Main-track derailment

Canadian Pacific Railway

Freight train A13-31

Mile 50.7, Montana Subdivision

Stirling, Alberta

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

The occurrence

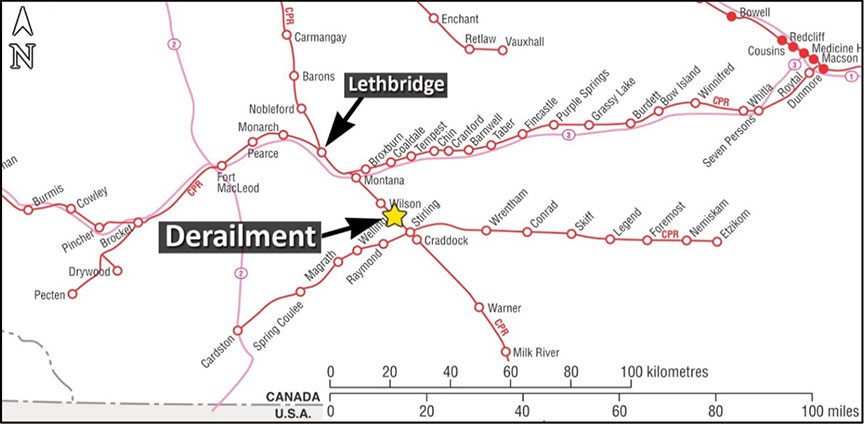

On 30 July 2018, a Canadian Pacific Railway (CP) train crew was ordered for 1230Footnote 2 in Lethbridge, Alberta (Figure 1). The crew was scheduled to operate freight train A13-31 southward on the Montana Subdivision from Lethbridge (Mile 64.8), to Coutts, Alberta (Mile 0.0), at the Canada/U.S. international border. The train departed at about 1355.

The distributed power train consisted of two 4400-horsepower locomotives at the head end, 100 covered hopper cars loaded with canola seed, and a 4400-horsepower locomotive at the tail end. The train weighed 14 213 tons and was 6114 feet long.

At 1525, while the train was operating southward at 22 mph, a train-initiated emergency brake application occurred. After the train came to a stop, the crew inspected the train and determined that 16 loaded covered hoppers, the 45th through 60th cars behind the lead locomotives, had derailed at Mile 50.7. The cars were in various positions along the right-of-way. At the time of the occurrence, the skies were clear, and the temperature was 32° Celsius.

Crew information

The crew consisted of a locomotive engineer and a conductor. Both crew members were qualified for their respective positions, met established fitness and rest requirements, and were familiar with the territory.

Recorded information

The locomotive event recorder information was reviewed. It was noted that the brakes were released and the throttle was in idle when the train was approaching the occurrence location.

The lead locomotive was equipped with a forward-facing camera. Based on a review of this recording, no track anomalies were evident as the head end of the train passed over the occurrence site.

Subdivision information

The Montana Subdivision is predominantly single main track that runs north–south between the Canada/U.S. border and Mile 64.8, station Montana,Footnote 3 which is also the junction with the Taber Subdivision. Train movements on the Montana Subdivision are controlled by the Occupancy Control System, as authorized by the Canadian Rail Operating Rules, and supervised by a rail traffic controller located in Calgary, Alberta.

The average train traffic on this subdivision is about 3 trains per day, with an annual tonnage of about 5.5 million gross tons (MGT). In the vicinity of the derailment, the maximum authorized speed for freight trains was 35 mph, making it Class 3 track according to the Transport Canada–approved Rules Respecting Track Safety, which are also known as the Track Safety Rules (TSR).Footnote 4

Track information

The derailment occurred within an area of 2 left-hand curves near the end of a descending grade (ranging from 0.2% to 0.71%) starting from Mile 52. There was a 4 degree 15 minute curve from Mile 51.03 to Mile 50.86 and a 4 degree 9 minute curve from Mile 50.86 to Mile 50.61. This degree of curvature is not considered excessive.

