario Ministry of the Environment and Climate Change and Environment and Climate Change Canada. Reduced sampling continued along and within the river until November 2015. During the winter, the sites were inspected on a monthly basis as part of monthly groundwater sampling and product collection events. Surface water monitoring resumed in the spring of 2016 and was expected to continue on a quarterly basis for an indefinite period.

Despite these efforts, a thin sheen of oil on the river surface and some dead fish were reported by concerned citizens during the summer of 2016. CN followed up on these concerns and continued to sample and test the soil, sediment, and water in the areas identified. Tests were also conducted on some of the dead fish. Initially, an independent review determined that the test results met regulatory standards, and the results were shared with community leaders. However, at the time that this TSB investigation report was released, Environment and Climate Change Canada was continuing to investigate alleged violations of the pollution prevention provisions of the Fisheries Act.related to this accident.

1.7.3 Wastewater treatment

A water treatment plan was initiated to treat all recovered impacted water. A mobile wastewater treatment unit (MTU) was sent to the accident site. However, after several attempts to treat the impacted water, it was determined that on-site treatment would not be possible due to the levels of petroleum hydrocarbons present in the water. Arrangements were made with an off-site disposal facility operated by Clean Harbours in Sarnia, Ontario, which was approved by the province to accept the impacted oily water.

The oil/water mixture collected at the site was stored in temporary fixed-axle storage tanks (frac tanks). Several of the frac tanks were set up with a series of baffles that helped concentrate the oil as much as possible. The concentrated oil was removed from the tops of the frac tanks and packaged in dedicated frac tanks as a separate waste stream. The concentrated oil was sampled and analyzed for potential recycling or reuse. The remaining oily water and emulsion was shipped by tank truck for off-site disposal. The water was separated and treated. When it was determined that the water met regulatory requirements, it was discharged back into the natural environment.

Although the most significant wastewater treatment activities had been completed, a small amount of oil remained in the ecosystem, as confirmed by water tests taken throughout the cleanup process. However, independent test results showed that water quality in the ground, river, and lake met regulatory standards.

1.7.4 Groundwater monitoring

A total of 19 groundwater monitoring wells were installed to verify the direction of groundwater flow and depth, and to determine whether groundwater had been impacted. The wells were installed around the site perimeter, which included both sides of the CN right-of-way within the CN property limits and on Crown land.

Petroleum was detected in 3 wells located along the containment area and the CN right-of-way property boundary. Following remediation of the containment area, the detected concentration of petroleum at these 3 wells decreased to the point where it was considered to be of minor residual impact rather than a leak within the containment system.

As of June 2017, 2 of the wells located on Crown land exceeded provincial standards for hydrocarbons, and monitoring was ongoing.

In September 2016, an additional 10 monitoring wells were installed along the west bank of the Makami River. As of June 2017, one of the 10 new wells exceeded provincial criteria for toluene and petroleum hydrocarbons, and ongoing monitoring was required.

1.7.5 Sediment dredging

Sediment dredging from the riverbed was completed under the approval of the Ontario Ministry of Natural Resources and Forestry, the Ontario Ministry of the Environment and Climate Change, and Fisheries and Oceans Canada. The dredging consisted of vacuum removal of sediment within a section of the river, beginning upstream of the CN rail bridge and continuing downstream to the Bailey roadway bridge. The start and end points of the sediment removal were determined by an ecological risk assessment that included the collection and analysis of sediment samples taken throughout the entire river. The depth of sediment removal ranged from 15 cm to 30 cm, depending on the topography of the riverbed. Impacted sediment was removed and disposed of at a licensed facility.

Water effluent from the sediment dredging was treated using an on-site MTU. The MTU, which was provincially governed and approved, was operated under a mobile Certificate of Approval or Environmental Compliance Approval that contained sampling requirements and discharge criteria. The criteria were strictly adhered to before any treated water was discharged back to the natural environment. In October 2015, water treatment was terminated after the sediment dredging operations were completed.

In 2016, local residents continued to report the presence of oil sheens on the river surface when sediment was disturbed. In response, CN re-established a consultation panel of experts in the fall of 2016. The panel included representatives from Environment and Climate Change Canada, Fisheries and Oceans Canada, the Ontario Ministry of Natural Resources and Forestry, the Ontario Ministry of the Environment and Climate Change, the Gogama Local Services Board, and the Mattagami First Nation, as well as subject-matter experts in sediment remediation.

It was subsequently agreed by all parties that additional riverbed dredging operations were to be conducted within the area of the rail bridge and in 2 areas just south of Bailey Bridge. The riverbed in each of the 3 areas was vacuumed, dredged, and cleared of sediment. To help the sediment re-establish continuity and create new fish spawning areas, the riverbed was then restored by placing a layer of clean pit stone (cobble and boulder-sized) which was covered with pea gravel. The elevations and amount of material added were assessed on a case-by-case basis, based on pre-dredge elevations and the volume of material removed. Sampling of the river and derailment site is to resume in the spring of 2017.

1.7.6 Shoreline cleanup

Two shoreline cleanup assessment techniques (SCAT) were completed to address the potential impacts to the river and lake shorelines. The SCAT teams included representatives from Environment Canada, the Mattagami First Nation, the Gogama local services board, and several SCAT-certified technicians. Visual and physical inspection of the shorelines, accessible surface water, and associated vegetation were conducted on the entire river downstream of the derailment as well as the north, south, and island shorelines of Minisinakwa Lake. Both assessments were documented in a full SCAT report.

The first SCAT assessment identified 4 areas along the river as well as locations on the north shore of Minisinakwa Lake and the main island that had signs of oil deposit or staining. The second SCAT assessment identified relatively small areas of wetland and upland grasses within the river that showed staining. SCAT crews subsequently cut and removed all impacted vegetation.

1.7.7 Soil excavation and containment

There was a significant volume of impacted soil adjacent to the north rail bridge abutment. This area contained natural low-lying wetlands where pike had historically spawned. Because these areas were prone to seasonal flooding and high spring water levels, it was imperative to excavate the impacted soils as soon as possible to minimize damage to the fish stock and eliminate the potential for impacted soils to be washed from the site and downstream into the river.

