Main-track train derailment

Canadian Pacific Railway

Train 201-27

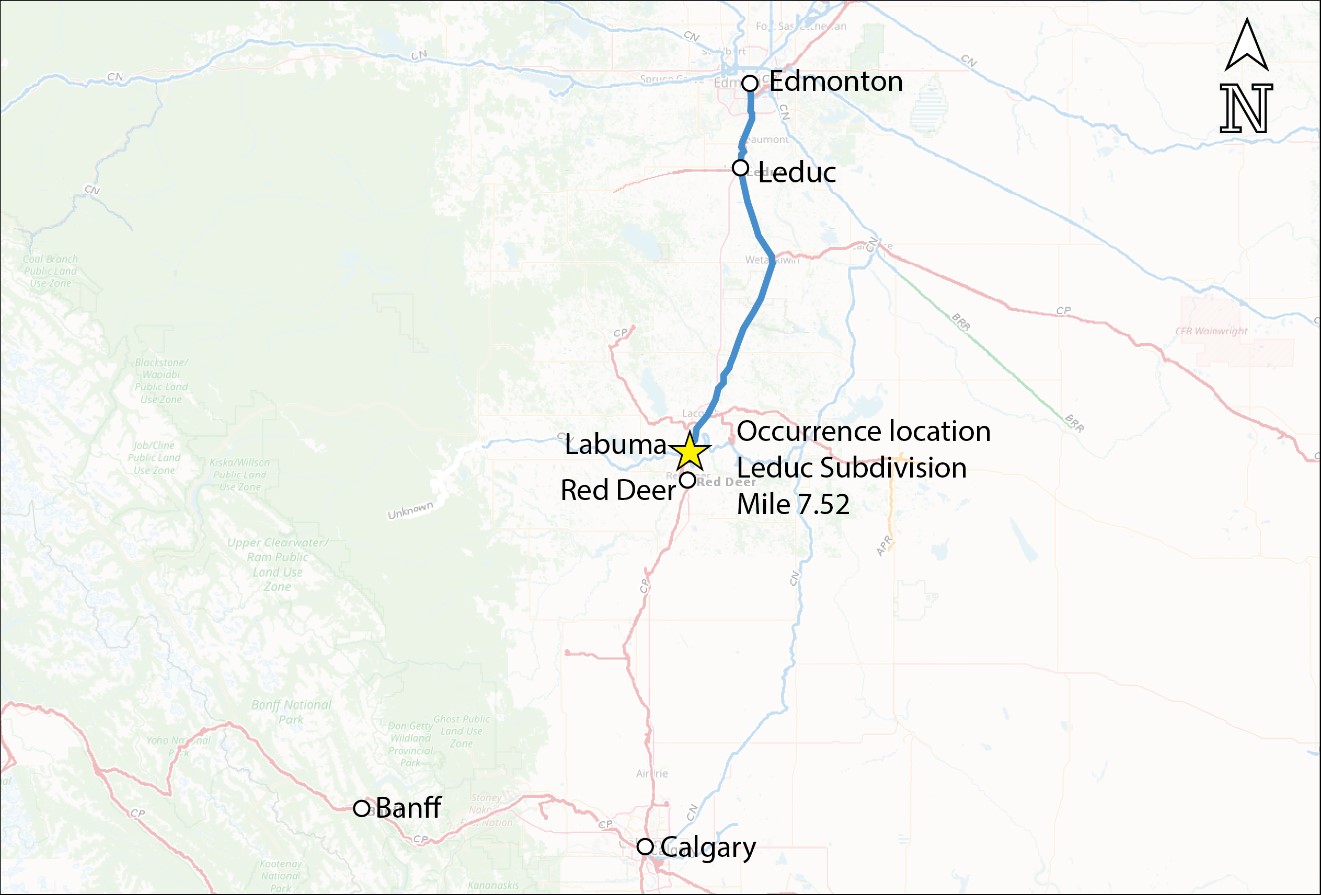

Mile 7.52, Leduc Subdivision

Blackfalds, Alberta

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

On 27 September 2019, at approximately 2236 Mountain Daylight Time, Canadian Pacific Railway train 201-27, travelling southward at approximately 22 mph on the Leduc Subdivision, derailed 9 loaded tank cars carrying flammable liquids (positions 51 to 59) at Mile 7.52 near Blackfalds, Alberta. As a result of the derailment, diesel fuel (UN1202) was released from 1 tank car, and octanes (UN1262) were released from 2 tank cars. There were no injuries or fire.

1.0 Factual information

Canadian Pacific Railway (CP) train 201-27 originated from Lambton Park (Edmonton, Alberta) and was travelling southward en route to Coquitlam, British Columbia. The distributed-power mixed-freight key train (Appendix A) had locomotive CP 8008 on the head end and CP 8756 on the tail end, with 70 loaded cars and 5 empty cars. It weighed 9249 tons and was 4321 feet long. The operating crew consisted of a locomotive engineer and conductor; both crew members met established rest and fitness requirements and were qualified for their respective positions. The train had undergone a successful No. 1 brake testFootnote 1 before departing Lambton Park.

