Safety issue investigation (SII)

Expanding the use of locomotive voice and video recorders [LVVR] in Canada

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Preface

In May 2015, the Transportation Safety Board of Canada launched a Class 4 safety issues investigation (safety study) on the use of locomotive voice and video recorders under the Canadian Transportation Accident Investigation and Safety Board Act. Transport Canada and key rail stakeholders were invited to participate in this study. The safety study identified some best practices, identified and evaluated implementation issues, examined potential safety benefits of the expanded use of on-board recorders, and collected background information for the development of an action plan to implement locomotive voice and video recorders.

Executive summary

The issue of on-board video and voice recorders has been on the Transportation Safety Board of Canada's (TSB's) Watchlist since 2012. Currently, there is no requirement to record crew communications and interactions in locomotive cabs. However, objective data are invaluable in helping investigators understand the sequence of events leading to an accident and in identifying operational and human factors issues, including those that may affect crew performance. When recorders are used proactively, as part of a safety management system, the information collected could also provide significant benefits to help identify and mitigate risks before accidents occur.

In May 2015, the TSB launched a Class 4Footnote 1 safety study on the use of locomotive voice and video recorders under the Canadian Transportation Accident Investigation and Safety Board Act. Transport Canada (TC)Footnote 2 and key rail stakeholders were invited to participate in this study. The safety study assessed, on a small scale, current technology, legislative and regulatory issues, operational and human factors issues, and potential safety benefits of the expanded use of on-board recorders. There were opportunities for open discussion among key stakeholders regarding how to use of this technology appropriately and how to reconcile differing perspectives on its use through various aspects of implementation.

Key observations for each type of assessment were captured and are summarized as follows:

Technology assessment

Voice and video recorders have been installed in some locomotives operating in Canada on a trial basis. Technology issues relating to the implementation of locomotive voice and video recorders (LVVRs) in these trials were identified. While some of the trial installations had common system characteristics, the results of the assessment show that companies were deploying a wide range of technology to explore the best means to achieve the safety benefits. The lessons learned on the use of recorders in the aviation and marine modes are a starting point for the development of this technology for rail.

Legislative and regulatory assessment

All concerned parties had opinions on the legal matters and employee rights relating to the use of LVVRs. One concern was that the use of on-board recorders could infringe on privacy and rights of company employees under the Canadian Charter of Rights and Freedoms. To prevent this infringement, it was suggested that guidelines and terms for the use of LVVR need to be established and that this could most easily be undertaken within the framework of a “just culture.”Footnote 3 Successful implementation of LVVR technology will depend on ensuring the appropriate balance of rights and obligations for the key stakeholders.

Operational and human factors assessment

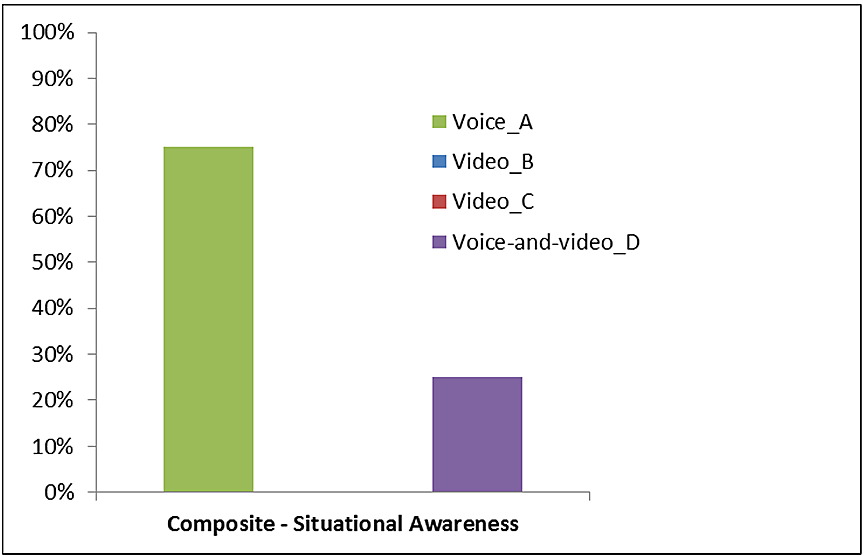

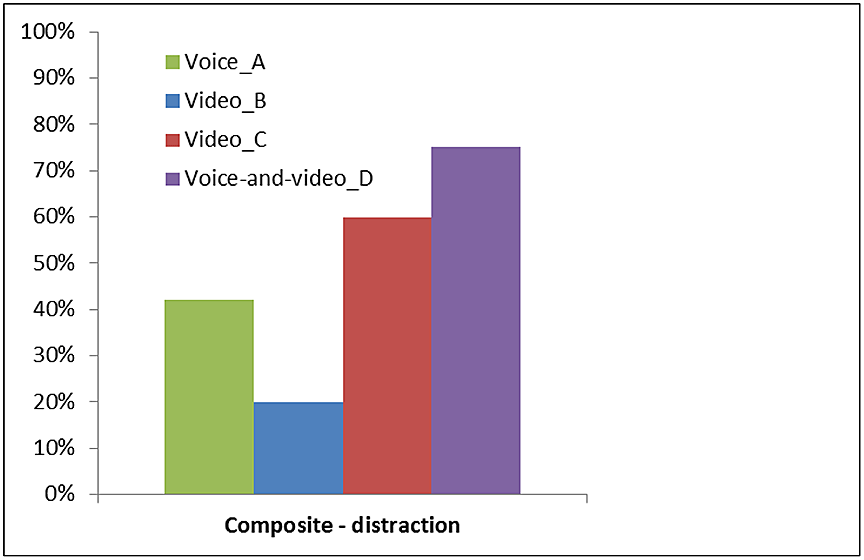

The extent to which 3 types of recording systems (voice-only, video-only, and voice-and-video) can be used to identify operational and human factors information was examined. Clear examples of both human factors and operational issues were observed, validating the potential for the use of this technology. Specific conclusions for these types of recording systems include the following:

- For voice-only systems, audio data when combined with forward-facing video data provide a meaningful amount of information concerning crew use of many locomotive controls as well as responses to external train control signals and to audible alarms.

- For video-only systems, the quality and coverage (i.e., camera angles, field of view) of the system influence the ability of observers to assess operational and human factors (such as crew interaction). A system that provides the most complete and direct view of crew members is most effective.

- For voice-and-video systems, it is important that the technology is of an appropriate level of quality to provide clear, unambiguous recordings in a reliable manner. This is the most effective option for assessing crew operational and human factors behaviour.

These results indicate that LVVRs, with the right combination of recording technologies, can provide data not only for accident investigations, but also for proactive identification of unsafe conditions that could lead to incidents and accidents.

Safety benefits assessment

As part of the safety study, the following potential uses of LVVR recordings were explored:

- understanding operations in the locomotive cab to identify unsafe conditions and to improve the operating environment;

- shaping behavioural change;

- identifying and rewarding best practices;

- identifying risky behaviours, followed by education, procedures, and training;

- considering progressive discipline; and

- enhancing crew safety and security.

Based on these discussions and the related operational and human factors assessments, it was established that LVVR technology could help enhance safety. However, there are strong disagreements among stakeholders on how to implement this technology in a way that maintains and protects the rights and obligations of all involved. Engagement in designing the implementation, procedures to protect individuals, and use within a just culture were the strongest suggestions for achieving these ends.

The safety study has identified some best practices, identified and evaluated implementation issues, and collected background information for the development of an action plan to implement LVVRs. There is general agreement among railway industry stakeholders on the fundamental value of this type of data. However, there are a number of outstanding differences of opinions on the appropriate use of LVVRs. If these differing perspectives can be reconciled, implementation of this technology could result in considerable safety benefits to the railway industry.

With the completion of this safety study on LVVRs, the following actions will be taken:

- The final report will be circulated to key stakeholders in the 4 transportation modes: Aviation, Marine, Rail and Pipeline.

- The TSB will initiate discussions with TC regarding next steps for the implementation of LVVRs and the expanded use of on-board recorders in all modes.

1.0 Introduction

The issue of on-board video and voice recorders (“on-board recorders”Footnote 4) has been on the Transportation Safety Board of Canada's (TSB's) Watchlist since 2012. Currently, there is no requirement to record crew communications and interactions in locomotive cabs. However, objective data are invaluable in helping investigators understand the sequence of events leading to an accident and in identifying operational and human factors issues, including those that may affect crew performance. In addition to their value in accident investigation, there is also potential safety value for these recorders when they are used in the context of proactive safety management.

The TSB is encouraged that railway industry stakeholders agree on the fundamental value of this type of data. The TSB is hopeful that outstanding differences can be resolved to allow use of on-board voice and video recordings as a reliable source of information for both investigative purposes and proactive safety management. The TSB is committed to working with Transport Canada (TC)Footnote 5 and the railway industry to remove legislative barriers to allow such use.

