Main-track train collision

Canadian Pacific Railway

Freight trains 602-242 and 113-01

Mile 62.0, Mountain Subdivision

Beavermouth, British Columbia

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

On 06 September 2015, at approximately 0223 Pacific Daylight Time, Canadian Pacific Railway Train 602-242, travelling eastward on the main track of the Mountain Subdivision, collided with westbound Canadian Pacific Railway Train 113-01, which was entering the siding track near Beavermouth, British Columbia. As a result of the collision, 2 locomotives and the first car behind the locomotives on train 602-242 as well as one set of trucks on the 64th car on train 113-01 derailed. The conductor of train 602-242 sustained a serious injury. No dangerous goods were released.

Le présent rapport est également disponible en français.

1.0 Factual information

1.1 The accident

On 05 September 2015, Canadian Pacific Railway (CP) Train 602-242 (train 602) departed Revelstoke, British Columbia, at approximately 2330.Footnote 1 It was travelling eastward on the Mountain Subdivision, destined for Sutherland, Saskatchewan.

On 06 September 2015, CP Train 113-01 (train 113) departed Field, British Columbia, at approximately 0030. It was travelling westward on the Mountain Subdivision, destined for Vancouver, British Columbia.

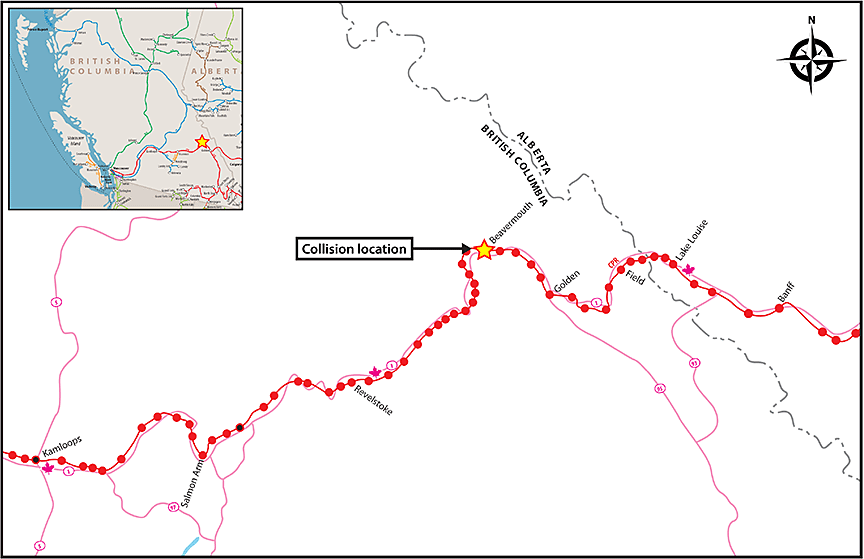

The 2 trains met at the siding located at Beavermouth, British Columbia, at Mile 62 of the Mountain Subdivision (Figure 1).

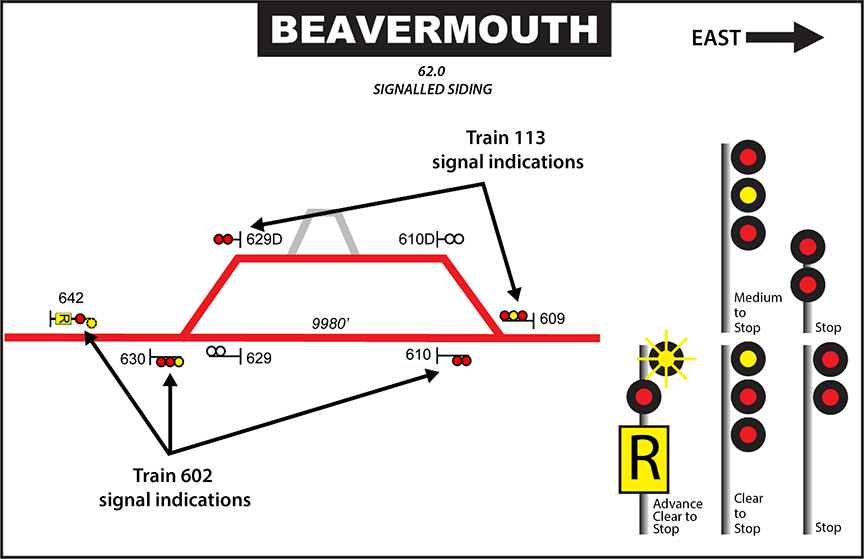

At approximately 0217, the head end of train 602 passed signal 642, the advance signal to Beavermouth, which was displaying an Advance Clear to Stop signal indication, Canadian Rail Operating Rules (CROR) Rule 415Footnote 2 (Figure 2). Train 602 was travelling at approximately 22 mph. The crew did not call out the indication of signal 642 within the cab of the lead locomotive, as required by CROR Rule 34.Footnote 3 The crew did not announce the indication of the signal over the radio, as required by CROR Rule 578.Footnote 4

At approximately 0218, the head end of train 113 passed signal 609, which was displaying a Medium to Stop signal indication, CROR Rule 427,Footnote 5 and continued westward, diverging into the Beavermouth siding at the east siding switch.

At approximately 0220, the head end of train 602 passed signal 630, which was displaying a Clear to Stop signal indication, CROR Rule 411,Footnote 6 and continued eastward on the main track past the west siding switch at Beavermouth. The crew of train 602 did not call out the signal indication within the cab or over the radio, as required by CROR Rules 34 and 578.

At about that time, the standby radio channelFootnote 7 was in use, as the rail traffic controller (RTC) was contacting several track foremen on the Mountain Subdivision to enquire about the arrangements made for train 113 to travel through various Rule 42 work zones.

Approximately 1000 feet east of the west siding switch, the locomotive engineer (LE) of train 602 dimmed the headlights and extinguished the ditch lights as the lead locomotive passed the head end of train 113 on the adjacent siding track.

Travelling at about 22 mph, train 602 continued eastward on the main track. The crew had no further discussion concerning the requirements of the Clear to Stop signal under which they were operating. As train 602 approached signal 610 at the east end of Beavermouth siding, the view of the signal was initially obstructed by train 113 owing to the height of the double-stack containers (20 feet 3 inches), the curvature on the adjacent siding track, and the height of the signal (20 feet). Approximately 450 feet before the east siding switch, some 10 seconds from the signal, the crew of train 602 observed the Stop signal indication on signal 610 and the tail end of train 113 extending beyond the east siding switch onto the main track.