1.1 The occurrence

The train experienced a train-initiated emergency brake application while travelling at 22 mph in throttle position 7Footnote 2 near Labuma, Alberta, approximately 8 km north of Red Deer, Alberta (Figure 1).

The train crew had not noticed any pre-existing track condition as the head-end portion of the train passed over the derailment location, nor did a subsequent review of recordings from the forward-facing video camera on the lead locomotive reveal any visible track defects at that location.

Once the train had stopped, the crew conducted an inspection and discovered that 9 cars had derailed. The derailed cars included 2 tank cars containing diesel fuel (Class 3, UN1202), 6 tank cars containing octanes (Class 3, UN1262), and 1 tank car containing jet fuel (Class 3, UN1863, Fuel, aviation, turbine engine). The derailment occurred at Mile 7.52 of the Leduc Subdivision, north of the Range Road 272 crossing. The point of derailment (POD) was on the east rail between the Labuma north switch at Mile 7.0 and the Canadian National Railway Company (CN) connection track at North Jct (junction), Mile 7.6 (Figure 2).

As a result of the derailment, diesel fuel was released from 1 tank car, and octanes were released from 2 tank cars. There were no injuries or fire reported.

At the time of the occurrence, the ambient temperature was about −1.2 °C, with wind from the northeast at 12 km/h. Light snow was falling.

1.2 Site examination

Site inspection revealed that 9 general-purpose non-pressurized tank cars had derailed north of the Range Road 272 crossing and had come to rest in various orientations. The 9 derailed cars were transporting diesel fuel, octanes, and jet fuel (Table 1). All 9 DOT 111 tank cars were compliant with specification CPC-1232.Footnote 3,Footnote 4

| Car no. | Position in train | Product | Orientation | Containment status |

|---|---|---|---|---|

| CTCX 743546 | 51 | Diesel fuel | On side, foul of the road | No product loss |

| CGTX 30182 | 52 | Diesel fuel | On side, east side of track | Released 107 258 L of diesel fuel |

| PROX 47041 | 53 | Octanes | On side, east side of track | No product loss |

| PROX 45852 | 54 | Octanes | On side, east side of track | No product loss |

| PROX 43787 | 55 | Octanes | On side, perpendicular to track | Released 107 466 L of octanes |

| PROX 43741 | 56 | Octanes | On side, perpendicular to track | Released 80 601 L of octanes |

| PROX 45379 | 57 | Octanes | On side, east of track | No product loss |

| PROX 47043 | 58 | Octanes | Upright on the track | No product loss |

| ICRX 215224 | 59 | Jet fuel | Upright on the track | No product loss |

Three of the derailed cars had sustained damage that led to containment failure:

- The 52nd car, CGTX 30182 (Figure 3), had released product from a knuckle collision impact, as well as from a puncture 2 inches in diameter, 12 inches below the initial breach.

- The 55th car, PROX 43787 (Figure 4), had released product from an end puncture.

- The 56th car, PROX 43741 (Figure 5), had released product from a bottom outlet valve that had been sheared off either from contact with the ground or from impact with derailment debris.

A review of maintenance records indicated that the 3 cars had been maintained to industry and regulatory standards.

About 180 feet of track was damaged or destroyed. Three rail sections were recovered from the east rail at the POD and were sent to CP’s test department in Winnipeg, Manitoba, for analysis.

The derailed equipment also collided with, and knocked over, a wayside support structure for an overhead 138 kV electrical power line; however, power transmission was not interrupted.

1.3 Incident response and remediation

The derailment site was secured, with all access points controlled under a unified command response. Attending on site were the Lacombe County Fire Department, CP, the Royal Canadian Mounted Police, Transport Canada (TC), Alberta Transportation, and Alberta Environment.

CP’s hazardous materials emergency response team contained the dangerous goods release, and vacuum trucks were used to remove spilled liquid from the derailment area.

Due to the dangerous goods release, Highway 2A was closed to vehicular traffic between Township Road 391 and Township Road 392. In addition, vehicular access to Range Road 272 was controlled on either side of the derailment site. Roadways were re-opened to vehicular traffic in the mid-afternoon on 28 September. No evacuation was required.

CP and its contractors performed site clean-up and remediation.

1.4 Particulars of the track

The Leduc Subdivision extends between South Edmonton, Mile 96.9, and Red Deer, Mile 2.8. Train movements on the subdivision are governed by an occupancy control system and supplemented with an automatic block signal systemFootnote 5 between Mile 7.5 and Mile 92.6, as authorized by the Canadian Rail Operating Rules and dispatched by a CP rail traffic controller located in Calgary, Alberta.

The maximum permissible freight train speed is 35 mph from Mile 2.8 to Mile 10.5, making this section of the subdivision Class 3 track under the TC-approved Rules Respecting Track Safety,Footnote 6 also known as the Track Safety Rules.

