Main-track train derailment

Canadian National

Mile 547.0, Chetwynd Subdivision

North of Anzac, British Columbia

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

The occurrence

At 0915 Pacific Daylight Time on 03 June 2021, Canadian National Railway Company (CN) freight train A47251-02 was proceeding southward at about 29 mph on the Chetwynd Subdivision when it derailed. The derailed train gradually decelerated from 29 mph to 0 mph. A train-initiated emergency brake application occurred as the train came to a stop with the head end at about Mile 547.2.Footnote 1 The train had originated in Chetwynd, British Columbia, and was destined for Prince George, British Columbia. An inspection by the train crew revealed that 38 cars had derailed upright. The derailed cars included 1 residue tank car, PXCX 200014, last containing hydrogen peroxide (UN2015), and 1 residue tank car, UTLX 66537, last containing sodium hydroxide solution (UN1824). No dangerous goods were released, and there was no fire. No injuries were reported.

The derailment took place at Mile 547.7 in a remote area about 85 miles north of Prince George. Near the point of derailment in the direction of travel, there is an 8° right-hand curve. The track then crosses a bridge over Parsnip River, after which there is a 6° left-hand curve (Figure 1).

The conventional train comprised 2 locomotives, 49 loaded cars, 27 empty cars, and 2 residue tank cars. It measured 4939 feet and weighed 7312 tons.

The crew consisted of 1 locomotive engineer and 1 conductor. The 2 crew members were qualified for their respective positions, met fitness and rest standards, and were familiar with the subdivision.

At the time of the occurrence, the temperature was 16 °C.

Site examination

The last 38 cars in the train consist had derailed in the 8° curve, some on the bridge over the river. All had remained upright.

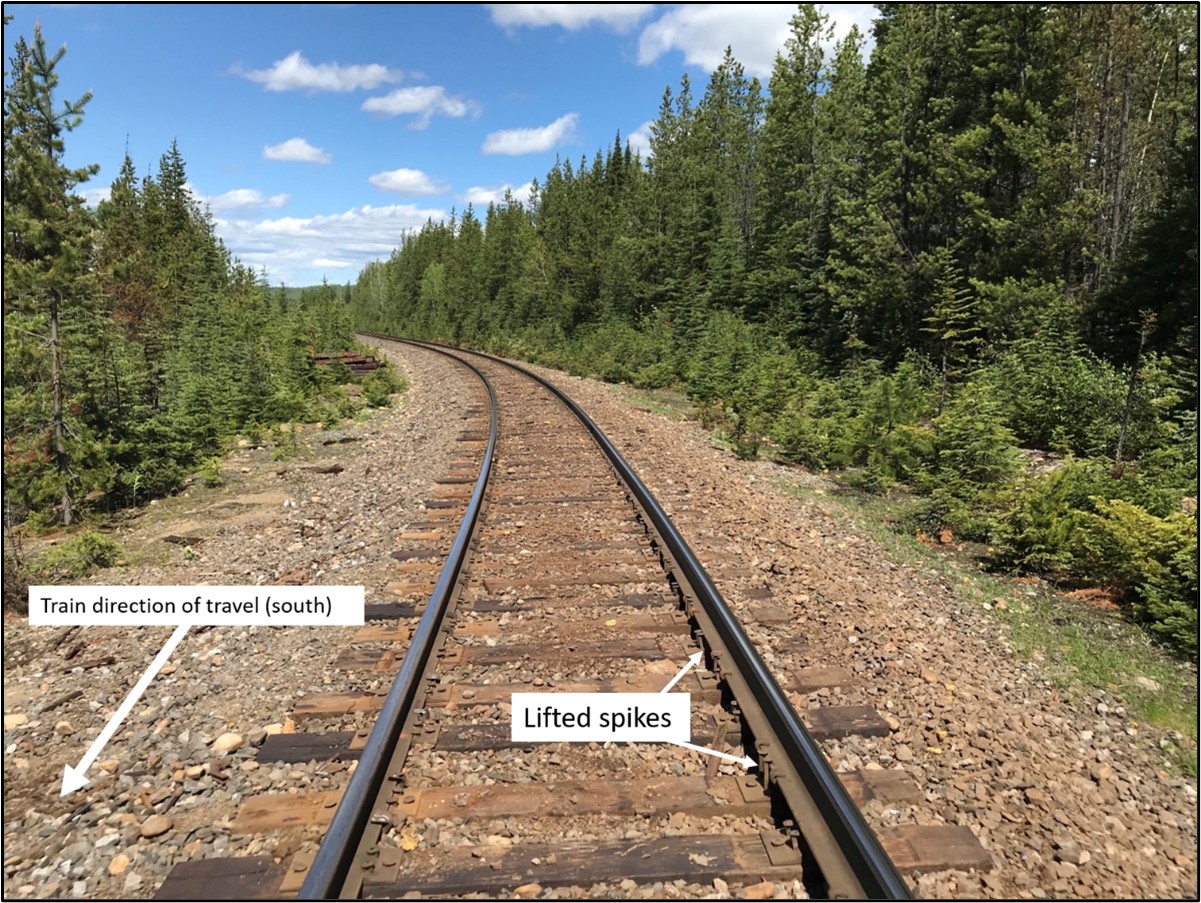

The gauge-side spikes of the high rail of the 8° curve had lifted away from, and out of, the tie plates (Figure 2). The high rail had rolled outward away from the train, thereby increasing the gauge and causing the cars to derail.