The LE of train 602 made an emergency application of the train brakes at 0223:08.9, applying the locomotive dynamic brakes and the locomotive independent brake (Appendix A). Train 602 was unable to stop in advance of signal 610 and struck the side of train 113. At the time of the collision, train 602 was travelling at about 16 mph. The lead locomotive of train 602 made contact with the rock face immediately to the south. Train 602 decelerated rapidly (from about 22 mph when the brakes were applied to a stop) within approximately 450 feet of the initial brake application.

Video footage from the lead locomotive forward-facing video camera indicated that signal 610 could have been partially visible to the crew of train 602 on 2 occasions. On both occasions, the signal would have been visible for less than a second through openings between double- and single-stack containers that were positioned on the intermodal rail cars of train 113. These glimpses of the signal were at an angle and on the left side of the centre field of view. They occurred approximately 17 seconds and 13 seconds before the crew had an unobstructed view of the signal. The train brakes were placed in emergency approximately 2 seconds after signal 610 came into clear view.

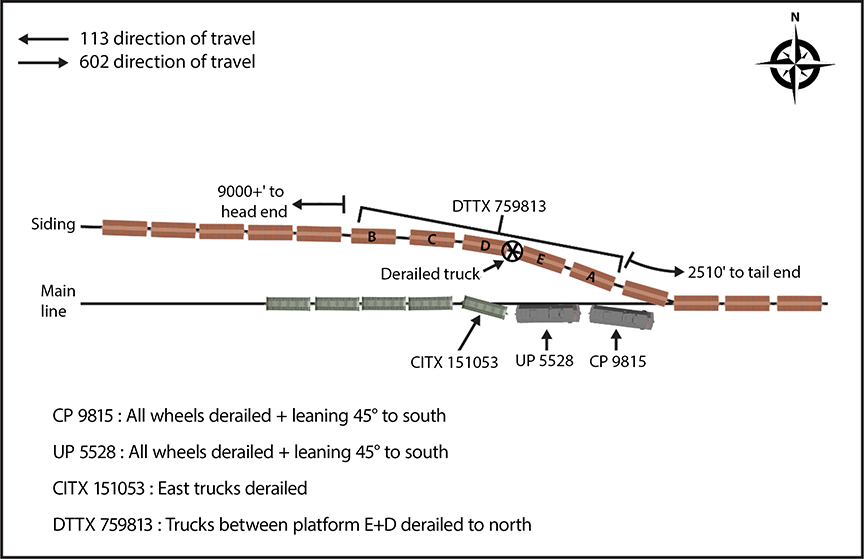

As a result of the collision, the 2 lead locomotives from train 602 (CP 9815 and UP 5528) came to rest at a 45° angle, leaning to the south against the rock face, immediately adjacent to the east siding switch (Photo 1). The first car (CITX 151053) behind the 2 locomotives derailed upright and was also leaning to the south. On train 113, one set of trucks on the 64th car (DTTX 759813) derailed (Figure 3). The conductor of train 602 received a serious injury. No dangerous goods were released.

1.2 Train 113

Train 113 consisted of 2 locomotives (a 4365 hp head-end locomotive and a 4400 hp mid-train locomotive) and 80 loaded intermodal flat cars. The train weighed approximately 11 000 tons and was approximately 12 000 feet long. The mechanical records for the rail cars and locomotives were reviewed, and no outstanding issues were noted. Before reaching Beavermouth, train 113 had travelled over the hot box detectors (HBD) located at Mile 74.8 and Mile 95.1. No warnings had been issued by these HBDs for this train.

The train crew consisted of a locomotive engineer and a conductor. Both crew members were familiar with the subdivision, met fitness and rest standards, and were qualified for their respective positions. The crew was tasked with operating train 113 from Field to Revelstoke, British Columbia.

1.3 Train 602

Train 602 consisted of 3 locomotives (two 4400 hp locomotives at the head end and a 4400 hp locomotive at the tail end) and 170 empty covered hopper cars. The train weighed approximately 5000 tons and was approximately 8000 feet long. The mechanical records for the rail cars and locomotives were reviewed, and no outstanding issues were noted. Before reaching Beavermouth, train 602 had travelled over the HBDs located at Mile 54.4 and Mile 44.9 as well as a wheel impact load detector located at Mile 47.8. No alarms had been issued by these wayside detectors for this train.

The crew for train 602 consisted of a locomotive engineer and a conductor. Both crew members were familiar with the subdivision, met fitness and rest standards, and were qualified for their respective positions. The crew was tasked with operating train 602 from Revelstoke to Field.

1.4 Work zones and slow orders on the Mountain Subdivision

At several locations along the Mountain Subdivision, track-maintenance activities were underway as part of a major track-restoration program. Consequently, train 602 had to obtain permission to operate through several CROR Rule 42 work zones. The train crew was in possession of a “train-specific” tabular general bulletin order (TGBO) that listed, as itemized bulletins, the work zones and slow orders. The TGBO also contained other bulletins relevant to operating over the assigned territory. The limits of the Rule 42 work zones were

- between Mile 125 and Mile 120 (Train 602 was cleared through this work zone at 2348 on 05 September 2015),

- between Mile 108 and Mile 95 (Train 602 was cleared through this work zone at 0009 on 06 September 2015, and

- between Mile 76 and Mile 67 (Train 602 was cleared through this work zone at 0132 on 06 September 2015).

Train 602 also passed through several CROR Rule 43Footnote 8 slow orders, including

- between Mile 86.5 and Mile 86.4, where it was required to reduce speed to 25 mph;

- between Mile 85.01 and Mile 84.6, where it was required to reduce speed to 25 mph; and

- at the west siding switch at Griffith, British Columbia, where it was required to reduce speed to 10 mph through the turnout.

For the Rule 42 work zone starting at Mile 76, train 602 encountered 4 additional Rule 43 slow orders, including

- between Mile 70.4 and Mile 70.1, where it was required to reduce speed to 10 mph;

- between Mile 69.4 and Mile 69.2, where it was required to reduce speed to 10 mph;

- between Mile 68.4 and Mile 68.1, where it was required to reduce speed to 25 mph; and

- between Mile 67.1 and Mile 66.6, where it was required to reduce speed to 25 mph.

At the time of the occurrence, the flags required by Rule 43 to identify the slow-order limits and to provide advance notification of the slow order (i.e., 2 miles in advance) were not yet in place.Footnote 9

Recorded information indicates that train 602 had traversed the slow order at Mile 70.4 at about 18 mph and the slow order at Mile 69.4 at about 26 mph.

As the train was approaching Beavermouth, the crew realized that they had not reduced their speed when they had operated through the two 10-mph restrictions located within the limits of the Rule 42 work zone. The crew had not notified the RTC of the non-compliance before the collision took place. Both crew members were aware that other crews had been disciplined previously for similar instances of non-compliance.