The track is on a 0.5% descending grade southward. It consists of 115-pound Algoma REFootnote 7 continuous welded rail, manufactured in 1980 and installed on 14-inch tie plates fastened to hardwood ties with 3 spikes per plate.

Train traffic through the area of the POD was 35.6 million gross ton-miles per mile (GTM/M) in 2016, 36.4 GTM/M in 2017, and 41.78 GTM/M in 2018.

Table 2 shows the volume of dangerous goods on the Leduc Subdivision for the 3 years preceding the occurrence.

| Year | Number of car loads |

|---|---|

| 2017 | 92 168 |

| 2018 | 113 027 |

| 2019 | 110 918 |

1.4.1 Track upgrades

CP reported that, in 2018, 6638 ties were installed to break up clusters of worn ties, and 141 134 feet of new 136-pound rail were installed on curves to eliminate track joints.

However, the track between the Labuma north switch and North Jct (including the POD), as well as the CN connection track (including the Range Road 272 crossing), were not part of this upgrade.

1.4.2 Rail wear

The Track Safety Rules require railways to set standards for rail wear. Wear limits for rail are a combination of vertical and gauge (lateral) wear. For the track in this occurrence, vertical wear was measured at ⅝ inch and gauge (lateral) wear was ¼ inch. According to CP’s Red Book of Track & Structures Requirements, for 115-pound RE rail with vertical wear of ⅝ inch, lateral wear exceeding 3/16 inch requires rail to be removed from track.Footnote 8

1.5 Laboratory analysis of the failed rail

The CP test department received the 3 pieces of broken rail recovered at the accident site. The pieces fit together and measured a total length of 60 inches.

Examination of the recovered rail revealed that the rail head running surface displayed gauge corner shellingFootnote 9 and head checkingFootnote 10 (Figure 6).

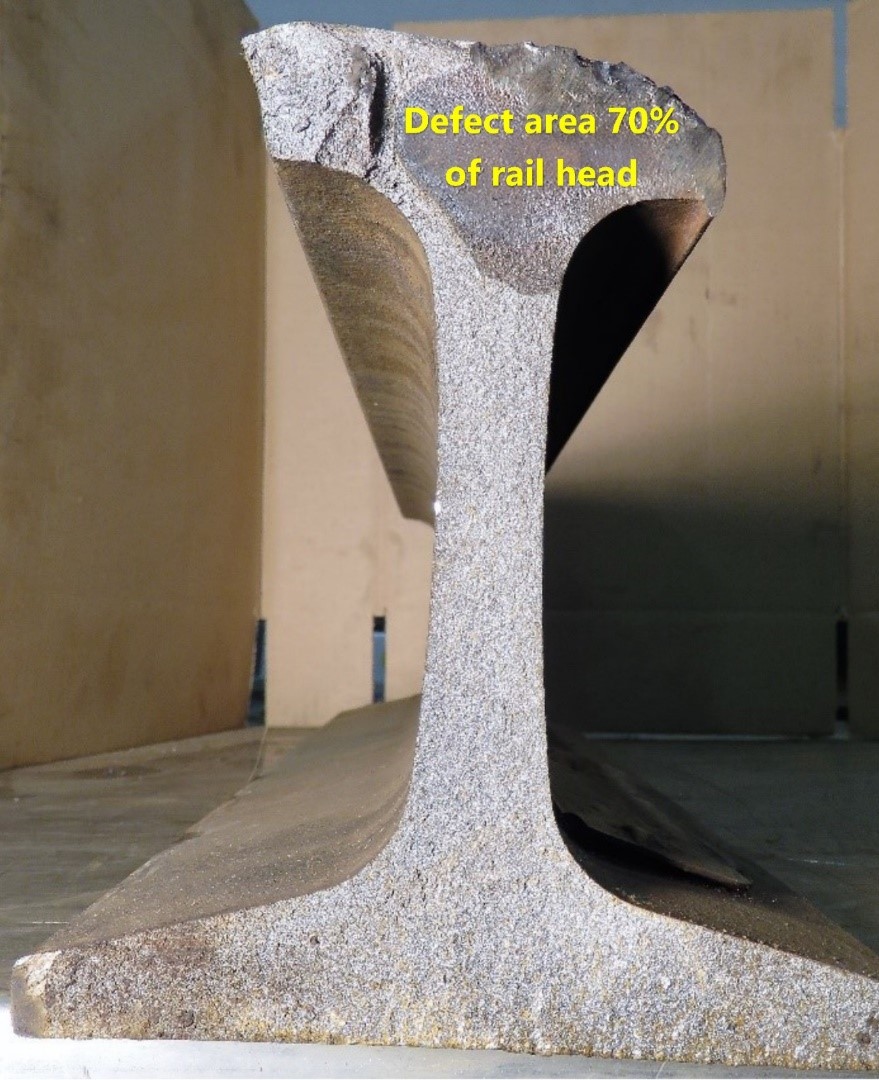

Two of the pieces of recovered rail exhibited pre-existing detail fractures on the fracture faces. Detail fractures are classed within a group of fatigue defects known as transverse detail defects (TDDs), in which the plane of the crack is perpendicular to the running direction of the rail.

