Quad City Challenger II Advanced Ultralight – Bracket Failure

Place du Centre

200 Promenade du Portage, 4th Floor

Gatineau QC K1A 1K8

15 November 2018

Aviation Safety Advisory A18O0106-D1-A1

Related occurrence: A18O0106

Letter addressed to Civil Aviation, Transport Canada

Subject: Aviation safety advisory A18O0106-D1-A1 – Quad City Challenger II Advanced Ultralight – Bracket Failure

The purpose of this advisory is to alert your organization to the possible risks associated with the failure of attachment brackets securing wing lift struts on Quad City Challenger II Advanced Ultralight aircraft.

At approximately 0950 Eastern Daylight Time on 30 July 2018, the right wing of a privately owned Quad City Challenger II Advanced Ultralight aircraft (registration C-IGKT, serial number CH2-1199-1919) separated from the aircraft when it was at an altitude of approximately 1000 feet above Talon Lake, Ontario, 14.3 nautical miles east of North Bay Airport (CYYB), Ontario. The aircraft entered an uncontrolled descent and collided with terrain in a wooded area. A post-impact fire ensued. The pilot was fatally injured and the aircraft was destroyed.

As part of the investigation into this accident (A18O0106), which is ongoing, the TSB retrieved and examined both right wing lift struts (front and rear) and the respective attachment brackets. It was determined that the bracket securing the right front lift strut to the fuselage failed while in flight as a result of fatigue. Following this failure, the lift strut detached from the fuselage and the right wing separated from the aircraft.

Details from the examination of the failed right front lift strut bracket:

- The bracket had 402.2 hours since installation (including the accident flight).

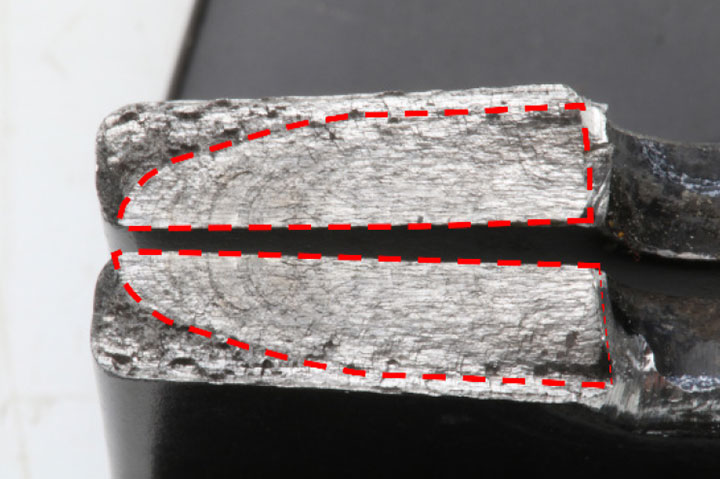

- A fatigue crack was found across the bottom end of the bracket, through the bolt hole and parallel to the bracket sides (Figure 1).

- The initiation point of the crack was determined to be on the edge of the bolt hole.

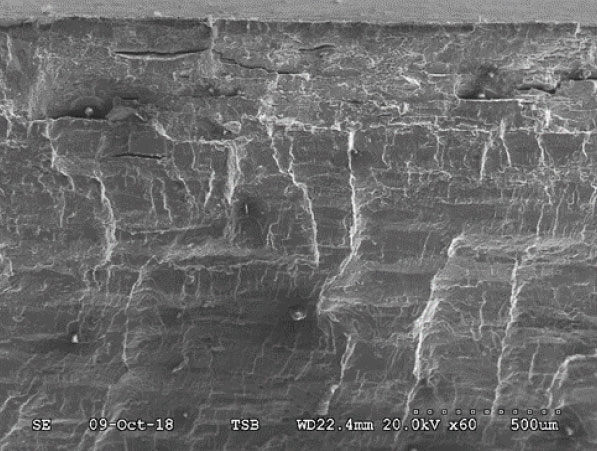

- The fatigue region (Figure 2) accounts for more than 60% of the cross-section area of the bracket. It shows striations along the fracture surface, which are an indication of the fatigue cycles.

- The scanning electron microscope observation of the fracture surface found a significant number of secondary and parallel cracks underneath the surface of the bracket (Figure 3). These cracks resemble material delamination, a material defect introduced likely due to, or consistent with, the fabrication process used.

- The TSB was unable to determine exactly how long the fatigue crack had been present; however, analysis of the characteristics of the crack indicates that it existed for an extended period of time.

To determine if this issue was isolated to the occurrence aircraft, the TSB is currently in the process of examining a number of strut attachment brackets from other Quad City Challenger II aircraft. So far, 22 brackets have been examined, and within that group, 8 brackets were found to have cracks. The time-in-service of those 8 brackets ranged from 4.1 hours to 830 hoursFootnote 1. The cracks identified vary in size and origin; some resulted from fatigue, whereas others were caused by material delamination.

The strut attachment brackets used on the Quad City Challenger II have been in service for 35 years and are installed on more than 4400 aircraft worldwide, including 608 in Canada. There has been one previous known failure of a front lift strut bracket, which occurred in the U.S., where overtightening or over-torqueing was identified as a possible cause; however, there was no evidence that overtightening or over-torqueing was a causal factor in this occurrence.

Advanced ultralights in Canada are required to be maintained according to the manufacturer's recommendations. Maintenance documents for the Quad City Challenger II indicate that the brackets and their associated bolts and nuts are to be inspected for tightness, cracks, play and safeties at the 50-hour inspection; however, the documents do not detail any recommended torque values to be used or types of inspections to be performed to identify possible cracking. These maintenance documents also require the brackets to be replaced completely at 500 hours time-in-service.

The occurrence aircraft's journey log indicated that a 25-hour inspection had been completed on 06 May 2018; however, the manufacturer does not require or have a specific checklist for a 25-hour inspection. It could not be determined if this inspection was conducted using 50-hour inspection checklist, or if the brackets had been inspected.

In this accident, a fatigue crack on the right front lift strut bracket went undetected within the 50-hour inspection cycle and failed before the 500-hour stipulated life span. Examination of other brackets obtained from other aircraft, with various time-in-service, suggest this issue may not be isolated to the occurrence bracket. Cracks that develop on airframe components need to be identified before the component fails completely; this is especially true when the component's failure can result in an irrecoverable loss of control in flight.

The TSB encourages your organization to take the necessary steps to reduce the likelihood that the bracket failure identified in this occurrence reoccurs.

The TSB would appreciate being advised of any action that is taken in this regard.

Original signed by

Natacha Van Themsche

Director of Investigations – Air

Cc.

- Quad City Ultralight Aircraft Corporation

- National Ultralight Inc.

- Canadian Owners and Pilots Association

- The Recreational Aircraft Association Canada

- Ultralight Pilots Association of Canada

- Experimental Aircraft Association

- National Transportation Safety Board

- Accident Investigation and Prevention, Federal Aviation Administration

Background information

Occurrence No.

A18O0106

Safety Communication No.

A18O0106-D1-A1

Contact

Jean-Pierre Regnier, Senior Investigator, Operations (S&P), Head Office, Gatineau, Quebec