1.5 Subdivision and track information

Extending between Field (Mile 0.0) and Revelstoke (Mile 125.70), the Mountain Subdivision comprises both single main track and double main tracks. Train movements are governed by the centralized traffic control (CTC) system, as authorized by the CROR, and are supervised by an RTC located in Calgary, Alberta.

In the vicinity of the Beavermouth siding, the track is Class 3, according to the Transport Canada (TC)–approved Railway Track Safety Rules (TSR). The maximum authorized timetable speed for the Mountain Subdivision is 35 mph for freight trains on the main track and 30 mph for those on the siding track.

The track consisted of a single main track oriented in an east–west direction. The rail was continuous welded rail, and the ballast consisted primarily of crushed rock. The cribs were full, and the shoulders extended approximately 18 inches beyond the tie ends. No significant track defects were noted in the most recent inspection, which had been conducted on 04 September 2015. The track was in good condition.

The rail in the vicinity of the occurrence was 136-pound Nippon Steel, manufactured in 1987. The tie plates were 16-inch double-shoulder rolled plates in good condition with a 2/2 spiking pattern. The rail was secured with elastic fastenings and no anchors.

1.6 Rule 42 – Planned Protection

For planned protection, Rule 42 signals must not be in place more than 30 minutes before or after the times stated in General Bulletin Orders (GBO) unless provided for in the GBO.

Rule 42 (b) states that

(b) A movement in possession of the Form Y must not proceed beyond the red signal located at the mileage stated in the GBO, enter the track limits stated in the GBO, or make a reverse movement within such track limits until instructions have been received from the foreman named in the GBO.

Such instructions must be received in writing. Before providing instructions, the foreman must state the status of sub-foremen. Before copying instructions, the train crew must repeat the status of sub-foremen to the foreman.

Other requirements of Rule 42 include

(c) The instructions must be repeated to, and acknowledged by, the foreman named in the GBO before being acted upon.

(d) When a signalled turnout is within two miles of Rule 42 protection which does not apply on all tracks, every movement must approach such location prepared to comply with the requirements of Rule 42 until it is known which route is to be used.

When a specific track is to be used, instructions from the foreman must specify the track to which the instructions apply.

1.7 Rule 43 – Slow Track Protection

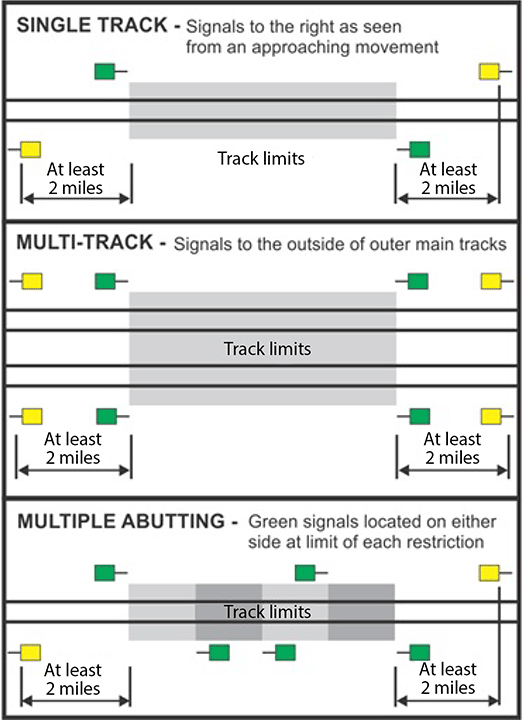

CROR Rule 43 regarding signal placement (Figure 4) states (in part):

Form V GBO slow track protection will be marked in the field by a:

- yellow signal to the right of the track as seen from an approaching movement at least two miles in each direction from the outermost limits indicated in the GBO, and

- green signal to the right of the track as seen from an approaching movement in each direction, immediately beyond the defect…

When the placement of signals as prescribed by Rule 43 is delayed, the following will be added to the Form V: “Signals may not be in place.”

- A movement must not exceed the speed requirement of the GBO while at/or between opposing green signals.

1.8 Weather

At the time of the occurrence, the weather was clear and the temperature was 10 °C.

1.9 Centralized traffic control

CTC is a method of traffic control that employs interconnected track circuits and signals in the field to control movements. Computer displays and controls are installed in the RTC office. Signals are actuated by the presence of an open circuit. The signal indications in the field provide authority for a movement to occupy the main track. They also provide

- information to train crews indicating the speed at which they may operate and how far they are permitted to travel; and

- protection against certain conditions (e.g., the block ahead is occupied, a rail is broken, or a main track switch is left open).

CTC does not provide automatic enforcement to slow or stop a train before it passes a Stop signal or other point of restriction. Train crews must be familiar with the signal indications specified in the CROR and must control their trains in accordance with these rules.

In the RTC office, track occupancy is displayed on the RTC's computer screen. Track occupancy normally indicates the presence of a train, but can also be an indication of an interrupted track circuit (e.g., a broken rail or a switch left open). The RTC can control certain signals (“controlled signals”) by setting them to a Stop indication or by requesting that they display permissive indications.

When an RTC requests signals for a train, the signal system determines how permissive the signals will be, based on other track occupancies and how many consecutive signals have been requested.

1.10 Rail traffic controller meet planning and communication

In general, in anticipation of a meet, CP RTCs consider several factors, including

- crossings at the proposed meet location that may be blocked during the meet;

- key trains,Footnote 10 as such trains must hold the main track at meets according to TC's Rules Respecting Key Trains and Key Routes, effective 19 February 2016Footnote 11; and

- dimensional shipments (e.g., wide loads) that may be prohibited from using sidings during a meet.

For long-train meets, RTCs must ensure that at least one of the trains will fit in the clear (i.e., on the main track or in the siding). RTCs must employ strategies that best accommodate the meet. If there are no restrictions for either train approaching a meet, it is common practice even though this is not required, at CP for RTCs to line the first train that arrives into the siding. Less than 5% of train traffic (about 1 or 2 trains per day) on the Mountain Subdivision were over siding length.Footnote 12

In this occurrence, neither train 602 nor train 113 were key trains, and neither train was handling dimensional shipments that would have precluded entry into a siding. In addition, potentially blocked crossings were not an issue at Beavermouth. The Beavermouth siding was 9980 feet long, whereas train 113 was approximately 12 000 feet long. None of the sidings on the Mountain Subdivision were long enough to accommodate train 113.