Following the 2012 accident involving a VIA Rail Canada Inc. (VIA) passenger train near Burlington, Ontario,Footnote 6 there have been a number of industry initiatives to advance this issue. These include the 2012 study conducted by the Advisory Council on Railway Safety (ACRS) Working Group on Locomotive Voice and Video Recorders.Footnote 7 More recently, there have been a number of railway-initiated studies and proposals for trial implementations of locomotive voice and video recorders (LVVRs), including the Canadian National (CN) pilot study in the United States and the VIA pilot study involving voice recorders. There have also been a number of initiatives by the Federal Railroad Administration (FRA) and the Association of American Railroads (AAR) in the U.S. In addition, some equipment manufacturers have moved forward with developing systems and equipment for on-board recorders that are, or can be, interfaced with other locomotive recording devices such as forward-facing cameras and locomotive event recorders (LERs).

This safety study, conducted as a TSB Class 4 investigation under the Canadian Transportation Accident Investigation and Safety Board Act (CTAISB Act), was convened in May 2015 to explore the implementation of LVVRs in Canada. The LVVR safety study was conducted in collaboration with TC and with the participation of a number of key railway stakeholders, including

- the Railway Association of Canada (RAC), representing the overall railway interests, including the specific interests of railway members not involved in the study such as short-line railways;

- CN, Canadian Pacific Railway (CP) and VIA, representing the interests of major railways;

- GO Transit, representing the interests of commuter railways; and

- Teamsters Canada Rail Conference (Teamsters) representing the interests of railway operating employees.

1.1 Scope and objectives of safety study

This safety study provides information on the technology, safety benefits, operational best practices, and legal aspects of LVVR. Specific objectives of the study include

- documenting operational practices used in the current trials to support maximal use of information recorded while maintaining privacy and security of the information;

- identifying key aspects of the technology that would need to be in place to ensure that the equipment is sufficiently robust, provides the information required, and maintains the information in a format readily accessible to all permitted parties;

- examining the results of pilot implementations of variations of the technology, including the identification of safety information that can be obtained using this technology;

- summarizing the legal, regulatory, and privacy aspects of the initiative in order to provide an informed basis for deciding the most appropriate legal framework for implementation; and

- summarizing perspectives on appropriate use.

During scoping of the safety study, the following issues and limitations were incorporated into the plan:

- The pilot studies of the use of LVVRs included the operators that undertook trials within the timeline of the safety study. Some of these trials included operations in the U.S. The technology assessed was limited to the systems that had been implemented by the participating railways. Development of an industry standard was not within the scope of this study.

- The review of the legal context was restricted to identifying and summarizing key themes, rather than analyzing detailed jurisprudence.

- The operational/human factors review was restricted to assessing sample on-board recordings from each railway in order to assess the effectiveness of technology and the type of safety information that can be obtained. See Appendix A for the guiding principles for conducting these assessments.

In summary, the scope of the safety study was established to provide a sound basis for going forward, including identifying potential technology and operational pitfalls and providing opportunities for open discussion of privacy/operational issues by the study participants.

1.2 Data recorders within the transportation industry

1.2.1 Data recorders for safety investigations

In the aviation mode, flight data recorders (FDRs) have been required since the early 1960s,Footnote 8 and cockpit voice recorders (CVRs) have been required since 1964. In the marine mode, the use of voyage data recorders (VDRs), which include voice recordings as well as parametric data and images of radar, has been mandated by the International Maritime Organization (IMO) since 2002.Footnote 9 The data from these types of recorders have provided essential information about operations leading up to and during an accident. Without these recordings, many safety deficiencies would have been difficult to verify or would not have been identified at all.

In the rail mode, LERs record key parameters relating to train operations and performance. Like FDRs and VDRs, LERs provide information on some operator actions. This information is essential for accident investigation. Currently, no country has required the installation of voice and/or video recorders within the locomotive cab. In the rail industry, as in the aviation and marine industries, interoperability across international boundaries must be considered by companies to ensure consistency in their operations. This often leads to the implementation of similar approaches to regulations and rules.

In the aviation and marine modes, the International Civil Aviation Organization (ICAO) and the IMO provide specific guidance and standards on the technology and use of the information collected. However, for the rail industry, there is no international organization to prescribe or recommend obligations and practices relating to this technology.

Similar to the rail mode, there are no current requirements in aviation to have CVRs. However, there have been a number of safety recommendations regarding such recorders from various accident investigation agencies, including the U.S. National Transportation Safety Board (NTSB).Footnote 10 Some aircraft/helicopter manufacturers (or operating companies) have had video recorders installed on a voluntary basis.

1.2.2 Expanded use of on-board recordings

Companies' safety management systems (SMSs) require the collection and analysis of safety data, either reactively, following an occurrence, or proactively, as part of the ongoing identification of hazards or the assessment of whether hazards have been successfully mitigated. Triggers for collecting safety data can include known higher-risk operations, new operations, and locations/activities identified through trend analysis.

For transportation companies, operations monitoring is an important, proactive safety process. Although monitoring is not necessarily restricted to information on the work of employees in safety-critical positions, this is often the key focus because of the clear benefits to safety. Monitoring is a means for a company to assess whether it is meeting its safety targets, to assess whether safety actions are having the expected effect, and to monitor for new hazards. Different perspectives can lead to various uses of the collected data, including compiling safety statistics, identifying the need for system design changes, and understanding how to better ensure compliance with rules. The use of safety data depends on the type of hazard and on the company's approach to safety for that issue.

For railway companies, proactive safety data can include

- voluntary hazard reports from employees;

- radio surveillance;

- track-side and yard observations;

- road trips to conduct performance management or efficiency tests;

- automated monitoring of equipment;

- analysis of LER information; and

- analysis of the results of Railway Employee Qualification Standards for Operating Crew examinations.

These data elements can provide different insights into the operating practices of employees. Each data collection method has its own cost–benefit profile. For instance, road trips to conduct performance management or efficiency tests enable supervisors to observe operating conditions and employee actions first-hand. These performance management reviews and efficiency tests can help to identify the causes of unsafe behaviours. However, this method is relatively expensive, requiring considerable time from the supervisor. In addition, there is the risk that the behaviour observed will not match what normally occurs when employees are not being observed.

If safety information required to support the SMS cannot be efficiently and effectively collected using existing methods, the use of LVVRs may be appropriate. There are other emerging opportunities for collecting safety data, including recording of radio communications and remote monitoring of locomotives. In addition, analysis of existing data sources, including LER data, can provide insights into operator performance.Footnote 11 The choice of data collection method depends on efficiency, effectiveness, cost, and considerations of privacy.

Voice and video recording technology is constantly evolving. Its widespread availability and affordability today enable new opportunities in all modes of transportation for those requiring data relating to observation, documentation, and assessment of operator behaviour in work situations. Recently, academic “naturalistic” studies of drivingFootnote 12Footnote 13 have used video, voice, and vehicle performance recordings to discreetly observe everyday vehicle operations. By assessing real-world operator behaviour, it is possible to better understand the conditions that contribute to unsafe actions and situations.

Recent experience relating to this type of collection of video and voice data suggests the following:

- This approach represents an improvement over historical methods used to observe operator performance, which often relied on trained researchers accompanying study participants or supervisors sitting next to operators, while recording on paper the behaviours observed.

- The historical methods afford the collection of only limited information, which can be vulnerable to limitations, including expectancy or observer bias, in which the participants' behaviour can be influenced by the physical presence of the observer. Another possible limitation is the potential for confirmation bias on the part of the observer, in which behaviour is interpreted subjectively to support previously formed hypotheses.

- Subjective self-reporting of behaviour by vehicle operators is another method used to study operator behaviour. However, the usefulness of self-reporting can be limited, especially if there is a tendency to self-report only those behaviours that are likely to be perceived positively.

- It is anticipated that the implementation of LVVR could allow the benefits seen in academic studies of driver performance to be brought to the rail industry by enabling better understanding of the actual performance of train operators while at work.

1.3 Recent TSB investigations and developments in Canada relating to on-board recorders

In January 1999, a VIA passenger train, travelling at 97 mph, passed a stop signal near Trenton, Ontario. Following an emergency brake application, the train came to a stop. There were no injuries to passengers or crew members. It was determined that the crew members had been engaged in conversations just before the occurrence. This distraction had likely contributed to the incident. Had the controlling locomotive cab been equipped with a voice recorder, it may have been possible to determine more definitively the effectiveness of the crew's communications as they approached the occurrence location.Footnote 14 In July 2003, the TSB recommended that

The Department of Transport, in conjunction with the railway industry, establish comprehensive national standards for locomotive data recorders that include a requirement for an on-board cab voice recording interfaced with on-board communications system.

Transportation Safety Recommendation R03-02

In February 2012, a VIA passenger train entered a crossover near Burlington, Ontario, while travelling at about 67 mph. The crossover had an authorized speed of 15 mph. The locomotive and all 5 passenger coach cars derailed. The operating crew members were fatally injured, and 45 people sustained various injuries. The investigation report stated that, in the absence of voice and video recorders, it was difficult to identify (with certainty) the human factors that contributed to the inappropriate crew response to the signal indications displayed. In addition, the dynamics and interaction between the 3 operating crew members could not be accurately determined.Footnote 15 In June 2013, the TSB recommended that

The Department of Transport require that all controlling locomotives in main line operation be equipped with in-cab video cameras.