A total of 8 lined soil containment cells were constructed to store contaminated soil until it could be transported to an approved landfill site. Impacted soil was loaded into the cells and stored while soil excavation and sample testing was completed. Each cell could contain about 2500 m³ (5000 tonnes) of soil. The cells were tarped to prevent precipitation from entering the contaminated soil. A total of about 37 500 m³ of contaminated soil was shipped by truck to an approved landfill in Cartier, Ontario.

1.7.8 Product recovery from CN right-of-way

A non-permeable liner and sheet pile wall were installed along the east and west sides of CN's right-of-way property boundary. The liner and sheet pile were tied into a concrete cut-off wall that was connected to the bridge abutment. This arrangement created a containment basin for any remaining product that might seep out of the ballast. Each month, any remaining product was removed and disposed off-site at a certified facility.

1.7.8 Site restoration

CN submitted a detailed restoration plan to the regulatory agencies and to the Mattagami First Nation for consideration and comment. Site restoration, which included a diverse planting program to return the lost vegetation species that were native to the area, was completed with the assistance of the local Mattagami First Nation in the fall of 2016. Shoreline restoration was completed in the fall of 2016. A fish spawning lagoon was created in the vicinity of the bridge.

CN prepared a remediation report, which was made available to the regulators and the Mattagami First Nation. A follow-up report was to be prepared to document the restoration work and any additional remedial work required to complete site restoration. Following each sampling program, a summary report was prepared and submitted to the Ontario Ministry of the Environment and Climate Change. These summary reports were to continue until it was determined that no further monitoring or remedial action was required. Normally, site restoration is not considered complete until approval for site closure is received from the Ontario Ministry of the Environment and Climate Change.

1.8 Track and subdivision information

All railway lines are defined as a particular class of track that is related to the condition or maintenance level of the track. The Transport Canada (TC)–approved Rules Respecting Track Safety, also known as the Track Safety Rules.(TSR), outline classes of track and the associated maximum permitted train speeds for each class. Under the TSR, the lowest class of track is Class 1, which restricts freight train speed to a maximum of 10 mph, and the highest class of track is Class 5, which has a maximum permitted freight train speed of 80 mph.

CN's Ruel Subdivision consists of a single main track that extends westward from Capreol, Ontario (Mile 0.0) to Hornepayne, Ontario (Mile 296.2). Train movements on the subdivision are governed by centralized traffic control (CTC), as authorized by the Canadian Rail Operating Rules.(CROR), and supervised by a rail traffic controller (RTC) located in Toronto, Ontario.

In the vicinity of the derailment, the track is Class 4. The authorized track speed is 50 mph for freight trains and 55 mph for passenger trains. Traffic on the Ruel Subdivision consisted of an average of 18 freight trains per day. A VIA Rail Inc. passenger train operated westbound on Wednesdays and Sundays, and eastbound on Wednesdays and Fridays.

The track throughout the derailment area is tangent single mainline generally oriented in an east-west direction. It consists of 136-pound continuous welded rail (CWR) manufactured by Sydney in 1993. Rail wear was measured at 8 mm, which was less than 75% of the vertical condemning limit. The rail was laid on 14-inch double shoulder tie plates supported by No. 1 hardwood ties spaced at 20-inch centres, secured with 5 spikes per plate, and box-anchored every second tie. The ties were in fair condition. The ballast was clean crushed rock. The shoulders were about 12 inches wide, the cribs were full, and the drainage was good.

The Makami rail bridge was a 99-foot-long single span, open-deck, thru-plate girder bridge built in 1910. The bridge had 115-pound guard rails spiked to the bridge timbers with transition ties on both ends. It was inspected annually. The last inspection had been conducted on 17 September 2014, with no defects recorded.

Between 2010 and 2014, rail freight traffic on the Ruel Subdivision had increased from 32.8 million gross ton miles per mile (MGTM/M) to 47.1 MGTM/M (Table 1). During the same period, the number of car loads of petroleum crude oil had increased from 62 to 75 186.

| Year | Freight (MGTM/M)* |

Freight GTM (thousand) |

Crude oil GTM (thousand) |

Crude oil (carloads) |

Crude oil (MGTM/M) |

|---|---|---|---|---|---|

| 2010 | 32.8 | 9 709 654 | 2 263 | 62 | 0.007 |

| 2011 | 35.3 | 10 452 629 | 71 369 | 2 843 | 0.240 |

| 2012 | 36.8 | 10 897 795 | 459 077 | 19 399 | 1.549 |

| 2013 | 37.2 | 11 013 838 | 835 271 | 34 384 | 2.819 |

| 2014 | 47.1 | 13 956 400 | 1 937 152 | 75 186 | 6.540 |

* The terms million gross tons (MGT), gross ton miles (GTM), MGTM, and MGTM/M are used interchangeably in the rail industry.

1.9 Track inspection

For federally regulated track, the minimum regulatory requirements for track inspection are set out in the TSR. Where track is identified as not meeting the track safety rules, the railway company must immediately bring the track into compliance or halt operations over that track.Footnote 16

1.9.1 Visual inspection

The TSR require Class 4 track to be visually inspected twice a week. During the winter of 2015, CN instituted a requirement for daily track inspections in the Northern Ontario Zone because of temperature, snow, and track conditions. The track was visually inspected by an assistant track supervisor (ATS) on 04 March 2015. No defects were noted in the area of the joint.

1.9.2 Track geometry inspection

According to the TSR, for Class 4 track with more than 35 MGT of annual traffic, a track geometry inspection must be performed with a heavy geometry inspection vehicle at least 2 times a year.

On the Ruel Subdivision, CN conducted track geometry testing 4 to 6 times per year.Footnote 17 The most recent track geometry car inspection had been completed on 02 November 2014, about 3 months prior to the derailment. No defects were detected within a mile of the derailment location.