To avoid this meet, the RTC could have held train 113 at Donald, British Columbia, (Mile 52.2) until train 602 arrived. Donald is at the end of the multi-track portion of the subdivision when travelling west from KC Junction. Alternatively, the RTC could have held train 602 at Rogers (Mile 68.2) until train 113 arrived. Rogers is at the end of the multi-track portion of the subdivision when travelling east from the Connaught and Mount Macdonald Tunnels. The meet was planned at Beavermouth to avoid the train delay involved in either of these options. On the day of the occurrence, there was a restriction on the use of the west siding switch at Beavermouth for eastward movements. That restriction was contained in GBO M144, which stated

Train 113 arrived at Beavermouth approximately 2 minutes before the arrival of train 602. The crew of train 602 was not advised by the RTC that train 113 was over siding length, nor was there a requirement for the RTC to communicate this information. CP does not normally give specific information about meets, including the presence of over-siding-length trains, as CP believes that such information could cause a train crew to misconstrue information displayed by the signal system and to expect signal indications to be less restrictive than they actually are.

CP RTC bulletin 2391 (effective 07 August 2015) states (in part):

CP provided the following example:

A train crew may, when possible, contact opposing trains via radio to indicate that their train is over siding length. In this occurrence, this communication did not take place, as the availability of the radio channel was limited that day because of operational demands related to the track work being performed on the subdivision.

1.11 Reporting of operating rule infractions by train crews

If a train crew becomes aware that they have not complied with the requirements of the CROR, the railway's expectation is that the crew will report the non-compliance to the proper authority at the earliest possible opportunity. The proper authority would normally be the RTC or the crew's immediate supervisor.

Class 1 railways in Canada enforce strict discipline for non-compliance with key operating rules. Infractions are usually investigated by railway management, and disciplinary measures may be taken if non-compliance is deemed to be serious. Discipline takes the form of demerit points or suspension without pay. The number of demerit points and/or the duration of the suspension are normally proportionate to the railway's perception of the seriousness of non-compliance. However, employees who self-report non-compliance may receive less discipline than those who do not.

Railway employees can be dismissed or suspended without pay indefinitely for the accumulation of demerit points (usually 60). Accumulated demerit points can be eliminated or earned back through working consecutive months without an infraction (e.g., 20 points for 1 year free of non-compliance, provided the railway has not deemed the employee to be unfit for continued company service).

1.12 Mental models during train operations

Train crews are continually forming mental models of the world around them. Mental models are internal structures that allow individuals to describe, explain, and predict events and situations in their environments.Footnote 13 Mental models are developed based on several factors, including experience, knowledge, perception, and comprehension of external cues available in the work environment. Once a mental model is adopted, it is very resistant to change. In order for people to change their mental models, the existing model must be superseded by another, with the new information being sufficiently compelling to result in an update of the mental model. The human working memory has a limited capacity, so not all the cues available in the work environment will be retained. This results in simple and incomplete mental models that are developed internally to understand and make sense of a dynamic and complex work environment.Footnote 14

1.13 Defences for signal indications

The level of safety afforded by wayside signal systems has advanced beyond their original design, which dates back more than 100 years, as advanced signal indications have been installed. However, strict rules compliance is required, as train crews are expected to react to the progression of wayside signal indications.

In a complex system, such as rail transportation, even the most rigorous set of rules may not cover every contingency and interpretation by individuals. In addition, even motivated and experienced employees are subject to the normal slips, lapses, and mistakes that characterize human behaviour. The defence-in-depth philosophy advocated by safety specialists for complex systems involves multiple and diverse lines of defence to mitigate the risks of normal human errors.

Following its investigation into the 1998 train collision involving 2 CP trains near Notch Hill, British Columbia,Footnote 15 the Board determined that backup safety defences for signal indications were inadequate. The Board recommended that

The Department of Transport and the railway industry implement additional backup safety defences to help ensure that signal indications are consistently recognized and followed.

Transportation Safety Recommendation R00-04

Following its investigation into the 2012 derailment and collision of a VIA Rail Canada Inc. (VIA) passenger train near Burlington, Ontario,Footnote 16 the Board recommended that

The Department of Transport require major Canadian passenger and freight railways implement physical fail-safe train controls, beginning with Canada's high-speed rail corridors.

Transportation Safety Recommendation R13-01

In its March 2016 reassessment of TC's responses to these recommendations, the Board indicated that both recommendations were related to the TSB Watchlist issue “Following signal indications,” which discusses the risk of serious train collision or derailment if railway signals are not consistently recognized and followed. The Board assessed these responses as follows:

The ACRS (Advisory Committee on Railway Safety) Working Group will provide TC with a written report on options and recommendations to address this issue. This work is now scheduled to be completed by spring 2016. Although action has been initiated to study the deficiency which could yield an appropriate solution in the long term, there still remains no short-term plans to address the risk of train collision or derailment in the absence of additional backup safety defences.

The Railway Association of Canada (RAC) indicates that locomotive voice and video recorders will provide a safety defense with regards to this issue. There may be safety benefits from the use of these recorders relating to the consistent recognition of signals. However, the Board cautions that any defen[c]e[-]in-depth concept of system safety design cannot be satisfied solely through additional layers of crew monitoring. Additional layers of physical defenses are still required so that the risk of serious train collision or derailment can be effectively mitigated.

As it is too early to assess the results of the working group study on options and recommendations, the Board considers the response to the recommendation to be Satisfactory in Part.

1.14 Technologies to help ensure signals are followed

The railway industry has developed various technologies to address the risk of misinterpreting or not following signal indications. Cab signalling systems have been in use in the U.S. for over 90 years, and positive train control (PTC) is being developed and tested.

1.14.1 Cab signalling systems

Cab signalling is a communications system that provides track status information to a display device mounted inside the locomotive cab. The simplest systems display the wayside signal indication, while more advanced systems also display maximum permissible speeds. The cab signalling system can be combined with automatic train control to warn operating crews of their proximity to points of restriction and to initiate enforcement action to slow or stop a train.Footnote 17 Cab signals can reduce the risk of signal-recognition errors.

In 1922, the U.S. Interstate Commerce Commission made a ruling that required U.S. railroads to install some form of automatic train control in one full passenger division by 1925. In response to this ruling, the first cab signalling systems were developed and put into use in the U.S.Footnote 18 Cab signalling systems have evolved and remain in use in some U.S. passenger train corridors. In Canada, there is no cab signalling system in use by freight or passenger railways.

1.14.2 Positive train control

PTC is an emerging train-control technology that is designed to prevent

- train-to-train collisions,

- overspeed derailments,

- incursions into work zone limits, and

- movement of a train through a switch left in the wrong position.

If the operating crew does not initiate an adequate response, the PTC system is intended to automatically slow or stop the train. In the U.S., PTC technology has been under development for many years.

