Main-track derailment

Canadian National Railway Company

Joliette Subdivision

near L’Assomption, Quebec

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

The occurrence

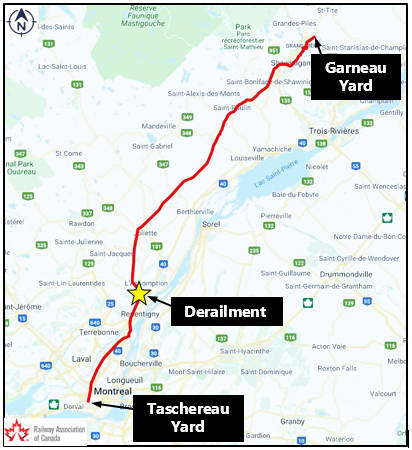

On 24 April 2019, a Canadian National Railway (CN) train crew was called for 0020Footnote 1 at Garneau Yard, in St-Georges-de-Champlain, Quebec. The crew was scheduled to operate freight train M36921-23 southward, from Garneau Yard (Mile 40.1 of the Joliette Subdivision) to Taschereau Yard (Mile 144.4 of the St-Laurent Subdivision). The required pre-departure and roll-by inspections were completed with no defects noted, and the train departed at about 0050.

The train consisted of 2 head-end locomotives, 69 loaded cars, 17 empty cars, and 8 residueFootnote 2 cars. The train weighed about 10 000 tons and was approximately 5700 feet long.

At about 0340, while the train was travelling at 40 mph near L’Assomption, Quebec (Figure 1), a train-initiated emergency brake application occurred. Once the train had stopped, the crew performed an inspection and determined that 13 cars (the 77th to the 89th cars from the head-end locomotives) had derailed and come to rest in various positions along the right-of-way at Mile 117.40 of the Joliette Subdivision. Before the emergency brakes were applied, the crew had not noticed any track or train handling anomalies. There were no injuries, and no dangerous goods were released.

At the time of the occurrence, the temperature was 4 °C, and it was raining.

Crew information

The crew consisted of a locomotive engineer and a conductor. The 2 crew members were qualified for their respective positions, met the fitness and rest standards, and were familiar with the subdivision.

Subdivision and track information

The Joliette Subdivision is a single main track running north-south from Mile 40.1 at St-Georges-de-Champlain, Quebec, to Mile 127.8 at Pointe-aux-Trembles, Quebec. Train traffic is governed by the occupancy control system up to Mile 123.8 and by the centralized traffic control system thereafter, in accordance with the Canadian Rail Operating Rules (CROR). All movements are supervised by a CN rail traffic controller located in Montréal, Quebec.

Rail traffic on this corridor consists of about 6 freight trains and 1 passenger train per day, for a total annual tonnage of about 10.1 million gross tons (MGT). This subdivision is not considered a “Key Route”Footnote 3 under the Transport Canada–approved Rules Respecting Key Trains and Key Routes.

The track on the Joliette Subdivision is a Class 4 track under the Transport Canada–approved Track Safety Rules (TSR). However, in the area of the derailment, the maximum allowable speed is 45 mph for freight trains and 50 mph for passenger trains.

The track consisted of 115-pound continuous welded rail, manufactured between 1977 and 1994. The track lay on No. 1 hardwood ties in good condition, secured on 11-inch double-shouldered tie plates and fastened with 4 spikes per plate. The rail, which was within established wear limits, was secured using 4 anchors every 3 ties. The ballast was crushed rock and was in good condition. The subgrade and drainage were adequate in the vicinity of the occurrence.

Five wayside inspection systems (WIS)Footnote 4 had been installed on the train’s route:

- Charette (Mile 60.0, Joliette Subdivision)

- Saint-Norbert (Mile 90.6, Joliette Subdivision)

- L’Assomption (Mile 118.1, Joliette Subdivision)

- Rivière-des-Prairies (Mile 130.5, St-Laurent Subdivision)

- St-Laurent (Mile 142.6, St-Laurent Subdivision)

There were also 2 dragging equipment detectors on the Joliette Subdivision (Mile 77.98 and Mile 108.42).