Table 2 provides a summary of CN priority, near-urgent, and urgent geometry defects on the Ruel Subdivision from 2011 to 2014.

| Defect type | 2011 | 2012 | 2013 | 2014 |

|---|---|---|---|---|

| Priority | 14 538 | 30 634 | 13 827 | 9 053 |

| Near-urgent | 5 030 | 11 971 | 5 326 | 2 289 |

| Urgent | 390 | 892 | 308 | 302 |

| Total | 19 958 | 43 497 | 19 461 | 11 644 |

CN Engineering Track Standards.(ETS), track standard (TS) 7.1, "Track Geometry," specifies (in part) that

- Deviations exceeding Transport Canada Track Safety Rules……for track geometry are defined as "URGENT" defects.Footnote 18

TS 7.1 further indicates that

- Where a portion of the track exceeds the limits defined as "URGENT", one of the following actions must be immediately taken before the operation of the next train over the defect(s):

- the defect must be repaired to within the allowable tolerances;

- […]if the defect is a speed-related type, a temporary slow order (TSO) must be placed restricting trains to a maximum speed which is within the track class allowed for the severity of the defect(s); or

- operation over the track must be halted.Footnote 19

Deviations approaching track geometry limits specified in the TSR are defined as "NEAR-URGENT" conditions. CN TS 7.1, Item 3, states that

- NEAR-URGENT conditions will be identified by the Geometry Car and must be inspected within 72 hours and remedial action must be taken within 30 days.

TS 7.1, Item 4, states that

- Deviations exceeding CN recommended maintenance tolerances are defined as "PRIORITY" conditions. Where a portion of track exceeds the limits defined as priority, the condition must be monitored until it is repaired to ensure it does not escalate to an "URGENT" defect.Footnote 20

1.9.3 Rail flaw inspection

According to the TSR, on Class 4 track with more than 35 MGT of annual traffic, a rail flaw inspection must be performed at least 4 times a year. Inspection equipment must be capable of detecting rail defects between joint bars in the area enclosed by the joint bars.

CN performs rail flaw inspections on the Ruel Subdivision approximately every 20 days throughout the winter months and every 37 days throughout all other seasons.Footnote 21 The 2 most recent tests had been conducted by Sperry Rail Service on 06 February 2015 and 02 March 2015. No rail defects were detected in the south rail in the vicinity of the derailment.

Between January 2014 and March 2015, rail flaw testing on the Ruel Subdivision identified 570 flaws (Table 3), which included 332 localized surface collapses (LSC), 87 rail end batters (REB) and 19 crushed heads (CH). These rail surface conditions primarily occurred in 136-pound rail manufactured by Sydney and Algoma from 1990 to 1999 and required a significant amount of monitoring and/or repair work for inspectors and maintenance crews. VSH defects accounted for 5% of the detected defects.

| Rail surface condition or rail defect | Number | Percentage * |

|---|---|---|

| Bolt hole | 31 | 5% |

| Crushed head | 19 | 3% |

| Defective weld – field | 35 | 6% |

| Defective weld – plant | 8 | 1% |

| Detail fracture | 12 | 2% |

| Horizontal split web | 3 | 1% |

| Horizontal split head | 7 | 1% |

| Localized surface collapse | 332 | 58% |

| Rail end batter | 87 | 15% |

| Split web | 5 | 1% |

| Vertical split head | 31 | 5% |

| Total | 570 | 100% |

* Some values have been rounded

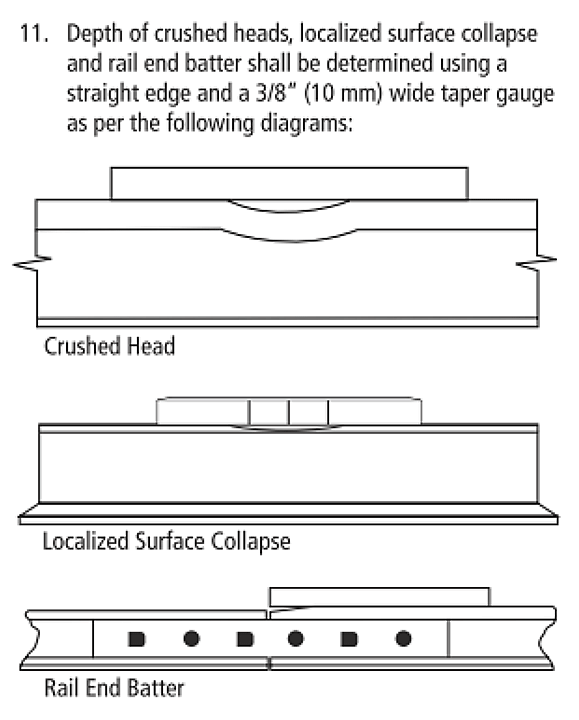

1.10 Rail end batter, localized surface collapse, and crushed head rail surface conditions

Rail end batter (REB) occurs at a rail joint when the ends of the rail heads within the joint are mismatched and/or the gap between the rail ends is too large. REB is indicative of degrading joint support that can result in excessive joint movement which can be further degraded by mechanical interaction from repetitive wheel loadings. If not properly addressed in the field, REBs can ultimately result in joint failure and derailment.

A localized surface collapse is characterized by plastic metal flow, leading to the flattening out and deformation of the rail head above the plane of the rail head / web fillet (Figure 12). A crushed head (CH) is similar to a localized surface collapse (LSC) with the exception that CH deformation of the rail head extends to below the plane of the rail head /web fillet. LSCs and CHs are normally caused by mechanical interaction from repetitive wheel loadings. They can result in high contact stresses and can lead to or accelerate the development of other rail defects such as a transverse detail defect (TDD) or a vertical split head (VSH) which can fail rapidly and result in a derailment.

Rail flaw technology to detect LSC, REB, and CH conditions is relatively new. CN has recorded surface conditions such as LSCs, CHs, and REBs since 2005. In 2010, more defined guidelines for these types of conditions were introduced. Since that time, there has been a significant increase in the number of conditions detected. Some railways have developed comparable, but not harmonized, thresholds to detect and record these conditions. Before this technology was implemented, these conditions were usually detected by visual inspection, but relatively few were identified. After this technology was implemented, the number of these rail surface conditions identified has significantly increased.

Although CN considered the workforce to be adequate and properly equipped, the larger number of LSC, REB, and CH rail surface conditions that were identified represented a significant increased workload. This was especially true in the spring, when the workforce was actively engaged in removing rail plugs and rail joints installed in CWR territory during the winter months when rail defects were removed. Each LSC, REB, and CH rail surface condition had to be monitored and measured, and then removed if the standards specified in CN ETS TS 1.7, "Rail Testing and Remedial Action for Broken Rail", were exceeded. The standards identify that:

- Item 10a requires the monitoring of LSC conditions that are less than 5 mm in depth, on rail worn to less than 75% of the vertical rail wear condemning limit.