A collision in September 2008 between a Metrolink passenger train and a Union Pacific freight train in Chatsworth, California, prompted the passage of the Rail Safety Improvement Act of 2008. This legislation mandated that PTC be installed on the higher-risk rail lines in the U.S. by 2015. However, due to several technical challenges, the U.S. implementation of PTC was extended beyond the 31 December 2015 deadline to 31 December 2018, with a further possible 2-year extension on a railroad-by-railroad basis.

In Canada, there are no PTC systems in use by freight or passenger railways, and there are no planned PTC installations. Any application of PTC in Canada likely would not occur until a number of years after the U.S. implementation is complete. However, to meet the PTC requirements for their U.S. operations, both Canadian National Railway (CN) and CP have PTC implementation plans:

- As part of CP's implementation plan, 505 locomotives are planned to be equipped with the required on-board systems. CP plans to install PTC on approximately 2112 route miles of track in the U.S.

- As part of CN's PTC implementation plan, 586 locomotives will be equipped with the required on-board systems. CN will install PTC on approximately 3563 route miles of track in the U.S.

For both CN and CP, the PTC system will be based on the Interoperable Electronic Train Management System (I-ETMS). CN will install it on 39 subdivisions, and CP will install it on 22 subdivisions, corresponding to 62% and 89% of their total U.S. route miles (excluding yard limits), respectively. I-ETMS is a locomotive-centric, train control system that uses a combination of locomotive, office, and wayside data that are integrated using a radio network. This system will provide the following functions:

- alert train crews to pending authority and speed limit violations, including passing a stop signal;

- stop trains before they exceed authority and speed limits, including signals at stop;

- interrogate upcoming wayside signals and switches on a train route when operating in I-ETMS territory; and

- protect work zone limits by enforcing compliance with work zone restrictions.

This system is under development and is awaiting Federal Railroad Administration certification for use in revenue service.

1.15 Other occurrences involving misinterpretation/misperception of wayside signals

Since 2007, the TSB has conducted 8 investigations into train collisions, derailments, or movements exceeding limits of authority in which an operating crew's misinterpretation and/or misperception of wayside signal indications was a cause or contributing factor:

R14T0294 (Newtonville)Footnote 19 ― On 28 October 2014, VIA Rail Canada Inc. passenger train No. 62 (VIA 62) was proceeding eastward from Toronto, Ontario, to Montréal, Quebec, on the south track of the CN Kingston Subdivision near Newtonville, Ontario. At 1015 Eastern Daylight Time, VIA 62 passed Signal 2784S, which was displaying Stop, while travelling at about 68 mph. The train was brought to a stop and an emergency radio call was broadcast. The lead locomotive had passed the Stop signal by approximately 900 feet. There were no injuries. There was no derailment or track damage.

R13C0049 (Dunmore)Footnote 20 ― On 18 May 2013, at approximately 1330 Mountain Daylight Time, CP train 351 was operating westward on the north main track of the Maple Creek Subdivision. Approaching Dunmore, Alberta, the train struck the side of eastward CP train 100, which was departing Dunmore from the north main track through the crossover on to the Depot 1 track. As a result of the collision, the 2 lead locomotives and the following 2 cars on train 351 derailed. On train 100, 2 cars derailed and several other cars sustained damage. The conductor of train 351 sustained minor injuries and was taken to hospital.

R12T0038 (Aldershot)Footnote 21 ― On 26 February 2012, VIA Rail Canada Inc. passenger train No. 92 (VIA 92) was proceeding eastward from Niagara Falls, Ontario, to Toronto, Ontario, on track 2 of the CN Oakville Subdivision near Burlington, Ontario. After a stop at Aldershot Station (Mile 34.30), the train departed on track 2. The track switches were lined to route the train from track 2 to track 3, through crossover No. 5 (Mile 33.23), which had an authorized speed of 15 mph. VIA 92 entered crossover No. 5 while travelling at about 67 mph. The locomotive and all 5 passenger cars derailed. The operating crew were fatally injured, and 45 people (44 passengers and the Service Manager) received various injuries.

R11E0063 (Edmonton)Footnote 22 ― On 23 June 2011, at approximately 0625 Mountain Daylight Time, CN freight train Q10131-21, proceeding westward at 25 mph on the Wainwright Subdivision, collided with the tail end of CN freight train A41751-23 at Mile 262.76. As a result of the collision, 2 intermodal flat cars derailed (3 car bodies) and locomotive CN 2234 was damaged.

R10Q0011 (Saint-Charles-de-Bellechasse)Footnote 23 ― On 25 February 2010, VIA train No. 15 was proceeding westward from Halifax, Nova Scotia, to Montréal, Quebec. At approximately 0425 Eastern Standard Time, near Saint-Charles-de-Bellechasse, Quebec (Mile 100.78 of the CN Montmagny Subdivision), the train entered a siding switch, which had an authorized speed of 15 mph, while travelling at approximately 64 mph. Two locomotives and 6 passenger cars derailed. Two locomotive engineers and 5 passengers were injured.

R10V0038 (KC Junction)Footnote 24 ― On 03 March 2010, at approximately 1410 Pacific Standard Time, CP train 300, operating eastward on the north track of the Mountain Subdivision approaching KC Junction, British Columbia, struck the side of westbound CP train 671 when it was departing Golden, British Columbia, from the north track through the crossovers onto the south track. As a result of the collision, 3 locomotives and 26 cars derailed.

R09V0230 (Redgrave)Footnote 25 ― On 30 October 2009, at approximately 2225 Pacific Daylight Time, CP train 355, operating westward on the signalled siding track on the Mountain Subdivision at Redgrave, British Columbia, struck the side of eastbound CP train 110, which had stopped on the main track. As a result of the collision, 2 locomotives and 6 cars derailed.

R07E0129 (Peers)Footnote 26 ― On 27 October 2007, at 0505 Mountain Daylight Time, the crew on CN train 417, operating westward on the main track of the Edson Subdivision, initiated an emergency brake application approximately 475 feet from a stop signal at the west end of Peers, Alberta. The train was unable to stop before passing the signal and collided with eastbound CN train 342, which was entering the siding. As a result of the collision, train 417's locomotives and 22 cars derailed, and 5 cars on train 342 derailed.

1.16 Interaction between train crew members

Many aspects of the dynamics and interaction between crew members cannot be fully examined, as on-board voice and video recordings are not normally available. Crew interactions that may be of interest when examining the safety of train operations include

- Were all signals correctly identified?

- Were all signals called as required?

- Were all signals acknowledged?

- Were there any distractions in the cab?

Objective data are invaluable to investigators in helping them understand the sequence of events leading up to an accident and in identifying operational issues involving human factors and crew performance. Voice recordings would allow TSB investigators to confirm crew communications as well as crew actions and interactions. Such information would also allow accident investigators to eliminate more quickly extraneous factors that did not play a role in the accident. Technology for recorded information is abundant and has been for some time. The aviation industry has had cockpit voice recordings for over 30 years.

