Main-track train derailment

Central Maine & Quebec Railway

Freight train 630

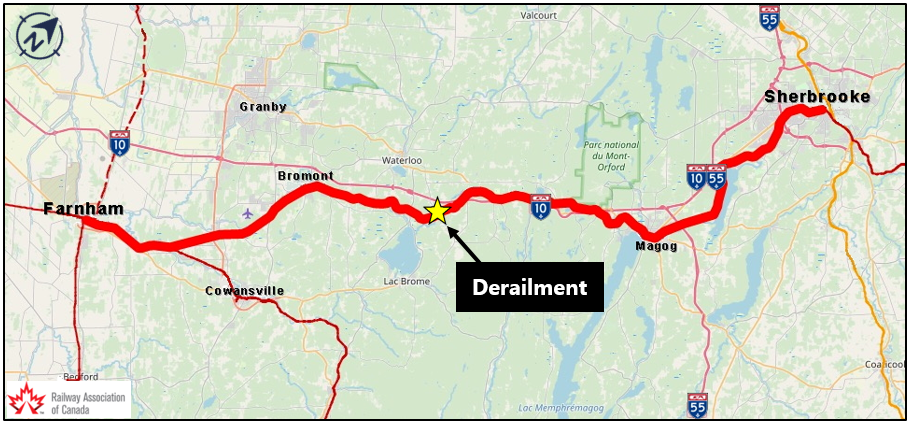

Mile 103.73, Sherbrooke Subdivision

Bolton-Ouest, Quebec

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

The occurrence

On 16 November 2019, a Central Maine & Quebec RailwayFootnote 1 (CMQ) train crew was called for 1400Footnote 2 at Sherbrooke, Quebec. The crew was scheduled to operate freight train 630 westward, from Sherbrooke (Mile 68.5 of the Sherbrooke Subdivision) to Farnham, Quebec (Mile 6.3 of the Adirondack Subdivision). The required pre-departure inspections were completed with no defects noted, and the train departed at about 1445.

The train consisted of 3 head-end locomotives, 42 loaded cars (1 of which was loaded with dangerous goodsFootnote 3) and 3 empty cars. The train weighed about 5500 tons and was approximately 3100 feet long.

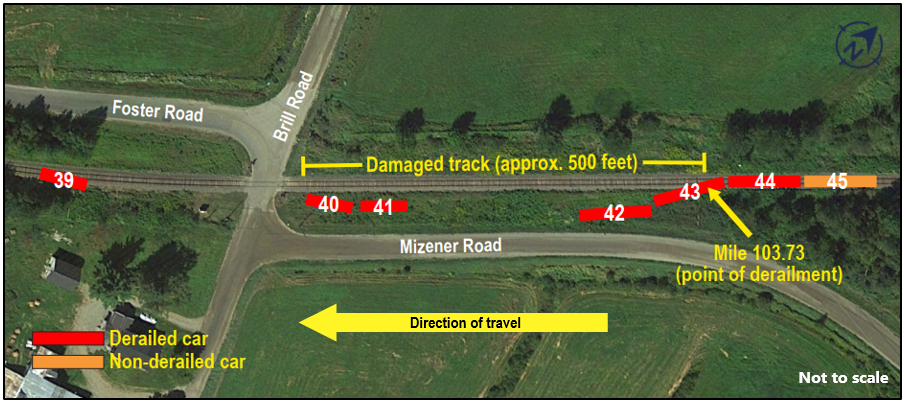

At about 1640, while the train was travelling at 16 mph near Bolton-Ouest, Quebec (Figure 1), a train-initiated emergency brake application occurred. Once the train had stopped, the crew performed an inspection and determined that 6 cars (the 39th to the 43rd from the head-end locomotives) had derailed and come to rest in various positions along the right-of-way starting at Mile 103.73 of the Sherbrooke Subdivision. Before the emergency brakes were applied, the crew had not noticed any track or train handling anomalies. There were no injuries, and no dangerous goods were released.

At the time of the occurrence, the skies were clear and the temperature was −10 °C. There was approximately 6 inches of snow on the ground near the occurrence site.

Site examination

The 39th car was the first to derail. It was upright, still partly on the track, approximately 225 feet west of the Brill Road crossing. The 40th and 41th cars were lying on their sides, approximately 50 feet from the east side of the crossing. The 42nd car was lying on its side, below the right-of-way. The 43rd car was standing across the track and was still coupled to the next car (the 44th car), which was upright on the track. The 45th car, the last car of the train, was upright and had not derailed (Figure 2). The first 3 cars that derailed were boxcars loaded with rolls of paper, and the last 3 cars were centerbeam flat cars loaded with lumber.