Track inspection

The TSR outline the minimum maintenance standards and the related track inspection requirements. In addition to the TSR, CN has its own Engineering Track Standards (ETS), whose guidelines meet or exceed the TSR requirements.

In the area of the derailment, track inspections had been carried out in compliance with the TSR. The most recent inspection was done by a qualified CN inspector on 23 April 2019. No defect was found.

The rail was tested for internal flaws on 25 January 2019, and the latest track geometry test was conducted on 12 November 2018. No urgent or near-urgent geometry defects were identified near the site of the derailment.

Site examination

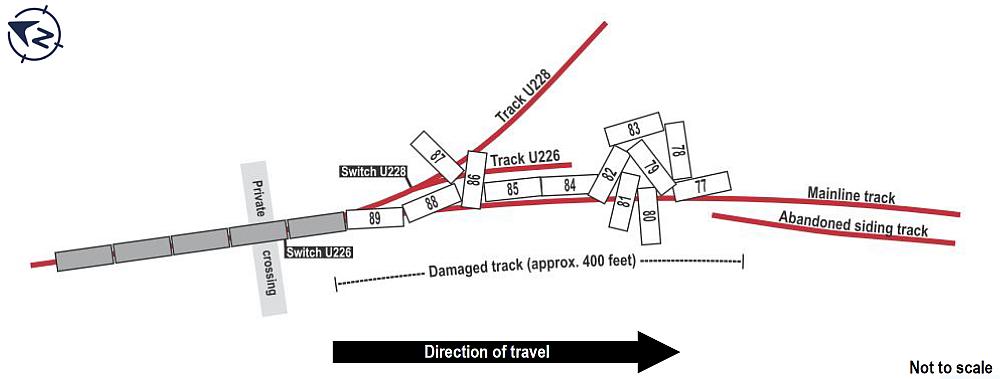

The 77th car (OCAX 6416) was lying on its side, outside of the curve (Figure 2). The next 11 cars (the 78th to the 88th cars) had derailed in an accordion-type manner. The 89th car (TOBX 889054) was upright with only the front truck wheels derailed. The last 5 cars behind the 89th car were on the rail.

The trucks of the derailed cars, along with the wheelsets and their wheels, had separated and were scattered on both sides of the track.

A burnt-off axle journal stub (Figure 3) and several broken roller bearing components were found in the grass on the east side of the track, beginning at Mile 116.85. The overheating components burned the vegetation around them. The components were sent to the TSB Engineering Laboratory for examination to determine the cause of the bearing failure.

Rail fastening elements and ties on the east side of the track showed fresh abrasion marks starting at Mile 116.89. About 150 feet away, a deep groove was visible in the ballast and on the ties between the 2 rails. The wooden planks of a private crossing and the frog of turnout U226, located at Mile 117.24, showed signs of damage. These marks show that after the axle journal broke and the wheelset derailed, the truck was dragged about 2700 feet to the site of the main pileup of derailed cars. From this point, about 400 feet of main track was destroyed.

Examination of car TR 405202

TR 405202 (the 78th car), a boxcar loaded with paper, was the first to derail. The No. 1 wheelset of the B-end truck was found under the pile of cars. The right wheel (R1) of the axle had separated and shifted laterally against the left wheel. The end of the axle had melted, and the axle journal of the right wheel and the entire roller bearing assembly were missing (Figure 4).

The underside of the car body showed a deep cut and rub marks, beneath the body bolster of the B-end truck, as well as heat- and smoke-related discolouration across from the R1 wheel position.

Axle examination

The damaged axle was manufactured in August 1970 and reconditioned in October 1979. The wheels were originally mounted on the axle in August 1998. The roller bearingsFootnote 5 were reconditioned in September 2005.

The R1 axle journal overheated and separated from the axle. The remaining axle journal profile was conical in shape, which is typical of a torsional deformation.