- Item 10b outlines the limits for REB in the winter months:

During the winter months (as determined by the Regional Chief Engineer), the following applies to in-track rail joints in Class 3 track and greater with annual MGT's of 10 or greater.

If joint rail end batter is found to be it. [ sic.

| > 3.5 mm | > 4 mm | >= 5 mm |

|---|---|---|

|

|

|

The depth of an LSC or REB is measured using a straight edge, as shown in Figure 13.

The TSR contain no guidance or condemning criteria for LSCs, REBs or CHs. In Canada, they are categorized as rail surface conditions rather than rail defects. While they are not considered service failures, they are considered to be leading indicators of degrading track condition and potential emerging rail defects.

In comparison, the U.S. Department of Transportation (DOT) (i.e., the Federal Railroad Administration (FRA)) considers "flattened rail,"Footnote 22 the FRA equivalent of LSC, to be a defect when it is 3/8 inch or more in depth and 8 inches or more in length. Remedial action for this defect consists of limiting operating speed over a defective rail to 50 mph or to the maximum allowable speed permitted for the class of track concerned, whichever is lower.Footnote 23

1.11 Vertical split head rail defects

A VSH defect is a progressive longitudinal fracture through or near the middle of the rail head, extending into or through it. The origin is web streaking and segregation that create an internal longitudinal seam. Web streaking and segregation are indications that inclusions in the steel have congregated along the centreline of the rail rather than being evenly distributed during the manufacturing process. Vertical separation will progress longitudinally and vertically (parallel to the side of the head), and may gradually turn toward the gauge or the field side of the rail head. Defect growth is normally very rapid once the seam or separation has opened up anywhere along its length.

During manufacturing, rail is generally formed by rolling continuous rectangular cast steel billets through a series of rollers at controlled temperatures in a steel blooming mill. Each rail is assigned a heat number which is hot stamped on the rail web. Rails in the same heat may have different properties (and defects) depending on the quality control in the casting and rolling process. During the rolling process, some impurities can be forced into the centre of the rail web. When subjected to macroscopic examination, the impurities display as a tight seam within the web. On some occasions, the seam extends into the head of rail. This becomes problematic when the rail head wears down and the seam is exposed to dynamic loading due to service conditions (i.e., wheel loads as they traverse the rail). Once exposed to dynamic loading, the seam, which is not detectable by rail flaw detection until it opens, can rapidly deteriorate and result in a VSH rail failure.

Sydney Steel CompanyFootnote 24 had experienced a number of process and quality control problems with its rail manufacturing throughout its history. One problem had been the presence of centreline streaking that extended into the rail head. Once a rail head had sufficient wear, the tip of the centreline streaking was in an area of the rail head that was subjected to the highest rolling contact forces, making it more susceptible to rapid VSH development and fracture propagation.

The U.S. Department of Transportation FRA Title 49 CFR, Part 213, Track Safety Standards: Improving Rail Integrity: Final Rule, dated 24 January 2014, discusses the development of internal rail flaws and the risk of failure. The Final Rule states that, in practice, the growth rate of rail defects is considered highly inconsistent and unpredictable. High traffic volumes load the rail and accelerate defect growth. The tonnage required to influence defect development is also considered difficult to predict. However, once a defect is initiated, tonnage influences its internal development and growth.Footnote 25

Although difficult to detect visually, a crack or rust streak may show in the head/web fillet area under the head. There may also be signs of sagging or dropping, or pieces may split off the side of the head.

The Sperry Rail Service Rail Defect Manual.describes VSH defects as dangerous fatigue defects because:

- It is usually not visible on the rail surface until it has grown to a length of several feet.

- As VSH usually extends longitudinally for some distance, a considerable portion of the rail head is weakened.

- If the split is on the gauge side of the rail and breaks off in service, car wheels will tend to climb to the top of the rail or drop into gauge thus causing a derailment.

- When the rail breaks in-service, it may break into several pieces.Footnote 26

VSH defects are a common fatigue defect and considered dangerous given that they can develop rapidly and their presence is difficult to detect, even with ultrasonic inspection. In 2014, Sperry Rail Service detected a total of 33 241 defects while testing 134 054 miles of CN track in Canada. VSHs accounted for 1533 (4.6%) of these defects. During the same period, CN reported 692 rail in-service failures, 76 (11%) of which were due to VSH defects.

1.12 Plug rail repair at Mile 88.75

The CTC signal control system on the Ruel Subdivision is divided into a series of sections or "blocks" that are electrically isolated from each other. Signals at each end of a block control movements into and out of that block. When a train is in a block, signals at each end of the block are RED, meaning "stop", and the RTC display will indicate that the block is occupied. Signals can also default to a RED indication when a broken rail occurs in the block.

On 04 March 2015, at about 1935, the signals controlling traffic into the Gogama-Bethnal block (Mile 86.20 to Mile 94.70) unexpectedly changed to a RED indication, prohibiting rail traffic from entering the block. Therefore, it was necessary to quickly find the source of the RED signal activation.

The regular track maintenance foreman (TMF) was not available, because he had been called out to replace a defective rail east of Gogama. The track supervisor (TSPVR) instructed the snow patrol foreman (SPF), who was a thermite welding foreman during the summer, and a helper on light duties who was unable to assist much physically, to determine the source of the RED signal activation. At 2021, the SPF obtained a track occupancy permit (TOP) and proceeded by high-rail vehicle to investigate. The SPF was followed by a signal maintainer on the same TOP. At about 2050, the SPF, the helper, and the signal maintainer located a broken thermite weld in the south rail at Mile 88.75.

The SPF took a picture of the broken rail, sent it to the TSPVR, and requested instructions on how to proceed. Given the 4-inch offset of the broken rail, the TSPVR indicated that the broken rail would need to be changed out before any trains would be able to pass over the area. However, the section work crew was at the end of its shift and nearing the end of available hours to operate the track force optimization (TFO) vehicle. The TSPVR instructed the SPF and the helper to change out the rail. The SPF was also a qualified track foreman and, as such, was considered qualified to change out the broken rail.