The track in the area of the derailment had been visually inspected by hi-rail on 16 July and on 20 July 2018, and no defects were detected. On 20 July, a track evaluation carFootnote 5 test was conducted. Two near-urgent defects (spiral cross-level over 31 feetFootnote 6 at Mile 50.7 and at Mile 50.8) and two near-urgent track gauge defects (6 feet of track with a gauge of 7/8 inch at Mile 50.9 and 7 feet of track with a gauge of 1 inchFootnote 7 at Mile 51.0) were detected.

In response to the results of the track evaluation car test, a temporary slow order (TSO) was issued that restricted train speed to 10 mph between Mile 49.4 and Mile 51.9. Track surfacing work was completed to correct the defects. On 29 July 2018, the day before the occurrence, the train speed restriction in the TSO was changed from 10 mph to 25 mph.

When the track surfacing work was performed, the rail temperature was about 24° Celsius. Before the speed restriction in the TSO was raised from 10 mph to 25 mph, about 14 000 tons of train traffic (1 train) had travelled over the track.

The CP Red Book of Track and Structures Requirements (the Red Book) was developed to provide guidance to CP engineering personnel. The Red Book requirements meet or exceed the TSR requirements. Section 8.7.2 (d) of the Red Book specifies (in part) that 2 trains each greater than 5000 tons must be able to pass at 10 mph before the speed is increased to 25 mph.Footnote 8

Between Mile 49.0 and Mile 51.0, the high rail (the rail on the north side of the track) consisted of 136‑pound continuous welded rail (CWR) manufactured by Nippon in 2015. The low rail at this location (the rail on the south side of the track) was CWR manufactured by Algoma in 1983. The rail was set on 14‑inch standard tie plates and secured with 5 spikes per tie plate. The ballast was in good condition with full cribs. The drainage was good in the vicinity of the occurrence. The ties in the curves were about 50% hardwood and 50% softwood.

Subpart D II (c) of the TSR requires Class 3 track to have at least 10 crossties in each 39-foot segment of track that are not

(1) broken through;

(2) split or otherwise impaired to the extent the crossties will allow the ballast to work through, or will not hold spikes or rail fasteners;

(3) so deteriorated that the tie plate or base of rail can move laterally more than ½ inch relative to the crossties; or

(4) cut by the tie plate through more than 40 percent of a tie's thickness.Footnote 9

Because Class 3 track will typically have 23 ties for every 39 feet of track, the requirement to have 10 good ties per 39-foot segment could mean that there are up to 13 defective ties (i.e., up to 57% of the ties could be defective). Based on the railway inspection records, about 42% of the ties between Mile 50.6 and Mile 51.0 were defective.

Simulation of in-train forces generated by the occurrence train

A simulation of the in-train forces generated by the occurrence train was conducted by CP using the VAMPIRE software.Footnote 10 The simulation confirmed that there were lateral forces through the curves near the point of derailment of approximately 10 to 12 kips.Footnote 11

Based on the wheel flange marks across the rail head (Figure 2), the high rail had likely canted outwards, allowing the wheel on the inside rail to drop into the gauge. For lateral forces of 10 to 12 kipsFootnote 12 to cause the gauge to spread, weakened securement of the rail (e.g., poor tie condition) was likely present.

Although only a small section of track (between Mile 50.53 and Mile 51.01) had been identified by the track evaluation car as having wide gauge, the gauge of the track can spread if defective ties are clustered rather than being evenly distributed.

Safety messages

In this occurrence, the track met the requirements of the TSR and CP's Red Book with respect to the allowable percentage of defective ties. However, the track was still vulnerable to lateral in-train forces in the range of 10 to 12 kips. This occurrence illustrates the importance of performing timely replacement of defective ties, particularly on curves.

This concludes the TSB's limited-scope investigation into this occurrence. The Board authorized the release of this investigation report on 27 February 2019. It was officially released on 04 March 2019.