Main-track train derailment

Canadian Pacific Railway

Freight train 118-01

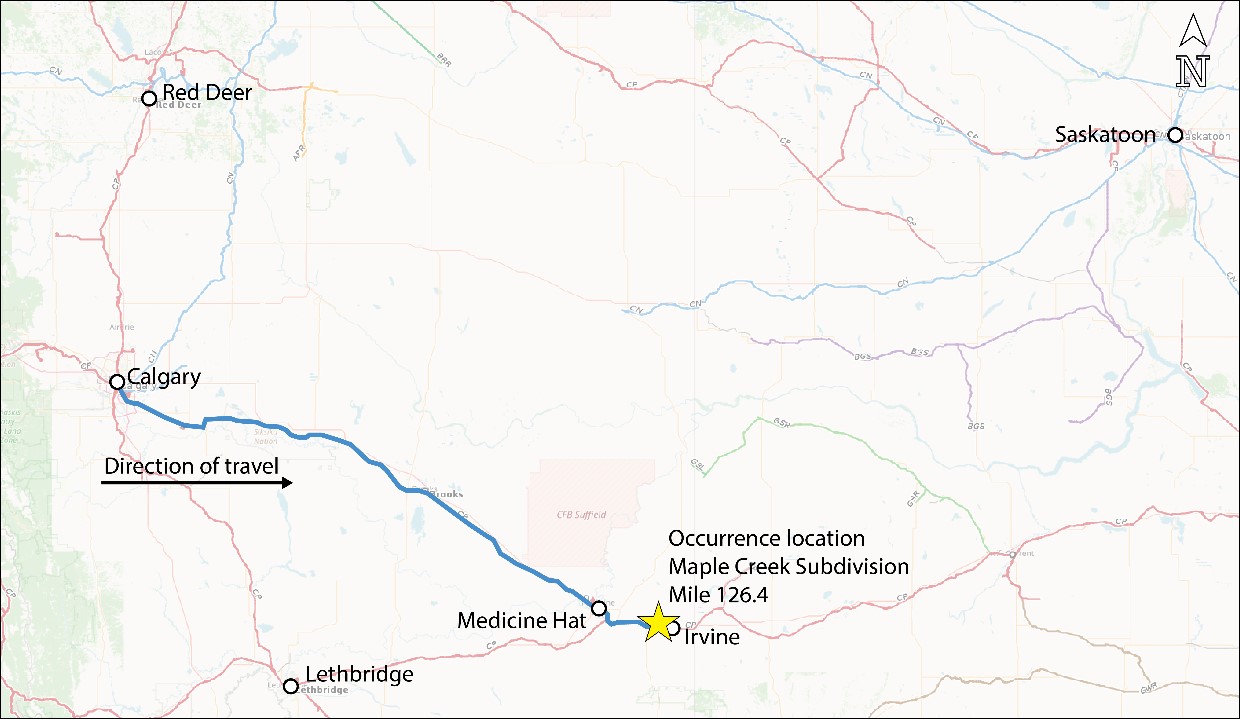

Mile 126.4, Maple Creek Subdivision

Irvine, Alberta

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

The occurrence

On 02 August 2019, at 1515,Footnote 1 Canadian Pacific Railway (CP) freight train 118‑01 was proceeding eastward at about 37.3 mph on the Maple Creek Subdivision when the mid-train remote control locomotive and the following 21 cars derailed at about Mile 126.4. The derailment involved 5 cars containing dangerous goods and occurred near the hamlet of Irvine, Alberta (Figure 1).

The distributed power (DP) train was configured with 2 locomotives at the head end and 1 mid-train remote-controlled locomotive. The mid-train locomotive was positioned 36 cars behind the head end of the train. The train consisted of 108 cars (83 loaded and 25 empty) and was 9873 feet long and weighed 11 685 tons.

Following a crew change, the train departed Medicine Hat, Alberta, at 1433, destined for Maple Creek, Saskatchewan. The train was proceeding at about 37.3 mph when it experienced a train-initiated emergency brake application. Post-accident inspection revealed that the mid-train remote-controlled locomotive and the following 21 cars had derailed. There were 5 dangerous goods tank cars involved in the derailment: 3 loaded tank cars containing styrene monomer (UN2055) and 2 residue tank cars that last contained methanol (UN1230), both Class 3 flammable liquids.

Before the train departed Medicine Hat, it received a No. 1 air brake test in Dunmore, Alberta, with no exceptions noted. It passed a hot box and dragging equipment detector at Mile 134.6 on the Maple Creek Subdivision at 1502, with no exceptions noted. The ambient temperature recorded by the detector was 34.4 °C. The train had passed a wheel impact load detector (WILD) at Mile 147.5 on the south track of the Brooks Subdivision, near Carseland, Alberta, earlier that day at 0804, with no exceptions noted. The locomotive event recorder (LER) download was reviewed and no train handling anomalies were noted.

Site examination

The derailment site was initially cordoned off due to the potential for a dangerous goods release. Preliminary site examination revealed that 2 cars, PROX 23223 and PROX 23282, were on their sides, leaking styrene monomer at a slow rate. Tank car GATX50642 was badly damaged, including tears in the tank, and contained residue methanol. Despite the damage, there was no loss of product from that tank car.