Transportation Safety Recommendation R13-02

Other TSB investigation reports have reiterated the above recommendations.Footnote 16

The results of these investigations suggest that on-board LVVR is the only objective and reliable method to more definitively determine the causal relationship between a railway occurrence and human factors such as employee communications, distractions, fatigue, and training. When causal links and related safety deficiencies can be confirmed, the resulting recommendations can be better tailored to address the root issues and to maximize rail safety improvements.

In 2012, the issue of on-board voice and video recorders was added to the TSB's Watchlist because of the lack of progress on the implementation of TSB recommendations. Since 2012, efforts among TC, companies, and unions to come to agreement on on-board LVVR have been generally unsuccessful and have stalled voluntary implementation initiatives.

Other recent developments in Canada relating to on-board recorders include the following:

- A 2006 Working Group Report, composed by TC, FRA, industry, and unions concluded that the rationale for the implementation of voice data recorders on aircraft (that is, lower survivability of aviation accidents) did not generally apply to the rail mode.

- A 2007 Railway Safety Act (RSA) Review and 2009 Working Report noted that, based on the TSB's 2003 recommendation, the use of voice data can make an important contribution to the determination of causes of and factors contributing to accidents and incidents by providing insight into the conduct and capacity of the locomotive crew. Recommendation No. 44 in the 2007 RSA Review was crafted to that effect. However, in 2011, the Working Group recommended against further pursuing the issue because of potential privacy concerns, limited identified safety benefits, and attempts to harmonize with the U.S., which had decided not to mandate on-board locomotive voice recorders.

- Following the February 2012 accident near Burlington, Ontario, the Minister of Transport requested further assessment of the issue of on-board LVVR. The ACRS established an LVVR working group. Industry disagreed with the use of LVVR data for TSB only, and requested access to voice and video recorder information for the purposes of monitoring compliance. Unions strongly opposed that request, based on concern that employees could be subject to disciplinary action following compliance monitoring. The ACRS working group determined that outward-facing cameras alone would offer little safety benefit. The working group agreed that installing on-board devices on a voluntary basis was the preferred approach and that the cost–benefit profile could be justified only if railways could use the recordings as part of safety and compliance monitoring. Subsequently, VIA committed, on a voluntary basis, to test and install voice recorders on its 73 locomotives by adding on-board microphones to its existing outward-facing video recording system. Rocky Mountaineer and GO Transit have also installed trial systems on a voluntary basis.

- In November 2013, the Minister of Transport requested that the Standing Committee on Transport, Infrastructure and Communities review and report on the Canadian regime for the safe transportation of dangerous goods and the role of SMSs. The committee recommended that

- Transport Canada require the use by railways of on-board voice and video recordings as part of a company's safety management system, consistent with the Transportation Safety Board's recommendation.

- In February 2016, the Minister of Transport tabled in Parliament the report of the Canada Transportation Act Review, in which Recommendation 10b calls for “TC to develop a formal strategy for the implementation of in-cab voice and video recorders by 2020.”Footnote 17

1.4 Recent NTSB investigations and developments in the United States relating to on-board recorders

In the U.S., following a number of railroad accidents,Footnote 18 the NTSB issued recommendations relating to on-board recorders. In 1997, the NTSB recommended that voice recorders be required for exclusive use in accident investigation. Then, in 2007, the NTSB recommended that the installation of both voice and video recorders be required for investigative purposes.

In September 2008, a Metrolink passenger train collided head-on with a Union Pacific Railroad freight train near Chatsworth, California. The accident resulted in 25 fatalities, including the locomotive engineer of the Metrolink train. The NTSB investigationFootnote 19 determined that a red signal was passed when the locomotive engineer of the Metrolink was distracted while using a personal wireless device. The NTSB found that an on-board LVVR would have provided investigators with better knowledge of the crew member's actions before the accident. On-board recordings would have helped to identify the key causal factors and might have facilitated the development of more effective safety recommendations. The NTSB also noted that LVVR technology could help identify design deficiencies or equipment malfunctions. In addition, the NTSB noted that, for accident prevention, LVVR technology should be used by company management in efficiency testing and performance management programs.

In January 2016, the NTSB placed Expand use of recorders to enhance transportation safety on its 2016 Most Wanted ListFootnote 20 and called for:

For this issue, the NTSB urges the following actions (in part):

While it is concerned about invading individual privacy, the NTSB does not believe that employee privacy should take precedence over public safety, given the many accidents and incidents in all transportation modes. The NTSB has investigated a number of accidents and incidents that involved vehicle operator distraction. Further, the NTSB believes that workers in safety-critical positions in all industries should expect to be observed in the workplace. The NTSB has indicated that complete privacy in settings such as a locomotive cab, where lives of many are entrusted to the care of one, is not persuasive.

Other recent developments in the U.S. relating to on-board recorders include the following:

- In 2014, the Railroad Safety Advisory Committee established the Recording Devices Working Group to develop regulatory recommendations to address the installation and use of recording devices in controlling locomotives. By spring 2015, it was determined that there was no consensus on how to proceed with this issue within the working group.

- In December 2015, President Obama signed into law the Fixing America's Surface Transportation Act. This Act requires the passage of the Passenger Rail Reform and Investment Act of 2015, to promulgate regulations requiring the installation of inward- and outward-facing image recorders in controlling locomotive cabs and in the cab car operating compartments for passenger trains. The Act also includes certain baseline requirements, such as prohibiting the use of recordings by railroad carriers to retaliate against an employee.

- In spring 2016, the FRA announced that it would proceed with a Notice of Proposed Rulemaking. The FRA indicated that

- This rulemaking would require the installation of inward- and outward-facing locomotive video cameras on controlling locomotives of trains traveling over 30 mph. The recordings would be used to help determine the cause of railroad accidents in order to prevent the occurrence of similar accidents. They would also be used to ensure railroad employee compliance with applicable Federal railroad safety regulations and railroad rules, particularly regulations prohibiting the use of personal electronic devices. This rulemaking would amend 49 CFR parts 217, 218, and 219.

- At May 2016, several U.S. railroads had installed video recorders in locomotive cabs. In the U.S., voice recordings are currently prohibited by law.

2.0 Assessment methodology for the safety study

2.1 Technology assessment for LVVR

The technology assessment for LVVR was conducted as follows:

- Assemble information on LVVR experience from the United States

With respect to LVVR technology, there have been a number of recent initiatives in the U.S., including pilot projects by CN and CP in their U.S. operations. The FRA and AAR have also initiated some work in this area through the Recording Devices Working Group of the Railroad Safety Advisory Committee. Information on the U.S. experience, including manufacturer information, was assembled to ensure that lessons learned were identified and made available for consideration. - Assemble information on the TSB experience in the aviation and marine modes

The TSB has valuable experience handling on-board voice recorders in the aviation and marine modes. Information on the TSB experience was assembled to ensure that lessons learned were identified and made available for consideration. - Assemble information on LVVR experience for railways in Canada

Some railways in Canada had already undertaken technical trials of LVVR equipment. Information from these trials, including manufacturer information, was assembled to ensure that lessons learned were identified and made available for consideration. - Analyze the assembled information and group the information by technology issue

- List key aspects of LVVR technology

Based on recent experience in Canada and a review of similar initiatives in the U.S. and in other transportation modes, a list of the key aspects of LVVR technology that would need to be addressed to ensure a successful implementation was compiled.

2.2 Legislative and regulatory assessment relating to on-board recorders

The relevant legislation and regulations relating to LVVR and on-board recordings in general were identified. The legislative and regulatory assessment was conducted as follows:

- Identify the applicable Canadian legislation and regulations across all modes, including rail, aviation, marine, and pipeline;

- Identify the international rules, regulations, or safety recommendations for Commonwealth and European Union member countries,Footnote 21 as well as for international organizations, across all modes;

- Summarize the legal issues in Canadian jurisprudence with respect to privacy and employment law that involve audio and video recordings in a variety of contexts; and

- Summarize the legal issues from the Canadian Charter of Rights and Freedoms (Charter)Footnote 22 relating to privacy and employment context that may have implications for government and industry.

For each transportation mode, research was conducted to identify the most current domestic legislation or regulations regarding the use of on-board recording technologies. The relevant provisions in the legislation or regulations were noted. Research was also conducted in the international arena. Where applicable, commonalities among different countries in their approach to implementating recording technology and to expanding the focus on safety issues were noted.

2.3 Operational and human factors assessment of on-board recordings

As part of the operational and human factors assessment, the adequacy of 3 types of recording systems—voice-only, video-only, and voice-and-video—was reviewed. Each type of recording system was assessed to determine whether it could provide valid, reliable, operational and human factors information to help identify safety-relevant behaviours. Technical issues relating to data capture, retention/storage, and data file management for the 3 types of recording systems were also identified.