The signal maintainer measured the rail head loss of the broken rail and notified the Gogama TMF that they would require a plug rail with 8 mm of head loss. The SPF proceeded to Gogama, where he met with the section work crew. A 157-inch plug rail with 8 mm of rail head loss was loaded on to the TFO vehicle. This plug rail had pre-drilled holes for joint bar bolts at one end. As the SPF was not familiar with the TFO vehicle, the section work crew provided the SPF with a familiarization briefing before the crew went off duty. Once briefed, the SPF drove to the Highway 144 crossing, put the TFO vehicle onto the track, and proceeded east to the site of the broken rail.

After arriving on site, the SPF prepared for the installation of the plug rail. The plug rail was unloaded and positioned. Snow and ice was cleaned away from the parent rail. A mark was made on the parent rail 68 inches west and 78 inches east of the broken weld to position the plug rail ends between ties. Eleven inches of material was cut from the plug rail. The parent rail was cut and the exposed rail ends were visually inspected for cracks or other anomalies.Footnote 27 No cracks were visually observed; however, a dye penetrant test was not performed to confirm the presence of any cracks. The CN requirement to perform a dye penetrant test on the exposed rail ends had not specifically been discussed between the SPF and the TSPVR.

The plug rail was rolled into the track with no joint gaps. Because the east end of the plug rail was pre-drilled for 132-pound joint bars,Footnote 28 only the west end of the plug rail had to be drilled. However, the drilling template was placed on top of the plug rail in a way that resulted in the outside hole being drilled too close to the joint. Consequently, an extra hole had to be drilled in the plug rail. The two holes were about ½ inch apart. This situation was discussed with the TSPVR, and the rail repair was approved for service. Once the drilling was complete, the plug rail was fully bolted, spiked, and anchored.

While the repair was being performed, the SPF received several phone calls and radio calls from the TSPVR, the RTC, and the Senior Manager Engineering (SME) for progress updates. The SPF was informed that a number of eastbound and westbound trains were already waiting.

The plug rail was not physically measured after the repair, but the SPF visually estimated that it was 2 mm higher than the parent rail at the east end of the installation. The SPF used a hand grinder to ease the transition between the two surfaces by grinding the top of the rail for about 2.5 inches from the east end of the plug rail. The hand grinder was used because the larger rail grinder was not available.

The work was completed at about 2245. The SPF cleared the track and drove back to the tool house to prepare for snow clearing duties for the remainder of the shift. The TOP was cancelled at 2307:40, and rail traffic was restored.

The TSPVR had intended to check the broken rail repair to ensure that it had been properly completed. However, the TSPVR became occupied the following morning responding to another derailment near Minnipuka, Ontario (Mile 243.50 on the Ruel Subdivision).

Between the time that the track repair was completed on 04 March 2015 and the occurrence on 07 March 2015, 44 trains, including other crude oil unit trains, had traversed the plug rail.

1.13 Snow patrol foreman and helper information

The SPF joined CN in 1998 and worked as a thermite welding foreman on production gangs during the summer, which primarily involved welding new rail to new rail. At the end of the summer/fall work season, the SPF became part of CN's winter workforce. At the time of the occurrence, the SPF was on snow clearing duties and was working a 9 days on, 5 days off cycle on the night shift, stationed at Gogama.

The helper had worked as a machine operator for CN for 8 years. On 03 March 2015, the helper had been sent to Gogama to work with the SPF while the regular machine operator was away. The helper was on light duties and had little experience in changing out broken rails and performing plug rail repairs.

1.14 Installing plug rails

The process for changing out a broken or defective rail and the related training were covered in various CN training classes and documents. Specifically, the installation of plug rails was covered in the Track Maintainer course and in an on-the-job training manual. Handling the rail with a crane was covered in the Crane Fundamentals course and the Crane Handbook. The standards regarding match marks, dye penetrant, and plug rail length were covered in CN's Engineering Track Standards.(June 2011) (ETS) and Recommended Methods (RM).

CN ETS TS 1.2, "Laying Rail - General," Item 13, states (in part) that

Item 13 further specifies the track speed reductions that are required if such repairs cannot be carried out immediately. This section of the ETS contains no guidance on the length of grinding required to provide a smooth transition between rail sections of plug rail repairs. In comparison, the CN Welders Manual.(2005), Chapter 17, states (in part):

- for flash butt welding, the maximum vertical offset for two rails thermite welded together must not exceed 1/8 inch (0.125 inches) [3 mm]; and

- if a difference in height exists, it should be corrected by grinding the high rail over a distance of 6 inches for every 0.01 inch of offset up to a maximum of 36 inches.

CN ETS section 1.7(2) states (in part):

Regarding dye penetrant testing, ETS 1.7(3) states (in part):

Dye penetrant testing shall be performed on rail ends:

- in the event of an in-service rail failure;

1.14.1 Dye penetrant testing

The required steps to perform when testing the rail with dye penetrant are listed in CN Recommended Method (RM) 1.7.3 (January 2015).

Dye penetrant testing is a 3-step process that involves spraying a cleaner, a penetrant, and a developer chemical on the exposed cut of the rail end. The test takes about 15 minutes to perform and can be done while preparing the plug rail for installation.

This test is based on capillary action, where a low-surface-tension dye penetrant fluid is sprayed on a rail end. After time has been allowed for penetration, excess penetrant fluid is removed and a developer is applied. The developer helps draw the penetrant out of a flaw or crack and onto the surface, making the crack visible. Dye penetrant testing can be conducted on rails at temperatures as low as −32 °C. However, for best results, both the penetrant and the developer should be kept warm. In cold weather, the penetrant should be sprayed on the rail ends immediately after the rail has been cut, as the heat from cutting will aid in opening any cracks that may be present.

1.14.2 Snow patrol foreman's familiarity with dye penetrant testing

The SPF was aware of the dye penetrant test but had never done it before or seen it done. When working as a thermite welding foreman, the SPF had worked primarily with new rail. The dye penetrant test was typically conducted for older rails removed from track due to an in-service failure.

On 27 January 2015, the SPF took the CN Engineering winter safety online exam, which included some questions about dye penetrant testing. The passing grade for the exam was 90%. On the first attempt of the exam, the SPF obtained a mark of 74% and had 12 incorrect answers, including a question about the dye penetrant testing. On the second attempt, the SPF answered the dye penetrant question correctly and obtained a mark of 96%.