A number of railway accident investigations in North America have led to findings, recommendations, and other safety communications in which human factors were identified as an underlying condition. Many of these investigations would have benefitted from a recording of crew communications immediately before the accident.

Following its investigation into the 2012 derailment and collision of VIA 92 near Burlington, Ontario,Footnote 27 the Board indicated that

The Department of Transport require that all controlling locomotives in main line operation be equipped with in-cab video cameras.

Transportation Safety Recommendation R13-02

In its most recent reassessment of the response to Recommendation R13-02 (March 2016), the Board stated:

This recommendation is related to the TSB Watchlist issue of “On-board video and voice recorders”. Without a requirement for on-board video and voice recorders on locomotives, key information to advance railway safety may not always be available. It is also related to recommendation R13-02, in which the Board recommended that the Department of Transport, in conjunction with the railway industry, establish comprehensive national standards for locomotive data recorders that include a requirement for an on-board cab voice recording interfaced with on-board communications systems.

The views of the railways and Transport Canada (TC) have not changed since last year. However, VIA and GO Transit have started to equip their locomotive fleets with on-board recorders. In addition, TC and industry stakeholders have been working collaboratively with the TSB on the joint LVVR [locomotive voice and video recorders] study. This study will provide valuable information for the review of the legislative and regulatory framework governing on-board recorders. The LVVR study is progressing well and a draft report will be completed in spring 2016.

However, in the absence of definitive commitments and plans to install on-board cab video and voice recorders on a widespread basis, the Board considers the response to Recommendation R13-02 as Satisfactory in Part.

In the U.S., Amtrak Acela locomotive cabs are equipped with in-cab voice recording interfaced with the locomotive event recorder. On 04 December 2015, the Fixing America's Surface Transportation Act (FAST Act, P.L. 114-94) was passed. The FAST Act requires all passenger railroads to install inward-facing cameras to better monitor train crews and assist in accident investigations, and outward-facing cameras to better monitor track conditions.

While some railways are considering installing in-cab voice and video recorders for day-to-day use in their safety management system, Canadian law, under the Canadian Transportation Accident Investigation and Safety Board Act, protects these recordings and does not currently allow their use, except as part of a TSB investigation.

2.0 Analysis

The analysis will focus on distraction, mental models, safety defences in centralized traffic control (CTC), placement of flags through slow orders, and rail traffic controller (RTC) meet planning and communication.

2.1 The accident

The collision occurred when train 602 was operated past the Stop signal at the east siding switch at Beavermouth and struck the side of train 113.

About 1 to 2 trains per day operating on the Mountain Subdivision were over siding length. Train 113 was an over-siding-length train. While the train was stopped at the signal before the west siding switch at Beavermouth, the tail end extended beyond the east siding switch by approximately 2510 feet and onto the main track.

The crew of train 602 was not aware that train 113 was over siding length and had likely developed a mental model that assumed that the tail end of train 113 would be clear of the east siding switch. Consequently, the crew operated train 602 with the expectation that they would encounter a permissive indication at signal 610, despite a prior indication requiring them to stop.

Identifying and communicating signals within the cab of a locomotive and announcing specific signals over the radio are key operational tasks intended to ensure a common understanding of signals and their requirements among crew members. On the day of the occurrence, significant track work was underway, resulting in higher-than-normal activity on the standby radio channel.

Given the higher level of radio activity, the crew of train 602 chose not to announce the requirements of the advance signals, to avoid transmitting over other safety-critical radio activity. The crew of train 602 did not take the opportunity to establish a common understanding of the signals approaching Beavermouth and at the west siding switch.

When a crew approaches a siding for a train meet, there is an increase in the cognitive workload required to safely complete the train operation. Having minimal external distraction for the train crew is preferable at these locations. In this occurrence, in the vicinity of the Beavermouth siding, the crew of train 602 realized that they had missed 2 slow orders earlier in the trip. Preoccupied with the potential consequences of missing 2 slow orders, the crew of train 602 were likely distracted as they approached the east siding switch at Beavermouth.

As train 602 approached signal 610 at the east end of the Beavermouth siding, the view of the signal (approximately 20 feet high) was initially obstructed by the double-stack containers on train 113 (20 feet 3 inches high) on the adjacent siding track. However, there had been 2 missed opportunities for the train crew to identify and react to the signal (i.e., approximately 17 seconds and 13 seconds before the signal came into clear view). As it was a clear night, the bright red signals would have been visible in sharp contrast against the darkness. The visual obstruction from the double-stack containers reduced the time that the signal aspect was in clear view. At approximately 450 feet from the signal, when the aspect of the signal became visible, the crew observed the Stop signal and immediately placed the train into emergency braking, but were unable to stop before colliding with train 113.

2.2 Rail traffic controller meet planning and communication

There is no requirement for train crews or the rail traffic controller (RTC) to advise train crews of an over-siding-length train. However, train crews may, when possible, contact opposing trains to indicate that they are over siding length. In this occurrence, this communication did not take place, as the radio channel was in extensive use.

If there are no other train restrictions, such as dimensional shipments, key trains, blocked crossings, or operational restrictions, Canadian Pacific Railway (CP) RTCs will generally route the first train that arrives at the meet location into the siding.

The switch at the west end of the Beavermouth siding could not be used to route an eastbound train into the siding. Train 113 was over siding length by approximately 2000 feet. The crew of train 602 was not aware that train 113 was over siding length. CP specifically discourages RTCs from sharing this information, as CP believes that it may lead a train crew to misconstrue information displayed by the signal system. CP expects train crews to follow signal indications in the CTC, in order to ensure safe operations in all circumstances.

Accurate mental models depend on access to concise and accurate information. Crews make use of the information that is available and invariably make assumptions to fill in the gaps. Given the relatively low frequency of meets with over-siding-length trains, crews are unlikely to expect that the train they are meeting will extend beyond the siding switch. As CP RTCs were discouraged from advising train crews of upcoming meets with over-siding-length trains, valuable information that would have helped the train crew adjust their mental model relating to the train meet was not available. If a train crew is not advised of an upcoming meet with an over-siding-length train, an inaccurate mental model about the meet can result, increasing the risk of a collision.

2.3 Placement of flags through Rule 43 slow orders

There was extensive track work being performed on the Mountain Subdivision at the time of the collision. Train 602 had operated through 3 separate Rule 42 work zones and through numerous Rule 43 slow orders.