2.3.1 Methodology framework

The approach to operational and human factors assessment involved the development of a methodology framework. This framework allowed for the review and assessment of

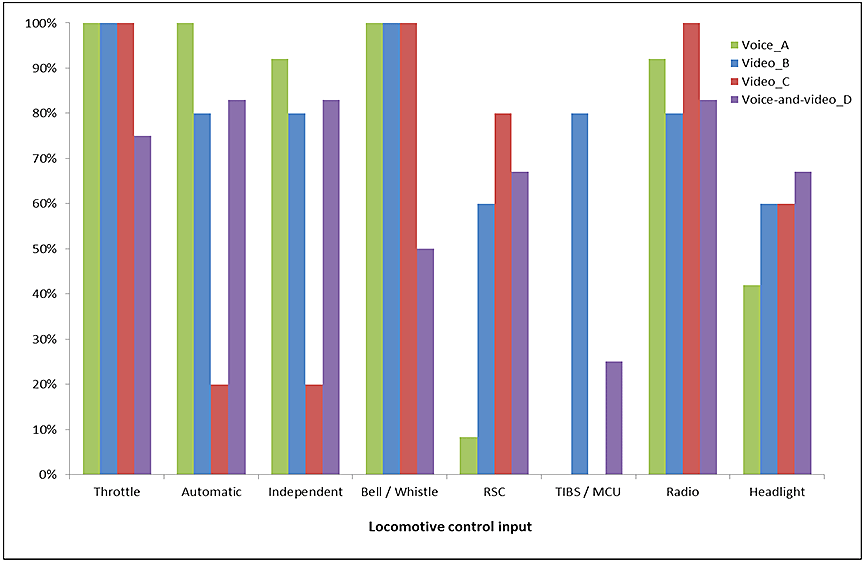

- locomotive control inputs,

- safety-relevant human factors issues, and

- operational practices for the capture and handling of on-board recordings.

2.3.1.1 Locomotive control inputs

Safety-relevant issues in train operation / train handling and their related locomotive control inputs were assessed. The relevant locomotive control inputs were identified through a high-level task analysisFootnote 23 of typical locomotive crew behaviour and requirements. A subset of locomotive control inputs were selected for review.

Broadly, this assessment was conducted for 2 categories of issues related to capturing (1) locomotive control inputs under normal operating conditions and (2) non-normal situations, such as emergency radio communications and on-board alarms. Deficiencies in these areas have the potential to be mitigated through, for example, the development and design of improved and targeted training programs, the design and implementation of more ergonomically designed locomotive controls and equipment, and/or changes to operating procedures.

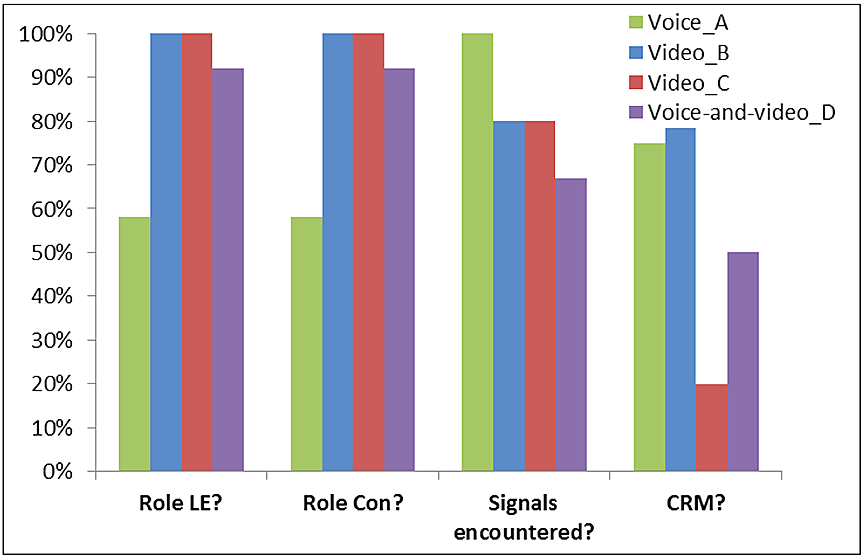

2.3.1.2 Safety-relevant human factors issues

A number of human factors issues that are known to affect safety and that can be managed effectively with appropriate defences were selected for review. The following is a brief description of each human factors issue:

- Crew resource management (CRM) is the effective management and use of all resources, human and technical, available to a locomotive crew to ensure the safe completion of a trip. Possible indications of effective CRM in locomotive crews include assertiveness, operational conversation among crew members, effective problem-solving, appropriate leadership, and adaptability.

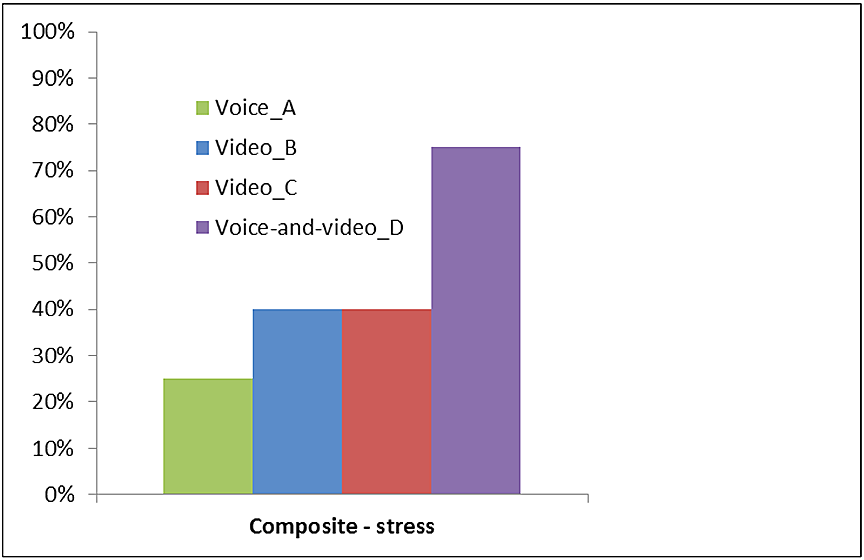

- Stress is a physiological state that, if not maintained at an optimal level, can adversely impact an individual's ability to perceive and evaluate cues from the environment. Stress can result in attentional narrowing.

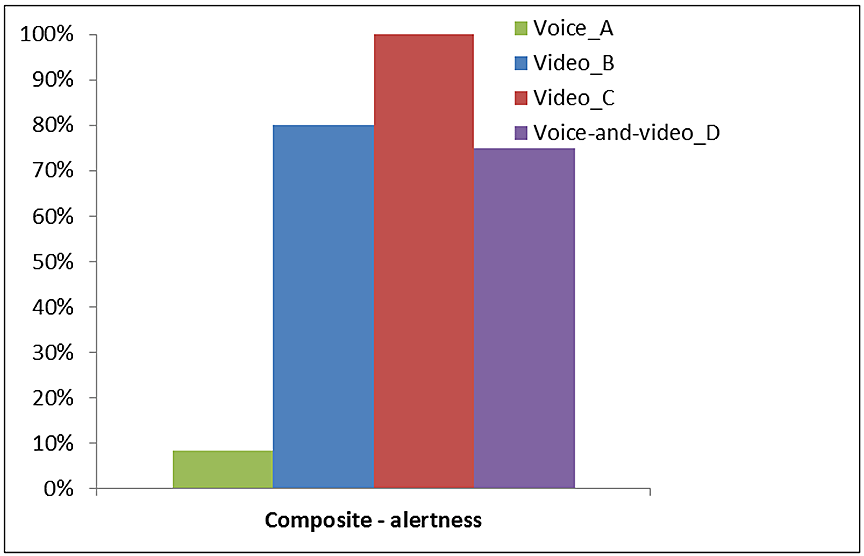

- Alertness/fatigue represents a physiological need for sleep. It results when a crew member has obtained an insufficient quantity and/or quality of restorative rest. Observable indicators of fatigue include yawning, momentary closing of eyes, and sleeping.

- Workload is a function of the number of tasks that must be completed within a given amount of time and the operator's ability to manage those tasks. If the number of tasks that must be completed increases, or if the time available decreases, then workload increases. Research shows that prosodicFootnote 24 features of speech, such as word frequency per unit of time, increase as a function of increased mental workload.Footnote 25 Shedding of tasks is an additional indicator of high workload.

- Situational awareness is “the perception of elements in the environment within a volume of time and space, the comprehension of their meaning, and the projection of their status in the near future.”Footnote 26 The accuracy of a locomotive crew member's situational awareness contributes to effective decision-making by enabling the crew member to make better-informed, more accurate predictions of the consequences of a decision. Indicators of reduced situational awareness include non-operational conversation, gaze directed away from controls or away from the forward view, and inaccurate knowledge of one's location.

- Distraction refers to the state of an individual when attention is directed toward a secondary, non-critical task. Inattention is the state of an individual when attention is not directed to safe operations, despite the absence of secondary tasks.

Readily observable indications of each of these human factors issues were identified, as means of assessing the presence of an issue in a recording. Ratings were assigned to indicate whether elements/signs of each human factors issue could be identified.

2.3.1.3 Operational practices relating to the capture and handling of on-board recordings

The operational and human factors assessment included a review of some of the technical issues relating to LVVR data capture, retention, and file handling/management, including

- the ability of the recording equipment to adequately capture data (Note: for the systems that recorded video, this meant image clarity and luminance, and the alignment and coverage area of the camera [or cameras]. For the systems that recorded audio data, this meant the microphone's [or microphones'] directionality and sensitivity);

- the size of the recorded files;

- whether LER data were synchronized with the LVVR data;

- whether LVVR data were time-stamped or otherwise provided accurate time and date information; and

- whether there were other means to identify LVVR data independently.