The size of a TDD is commonly recorded as a percentage of the head area of the rail. The analysis determined that the TDD observed on the primary fractured rail accounted for approximately 70% of the rail head cross-section (Figure 7). This TDD was observed at the primary fracture and originated from the root of a spall.Footnote 11 A second pre-existing detail fracture that accounted for approximately 25% of the rail head cross-section was observed at the second break.

The photo of the rail fracture face in Figure 7 shows a well-defined defect that closely resembles a defect with normal and sudden growth patterns.Footnote 12

The chemical composition and hardness of the rail were considered typical for plain carbon steel that conformed to CP specifications dated 01 November 1980. The rail internal condition was sound and homogeneous. There was no evidence of any material, manufacturing, or metallurgical defects in the rail.

1.6 Transverse detail defects

A transverse detail defect is a progressive fracture of the rail starting from a longitudinal separation close to the running surface, usually originating at the upper gauge corner, and spreading transversely through the rail head. The defect may not be identified until the rail breaks because the longitudinal separation or seam in a detail fracture is rarely exposed. Thus, failure can occur before the defect becomes visible. The defect generally results in a complete break in the rail, when the remaining head area can no longer support the load.

The growth rate of a TDD is considered highly unpredictable. Research has been conducted to develop models to predict growth rates. The results indicate that the number of detail fractures increases exponentially in relation to tonnage carried. From initiation to 10% of the rail cross-sectional head area, defects grow relatively slowly, but the rate of growth increases after 10%. From 10% to 80% of the cross-sectional head area,Footnote 13,Footnote 14 detail fractures grow at a constant rate over time. However, at some point, around 80%, the growth rate increases exponentially, leading to total rail failure.

1.7 Detection of transverse detail defects through ultrasonic testing

Railways typically monitor rail health with frequent testing using a rail flaw detector (RFD). Ultrasonic testing (UT) is the RFD testing method for identifying internal rail defects such as TDDs to proactively manage the risk of rail failures.

UT hi-rail vehicles are equipped with an undercarriage test platform that contains multiple fluid-filled roller search units for each rail. Each unit contains a number of transducers that emit high-frequency ultrasonic sound energy into the rail. The liquid filler facilitates the transmission of the sound energy from the transducers into the rail. Analysis of the path of the sound energy penetrating the rail can lead to detection of vertical and transverse defects within the rail, as well as non-metallic inclusions and voids.

A defect is suspected if any condition results in the ultrasonic signal being reflected before reaching the the base or side of the rail. The RFD operator must use skill and experience to determine the validity of such an indication. The operator may erroneously conclude that a rail defect is present when, in fact, it is not (false positive) or that an indication is spurious when, in fact, it is real (false negative).

UT can be a reliable, efficient, and effective method of RFD testing. However, as with all non-destructive testing methods, it has limitations. Among these, the detectability of defects depends on the size and orientation of the transverse portion of the defect. As well, test results can be affected by contamination on the rail surface and by other factors, such as rail head checking and shelling.Footnote 15 Such conditions can inhibit the transmission of sound energy into the rail head, masking internal defects. Rail surfaces must be smooth and clean to optimize defect detection.

1.8 Testing of the occurrence rail

The frequency of RFD testing on the Leduc Subdivision exceeded regulatory requirements.Footnote 16

In 2019, before the occurrence, the rails in the area of the derailment were tested using UT by Sperry Rail ServiceFootnote 17 on 5 separate occasions: 23 January, 13 March, 06 May, 23 July, and 28 August. During the first 4 tests, 3 head and web joint and 2 bolt hole joint defects were detected. No defects were found in the area of the derailment during the 28 August 2019 test. Whether the TDD in this occurrence was present when the last UT was carried out 30 days before the derailment cannot be known with certainty. The operator performing the tests was a qualified operator with 15 years of experience using RFD equipment.

The track geometry was tested 4 times by an unmanned geometry car in 2019 and twice by a track evaluation car on 16 April 2019 and 25 July 2019. On both occasions, the test detected 3 priority defects:Footnote 18 SPXLV (spiral cross level over 31 feet), RC/20 (rate of change over 20 feet), and RC/62 (rate of change over 62 feet) between Mile 7.54 and Mile 7.58, at the beginning of the curve of the CN connection track to the north. The 16 April 2019 test also found an urgent SPXLV defect at Mile 7.58. This urgent defect was protected with a 72-hour slow order. The area was surfaced on 18 April 2019 to remove this defect.

The track was last visually inspected on 27 September 2019, the day of the occurrence, and no defects were noted.

1.9 Rail grinding

To optimize the effectiveness of the ultrasonic inspection technology, rails can be ground to remove rail surface defects. There are no regulatory requirements regarding rail grinding.

Rail grinding using a 24-stone on-track switch and crossing grinding machineFootnote 19 was conducted on the Leduc Subdivision in the area of the derailment on 15 June 2019. The rail surface examined after the derailment showed head checking and shelling despite this grinding (Figure 6).