The R1 roller bearing was destroyed, with all its components showing discolouration, smearing, and plastic deformation. The TSB’s examination revealed that the cup raceway showed signs of spalling about 6 inches in circumference on the inner face (Figure 5). This wear most likely led to the gradual failure of the bearing cage and the seizing of the tapered rollers (Figure 6), resulting in the overheating of the assembly, the breaking of the axle and the derailing of car TR 405202.

Wayside inspection systems

The inspection of freight cars is governed by the Transport Canada-approved Railway Freight Car Inspection and Safety Rules. In addition to satisfying these inspection rules, some railway companies have also chosen to equip their networks with WIS that assess the condition of rolling stock while it is on route.

Of these systems, hot bearing detectors (HBDs) are the main tool for identifying the deterioration and overheating of roller bearings in real time. As a train passes over an HBD, optical sensors measure the bearing temperature; when they detect a temperature variation above a set limit, they trigger an alarm, allowing the railway company to take appropriate action. HBDs also monitor changes in bearing temperature throughout a train’s trip. Their effectiveness in detecting trends is related to the number of detectors passed over, the distance between each one, and how accurately they are calibrated.

Apart from Key RoutesFootnote 6, each railway company determines the distance between HBDs based on criteria such as the geographic location of the corridor, traffic volume and type, and maximum allowable speed.

Data recorded for car TR 405202

The data recorded for car TR 405202 showed that the temperature of the R1 wheel roller bearing was 74 °F when the train passed over the Charette HBD (Mile 60.0), or 42 °F above the measured ambient temperature, which was 32 °F. At that time, the average temperature of the other bearings on that side of the car was 49 °F above the ambient temperature. About 30 miles further, as the train passed over the St-Norbert HBD (Mile 90.6), the R1 wheel roller bearing’s temperature was 71 °F, or 39 °F above the measured ambient temperature (32 °F). The average temperature of the other bearings on that side of the car was 40 °F above the ambient temperature.

The R1 roller bearing overheated to the point of catastrophic failure between detectors. The melted burnt-off axle journal stub was found at Mile 116.85, 26.25 miles past the St-Norbert HBD and 1.25 miles prior to the next detector.

Other related occurrence

During another occurrence, which took place on 02 June 2013 (report R13T0122), the TSB investigated the derailment of 6 container cars of Canadian Pacific Railway (CP) freight train 119-01 at Mile 112.70 of the Parry Sound Subdivision in Wanup, Ontario. The investigation determined that the derailment was caused by the failure of a roller bearing on one of the cars. The bearing deteriorated quickly after passing over an HBD which did not detect any overheating.

Safety action taken

Following the occurrence, Canadian National Railway added a process to its corridor risk assessments whereby the spacing of WIS on secondary lines is examined within major metropolitan areas.

This report concludes the Transportation Safety Board of Canada’s investigation into this occurrence. The Board authorized the release of this report on . It was officially released on .

About the investigation

This report is the result of an investigation into a class 4 occurrence. For more information, see the Occurrence Classification Policy.

Terms of use

Non-commercial reproduction

Unless otherwise specified, you may reproduce this investigation report in whole or in part for non‑commercial purposes, and in any format, without charge or further permission, provided you do the following:

- Exercise due diligence in ensuring the accuracy of the materials reproduced.

- Indicate the complete title of the materials reproduced and name the Transportation Safety Board of Canada as the author.

- Indicate that the reproduction is a copy of the version available at [URL where original document is available].

Commercial reproduction

Unless otherwise specified, you may not reproduce this investigation report, in whole or in part, for the purposes of commercial redistribution without prior written permission from the TSB.

Materials under the copyright of another party

Some of the content in this investigation report (notably images on which a source other than the TSB is named) is subject to the copyright of another party and is protected under the Copyright Act and international agreements. For information concerning copyright ownership and restrictions, please contact the TSB.

Citation

Transportation Safety Board of Canada, Rail Transportation Safety Investigation Report R19D0065(released 08 November 2019).

Le présent rapport est également disponible en français.