Additionally, there was a small grass fire reported near the right-of-way. The cars had derailed on both sides of the right-of-way in an accordion fashion (Figure 2).

Emergency response and evacuation

The local police and fire department received the first calls about the derailment at about 1518 and arrived on scene at about 1540. CP’s Hazardous Materials & Emergency Response Team was also dispatched. At about 1552, the decision to evacuate the area was made. A 7 km2 area, including the hamlet of Irvine, was evacuated as a precaution, with approximately 300 people affected. Highway 1 was inside this evacuation area, was closed to traffic in both directions at 1603, and did not reopen until 2055. The site was secured and the evacuation was completed by about 2330.

The track was reopened to train traffic at about 1000 on 03 August 2019. The transshipment of the product from the 3 derailed loaded tank cars continued into the following week.

Weather

According to Environment and Climate Change Canada, the weather at the time of the occurrence was clear and hot, with a temperature of 34.5 °C. CP’s Revised Heat Slow Policy for Canada requires speed to be reduced to a maximum of 30 mph when the ambient temperature is 35 °C or greater.

Crew information

The crew consisted of a locomotive engineer and a conductor. Both crew members were qualified for their respective positions, met established fitness and rest requirements, and were familiar with the territory.

Subdivision and track information

The Maple Creek Subdivision runs east to west between Mile 0.0 at Swift Current, Saskatchewan, and Mile 147.4 at Medicine Hat. Train movements are controlled by the centralized traffic control (CTC) system, as authorized by the Canadian Rail Operating Rules (CROR), and supervised by a rail traffic controller (RTC) located in Calgary, Alberta. Train traffic for this corridor is about 18 trains per day, with an annual tonnage of approximately 80.8 millions of gross ton miles of traffic per mile of rail line (MGTM per mile) in 2018.

In the vicinity of the derailment, the track is Class 4 track as defined in the Transport Canada–approved Rules Respecting Track Safety, also known as the Track Safety Rules (TSR). The maximum timetable authorized speed for freight trains was 55 mph. The track consisted of 136-pound continuous welded rail (CWR) manufactured by Sydney Steel Corporation in 1998, set on 14-inch double-shouldered tie plates fastened to No. 1 hardwood ties with 3 spikes per plate. The rail was box-anchored at every tie and the ties were in good condition.