1.10 Other similar occurrences

In addition to this occurrence, the TSB has investigated 12 occurrences in the last 15 years in which rail surface conditions contributed to undetected rail defects.Footnote 20

1.11 Transportation of flammable liquids by rail

The 2013 accident in Lac-Mégantic, Quebec, in which 47 people were fatally injured after 63 tank cars carrying petroleum crude oil (UN1267) and 2 box cars derailed, resulted in fires, explosions, and the release of about 6 million litres of crude oil.Footnote 21 Following the accident, TC reviewed the requirements for the design of tank cars used for the transportation of flammable liquids. In May 2015, TC and the United States Pipeline and Hazardous Materials Safety Administration (PHMSA) introduced a new tank car standard (TC-117/DOT-117), established retrofit requirements, and specified implementation timelines to modernize and improve the tank car fleet for the transportation of Class 3 flammable liquids.

Also as a result of the Lac-Mégantic accident, the TSB issued 3 recommendations directly related to the transportation of flammable liquids by rail, 2 of which the Board has assessed as Fully Satisfactory.Footnote 22,Footnote 23

In the third recommendation, the Board recommended that

the Department of Transport and the Pipeline and Hazardous Materials Safety Administration require that all Class 111 tank cars used to transport flammable liquids meet enhanced protection standards that significantly reduce the risk of product loss when these cars are involved in accidents.

TSB Recommendation R14-01

In its March 2021 reassessment of PHMSA’s responses to Recommendation R14-01, the Board acknowledged PHMSA’s efforts in collecting information on tank car retrofits and reporting this information annually. The Board noted that a well-defined phase-out schedule of older tank cars is in place and that PHMSA is monitoring the industry’s progress in that regard. This will help ensure that, by 01 May 2029,Footnote 24 all flammable liquids in the United States are transported in more robust Class 117 tank cars. Therefore, the Board considered PHMSA’s response to Recommendation R14-01 to show Satisfactory Intent.Footnote 25

In its March 2021 reassessment of TC’s responses to Recommendation R14-01, the Board acknowledged TC’s implementation of improved risk control measures for trains carrying large volumes of flammable liquids. The Board also noted that a well-defined phase-out schedule of older tank cars is in place and that TC is monitoring the industry’s progress in that regard. These steps will help ensure that, by 01 May 2025, all flammable liquids in Canada are transported in Class 117 tank cars.

The Board also acknowledged TC’s continuing efforts to characterize and evaluate the crashworthiness of Class 117 tank cars involved in accidents. The Board noted that ongoing TSB investigations (R19W0050 and R19W0320) will assess the performance of Class 117 tank cars in train accidents and the subsequent risk of product loss. Until the results of these assessments are known, the Board considered TC’s response to Recommendation R14-01 to show Satisfactory Intent.Footnote 26

Following an occurrence on 14 February 2015 in Gladwick, Ontario, in which a CN crude oil unit train derailed 29 tank cars, 19 of which were breached and released about 1.7 million litres of petroleum crude oil,Footnote 27 the Board recommended that

the Department of Transport conduct a study on the factors that increase the severity of the outcomes for derailments involving dangerous goods, identify appropriate mitigating strategies including train speeds for various train risk profiles and amend the Rules Respecting Key Trains and Key Routes accordingly.

TSB Recommendation R17-01

Since this recommendation, TC commissioned the National Research Council Canada to complete a report entitled Study on the Factors that Increase the Severity of the Outcomes for Derailments Involving Dangerous Goods and Identification of Mitigation Measures, available to the public as of September 2020, and TC approved the revised Rules Respecting Key Trains and Key Routes on 22 February 2021, with an effective date of 22 August 2021. In its March 2021 reassessment of TC’s response to Recommendation R17-01, the Board stated that both measures were completed and that Recommendation R17-01 had been fulfilled. The Board considered the response to Recommendation R17-01 to be Fully Satisfactory.Footnote 28

1.11.1 Actions taken in response to derailments involving flammable liquids

Because the railway networks in Canada and the United States are interconnected, the transportation of flammable liquids by rail is an issue that affects all of North America. Since 2013, in response to the challenge, the following initiatives have been completed or are underway:

- Railway companies have developed emergency response assistance plans for whenever large volumes of liquid hydrocarbons are being transported.

- TC requires railway companies to set criteria for the operation of trains carrying dangerous goods (e.g., speed restrictions within census metropolitan areas).

- Transport Canada Ministerial Order 20-10 requires railway companies to conduct route planning and analysis. As well, the Rules Respecting Key Trains and Key Routes, effective 19 February 19 2016, require companies to conduct risk assessments and periodic updates based on significant change to determine the level of risk associated with each key route over which the company operates key trains to ensure that the risk control measures are effective (Appendix A).

- Railway companies are required to share information with the communities along the railway right-of-way about the types and quantities of dangerous goods transported.

- The “legacy” tank cars (DOT/TC-111) are no longer permitted to be used to transport crude oil.

- The newer tank cars are being built to more robust safety standards.