The paved surface of the Brill Road crossing at Mile 103.87 was damaged and deeply marked by the first derailed car.

East of this railway crossing, approximately 500 feet of track was destroyed. The north rail was still in place for most of that distance, but the south portion of the roadbed had been swept away by the scraping effect of the derailed cars, including the south rail and a large majority of the wood ties.

The damage extended to the location of the 43rd car. Eastward beyond this point, the track was intact. The south rail had broken at the point of derailment, at Mile 103.73.

Crew information

The crew consisted of a locomotive engineer and a conductor. The 2 crew members were qualified for their respective positions, met the fitness and rest standards, and were familiar with the subdivision.

Subdivision and track information

The Sherbrooke Subdivision is a single main track running east–west from Mile 0.0 at Lac-Mégantic, Quebec, to Mile 125.6 at Brookport, Quebec. Train traffic is governed by the occupancy control system, in accordance with the Canadian Rail Operating Rules. All movements are supervised by a RailTerm rail traffic controller located in Montréal, Quebec.

The track is a Class 2 track under the Transport Canada–approved Track Safety Rules (TSR). The maximum allowable speed is 25 mph for both freight and passenger trains. Rail traffic on this corridor consists of about 2 freight trains and 1 passenger train per day, for a total annual tonnage of about 1.3 million gross tons (MGT). This subdivision is not considered a “key route”Footnote 4 under the Transport Canada–approved Rules Respecting Key Trains and Key Routes.

In the area of the derailment, the track was tangent for approximately 700 feet and had a downward grade to the west of about 0.2%. The rails, each measuring 39 feet, were bolted with 4-hole joint bars. Their date of manufacture varied, with the oldest rails dating back to the 1940s. They were laid on No. 1 hardwood ties with single-shouldered 10-inch tie plates, each fastened with 2 or 3 spikes. The rails were box-anchored with 4 anchors every 3rd tie. The ballast consisted of crushed rock with shoulders approximately 12 inches from the tie ends.

Track inspection

The TSR outline the minimum maintenance standards and the related track inspection requirements. In addition to the TSR, CMQ has its own Standard Practice Circulars, whose guidelines meet or exceed the TSR requirements.

Track inspections in the subdivision had been carried out in compliance with the TSR. The most recent inspection was done by a qualified CMQ inspector on 11 November 2019. No track defect was found in the area of the derailment.

The latest track geometry test was conducted on 12 July 2019. No urgent or near-urgent geometry defects were identified near the site of the derailment.

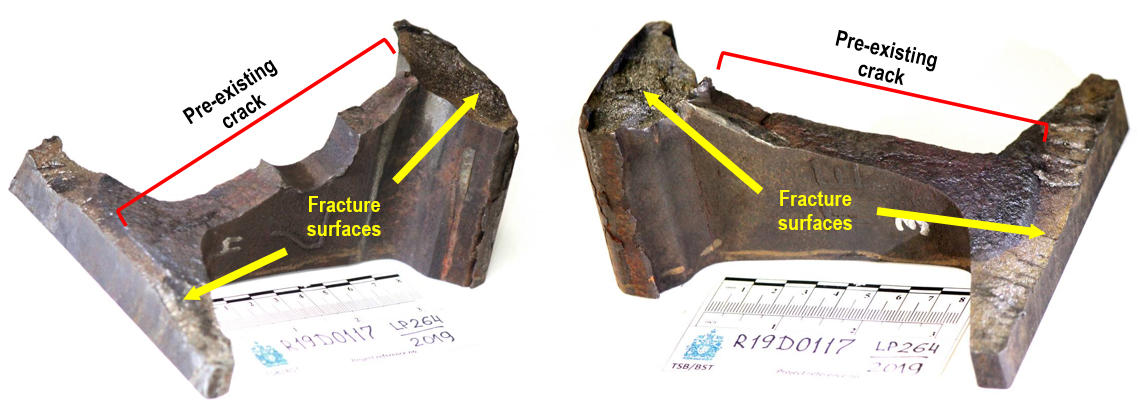

An ultrasonic rail test to detect possible internal rail defects was conducted on this section of track on 18 October 2019. At Mile 103.73, the south rail (left side of a westward train) could not be examined due to the shelling of the running surface of the rail. Therefore, on 14 November 2019, this rail had been replaced with a partly worn railFootnote 5 measuring 39 feet long (Figure 3).