Some of the Rule 43 slow orders were not being protected by flags. While these slow order locations were identified on the tabular general bulletin order, the absence of warning flags made it more difficult for train crews to locate and comply with these slow orders. If Rule 43 slow orders are not identified with trackside flags, there is an increased risk that train crews will inadvertently miss these slow orders and operate their trains through these locations at a higher speed than permitted.

2.4 Safety defences against signal-recognition errors

Several safety defences in place on the Mountain Subdivision are designed to prevent accidents of this type. Some of these defences are associated with the train control system (i.e., CTC), and some are associated with the Canadian Rail Operating Rules (CROR) and the railway's General Operating Instructions (i.e., administrative defences).

Wayside signals include a physical signal installation combined with an administrative requirement to follow the signal indication. This defence relies on the crew to observe the signal, to recognize the intent of the signal, and then to take appropriate action. Operating rules and company General Operating Instructions require that all signals be identified and announced within the cab of the locomotive and that other signals (e.g., the advance signal to the next controlled location) be announced over the railway radio system.

In addition to the CTC physical installations and administrative defences, a number of technologies can provide a safety defence against signal-recognition errors. For example, cab signalling systems can enhance CTC by providing a continuous display of signal indications within the locomotive cab. Cab signalling was developed in the U.S. some 85 years ago. Since then, this technology has evolved to its current form, in which this train protection system can be overlaid on the CTC system.

Positive train control (PTC) technology, under development and in limited use in North America, can offer additional defences in some circumstances. For example, if an operating crew does not respond appropriately to a signal or other restriction, PTC is supposed to alert the crew that they are not reacting as expected. If there is no further action by the crew, the system should then intervene to slow or stop the train by applying the brakes.

Since 2007, the TSB has investigated 8 other occurrences involving a collision, derailment, or movements exceeding limits of authority, in which the misinterpretation and/or misperception of wayside signal indications by an operating crew was a cause or contributing factor. Following the Aldershot investigation,Footnote 28 the Board issued Recommendation R13-01, which called for the implementation of physical fail-safe train controls.

Additional layers of physical defence are required so that the risk of serious train collision or derailment can be effectively mitigated. In addition, there remains no short-term plan to help ensure that railway signal indications are always followed in the absence of additional backup safety defences. If existing signal systems are not enhanced to include physical fail-safe capabilities, failures to follow signal indications will continue, and the risk of train collisions and derailments will persist.

2.5 Locomotive voice and video recorders

Many aspects of the dynamics and interaction between crew members cannot be fully examined, as on-board voice and video recordings are not normally available. Crew interactions that may be of interest when examining the safety of train operations include

- Were all signals correctly identified?

- Were all signals called as required?

- Were all signals acknowledged?

- Were there any distractions in the cab?

On-board recordings are useful for accident investigations and could also be useful for proactive safety management.

With respect to accident investigations, information from on-board voice and video recorders can quickly direct the focus of an investigation by identifying obvious hazards or causal elements and by eliminating extraneous factors that are shown not to be involved in the accident. Accident-investigation agencies benefit from more efficient, timely, and accurate collection, assimilation, and analysis of information. This will result in more timely communication of safety deficiencies.

In addition to the safety benefits for accident investigators, on-board recordings could be used proactively by railways to help examine potential operational gaps in procedures and training. Specifically, there may be potential for railway companies to use on-board voice and video recordings proactively in a non-punitive way to enhance their safety management systems, which would help reduce risk and improve safety before an accident occurs. However, in its most recent assessment of the response to Recommendation R13-01, the Board cautioned that any defence-in-depth system safety design cannot be satisfied solely through additional layers of crew monitoring.

3.0 Findings

3.1 Findings as to causes and contributing factors

- The collision occurred when train 602 was operated past the Stop signal at the east siding switch at Beavermouth and struck the side of train 113.

- The crew of train 602 was not aware that train 113 was over siding length, and the crew had likely developed a mental model that assumed that the tail end of train 113 would be clear of the east siding switch. Consequently, the crew operated train 602 with the expectation that they would encounter a permissive indication at signal 610, despite a prior indication requiring them to stop.

- The crew of train 602 did not take the opportunity to establish a common understanding of the signals as they approached Beavermouth and at the west siding switch.

- In the vicinity of the Beavermouth siding, the crew of train 602 realized that they had missed 2 slow orders earlier in the trip.

- Preoccupied with the potential consequences of missing 2 slow orders, the crew of train 602 were likely distracted as they approached the east siding switch at Beavermouth.

- The visual obstruction from the double-stack containers on train 113 on the adjacent siding track reduced the time that the signal aspect was in clear view.

- As Canadian Pacific Railway rail traffic controllers were discouraged from advising train crews of upcoming meets with over-siding-length trains, valuable information that would have helped the train crew adjust their mental model relating to the train meet was not available.

3.2 Findings as to risk

- If a train crew is not advised of an upcoming meet with an over-siding-length train, an inaccurate mental model about the meet can result, increasing the risk of a collision.

- If slow orders are not identified with trackside flags, there is an increased risk that train crews will inadvertently miss these slow orders and operate their trains through these locations at a higher speed than permitted.

- If existing signal systems are not enhanced to include physical fail-safe capabilities, failures to follow signal indications will continue, and the risk of train collisions and derailments will persist.

3.3 Other findings

- There may be potential for railway companies to use on-board voice and video recordings proactively in a non-punitive way to enhance their safety management systems, which would help reduce risk and improve safety.

- In this occurrence, heavy radio use for essential operational purposes precluded the crew of train 113 from sharing the information that train 113 was over siding length.

4.0 Safety action

4.1 Safety action taken

On 09 September 2015, Transport Canada (TC) issued a Notice and Order under subsection 31(2) of the Railway Safety Act to Canadian Pacific Railway (CP) concerning undue delays in flag placement for Canadian Rail Operating Rules (CROR) Rule 43 slow orders on the Mountain Subdivision. CP was requested to

- ensure that, in the application of Rule 43, fixed signal flags are placed within 24 hours;

- ensure that Rule 43 slow orders within 1 mile or less of another Rule 43 slow order are consolidated; and

- prioritize issuing main track occupancies to employees placing fixed signal flags for Rule 43 slow orders.

On 30 September 2015, a letter of non-compliance was issued to CP regarding 17 instances of non-compliance with CROR Rule 44(g) respecting the placement of flags within 24 hours on the Mountain Subdivision.

In response, CP indicated that CP's Engineering Department had reviewed the requirements for managing slow orders, as well as the requirements for flag placement as identified in Rule 44(g), and had instituted a process to ensure future compliance with all related CROR requirements.