- The most vulnerable tank cars used to transport crude oil were removed from service.

- By 01 May 2025, all flammable liquids must be transported in DOT/TC-117 tank cars, which are built to more robust safety standards. Thus, DOT/TC-117 tank cars will become the minimum standard.

1.11.2 TSB investigations involving the release of dangerous goods from tank cars

Since the Lac-Mégantic accident, the TSB has investigated a number of occurrences involving the release of dangerous goods from tank cars following a derailment or collision. These occurrences highlight the vulnerability of tank cars to accident damage and product release. Appendix B lists completed TSB investigations of these occurrences.

2.0 Analysis

The train was operated in a manner consistent with company and regulatory requirements. The cars involved in the derailment had been maintained in accordance with industry standards, and no pre-existing defects were discovered that played a role in this derailment. Therefore, the analysis will focus on the condition of the rail at the point of derailment, the detection of transverse detail defects (TDDs), and the transportation of flammable liquids by rail.

2.1 The occurrence

A TDD at the point of derailment had originated from head check cracks at the upper gauge corner of the rail head. Over time, the crack had progressed in normal and sudden growth pattern to cover approximately 70% of the cross-sectional area of the rail head. The remaining rail section then failed in overstress once it could no longer support service loads.

The fractured rail broke up under the train, creating a gap in the track and leading to the derailment of the 51st to the 59th cars.

Finding as to causes and contributing factors

The train derailed when a sudden and catastrophic rail failure occurred under the train, due to an undetected TDD.

2.2 Rail ultrasonic testing

Ultrasonic testing (UT) is the primary method used to detect internal rail defects and control the risk of rail failures. It has proven to be a reliable, efficient, and effective method to test rail, but it has limitations. Detail fractures cannot always be detected or identified because of their orientation in relation to the surface of the rail, or because they are masked by rail surface contamination or defects above the detail fracture. Under these conditions, the ultrasonic signal may not adequately penetrate the rail surface.

The TDD had originated from the root of a spall on the gauge corner of the rail head.

Finding as to causes and contributing factors

The defect grew to a critical size, such that the remaining rail could no longer support the load of the passing train.

Despite frequent testing using a rail flaw detector, including a test conducted 30 days before the derailment, the defect remained undetected.

Whether the TDD in this occurrence was present when the last UT was carried out 30 days before the derailment cannot be known with certainty.

2.3 Rail surface condition

UT can be unreliable when the rail surface condition is poor or contaminated. Rail grinding programs remove rail surface defects and maximize the effectiveness of ultrasonic inspection technology. Since 2005, the TSB has investigated 12 other occurrences involving rail breaks due to undetected internal defects.

Finding as to risk

If surface defects on rails are not removed before ultrasonic testing using a rail flaw detector, there is a risk that internal rail defects will remain undetected, leading to rails breaking under load by passing trains and subsequently to derailments.

Findings as to causes and contributing factors

The rail surface condition likely inhibited the transmission of the UT signals into the rail head, adversely affecting the ability of the inspection equipment to detect internal defects.

The extent and depth of head checking and shelling on the rail surface indicate that the rail grinding conducted on 15 June 2019 was insufficient to remove the rail surface contamination and defects before UT on 28 August 2019.

2.4 Rail wear

At the point of derailment, the rail exhibited vertical wear of ⅝ inch and gauge (lateral) wear of ¼ inch. For 115-pound RE rail with vertical wear of ⅝ inch, lateral wear exceeding 3/16 inch requires rail to be removed from track.

Finding as to causes and contributing factors

Although lateral wear exceeded railway requirements by 1/16 inch, requiring rail to be removed from track, the rail remained in service until an undetected TDD progressed to the point of failure.

2.5 Transportation of flammable liquids by rail

Following the accident in Lac-Mégantic in July 2013,Footnote 29 Transport Canada (TC) reviewed the requirements for the design of tank cars used for the transportation of flammable liquids. In May 2015, TC and the United States Pipeline and Hazardous Materials Safety Administration introduced a new tank car standard (DOT/TC-117), established retrofit requirements, and specified implementation timelines to modernize and improve the tank car fleet for the transportation of Class 3 flammable liquids. However, mandatory requirements for the shipment of all Class 3 flammable liquids by rail in DOT/TC-117 tank cars do not take effect until 01 May 2025.

Since the Lac-Mégantic accident, the TSB has investigated 9 occurrences involving the release of dangerous goods from tank cars following a derailment or collision. These occurrences highlight the vulnerability of tank cars to accident damage and product release.

In this occurrence, the train was travelling at 22 mph when it derailed, well below the maximum permissible track speed of 35 mph. The damage sustained by the 3 DOT/TC-111 tank cars that released product highlights the vulnerabilities of these tank cars. While only 3 cars lost product, there was potential for more catastrophic consequences. The fact that the 3 cars that lost product were compliant with specification CPC-1232, and had design improvements over the legacy DOT/TC-111 tank cars, supports the need for the ongoing replacement of these older tank cars with ones designed to the new standard.