1.15 Procedural errors

Errors of omission, including skipping steps in a maintenance procedure, have been shown to be among the most frequent errors during maintenance activities. These types of errors are more likely to occur in situations where the required step is not critical to achieving the main goal of the maintenance activity or takes place after the main goal has been achieved, and where there are few environmental triggers to remind the maintainer that a step needs to be performed. Tasks that have recently changed, or need to be conducted in a manner or order that is unusual for the maintainer, are also more prone to errors of omission.Footnote 29

In situations where reminders cannot be built into the maintenance task itself, external reminders are the simplest countermeasure to ensure that critical steps are completed. To be effective, reminders need to be timely (visible at the appropriate time) and compelling (prevent the task from being completed without a procedural check). Commonly used means of building these characteristics into a reminder include the use of checklists or task cards for commonly performed maintenance tasks and independent checks of critical maintenance activities before returning equipment to service.

1.16 Canadian National Railway Company engineering employee development

Unionized engineering employees were initially hired as track maintainers. Track maintainer training consisted of a 3-week course at CN's training centre in Winnipeg. The first week covered general introductory topics related to working for CN, the second week was specific to the role of a track maintainer, and the third week was devoted to CROR training.

Candidates were required to pass an exam related to track maintenance at the end of the second week in order to proceed to rules training. There were very few failures at this stage of the training. A rules test was administered at the end of the third week. About 75% of the candidates successfully passed the rules test on their first attempt. Candidates who were unsuccessful could attempt the test a second time after 90 days of field experience. The success rate on the second attempt was approximately 95%.

Once qualified as track maintainers, employees could bid to become a track foreman (TF). The TF course was a 10-day course and included a number of mandatory courses, including track inspection guideline (TIG) training, CWR training, and crane qualification. TFs were required to renew their TIG and CWR training every 3 years; this was tracked through CN's training management system.

1.17 Canadian National Railway Company engineering organization on the Ruel Subdivision

CN's Ruel Subdivision extends westward for 296.2 miles from Capreol (Mile 0.0) to Hornepayne (Mile 296.2). To facilitate track inspection and maintenance activities, the subdivision is divided into an eastern portion (from Mile 0.0 to Mile 183.2) and a western portion (from Mile 183.2 to Mile 296.2).

On the eastern portion of the Ruel Subdivision, a TSPVR and 2 ATSs were responsible for all maintenance activities, including the supervision of all related engineering maintenance personnel. One ATS was responsible for about 87 miles at the east end of the eastern portion, and the other ATS was responsible for about 97 miles at the west end of the eastern portion. Track maintenance personnel consisted of about 18 to 24 permanent employees during the summer. About 34 temporary employees were added during the winter.

The TSPVR reported to the senior manager engineering (SME) for the Northern Ontario Zone. The SME was 1 of 4 CN SMEs within the province of Ontario and was responsible for a territory which included parts of the Bala, Caramat, and Newmarket Subdivisions, and all of the Ruel and Soo Subdivisions. The SME reported to 1 of 2 assistant chief engineers for CN's eastern region, who in turn reported to the eastern regional chief engineering.

1.18 Track maintenance challenges on the Ruel Subdivision

CN identified train velocityFootnote 30 as an issue having significant influence on the use of assets and cost control, which are 2 of CN's 5 strategic business pillars.Footnote 31 All engineering employees understood the sense of urgency to move trains as quickly and as safely as possible.

Train delays that affect velocity can create inter-functional pressures within the company. These pressures can sometimes create conflict between track maintenance decisions and train operations. Because of the importance of keeping trains moving, it can be challenging for track maintenance personnel to obtain adequate track time to conduct the required track inspection, maintenance, and repairs, particularly in a remote territory with limited road access.

1.19 Regulatory oversight

TC promotes safe and secure transportation systems in the air, marine, rail, and surface modes, as well as the safe transportation of dangerous goods (DGs). To do so, TC develops safety regulations and standards, and, in the case of railways, it facilitates the development of rules by the rail industry. Once the rules are approved, TC is then responsible for enforcing the rules through a number of inspection programs to monitor compliance with rules and regulations. Track inspections are targeted using a risk-based approach. TC also has a national inspection program that randomly selects track segments to be inspected each year. Primary traffic corridors usually receive more attention than secondary main lines.

Rail safety is governed by the Railway Safety Act, the objectives of which are to:

- promote and provide for the safety and security of the public and personnel, and the protection of property and the environment, in railway operations;

- encourage the collaboration and participation of interested parties in improving railway safety and security;

- recognize the responsibility of companies to demonstrate, by using safety management systems and other means at their disposal, that they continuously manage risks related to safety matters; and

- facilitate a modern, flexible and efficient regulatory scheme that will ensure the continuing enhancement of railway safety and security.Footnote 32

TC has also developed the Railway Safety Management System Regulations.(SMS Regulations), which require railways to manage their safety risks.

1.20 Transport Canada regulatory track inspections

TC railway engineering inspectors are tasked with conducting railway infrastructure inspections across Canada. Railway subdivisions are not necessarily subject to regular TC inspections. Instead, TC uses a risk-based approach that considers various factors to identify specific subdivisions or areas of subdivisions that require targeted inspection. TC prioritizes inspections by considering different operational factors, including but not limited to rail and geometry defects, number of passenger trains, operating speeds, and traffic tonnage. Emerging track conditions such as LSCs and REBs, which are not considered defects under the TSR, are not specifically considered as part of the risk-based approach.

The TC inspection program has 3 components:

- A-component inspections: TC Headquarters develops a national inspection plan for the following year using a statistical model, identifies the number of inspections, and targets companies that are to receive these inspections.

- B-component inspections: TC regions focus on specific recurring issues requiring closer monitoring using a risk-based business planning process to identify the companies that are to receive these inspections.

- C-component inspections: These are unplanned and respond to issues emerging through the year, such as derailments and ad hoc inspections.

Using the national inspection plan, each TC region develops an operational plan to provide guidance to its rail safety inspectors on which companies, infrastructure locations, subdivision portions, operations, and maintenance employees to inspect. In TC's Ontario Region, each functional group performs a risk assessment to rank the subdivisions, yards, and maintenance facilities according to risk. Factors considered include accident history, compliance with standards and regulations, changes in operations, amount and type of traffic, hours of work, type of work performed, previous TC and railway inspections, and maintenance history. A significant increase in overall freight or DG traffic may be considered but does not necessarily influence which subdivisions are scheduled for inspection. Because LSCs are considered to be a condition and are not recognized as a defect in the TSR, any increase in LSC volume may not necessarily be reviewed, despite LSCs being leading indicators of a deteriorating rail condition. From the risk assessment, the inspections are prioritized so that locations or railway activities that have higher risk are inspected in a timely manner.