2.3.2 Assessment procedure for reviewing on-board recordings

Four subgroups were formed to assess the LVVR recordings provided by 4 Canadian railways. Participants within each subgroup included a TSB human factors investigator, a TSB rail investigator with operational experience, at least one operations representative from the railway company (railway), Teamsters delegates, and TC railway operations specialists.

Three types of on-board recording systems were evaluated:

- Voice-only (Railway A subgroup)

- Video-only (Railway B and Railway C subgroups), and

- Voice-and-video (Railway D subgroup).

As part of the operational and human factors assessment, a review of representative samples of locomotive voice and video recordings was conducted. A behaviour checklist was developed to guide the review of the on-board recordings and to facilitate discussion within the subgroup. The “voice-and-video” behaviour checklist is provided in Appendix B.

The behaviour checklist comprised a number of elements to be assessed during the review of each on-board recording, including

- information regarding the on-board recording;

- information regarding the crew;

- capturing in-cab crew interactions;

- capturing elements of human performance, including stress, fatigue/alertness, workload, situational awareness, and distraction/inattention;

- capturing locomotive control inputs under normal operating conditions; and

- capturing non-normal situations in the locomotive cab.

Between February 2016 and April 2016, 9 subgroup review sessions (Table 1) were conducted. Each review session lasted from 2 to 6 hours.

| Subgroup | Recording type | Number of review sessions | Number of recordings reviewed |

|---|---|---|---|

| Railway A | Voice-only | 3 | 14 |

| Railway B | Video-only | 2 | 5 |

| Railway C | Video-only | 1 | 5 |

| Railways D | Voice-and-video | 3 | 13 |

As it was not practical to examine all LVVR recordings from the trials in their entirety, a triage assessment was conducted for each on-board recording. Specific scenarios of interest, such as areas of heavy workload for train crew, low light conditions, time of day, shift length, and inclement weather, were identified. The triage assessment produced a number of partial recordings that were further examined by the subgroup.

The procedure for conducting the assessments of the extracted recordings was as follows:

- For each on-board recording, portions of the recording (i.e., typically 2 portions of approximately 10 minutes each) were reviewed by the subgroup.

- During group discussion, responses to the pre-determined questions on the behaviour checklist were documented.

- Data from the review sessions, including any qualitative comments, were documented.

- Differences among the LVVR system types or among environmental or operational conditions were identified.

- Comments from the subgroup members were explored. When appropriate, these comments were documented and grouped according to theme.

- Data for each railway were presented as follows:

- Environmental/ operational conditions;

- Ability to identify behaviour associated with safety-relevant operational issues, including normal operations, non-normal or emergency situations, and safety-relevant human factors issues; and

- Technical issues.

2.4 Safety benefit assessment for on-board recordings

The following activities were conducted for the safety benefit assessment:

- Review benefits from ACRS study—The final report from the 2012 LVVR study conducted by ACRS was reviewed.

- Identify LVVR benefits for investigations—The LVVR benefits for occurrence investigations were reassessed and documented.

- Identify LVVR benefits for SMS—The LVVR benefits within an SMS framework were assessed and documented.

- Identify other LVVR benefits—Other LVVR safety benefits were assessed and documented.

- Explore the appropriate uses of LVVR information—Summarize the perspective of members of the working group on appropriate use of LVVR.

The main point of controversy about the implementation of LVVR technology is what constitutes acceptable use. LVVR recordings have been recognized as invaluable for accident investigations. However, the expanded use of the on-board recordings, beyond accident investigations, has been strongly contested. Central to the debate have been positions about the public's right to safety and the operator's obligation to manage safety versus the employee's right to privacy and the employee's strong concerns about whether the employer will use the on-board recordings in a fair manner. The safety study documented the stakeholders' current perspectives on expanded use and on how the different points of view relating to this use can be reconciled.

Perspectives from participants in the working group were collected through facilitated discussion on the expanded use of on-board recordings. The appropriateness of each potential use was considered, including use of recordings

- to obtain safety-related data, such as for SMS, human performance analysis, recording operational compliance, and hazards identification;

- to identify and reward best practices;

- to shape behavioural change through the perception that operator actions are being monitored;

- to identify risky behaviours, followed by education, procedures, and training improvement; and

- to investigate the need for progressive discipline.

This was followed by an exercise to look for opportunities to reconcile the different perspectives on use. The objective of the exercise was not to reach consensus, but to understand and document the aspects of expanded use that would need to be considered for any successful solution going forward. The working group examined approaches that could be established to support the needs of all stakeholders if expanded use of on-board recordings is permitted, including

- procedures, including retention, de-identification, and chain of custody;

- oversight and enforcement;

- parties involved, including who should be present/invited when reviewing the recordings; and

- ensuring trust, such as through co-development and evolution of use within the company.

3.0 Results and observations

Key observations for each type of assessment were captured and summarized.

3.1 Results of technology assessment

The results of the technology assessment consisted of observations for

- on-board recorders for the aviation and marine modes;

- experience in the U.S. with LVVR technology; and

- LVVR technology installed for Canadian pilot trials.

3.1.1 On-board recorders for the aviation and marine modes

The TSB has extensive experience with aviation flight recorders, including FDRs and CVRs. More recently, the TSB acquired experience with marine VDRs.Information on the recorders used in these modes was assembled to ensure that lessons learned were identified and made available to the railway industry for consideration.

3.1.1.1 Summary of observations relating to data recorders in the aviation mode

CVRs provide significant information that is not recorded on FDRs but is essential for fully understanding accidents. CVRs have helped to establish crew actions and interactions with each other and in relation to defined and briefed procedures. CVRs can capture aural warnings and, when synchronized with the FDR, can establish the relationship between warnings and crew actions. CVRs also capture the sound environment, enabling the analysis of machinery such as aural warnings and propeller speed. These recordings can be used to establish who is in the cockpit. In addition, these recordings provide input to human factors analysis of crew dynamics, insights into stress levels, and tone of interactions among crew members.

Some CVRs have been difficult to use when there has been inadequate maintenance, leading to situations where the recordings are not available or not suitable. Poor sound quality due to background noise can sometimes be a problem, particularly if the system does not use “hot microphones.”Footnote 27 Various scenarios have led to recording durations that were too short and to relevant events being overwritten. These scenarios include inherent limitations of the memory capacity of older recorders, operational decisions not to secure recordings before they are overwritten, and failure to record key actions because they occurred early in a flight that was of longer duration than the recording.

3.1.1.2 Summary of additional observations specific to marine VDRs

The problem of poor sound quality can be particularly acute when fixed microphones are used on a large bridge, leading to significant distances between the speaker and the microphones. High levels of background noise recorded by the area microphone has been found to limit the clarity of the recording from some of the microphones used as part of VDR systems.

VDRs currently record both audio and other data in a single compressed file. Having only one file has been problematic when returning the data component to the owners, as the audio component, which is privileged, cannot easily be excluded from the media to be returned. The VDR file also contains radar images and can be very large (greater than 100 GB), which can result in difficulties with data handling and data storage.

There is no standard for VDR playback software or documentation relating to the recorded data. This means that playback requires software and cabling that is specific to the manufacturer and/or model. Users of this information must therefore keep current on the wide variety of procedures for data retrieval and maintain many different playback programs. In addition, the lack of common standards for VDRs has led, on occasion, to incorrectly recorded time parameters and difficulties in extracting parameters.

3.1.1.3 Lessons learned from the aviation and marine modes

The lessons learned include the following:

- Regular maintenance checks are required to ensure recording quality.

- There is a risk that critical data will be lost if recorder memory does not meet crashworthiness standards.

- The whole system, not only cameras and memory, must be robust, so that power failures and other equipment failures are immediately identifiable as rendering the system inoperable. It is not uncommon to find that recorder data has not been recorded correctly either due to a lack of an independent power supply or lack of crew knowledge of how to use the recorders in order to preserve the data.Footnote 28

- The first-generation CVRs recorded 4 audio channels of 30 minutes' duration on magnetic tape. Since 2003, newly manufactured large commercial aircraft have been required by ICAO to be equipped with a CVR capable of recording 2 hours; as of 01 January 2016, the ICAO requires all CVRs to be 2 hours, although this has been a U.S. Federal Aviation Administration requirement since 2012. TC regulations are not yet harmonized with this requirement. In the future, for new aircraft, the recording time for CVRs will be 25 hours, in order to capture long-duration flights (greater than 15 hours) and the pre- and post-flight activities. The intent of the standard is to ensure a duration that is sufficient to prevent overwriting significant events for either an extended journey or significant time powered. (Note: For rail, the duration should be at least the duration of the LER, which is specified as 48 hours in the U.S.Footnote 29) The current performance specification for VDRs is 12 hours, which is often too short to capture all of the events related to an accident.Footnote 30

- Any problems with the intelligibility of voice recordings significantly impact both usefulness of the recording and the time and resources required to analyze it. The use of hot microphones significantly improves sound quality of recordings and is likely to provide operational benefits by making communication easier in loud operating environments.

- Separate recording channels for each crew member, as well as an area microphone channel, improves the quality of recordings.

- Standardization of data retrieval and playback is preferred to minimize problems obtaining and playing data.