Finding as to risk

Until all Class 3 flammable liquids are transported in more robust tank cars, loss of product is likely to continue to occur in derailments, even at relatively low speeds, perpetuating the risk of significant damage to persons, property, and the environment.

2.6 Emergency response

A unified incident command structure was established, which included all responding jurisdictions and agencies. This command structure facilitated the rapid mobilization and efficient and effective use of resources.

Finding: Other

Appropriate measures were taken to protect the site and ensure public safety immediately following the derailment.

3.0 Findings

3.1 Findings as to causes and contributing factors

These are conditions, acts or safety deficiencies that were found to have caused or contributed to this occurrence.

- The train derailed when a sudden and catastrophic rail failure occurred under the train, due to an undetected transverse detail defect.

- The defect grew to a critical size, such that the remaining rail could no longer support the load of the passing train.

- Despite frequent testing using a rail flaw detector, including a test conducted 30 days before the derailment, the defect remained undetected.

- The rail surface condition likely inhibited the transmission of the ultrasonic testing signals into the rail head, adversely affecting the ability of the inspection system to detect internal defects.

- The extent and depth of head checking and shelling on the rail surface indicate that the rail grinding conducted on 15 June 2019 was insufficient to remove the rail surface contamination and defects before ultrasonic testing on 28 August 2019.

- Although lateral wear exceeded railway requirements by 1/16 inch, requiring rail to be removed from track, the rail remained in service until an undetected transverse detail defect progressed to the point of failure.

3.2 Findings as to risk

These are conditions, unsafe acts or safety deficiencies that were found not to be a factor in this occurrence but could have adverse consequences in future occurrences.

- If surface defects on rails are not removed before ultrasonic testing using a rail flaw detector, there is a risk that internal rail defects will remain undetected, leading to rails breaking under load by passing trains and subsequently to derailments.

- Until all Class 3 flammable liquids are transported in more robust tank cars, loss of product is likely to continue to occur in derailments, even at relatively low speeds, perpetuating the risk of significant damage to persons, property, and the environment.

3.3 Other findings

These items could enhance safety, resolve an issue of controversy, or provide a data point for future safety studies.

- Appropriate measures were taken to protect the site and ensure public safety immediately following the derailment.

4.0 Safety action

4.1 Safety action taken

4.1.1 Canadian Pacific Railway

The track between the Labuma north switch and the Canadian National Railway Company connection track switch, including the turnouts, was upgraded to 136-pound rail. The turnout frogs were also upgraded to lift-type frogs.

4.1.2 Transport Canada

On 06 November 2020, Transport Canada (TC) issued Ministerial Order 20-10, which provided additional requirements to operate a “higher risk key train” at prescribed speed limits. Among those additional requirements, railways may implement speed restrictions based on temperature rather than time of year. To do so, they must implement a winter operation risk mitigation plan that prescribes, for a subdivision or portions of a subdivision, a rail grinding frequency that ensures that rail surface conditions do not hinder the detection of internal rail defects during rail flaw inspections.

This report concludes the Transportation Safety Board of Canada’s investigation into this occurrence. The Board authorized the release of this report on . It was officially released on .

Appendices

Appendix A – Key trains and key routes

Train 201-27 was a mixed-freight key train with 27 of its 70 loaded cars containing hazardous materials, including diesel fuel (UN1202, positions 38 to 52), liquefied petroleum gas (UN1075, positions 31 and 37), octanes (UN1262, positions 30 and 53 to 58), and jet fuel (UN1863, positions 59 to 61). “Key train” is defined as

- an engine with cars

- that includes one or more loaded tank cars of dangerous goods that are included in Class 2.3, Toxic Gases and of dangerous goods that are toxic by inhalation subject to Special Provision 23 of the Transportation of Dangerous Goods Regulations; or

- that includes 20 or more loaded tank cars or loaded intermodal portable tanks containing dangerous goods, as defined in the Transportation of Dangerous Goods Act, 1992 or any combination thereof that includes 20 or more loaded tank cars and loaded intermodal portable tanks.Footnote 30

“Key route” is defined as

any track on which, over a period of one year, is carried 10,000 or more loaded tank cars or loaded intermodal portable tanks containing dangerous goods, as defined in the Transportation of Dangerous Goods Act, 1992 or any combination thereof that includes 10,000 or more loaded tank cars and loaded intermodal portable tanks.Footnote 31

Appendix B – TSB investigations involving the release of dangerous goods from tank cars

R20W0031 – CN derailment at Emo, Ontario, 18 February 2020

On 18 February 2020, a Canadian National Railway Company (CN) train was proceeding eastward at about 44 mph on the CN Fort Frances Subdivision. At 2036 Central Standard Time, the train experienced a train-initiated emergency brake application at Mile 108.22 near Emo, Ontario. Subsequent examination identified that 31 cars had derailed, including 26 crude oil cars. Five of the derailed crude oil cars had released petroleum crude oil. Six homes in the area were evacuated as a precautionary measure. There were no injuries and no fire.