On 15 June 2016, CP issued Rule of the Week 018, which highlights expectations for compliance with existing flagging requirements. Specifically, this Rule of the Week provides examples of situations in which the placement of flags at slow orders may and may not be delayed. It states (in part):

This report concludes the Transportation Safety Board's investigation into this occurrence. The Board authorized the release of this report on 23 November 2016. It was officially released on 25 January 2017.

Appendices

Appendix A – Locomotive event recorder data for CP 9815 06 September 2015

| Date | Time | Mile | Speed (mph) | Brake pipe pressure (pounds per square inch) | Throttle position | Dynamic brake | Brake cylinder pressure (pounds per square inch) |

|---|---|---|---|---|---|---|---|

| 2015-09-06 | 0223:04.1 | 61.254 | 21.8 | 89 | 0 | 0 | 0 |

| 2015-09-06 | 0223:04.4 | 61.252 | 21.8 | 87 | 0 | 0 | 0 |

| 2015-09-06 | 0223:05.3 | 61.247 | 21.8 | 85 | 0 | 0 | 0 |

| 2015-09-06 | 0223:06.5 | 61.240 | 21.8 | 83 | 0 | 0 | 0 |

| 2015-09-06 | 0223:08.9 Time of operator-initiated emergency brake application |

61.225 | 21.8 | 66 | 0 | 0 | 0 |

| 2015-09-06 | 0223:09.0 | 61.225 | 21.8 | 50 | 0 | 0 | 0 |

| 2015-09-06 | 0223:09.1 | 61.224 | 21.8 | 35 | 0 | 0 | 0 |

| 2015-09-06 | 0223:09.2 | 61.224 | 21.8 | 25 | 0 | 0 | 0 |

| 2015-09-06 | 0223:09.3 | 61.224 | 21.8 | 18 | 0 | 0 | 0 |

| 2015-09-06 | 0223:09.4 | 61.223 | 21.8 | 13 | 0 | 3 | 0 |

| 2015-09-06 | 0223:09.5 | 61.223 | 21.8 | 9 | 0 | 6 | 0 |

| 2015-09-06 | 0223:09.6 | 61.222 | 21.8 | 7 | 0 | 7.4 | 0 |

| 2015-09-06 | 0223:09.7 | 61.222 | 21.8 | 5 | 0 | 7.4 | 0 |

| 2015-09-06 | 0223:09.9 | 61.220 | 21.8 | 2 | 0 | 7.4 | 0 |

| 2015-09-06 | 0223:10.7 | 61.216 | 21.8 | 0 | 0 | 7.4 | 0 |

| 2015-09-06 | 0223:11.7 | 61.209 | 21.8 | 0 | 0 | 7.4 | 6 |

| 2015-09-06 | 0223:12.2 | 61.207 | 21.8 | 0 | 0 | 7.4 | 13 |

| 2015-09-06 | 0223:12.5 | 61.205 | 21.8 | 0 | 0 | 7.4 | 21 |

| 2015-09-06 | 0223:12.7 | 61.204 | 21.8 | 0 | 0 | 7.4 | 28 |

| 2015-09-06 | 0223:12.9 | 61.202 | 21.8 | 0 | 0 | 7.4 | 36 |

| 2015-09-06 | 0223:13.1 | 61.201 | 21.8 | 0 | 0 | 7.4 | 43 |

| 2015-09-06 | 0223:13.2 | 61.201 | 20 | 0 | 0 | 7.4 | 43 |

| 2015-09-06 | 0223:13.3 | 61.200 | 20 | 0 | 0 | 7.4 | 49 |

| 2015-09-06 | 0223:13.5 | 61.199 | 20 | 0 | 0 | 7.4 | 54 |

| 2015-09-06 | 0223:13.6 | 61.199 | 20 | 0 | 0 | 7.4 | 54 |

| 2015-09-06 | 0223:13.8 | 61.198 | 20 | 0 | 0 | 7.4 | 60 |

| 2015-09-06 | 0223:14.0 | 61.196 | 20 | 0 | 0 | 7.4 | 60 |

| 2015-09-06 | 0223:14.2 | 61.195 | 17.6 | 0 | 0 | 7.4 | 66 |

| 2015-09-06 | 0223:14.5 | 61.194 | 17.6 | 0 | 0 | 7.4 | 66 |

| 2015-09-06 | 0223:14.6 | 61.193 | 17.6 | 0 | 0 | 7.4 | 66 |

| 2015-09-06 | 0223:14.7 | 61.193 | 17.6 | 0 | 0 | 7.4 | 71 |

| 2015-09-06 | 0223:15.2 | 61.190 | 15.9 | 0 | 0 | 7.4 | 71 |

| 2015-09-06 | 0223:16.8 | 61.183 | 15.9 | 0 | 0 | 7.4 | 64 |

| 2015-09-06 | 0223:17.0 | 61.182 | 15.9 | 0 | 0 | 7.4 | 58 |

| 2015-09-06 | 0223:17.8 | 61.179 | 15.9 | 0 | 0 | 7.4 | 58 |

| 2015-09-06 | 0223:17.9 | 61.179 | 15.9 | 0 | 0 | 7.4 | 53 |

| 2015-09-06 | 0223:18.2 | 61.177 | 12 | 0 | 0 | 7.4 | 53 |

| 2015-09-06 | 0223:18.6 | 61.176 | 12 | 0 | 0 | 7.4 | 61 |

| 2015-09-06 | 0223:18.7 | 61.176 | 12 | 0 | 0 | 7.4 | 54 |

| 2015-09-06 | 0223:18.8 | 61.176 | 12 | 0 | 0 | 7.4 | 61 |

| 2015-09-06 | 0223:18.9 | 61.176 | 12 | 0 | 0 | 7.4 | 51 |

| 2015-09-06 | 0223:19.2 | 61.175 | 8.9 | 0 | 0 | 7.4 | 51 |

| 2015-09-06 | 0223:19.4 | 61.174 | 8.9 | 0 | 0 | 7.4 | 56 |

| 2015-09-06 | 0223:19.5 | 61.174 | 8.9 | 0 | 0 | 7.4 | 62 |

| 2015-09-06 | 0223:19.6 | 61.174 | 8.9 | 0 | 0 | 7.4 | 50 |

| 2015-09-06 | 0223:20.2 | 61.172 | 3.4 | 0 | 0 | 7.4 | 50 |

| 2015-09-06 | 0223:20.6 | 61.172 | 3.4 | 0 | 0 | 7.4 | 43 |

| 2015-09-06 | 0223:20.9 | 61.171 | 3.4 | 0 | 0 | 7.4 | 49 |

| 2015-09-06 | 0223:22.0 | 61.170 | 3.4 | 0 | 0 | 7.4 | 54 |

| 2015-09-06 | 0223:23.2 | 61.169 | 0 | 0 | 0 | 7.4 | 61 |