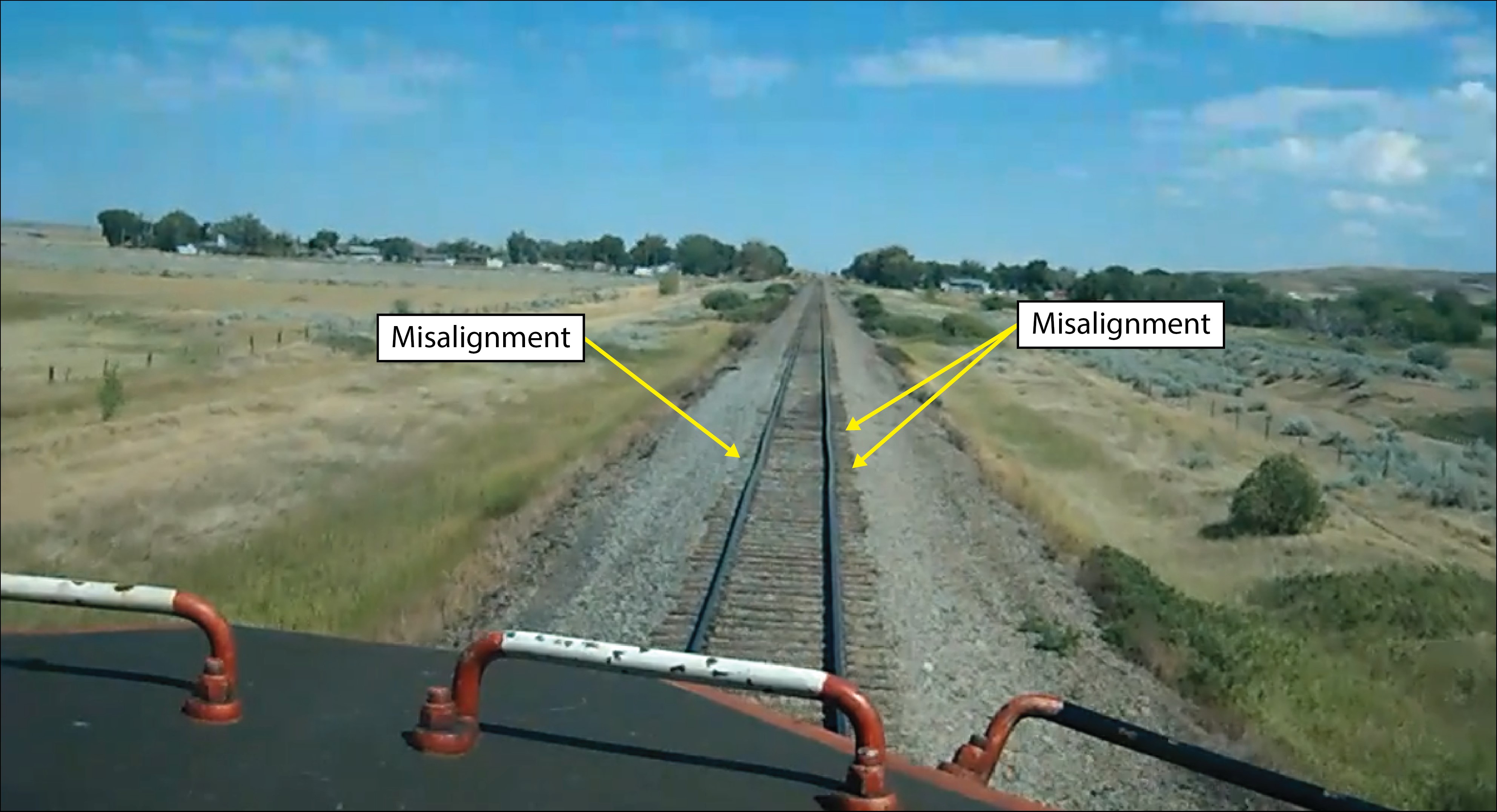

Forward-facing camera

The lead locomotive was equipped with a forward-facing camera. In the vicinity of the derailment, the locomotive camera showed a small misalignment and fresh ballast dumped along the north rail.

Track inspection and maintenance

CP’s autonomous track geometry test vehicle CP 60 detected an urgent alignment/rate of change (AL/RC) defect and an urgent design elevation (D ELV) defect of 1⅝ inches at Mile 126.3 on 24 July 2019. On tangent track, design elevation should be 0, i.e., both rails should be at the same elevation. Where a D ELV defect does appear in tangent track, it is usually due to differential settlement of the roadbed on one side of the track. Under a moving train, differential settlement may cause load transfer to the wheels on the low side of the track. The AL/RC defect is a combination alignment and cross-level defect.

The area between Mile 126.2 and Mile 126.6 was surfacedFootnote 2 on 25 July 2019. Subsequently, a temporary slow order (TSO) of 40 mph was applied between those mile points to have train tonnage consolidate the freshly surfaced track. The TSO was lifted on 26 July 2019.

CP’s Red Book of Track Structures & Requirements requires hot weather track inspections when the air temperature is expected to exceed 29 °C or if a heat slow order is in effect, as follows:

- conduct daily track inspections,

- heat track inspections should be conducted during the heat of the day; that is, during the time of the day that the rail temperature is expected to be at its highest, usually between 1200 and 1800 hours,

- daily hot weather track inspections may be suspended when the temperature has leveled off or moderated for more than 3 days and previous inspections have shown the track structure has stabilized.Footnote 3

The track in the derailment area was inspected visually on 29 July 2019 as required by the TSR. A heat patrol (i.e., a visual inspection) was conducted at 1430 on 01 August 2019 when the temperature reached 31 °C. All required track inspections were conducted according to the TSR and CP procedures.

Longitudinal forces in continuous welded rail

The efficient management of longitudinal forces in CWR is an important maintenance function for railways. CWR can experience large compressive and tensile longitudinal forces as a result of temperature changesFootnote 4 or track maintenance activities such as track lining and surfacing, and tie or rail replacement. Even if the track is not worked on, the rail can shift as a result of rail breaks, emergency brake applications, worn or defective anchors, poor quality or insufficient ballast, or soft subgrade. Compressive forces can induce track buckling while tensile forces can result in rail defect growth and rail pull-apart failures at joints.

A tight rail conditionFootnote 5 in the north rail was observed near the point of derailment on 11 April 2019. Tight rail conditions can result in wavy rail, movement of ties, and rail movement through the anchors. When these conditions are observed, there is too much steel in that section of track, increasing the potential for a track buckle. CP guidance called for the removal of ½ inch of rail from the north rail, which was completed on 11 April 2019. Removing ½ inch of steel from the north rail corrected the tight rail condition, and no further action was required.

Previous TSB investigations involving track buckles

The TSB has investigated a number of derailments involving track buckles.Footnote 6 In most circumstances investigated by the TSB, the track buckled under a passing train in an area of weakened or recently disturbed track structure. The weakened track structure had lower lateral resistance to a build-up of compressive longitudinal stresses.

Summary

The urgent track geometry defects identified in the 24 July 2019 inspection indicated that the subgrade beneath the north rail had settled. These defects were unrelated to the previous tight rail condition in the general area that had been identified and corrected in April 2019. The railway stabilized the track by surfacing it on 25 July 2019 and applied a TSO. In addition, the track was inspected in accordance with CP guidance and the TSR.

Despite the repair work and inspections, the track subgrade remained unstable and the track was therefore more susceptible to the effects of increased longitudinal forces produced by the high ambient temperatures.

This report concludes the Transportation Safety Board of Canada’s investigation into this occurrence. The Board authorized the release of this report on . It was officially released on .