- It should be possible to synchronize all recorded data using a common time source.

- Clear documentation of timing information and parameters collected is needed in order to support comprehensive, accurate analysis.

- A system that combines both data and video/audio must provide an easy means to separate protected information before returning the data and device to the owner.

- Recordings involving video have challenging storage requirements.

- Each manufacturer's playback system requires unique software and cables. If the memory unit is damaged, a large expense may be incurred to transfer the data and then to recover it from another system.

3.1.2 Experience in the United States with LVVR technology

Following recommendations for on-board recorders from the NTSB,Footnote 31 there have been a number of recent initiatives in the U.S. involving LVVR technology, including pilot projects/implementations by CN, CP, Kansas City Southern, Union Pacific Railroad, Metrolink, and New Jersey Transit. The FRA and AAR also initiated some work in this area through the Recording Devices Working Group of the Railroad Safety Advisory Committee. Information on the U.S. experience, including manufacturer information, was assembled to ensure that lessons learned were identified and made available for consideration within the Canadian railway industry. This is provided in detail in Appendix C.

Based on the review of U.S. experience, the following challenges and lessons learned for LVVR were identified:

- Remote downloading of video was not practicable due to large file size and high cost.

- Some hardware was not appropriate in a reduced-lighting environment or high-ambient-noise environment.

- Tampering with cameras occurred.

- A number of U.S. railway operators had not installed on-board microphones.

- Video recordings were not regularly synchronized with other data.

3.1.3 LVVR technology installed for Canadian pilot trials

One of the tasks within the technology assessment for this study was to identify common practices for the existing LVVR in Canada, installed for pilot trials. Technical evaluation of the installed systems was beyond the scope of this study. However, common characteristics of these systems were identified. Each of these systems represents potential recording technologies available at the time of the study.

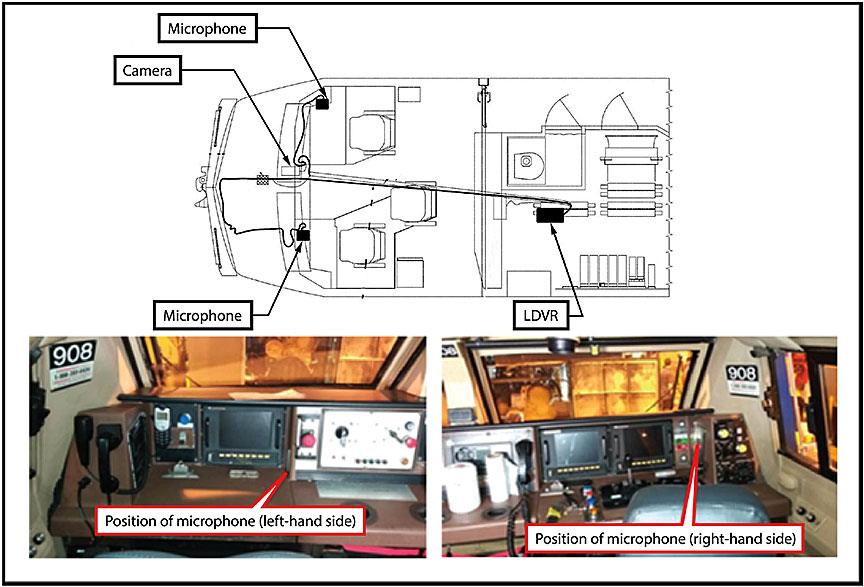

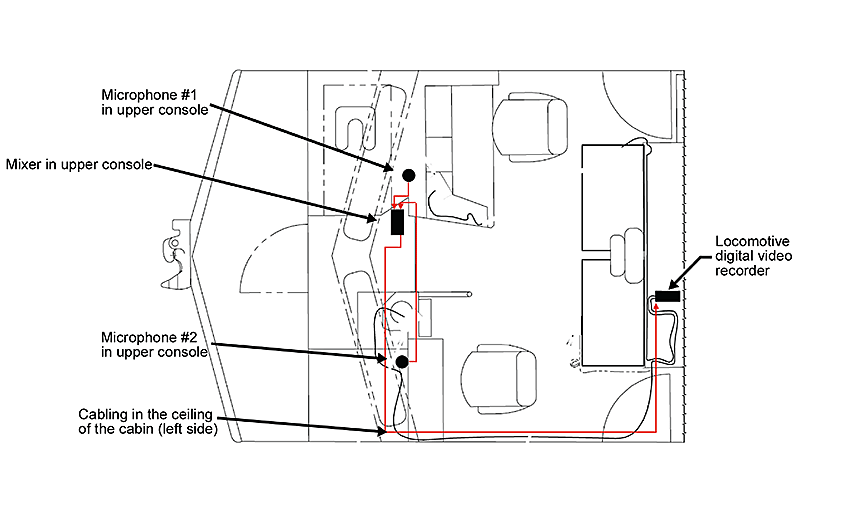

A detailed description of the characteristics of the technology used in each of the trial installations can be found in Appendix D. Common system characteristics of the 4 operators were identified and are summarized in Table 2. System schematics/layout for the 4 systems are presented in Appendix E.

3.1.3.1 Summary of the review of LVVR technology currently installed on Canadian railways

Cameras

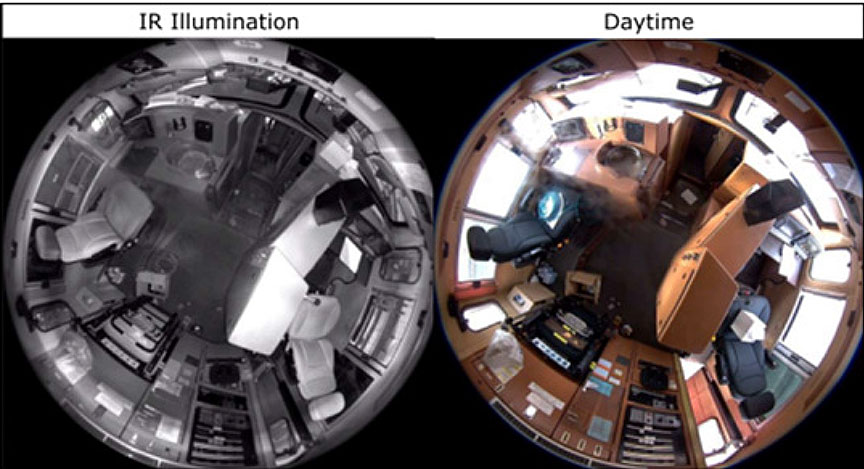

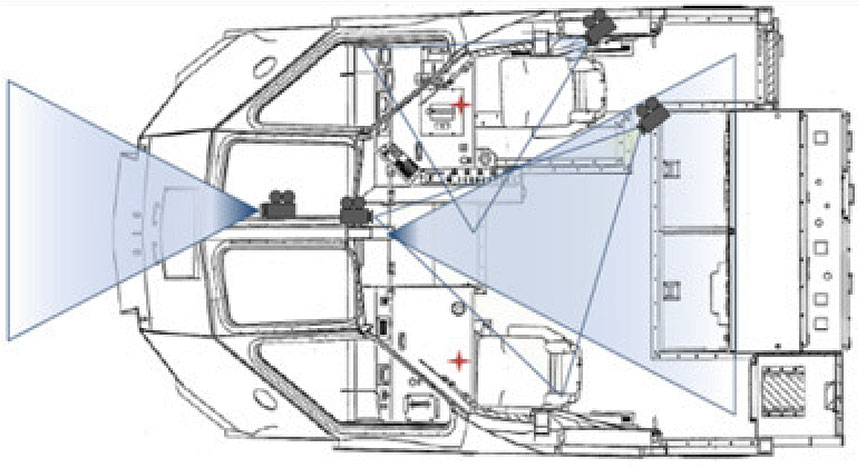

- All installations included at least 2 on-board overhead cameras that captured the locomotive engineer's work area and the conductor's work area. All systems included a forward-viewing camera. One system included a 3rd on-board camera that captured a view of the electrical cabinet area.

- All installations included a camera housing to prevent tampering.

- Some camera housings provided environmental protection to various standards.

- All cameras were colour cameras, with varying resolutions and frame rates. Some cameras included infrared capability for low light conditions.

- Camera and lens specifications varied significantly.

Microphones

- Two of the systems had on-board microphones, one located near the locomotive engineer's position and one located near the conductor's position. Background noise was filtered using various applications.

Recordings

- Recording durations varied depending on the capacity of the hard drive and the recording frame rate. Generally, the duration was at least 72 hours.

- Recording format varied. However, H.264 and MPEG4 were the most common formats.

- All systems used video encryption as a means of security.

System

- All systems were configured to start when the locomotive was powered on and remain on while power was provided. None of the systems used motion detection to start or stop the recording.

- Most installed systems (3 out of 4) used a battery backup to allow proper shutdown in the case of a power interruption. All systems had an automatic restart when power was restored.

- The installed equipment conformed to a variety of standards and environmental conditions. There were no common environmental standard specifications.

- Only one system used a means of crash protection for the recording system that met the FRA crashworthiness standard.Footnote 32

System management

- Video watermarks, including text or image overlay on the video, were not used in any system.