Table 4 summarizes the track inspections conducted by TC on the Ruel Subdivision since 2005.

| Year | From Mile | To Mile |

|---|---|---|

| 2005 | 148.3 | 223.5 |

| 2006 | 87 | 183 |

| 2007 | 0 | 86.7 |

| 2008 | 0 | 87 |

| 2010 | 87 | 127 |

| 2012 | 86 | 296 |

| 2013 | - | - |

| 2014 | - | - |

| 2015 (until February 2015) | - | - |

Between 2013 and the date of the occurrence, TC did not perform any track inspections on the Ruel Subdivision because geometry defects appeared to be declining. Following the accident, between 15 March 2015 and 19 March 2015, TC inspected the entire Ruel Subdivision and identified 67 non-compliant conditions that required remedial action and 59 other concerns and observations. These conditions had likely evolved since the last TC regulatory inspection (in 2012) and had existed before the accident, yet went undetected despite regular railway inspection.

1.21 Other TSB investigations involving regulatory inspections

Since May 2014, there have been 5 other TSB investigations where railway and/or TC inspections did not identify degrading track conditions, resulting in further deterioration of the track structure which ultimately led to a derailment (Appendix A). In 3 of the 5 occurrences, track joint or rail failure occurred in the immediate vicinity of pre-existing LSC or REB rail surface conditions which, although not condemnable, were being monitored at the time.

1.22 TSB safety issues investigation

In response to a series of train derailments on secondary main lines involving broken rails in the winter of 2003–2004, the TSB carried out a safety issues investigation.Footnote 33 The study established a significant relationship between rail defects and the level of bulk unit train traffic and found that the effect of increasing bulk train traffic had not been accommodated through regular maintenance. The same circumstances could also apply to mainline track. The study also identified that

- Railways recognized that the rate of track degradation was accelerated with increases in bulk unit train tonnage. However, an appropriate balance between increased track degradation and timely infrastructure maintenance and/or renewal was not always achieved.

- Compliance with the TSR in and of itself was insufficient to ensure safety since it did not provide a means to anticipate changing conditions such as increased traffic over the long term.

- There was a need for more proactive safety management system (SMS) processes to anticipate operational conditions which could lead to a degradation of safety margins.

1.23 Safety Management System Regulations

An SMS is "a systematic, explicit and comprehensive process for managing safety risks."Footnote 34 It is a means to ensure that a railway has the processes in place to identify the hazards in its operation and mitigate the risks. SMS was designed around evolving concepts about safety that are believed to offer great potential for more effective risk management. SMS was progressively introduced in the Canadian transportation industry because this approach to regulatory oversight, which seeks to ensure that organizations have processes in place to manage risks systematically, when combined with inspections and enforcement, is considered to be more effective in reducing accident rates.

Section 2 of the TC Safety Management System Regulations (2001).(the SMS Regulations), which were in force at the time of the accident,Footnote 35 states:

- A railway company shall implement and maintain a safety management system that includes, at a minimum, the following components:

- the railway company safety policy and annual safety performance targets and the associated safety initiatives to achieve the targets, approved by a senior company officer and communicated to employees;

- clear authorities, responsibilities and accountabilities for safety at all levels in the railway company;

- a system for involving employees and their representatives in the development and implementation of the railway company's safety management system;

- systems for identifying applicable

- railway safety regulations, rules, standards and orders, and the procedures for demonstrating compliance with them, and

- exemptions and the procedures for demonstrating compliance with the terms or conditions specified in the notice of exemption;

- a process for

- identifying safety issues and concerns, including those associated with human factors, third-parties and significant changes to railway operations, and

- evaluating and classifying risks by means of a risk assessment;

- risk control strategies;

- systems for accident and incident reporting, investigation, analysis and corrective action;

- systems for ensuring that employees and any other persons to whom the railway company grants access to its property, have appropriate skills and training and adequate supervision to ensure that they comply with all safety requirements;

- procedures for the collection and analysis of data for assessing the safety performance of the railway company;

- procedures for periodic internal safety audits, reviews by management, monitoring and evaluations of the safety management system;

- systems for monitoring management-approved corrective actions resulting from the systems and processes required under paragraphs (d) to (j); and

- consolidated documentation describing the systems for each component of the safety management system.Footnote 36

The SMS Regulations also require railway companies to

- maintain records to permit the assessment of safety performance (subsection 3(1));

- submit documentation and records to the Minister that demonstrate compliance with the regulations (subsection 4(1)); and

- produce safety management documentation upon request (section 6).

1.24 Canadian National Railway Company's safety management system

In accordance with the SMS Regulations, CN had developed and implemented a detailed SMS. Since 2008, CN's SMS had been enhanced each year and had been integrated into most facets of its operations. The SMS described company initiatives that correlate to the requirements of section 2 of the SMS Regulations .

With regard to paragraph 2(e) of the SMS Regulations that were in force at the time of the occurrence, CN had implemented systems for

- identifying safety issues and concerns, including those associated with human factors, third-parties and significant changes to railway operations;

- evaluating and classifying risks by means of a risk assessment; and

- identifying and implementing risk control strategies.

Specific actions included the following:

- Safety issues and concerns were flagged to CN management through hazard forms, health and safety committees, CN's Ombudsman and CN's Prevent Hotline (a joint venture with Saint Mary's University, Halifax, Nova Scotia), as well as through audits and trend analyses.

- CN had a formal risk assessment process that was used to evaluate and classify risks, including those associated with significant changes in railway operations, such as the opening of new yards and facilities, railway acquisitions, introduction of new technology, significant changes in business (volumes or product), and changes in personal protective equipment.

- Special corridor risk assessments were being carried out to assess and reduce risk in locations with high populations, waterways, or other environmental or topographical characteristics.

- Training was being provided to employees who performed risk assessments.

When human factors may have played a role in an accident, CN required further investigation before formulating corrective action, and the following was typically considered:

- Was the work properly planned, organized and supervised?