R19C0094 – CP derailment at Barons, Alberta, 02 September 2019

On 02 September 2019, a locomotive and 21 cars from a Canadian Pacific Railway (CP) freight train derailed at Mile 17.8 of the Aldersyde Subdivision near Barons, Alberta. Three of the cars involved were loaded dangerous goods tank cars that leaked an undetermined amount of octanes, a flammable liquid. Emergency services implemented a temporary evacuation order and rerouted vehicular traffic in the occurrence area due to the dangerous goods release. There were no injuries or fire reported.

R15E0173 – CP derailment at Scotford, Alberta, 08 December 2015

On 08 December 2015, at about 1515 Mountain Standard Time, CP switching assignment AS-01, which was being operated by a remote control locomotive system, derailed 4 loaded tank cars while performing switching operations. Two cars remained upright, 1 car came to rest on its side, and 1 car rolled into a ditch, coming to rest upside down and releasing most of its contents. The cars contained styrene monomer, stabilized (UN2055), a Class 3 flammable liquid. The released product was confined to the ditch. There were no injuries.

R15H0021 – CN derailment at Gogama, Ontario, 07 March 2015

On 07 March 2015, at 0242 Eastern Standard Time, CN crude oil unit train U70451-02 was proceeding eastward at about 43 mph on CN’s Ruel Subdivision when it experienced a train-initiated emergency brake application at Mile 88.70, near Gogama, Ontario. A subsequent inspection determined that the 6th to the 44th cars (39 cars in total) had derailed. As a result of the derailment, about 2.6 million litres of petroleum crude oil (UN1267) was released to atmosphere, water, or surface. The released product ignited and caused explosions, and some product entered the nearby Makami River. A CN bridge over the Makami River (at Mile 88.70) and about 1000 feet of track were destroyed. There was no evacuation, and there were no injuries.

R15H0013 – CN derailment at Gladwick, Ontario, 14 February 2015

On 14 February 2015, at about 2335 Eastern Standard Time, CN crude oil unit train U70451-10 was proceeding eastward at about 38 mph on CN’s Ruel Subdivision when it experienced a train-initiated emergency brake application at Mile 111.7, at Gladwick, near Gogama, Ontario. A subsequent inspection determined that the 7th through 35th cars (29 cars in total) had derailed. Nineteen of the tank cars were breached, and about 1.7 million litres of petroleum crude oil were released to either atmosphere or surface. The released product ignited, and the fires burned for 5 days. About 900 feet of mainline track was destroyed. There was no evacuation, and there were no injuries.

R15H0005 – CP derailment at Dublin, Ontario, 13 January 2015

On 13 January 2015, at 1118 Eastern Standard Time, CP freight train 118-10 was proceeding eastward on the Nipigon Subdivision at about 35 mph when it experienced a train-initiated emergency brake application at Mile 42.0 near Dublin, Ontario. Subsequent inspection determined that 21 cars had derailed. The derailed equipment included 7 dangerous goods tank cars loaded with propane (UN1075, liquefied petroleum gas). As a result of the derailment, 1 tank car lost its entire load and another tank car released product. One crew member sustained minor inhalation injuries.

R14W0256 – CN derailment at Clair, Saskatchewan, 07 October 2014

On 07 October 2014, at approximately 1135 Central Standard Time, CN freight train A40541-05 was proceeding westward on the CN Margo Subdivision when it derailed 26 cars, including 6 tank cars loaded with dangerous goods, at Mile 74.58 near Clair, Saskatchewan. Two of the tank cars, which were loaded with petroleum distillates (UN1268), released product that subsequently caught fire. As a precaution, approximately 50 residents within a two-mile radius were evacuated and Provincial Highway 5 was closed. Approximately 650 feet of track was destroyed. There were no injuries.

R14M0002 – CN derailment at Plaster Rock, New Brunswick, 07 January 2014

On 07 January 2014, at approximately 1847 Atlantic Standard Time, CN freight train M30831-06 was proceeding eastward when it derailed 19 cars and 1 distributed power locomotive in the Napadogan Subdivision, near Plaster Rock, New Brunswick. The distributed power locomotive and most of the derailed cars piled up at Mile 152.60. About 230 000 litres of hydrocarbons spilled from the tank cars and caught fire. Approximately 150 residents were evacuated within a 1.6-kilometre radius. A total of about 350 feet of railway track was destroyed. There were no injuries.

R13E0142 – CN derailment at Gainford, Alberta, 19 October 2013

On 19 October 2013, at 0100 Mountain Daylight Time, CN freight train M30151-18, proceeding westward from Edmonton, Alberta, to Vancouver, British Columbia, derailed 13 cars, including 4 tank cars containing petroleum crude oil and 9 tank cars of liquefied petroleum gas (LPG), at Mile 57.25 of the Edson Subdivision, near Gainford, Alberta. Of the derailed LPG tank cars, 2 were breached and caught fire. A third LPG tank car released product from the safety valve and ignited. About 600 feet of track was destroyed. There were no injuries. A total of 106 homes in the vicinity of the derailment were evacuated.