Recorded information

The lead locomotive was equipped with a locomotive event recorder (LER) and forward-facing video camera. A review of the data from the LER revealed no train handling anomalies, and a review of the forward-facing video revealed no visible track anomalies.

Subdivision information

The Chetwynd Subdivision runs north-south between Prince George (Mile 462.4) and Chetwynd (Mile 658.5). Traffic on the subdivision consists of 2 trains per day, usually loaded with southbound lumber products. There were 14.5 million gross ton-miles per mile (GTM/M) of train traffic recorded for 2020.

Train movements on the subdivision are controlled by the occupancy control system, as authorized by the Canadian Rail Operating Rules, and dispatched by a rail traffic controller located in Edmonton, Alberta. In the vicinity of the derailment, the track is Class 3 track according to the Transport Canada–approved Rules Respecting Track Safety, also known as the Track Safety Rules (TSR). At the time of the occurrence, the maximum authorized speed for freight trains was 40 mph from Mile 537.7 to Mile 577.4; however, a 30 mph permanent slow order was in effect from Mile 547.1 to Mile 547.9, due to a combination of the track geometry (the reverse curves) and the presence of the bridge.

In the 8° curve, the high rail consisted of 115-pound Nippon continuous welded rail (CWR) manufactured in 2014, and the low rail consisted of 115-pound Sydney CWR manufactured in 1998. The rail was laid on 14-inch tie plates, secured to a mix of softwood and hardwood ties with 5 spikes per plate. The curve was anchored every other tie with UnitFootnote 2 115 anchors on the high rail and Fair 115 anchors on the low rail. The ballast was 2.5-inch minus crushed rock, with 12-inch shoulders and full cribs; it was in good condition.

Curve elevation

Travelling southward, the 8° curve begins at about Mile 548 and extends for 1278 feet. The curve has 3.51 inches of superelevationFootnote 3 (SE), 1.49 inches less than balanced SE (the SE at which centrifugal forces are fully compensated), which for an 8° curve at 30 mph is 5 inches. CN engineering track standards limit SE to 5 inches and allow for curves to be up to 2 inches less than balanced SE; the TSR allow for up to 3 inches less than balanced SE. However, when curves with high numbers of defective ties are under-elevated, train forces can result in gauge-side spikes lifting as the high rail rolls or lifts out of the plates.

Rail cant

Rail cant is the amount of inward tilt applied to a rail through the tie plates to counteract rail overturning forces: flanging forces push the high rail toward the outside of the curve, and similarly lateral forces on the inside of the curve push out the low rail.

By design, rails are laid on tie plates that have a 1:40 slope or 1.43° tilt inwards. Any tilt outwards from this position is considered an outward rail cant defect, which can result in a widened gauge. Outward rail cant is characterized by poor or broken ties, over- or under-elevated curves, raised/missing/broken spikes, or excessive plate cutting.

Track inspection and maintenance

In accordance with the TSR, the track in the vicinity of the derailment was inspected twice weekly. In addition, the track was ultrasonically tested for rail defects 6 times in 2021 before the derailment, and no internal rail defects were detected in the curves between Mile 547 and Mile 548.

The track in the vicinity of the derailment also underwent inspection by a heavy track geometry test car. The most recent inspection before the occurrence was conducted on 25 May 2021. The inspection recorded 30 feet of 5.68° of near-urgent outward rail cant on the low rail at Mile 547.7 in the 8° curve. Near-urgent defects must be inspected within 72 hours and repaired within 30 days.Footnote 4 The near-urgent condition was inspected the following day on 26 May 2021. During this inspection, no track geometry defects were identified; however, it is likely that signs of gauge widening (such as sliding tie plates, bent spikes or plate cutting) were present, but not observed. There were no repairs made or additional operating restrictions put in place to address this defect before the derailment. The last regular track inspection prior to the derailment was conducted on 02 June 2021.

In 2020, 1190 feet of track between Mile 547.65 and Mile 566.46 was gauged,Footnote 5 including the curve where the point of derailment was located. A tie program that consisted of installing 55 352 ties between Mile 509.00 and Mile 566.65 began in the spring of 2021. The program was scheduled to be completed in October 2021.

On 28 April 2021, some new ties had been installed in the 8° curve to break up and reinforce clusters of defective ties, and the track had also been gauged on 05 May 2021. These actions, however, were insufficient to prevent the high rail from canting outward and rolling under the train.

Safety message

Nine days prior to this occurrence, a near urgent defect was identified, but the subsequent track inspection did not reveal track geometry defects, even though signs of gauge widening were likely present. When conducting track inspections in curves, it is important to pay particular attention to both rails for signs of instability, so that repairs or operating restrictions can be put in place.

This report concludes the Transportation Safety Board of Canada’s investigation into this occurrence. The Board authorized the release of this report on It was officially released on