Information on the broken rail

The broken rail was 100-pound RE-HF rail manufactured in 1947 by Algoma Steel of Canada.Footnote 6 A first section of the broken rail, measuring approximately 34 feet 8 inches long, was still in track. A second section, approximately 9 inches long, was found among the debris, still bolted to a pair of joint bars. Between these 2 sections, a 43-inch rail length was missing and could not be found. On the remaining section of the south rail, no markings were observed on the sides, other than the raised markings from the original manufacturing process.

A 20-inch piece of the broken rail, as well as the 9-inch fragment found among the debris, were sent to the TSB Engineering Laboratory for examination.

Examination of the broken rail

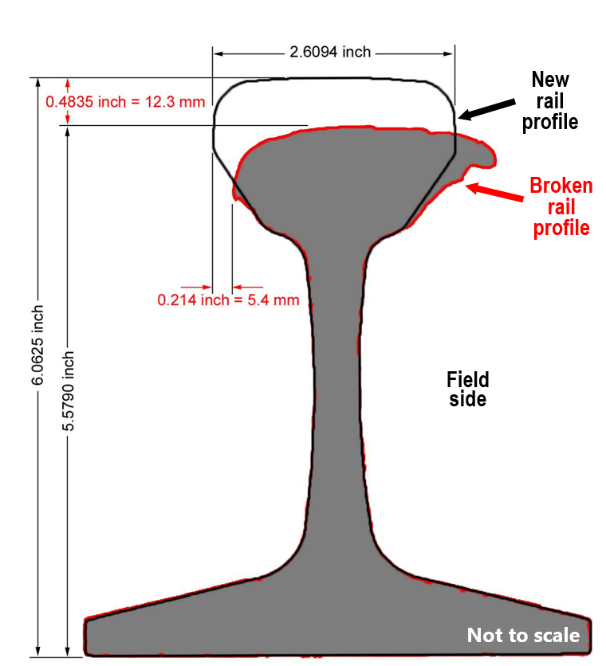

The laboratory examination (TSB Laboratory Report LP264/2019) revealed that the broken rail showed signs of advanced fatigue. It had longitudinal cracks at the head-web junction and, in many other locations, it had pre-existing internal transverse cracks in the rail web. Over time, these transverse cracks gradually extended to the lower portion of the rail head and the upper portion of the base (Figure 4), until they led to catastrophic rail failure as the train rolled over it.

In addition to internal cracks, the broken rail exhibited severe lateral plastic deformation and significant wear of the rail head. These conditions are associated with the repeated passage of heavy loads over a long period of time (Figure 5).

Wear on partly worn rails

According to the TSR, railway companies are required to establish maximum wear limit criteria for the rails in service on their network.Footnote 7

CMQ’s Standard Practice CircularsFootnote 8 in effect at the time of the occurrence included wear limits for several types of rails in service. They did not, however, contain a specific limit value for 100-pound RE-HF rail, the type of rail involved in this occurrence.

Canadian Pacific Railway (CP)Footnote 9 sets wear limits for rail in service from a combination of lateral and vertical measurements. With respect to wear on the running surface of 100-pound RE-HF rail, given a lateral wear measurement of 5.4 mm (as indicated in Figure 5), the allowed vertical wear limit would be set at 8.7 mm. When there is no gauge face wear, the maximum vertical rail wear limit would be set at 11.1 mm.

In this occurrence, the vertical wear on the running surface of the broken rail was 12.3 mm. Furthermore, there was no marking on the rail identifying the date of the last ultrasonic test. Given this level of wear, this section of rail should have been identified as scrap rail unfit for reuse.Footnote 10

Other relevant occurrence

Following a TSB investigation into the 03 August 2005 derailment in Wabamun, Alberta,Footnote 11 the Board recommended that

the Department of Transport establish “minimum standards for the quality and strength of maintenance rails.

TSB Recommendation R07-01

Given that the major freight railway companies had established minimum standards for replacement (maintenance) rails and that the May 2012 revision of the TSR specified that railway companies had to have such standards, the TSB assessed the Department of Transport's response to this recommendation as being Fully Satisfactory.

Safety message

Under the TSR, each railway company must establish adequate standards applicable to each type of rail in service to ensure that the structural integrity of the rail is not compromised. When evaluating rail for subsequent reuse, these standards must be applied consistently to ensure that defective rail is not inadvertently placed into service.

This report concludes the Transportation Safety Board of Canada’s investigation into this occurrence. The Board authorized the release of this report on . It was officially released on