- Some systems required the removal of the hard drive and/or the use of dedicated software in order to retrieve the recorded data.

- All systems synchronized the on-board recordings with the forward-facing camera.

- Some systems synchronized the on-board recordings with LER and global positioning system (GPS) data.

- All operators controlled the access to the system equipment for maintenance and testing purposes.

- All operators had procedures to maintain “chain of custody” of the recordings.

- For all systems, video and audio settings were configured at the time of installation.

| Characteristics | Common to all | Common to some | No commonality |

|---|---|---|---|

| Camera installation | 2 on-board cameras (engineer and conductor); 1 forward-viewing camera | Third on-board camera (wide view, including electrical cabinet) | None |

| Camera housing | For tamper protection | Provided environmental protection | None |

| Camera/lens specifications | Colour cameras | Infrared capability for low light | Various resolutions and frame rates |

| Auto start/stop | Start when locomotive is powered; do not use motion detection | None | None |

| Power interruption | Auto restart when power restored | Battery backup to allow shutdown | None |

| Environmental protection | None | None | Various environmental conditions and standards |

| On-board microphone installation | None | 1 microphone near engineer and 1 near conductor | Audio filtering required owing to background noise |

| Crash protection | None | None | One system met FRA crashworthiness standard |

| Recording duration | None | Typically 72 hours | Duration varied owing to hard drive capacity and frame rate |

| Recording format | None | H.264 and MPEG4 | None |

| Security and data access control | Watermarks not used Video encryption |

Require removal of hard drive for data access; dedicated software for playback | None |

| Synchronization with other data | On-board and forward-viewing | LER and GPS | None |

| System access for maintenance | Controlled access for maintenance and testing | None | None |

| User-programmable settings | All settings configured at installation—no user-configurable settings | None | None |

| Chain of custody for recordings | Processes in place | None | None |

3.2 Results of legislative and regulatory assessment

From a legal perspective, the expanded use of LVVR must be considered in a very complex environment. Consideration needs to be given to legislation and regulations concerning transportation, in Canada and cross-border in the U.S.; international standards for on-board recorders; and the complex issues relating to employers' and workers' rights and obligations, including the workers' reasonable expectation of privacy.

This section sets out the main issues in these areas in order to provide a basis for making decisions about future LVVR use. The results of the legislative and regulatory assessment consisted of observations relating to

- Canadian legislation and regulations,

- U.S. legislation and regulations,

- international standards and guidelines,

- challenges to surveillance in the workplace, and

- obligations and rights of an employer in regard to workplace recordings.

3.2.1 Canadian legislation and regulations

This section provides the relevant provisions from Canadian legislation pertaining to on-board recordings, for all modes.

Section 28 of the CTAISB Act speaks to the privileged nature of on-board recordings. It also addresses access to and use of those recordings by the TSB as well as other access and prohibited uses. Subsection 28(2) provides that:

(2) Every on-board recording is privileged and, except as provided by this section, no person, including any person to whom access is provided under this section, shall

(a) knowingly communicate an on-board recording or permit it to be communicated to any person; or

(b) be required to produce an on-board recording or give evidence relating to it in any legal, disciplinary or other proceedings.

There is some interpretational concern that these restrictions only exist when an accident or incident has occurred, or when the TSB has grounds to believe that a situation could, if left unattended, induce an accident or incident.

If the use of on-board recordings is expanded in any mode, to maintain consistency and fairness, changes will also need to flow through to the other modes of transportation where such recordings are present. The governing statutory provisions, which encompass the enabling acts as well as any regulations or rules subordinate to them, will therefore need to be reviewed.

As part of the Railway Safety Management System Regulations under the RSA, TC has required federally regulated railway companies to have an SMS in place since 2001. Central to any SMS is the proactive collection of data to ensure that hazards are identified and that mitigations are achieving their intended results. Section 5 of the Railway Safety Management System Regulations, 2015 states:

5 A railway company must develop and implement a safety management system that includes

(a) a process for accountability;

(b) a process with respect to a safety policy;

(c) a process for ensuring compliance with regulations, rules and other instruments;

(d) a process for managing railway occurrences;

(e) a process for identifying safety concerns;

(f) a risk assessment process;

(g) a process for implementing and evaluating remedial action;

(h) a process for establishing targets and developing initiatives;

(i) a process for reporting contraventions and safety hazards;

(j) a process for managing information;

(k) a process with respect to scheduling; and

(l) a process for continual improvement of the safety management system.

The expanded use of LVVR is a potential means of achieving these objectives. But, in order to proceed in this direction, consideration must be given to a wide range of legislation and regulations in Canada.

3.2.1.1 Governing acts and regulations regarding on-board recordings

The CTAISB Act would need amendments, and a number of statutes administered by TC could be affected. Under each statute, there are also numerous regulations or orders that could also be affected. Appendix F of this report provides a preliminary list of statutes that may fall within this category. Other federal statutes not directly related to transportation, such as the Access to Information Act and the Personal Information Protection and Electronic Documents Act (PIPEDA), must also be considered. The discussions on the implementation of LVVR have touched on the topics of privacy, access, and use. A comprehensive assessment is therefore required in order to examine the legal space encompassing labour and employment law, and the rights of both privacy and access to information. A section 8 analysis under the Canadian Charter of Rights and Freedoms may also be necessary if proposed legislation provides railway companies with access to the on-board recordings.

It will also be necessary to review the regulations under any relevant statutes that touch upon the installation, implementation, servicing, protection, and preservation of the recording devices in order to determine all the instances where amendments need to be made or new definitions added.

The following tables provide current legislative provisions that specifically reference “on-board recorder” or “on-board recording” (see section 3.2) for each transportation mode. The information in these tables is not exhaustive and should not be construed as legal opinion.

3.2.1.2 Examples of existing statutes and subordinate legislation referencing on-board recordings

Transportation accident investigation and safety

| Enabling statute and purpose | Sections referencing “on-board recorder” or “on-board recording” | Subordinate regulation(s) and purpose |

Sections referencing “on-board recorder” or “on-board recording” |

|---|---|---|---|

| Canadian Transportation Accident Investigation and Safety Board Act, SC 1989, c 3 An Act to establish the Canadian Transportation Accident Investigation and Safety Board and to amend certain Acts in consequence thereof |

S 28(1) (a), (b); (2)(a), (b); (3); (4); (5); (6)(b), (c); (7) | Transportation Safety Board Regulations, SOR/2014-37 Regulations made with respect to the activities of the TSB |

None |

Air transportation

| Enabling statute and purpose | Sections referencing “on-board recorder” or “on-board recording” | Subordinate regulation(s) and purpose |

Sections referencing “on-board recorder” or “on-board recording” |

|---|---|---|---|

| Aeronautics Act, RS 1985, c A-2 An Act to authorize the control of aeronautics |

S 22 (1)–(9); S 23 (1) (a), (b) (i), (ii); S 23 (3); (4) (a), (b); (5); (6) (a); & (8) |

Civil Aviation Regulations, SOR/96-433 Regulations Respecting Aviation and Activities Relating to Aeronautics |

S 605.33(1); (2); S 605.34(1) (b); (2); (3); (4) (a); (5) (b) |

Rail transportation

There are currently no audio or video recorders used in the railway industry that are equivalent in purpose and function to the CVR or VDR devices used in the aviation or marine industries.

Under section 3.1 of the RSA, the Minister of Transport is responsible for the development and regulation of matters to which the RSA applies, including safety and security, and for the supervision of all matters connected with railways and, in the discharge of those responsibilities, the Minister of Transport may, among other things, promote railway safety by means that the Minister considers appropriate; undertake, and cooperate with persons undertaking, projects, technical research, study or investigation; inspect, examine and report on activities related to railway matters; and undertake other activities that the Minister considers appropriate.

The authority to make regulations relating to on-board LVVR, including how to manage the information generated, is contained in the RSA, sections 18 and 37. However, depending on the approach taken, mandating LVVR could require legislative change to the Act, as well as new regulations.