- Was the employee properly trained and equipped?

- Did the employee have the opportunity for sufficient rest?

- Was the rule or work procedure well understood?Footnote 37Footnote 38

Despite having a formal risk assessment process, CN perceived the increased tonnage of crude oil shipments on the Ruel Subdivision during the 2014 year as a normal operating parameter. The increase in tonnage did not trigger CN to conduct a risk assessment or to review an existing one.

1.25 Safety culture

Safety culture can be defined as "shared values (what is important) and beliefs (how things work) that interact with an organization's structures and control systems to produce behavioral norms."Footnote 39 Safety culture is critical to effective safety management, because safety management processes will be ineffective in a culture that does not support the proactive sharing of safety information. Where a safety culture exists to support effective safety management, information pertaining to safety will be actively sought; employees will be trained to recognize hazards and rewarded for sharing safety concerns. In such a culture, failures will be scrutinized as an opportunity to learn, and new ideas will be welcomed.Footnote 40 An effective safety culture is critical to the processes required by an SMS that support the development of a resilient organization.

TC's SMS guidance document Rail Safety Management Systems Guide: A Guide for Developing, Implementing and Enhancing Railway Safety Management Systems.states that:

An effective safety culture in a railway company can reduce public and employee fatalities and injuries, property damage resulting from railway accidents, and the impact of accidents on the environment.

In simple terms, an organization's safety culture is demonstrated by the way people do their jobs—their decisions, actions and behaviours define the culture of an organization.

The safety culture of an organization is the result of individual and group values, attitudes, perceptions, competencies and patterns of behaviour that determine the commitment to, and the style and proficiency of, an organization's health and safety management system

Organizations with a positive safety culture are characterized by communications from various stakeholders founded on mutual trust, by shared perceptions of the importance of safety and by confidence in the efficacy of preventive measures.Footnote 41

The relationship between safety culture and safety management is reflected in part by the beliefs, attitudes, and behaviours of a company's management.

An effective safety culture includes proactive actions to identify and manage operational risk. It is characterized by an informed culture where people understand the hazards and risks involved in their own operation and work continuously to identify and overcome threats to safety. It is a just culture, where the workforce knows and agrees on what is acceptable and unacceptable. It is a reporting culture, where safety concerns are reported and analyzed and where appropriate action is taken. Finally, it is a learning culture, where safety is enhanced from lessons learned.Footnote 42

A company's policies determine how safety objectives will be met by clearly defining responsibilities; by developing processes, structures and objectives to incorporate safety into all aspects of the operation; and by developing the skills and knowledge of personnel. Procedures are directives for employees and communicate management's instructions. Practices are what really happens on the job, which can differ from procedures and, in some cases, increase threats to safety.

1.26 Safety culture at Canadian National Railway Company

In parallel with implementing SMS, CN had recognized the importance of building an effective safety culture which the company considered essential for SMS. To help strengthen its safety culture, CN has invested in training, coaching, and employee recognition and involvement.

In October 2014, CN co-hosted a safety culture symposium in Halifax, Nova Scotia, during which participants discussed and shared information on safety culture. CN also hosted a number of safety summits throughout its regions to promote two-way communication and best safety practices.

In 2014, among other initiatives, CN developed and implemented Looking Out for Each Other, a strategy that has become an integral part of CN's safety culture. The peer-to-peer engagement strategy was designed to

- raise awareness among employees of the top causes of incidents and injuries;

- identify and review safe work procedures;

- train employees to be aware of their surroundings and to recognize potential at-risk work practices or situations in the field;

- teach employees how to provide constructive feedback to peers; and

- learn from past incidents to prevent a reoccurrence of the same event and help each other stay safe.Footnote 43

1.27 Resilience: The safe operating envelope and requisite imagination

Resilience is generally defined as the ability to "withstand or recover quickly from difficult conditions."Footnote 44 A resilient organization or system is defined as being "able to effectively adjust its functioning prior to, during or following changes and disturbances, so that it can continue to perform as required after a disruption or a major mishap, and in the presence of continuous stresses."Footnote 45

Four cornerstones common to resilient organizations have been identified. The ability to adjust and adapt requires the organization to respond to events, monitor key change indicators, anticipate long term challenges and learn from experience. With these cornerstones in place, a resilient organization will

- know what to do (how to respond to regular events)

- know what to look for (how to monitor for potential problems)

- know what to expect (anticipating potential threats)

- know what has happened (having the right indicators to learn from experience).Footnote 46

These abilities help organizations balance potentially competing safety, efficiency, and workload pressures relevant to the operating environment.

An organization that is monitoring, anticipating, and learning effectively through proactive safety management processes and leading safety indicators will be able to respond to competing pressures and maintain an acceptable level of risk. Being poorly equipped to detect and understand the significance of small changes in the operating environment will increase risk until lagging indicators such as accidents or serious incidents provide clear indications that the system is out of balance.

One of the challenges is that safety reserves (procedures and practices that help maintain an acceptable margin of safety) can experience pressure from competing demands to increase efficiency. Mistaking safety reserves for inefficiencies will undermine safety goals.Footnote 47 Balancing competing demands is a challenge for individuals at all levels of an organization, because safety issues can emerge slowly and be difficult to detect. The human capability to appreciate the significance of information and events and to anticipate their impact on safety has been termed "requisite imagination."

Developing requisite imagination relies on individuals within the organization having

- expert track knowledge allowing anticipation and judgement of defect conditions;

- the will to think critically about the functioning of the system;

- effective training to develop these capabilities;

- sufficient spare capacity to respond to events; and

- a clear flow of information throughout the organization.Footnote 48

A comprehensive SMS would help an organization develop requisite imagination by ensuring that it has processes in place to support the 4 cornerstones of resilience, including

- effective procedures for normal and abnormal situations (responding)

- safety reporting and trend analysis (monitoring)

- risk identification and assessment (anticipating)

- incident investigation (learning).

"Proactive safety management helps organizations look ahead to notice the signs that risks are changing or increasing despite past records of success and increasing pressures for short term performance."Footnote 49 An effective safety culture is essential in order to realize the benefits of requisite imagination. The safety culture of an organization will largely determine the type and amount of information fed into safety management processes, and how such information will be received and addressed.

1.28 Significant accidents involving Class 111 tank car releases