Marine transportation

| Enabling statute and purpose | Sections referencing “on-board recorder” or “on-board recording” | Subordinate regulation(s) and purpose |

Sections referencing “on-board recorder” or “on-board recording” |

|---|---|---|---|

| Canada Shipping Act, 2001, SC 2001 c 26 An Act respecting shipping and navigation and to amend the Shipping Conferences Exemption Act, 1987 and other Acts |

None | Voyage Data Recorder Regulations, SOR/2011-203Footnote 33 Regulations Respecting Voyage Data Recorders and Related Activities |

None |

Pipelines

The pipeline industry currently employs a type of recording device in some operations centres.

| Enabling statute and purpose | Sections referencing “on-board recorder” or “on-board recording” | Subordinate regulation(s) and purpose |

Sections referencing “on-board recorder” or “on-board recording” |

|---|---|---|---|

| National Energy Board Act, RSC 1985, c N-7 An Act to establish a National Energy Board Canada Oil and Gas Operations Act, RSC 1985, c O-7 An Act to promote, in respect of the exploration for and exploitation of oil and gas, (a) safety, particularly by encouraging persons exploring for and exploiting oil or gas to maintain a prudent regime for achieving safety; (b) the protection of the environment; (b.01) accountability in accordance with the “polluter pays” principle; (b.1) the safety of navigation in navigable waters; (c) the conservation of oil and gas resources; (d) joint production arrangements; and (e) economically efficient infrastructures. |

None | National Energy Board Act Part VI (Oil and Gas) Regulations SOR/96-244 Regulations for Carrying Into Effect the Provisions of Division I of Part VI of the National Energy Board Act National Energy Board Onshore Pipeline Regulations |

None |

3.2.2 United States legislation and regulations

3.2.2.1 National Transportation Safety Board

Under the Freedom of Information Act, the NTSB is exempt from releasing CVR tapes.Footnote 34

3.2.2.2 Rail

The U.S. began implementing LVVR technology voluntarily in several large railways. The recently introduced bill (December 2015) to the 114th Congress of the U.S. Senate, Fixing America's Surface Transportation Act, is an attempt to reconcile various surface-transportation bills (i.e., road, marine, rail) and provide funding to improve or repair infrastructure, improve safety practices, and introduce new systems. This bill also includes the provisions of amendments for new LVVR technology, specific to the installation of in-cab audio and image recording devices in all controlling locomotive cabs and cab car operating compartments in passenger trains.Footnote 35 These recording devices will have a minimum 12-hour continuous recording capability; crash and fire protections for any in-cab image recordings that are stored only within a controlling locomotive cab or cab car operating compartment; and recordings accessible for review during an accident or incident investigation. The provisions also allow use of the recordings

- for an operator to verify that train crew actions are in accordance with applicable safety laws and the railroad carrier's operating rules and procedures;

- for assisting in an investigation into the cause of a reportable accident or incident; and

- for documenting a criminal act or monitoring unauthorized occupancy of the controlling locomotive cab or car operating compartment.

An in-cab audio or image recording obtained by a railroad carrier under this section may not be used to retaliate against an employee.

Similar to Canada, railroad operators in the U.S. are required to have LER.

3.2.2.3 Air

As of 2014, FDR and CVR are required only on U.S. aircraft that have 20 or more passenger seats or on aircraft that have 6 or more passenger seats, are turbo-charged, and require 2 pilots.

3.2.2.4 Marine

As in Canada, the IMO International Convention for the Safety of Life at Sea (SOLAS) Chapter V, Annex 10, Regulation 20 for VDRs applies.

3.2.2.5 Pipeline

Under the Pipeline Safety, Regulatory Certainty, and Job Creation Act of 2011, pipeline operators are required to monitor human factors. However, electronic surveillance is not currently used to monitor personnel working in a control centre. Operational data are recorded using supervisory control and data acquisition (SCADA) systems, which are computer-based tools that provide an integrated summary of remote pipeline sensors and controls.

3.2.3 International standards and recommended practices

In common-law countries, including Australia, New Zealand, and United Kingdom, the legislation and regulations typically are very similar to those in Canada with respect to the handling and protection of on-board recordings. However, in countries where civil-law structures are in place, such as France, Belgium, Italy, and Germany, judicial decision-makers are often the first-line authorities who have precedence with regard to the handling and disposition of on-board recordings. Therefore, on-board recordings tend to be used more frequently for judicial purposes.

In general, countries follow the overarching conventions and regulations set down by five international organizations:

3.2.3.1 International Civil Aviation Organization (ICAO)

ICAO provides the standards and recommendations for the use of CVRs.Footnote 36 In addition, the European Organisation for Civil Aviation Equipment (EUROCAE) provides the specifications for CVR performance requirements in its Minimum Operational Performance Specification (MOPS) document. Generic investigation procedures, under ICAO Annex 13, Aircraft Accident and Incident Investigation, provide that “the state conducting the investigation shall not make availableFootnote 37 specific records, including communications between persons having been involved in the operation of the aircraft, cockpit voice recordings and transcripts from such recordings and cockpit airborne image recordings and any part or transcripts from such recordings.” However, ICAO permits individual countries to file exceptions to its standards, and some countries have done so with respect to on-board recordings.

3.2.3.2 European Aviation Safety Agency (EASA)

Under European Union Commission Regulation No. 965/12012, EASA complies with ICAO standards. This regulation details the mandatory installation of a CVR and the specific requirements associated with its use during flight and post-flight and in the event of an occurrence.

3.2.3.3 European Union Agency for Railways (ERA)

Comprising representatives from each EU member state, the ERA was established to provide member states and the European Commission with technical assistance in the fields of railway safety and interoperability. This involves the development and implementation of technical specifications for interoperability (TSI) and a common approach to questions concerning railway safety. The main task of the ERA is to manage the preparation of these measures by working with the National Investigation Bodies on accident investigation methods, reporting, recommendations, and exchange of good practices.

Although Directive 2008/57/EC of the European Parliament on railway interoperability makes reference to locomotive event recorders in the use of TSIs, as yet there has been no formal approach to the introduction or implementation of LVVR technology.

3.2.3.4 International Maritime Organization (IMO)

In May 2012 the Maritime Safety Committee of the IMO adopted a revised recommendation on performance standards for VDRs, in force since 1 July 2014. Bridge audio is recorded, as well as images, chart(s) used, and settings from the electronic chart display and information system and from both radars.

Passenger ships and ships other than passenger ships of 3000 gross tonnage and upwards constructed on or after 01 July 2002 must carry VDRs to assist in accident investigations, under regulations adopted in 2000, which entered into force on 01 July 2002. The mandatory regulations are contained in chapter V on Safety of Navigation of SOLAS, 1974. Like the black boxes carried on aircraft, VDRs enable accident investigators to review procedures and instructions in the moments before an incident and help to identify the causes of an accident.

International Convention for the Safety of Life at Sea, chapter V, Regulation 20 – Voyage data recorders

Regulation 20 of SOLAS chapter V states that, to assist in casualty investigations, ships on international voyages, which are subject to the provisions of Regulation 1.4, must be fitted with a voyage data recorder (VDR). Ships covered by Regulation 20 include

1.1 passenger ships constructed on or after 1 July 2002;

1.2 ro-roFootnote 38 passenger ships constructed before 1 July 2002, not later than the first survey on or after 1 July 2002;

1.3 passenger ships other than ro-ro passenger ships constructed before 1 July 2002 not later than 1 January 2004; and

1.4 ships, other than passenger ships, of 3,000 gross tonnage and upwards constructed on or after 01 July 2002.

Under IMO, the ship owner, in all circumstances and at all times, owns the VDR and its data, except when an accident occurs. In the event of an accident, the investigation body is responsible for downloading the data and must provide a copy to the vessel owner at an early stage.

3.2.3.5 European Maritime Safety Agency (EMSA)

The European Maritime Safety Agency (EMSA) was established under Regulation (EC) No. 1406/2002 for the purpose of ensuring a high, uniform, and effective level of safety. Among its tasks, the agency has the role of supporting the member states in activities concerning marine accident investigations. The following documents provide the EMSA with IMO requirements (IMO MSC/Circ/1024) for shipborne VDRs and simplified VDRs (S-VDRs):

- Resolution A.861(20) – Performance standards for shipborne voyage data recorders (VDRs)

- Resolution MSC.163(78) – Performance standards for shipborne simplified voyage data recorders (S-VDRs)

- MSC/Circ.1024 – Guidelines on voyage data recorder (VDR) ownership and recovery

- Resolution MSC.214(81) – Adoption of amendments to the performance standards for shipborne voyage data recorders (VDRs) (Resolution A.861(20)) and performance standards for shipborne simplified voyage data recorders (S-VDRs) (Resolution MSC.163(78))

- MSC.1/Circ.1222 – Guidelines on annual testing of voyage data recorders (VDR) and simplified voyage data recorders (S-VDR)

Directive 2002/59/EC requires member states to ensure that data from VDR systems are used in an investigation and are properly analyzed. EMSA complies with IMO requirements.

An examination of a wide range of countries and the international rules and recommendations reveals that there is generally common agreement among nations to promote a high level of safety and security across all transportation modes. Although nation states have their own legislation regarding transportation, the nation states incorporate or, in some cases, completely adopt international standards, where they exist. However, these international standards are simply guidelines by which each nation state is expected to model its own legislation and practices. In general, the aviation industry leads the way in its implementation of on-board recording technologies, followed by the marine industry.

For the rail industry, the European Union Agency for Railways (ERA) is working towards:

- a better perspective on human factors in its Human Factors ProjectFootnote 39 (initiated in 2012); and

- an increased harmonization of investigation processes throughout Europe.

The key to the success of the rail safety initiatives launched by the ERA is cooperation and communication among rail stakeholders and transport ministries across the European Union. This cooperation and communication foster mutual understanding, agreements, and recognition of nationally accepted rules and best practices.

In many of the EU and Commonwealth member countries, the emphasis on improved rail safety has led to the consideration of enhanced recording requirements on trains. Key objectives common to these studies are

- to support systematic safety monitoring as a means of preventing incidents;

- to identify the driver, the train, and the infrastructure performance leading up to an incident; and

- to record information related to the performance of the locomotive and the crew.

As a result of independently conducted safety studies, recommendations are being issued through the respective investigative agencies. These recommendations are directed at improving monitoring systems, including driver activities and on-board communications.

3.2.4.Challenges to surveillance in the workplace