Potential brake valve failures on cars that have been in long term storage

Place du Centre

200 Promenade du Portage, 4th Floor

Gatineau QC K1A 1K8

19 July 2018

Safety advisory letter 617-04/18

Related occurrence: R18E0007

Letter addressed to Transport Canada

Subject: Rail Safety Advisory Letter – 617-04/18: Potential brake valve failures on cars that have been in long term storage

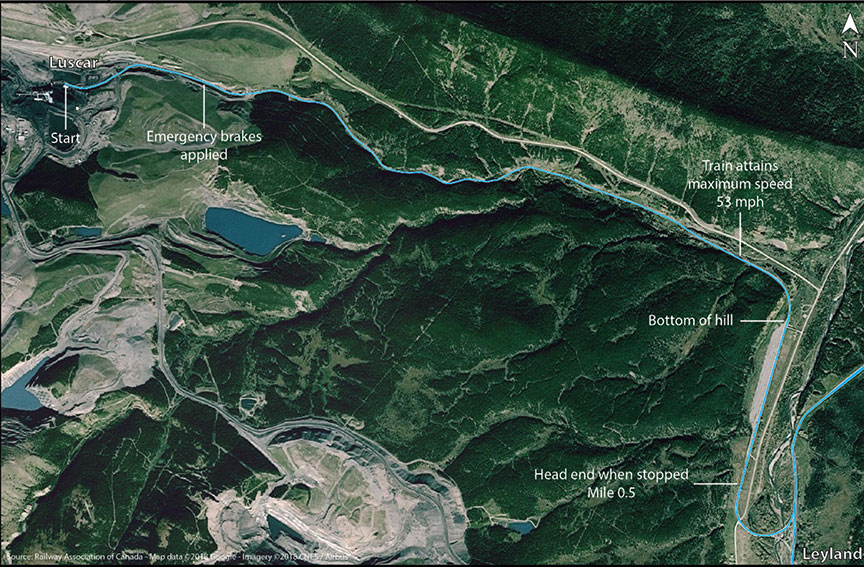

On 10 January 2018, at approximately 0245 MT, conventional Canadian National (CN) unit coal train L76951-10 (the train), proceeding southward on the Luscar Industrial Spur from the Teck Mine coal loading facility near Cadomin, Alberta, experienced a loss of control while proceeding down the steep mountain grade to Leyland, Alberta (Figure 1). The maximum descending grade on this track is 3.0%. The train was comprised of 3 locomotives and 58 loaded cars. It was 3296 feet in length and weighed 8097 tons. The maximum track speed for the Luscar Industrial Spur is 15 mph. Despite a full service brake application, with a fully-charged air brake system and full dynamic brake, the crew was not able to control the train's speed. At about Mile 4.5, the crew placed the train into emergency braking. However, the train continued to accelerate to 53 mph. Upon reaching the bottom of the grade at Mile 1.4, the train decelerated and came to a stop at Mile 0.5. The temperature at the time of the occurrence was -25°Celsius. (TSB Occurrence No. R18E0007)

When the train stopped, the conductor performed an inspection of the train, before attempting to recover the train air brakes and recharging the system. It was determined that 27 of the 58 cars did not have their brake cylinder pistons extended, indicating that the brakes on these cars either did not apply or had leaked off after being applied.

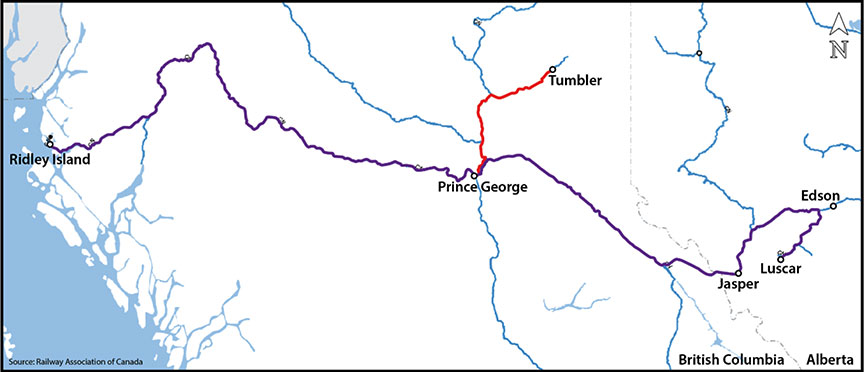

The coal cars had been leased from CIT Rail – North America (CITX) for use in CN's northwest coal operations (Figure 2). The CITX coal trainset had been in storage for about 21 months before being returned to service on 10 November 2017 and delivered to CN. The cars in this trainset were first placed in service about 11 years prior.

On 21 December 2017, there had been a previous incident involving air brake performance on the same unit coal trainset. While yarding the train in Tumbler, British Columbia, the crew separated the locomotives from the train with the angle cock on the standing train open. As expected, air vented rapidly from the brake pipe through the open angle cock and residual air in the brake pipe exhausted to atmosphere. However, after the exhaust ceased, air unexpectedly began again to exhaust from the brake pipe. As this situation can lead to an unintentional release of the train brakes, the crew reported the events. CN technical specialists examined the cars, but were unable to determine the cause. At that time, the ambient temperature was about −23° Celsius. Later in the day when the ambient temperature warmed up, the brakes were determined to have returned to normal functionality. On 27 December 2017, as a proactive repair, the DB-20 emergency portions of the brake valves were replaced on every car in the trainset.

Following the January 10 occurrence, various brake valve components were removed from the coal cars and sent to the manufacturer (New York Airbrake (NYAB)) for detailed examination. Specifically, 5 emergency portions from cars involved in the December 27 occurrence and 5 service portions from cars involved in the January 10 occurrence were examined. During testing under controlled temperature conditions, the failure mechanism experienced at the Luscar occurrence was duplicated.

In 2013, the Association of American Railroads (AAR) had identified the issue of cold temperature malfunctions during service brake applicationsFootnote 1. Testing had determined that worn rubber seals from the bottom cover exhaust port of the DB-10 service portions could shrink during extreme cold temperatures. This could then result in auxiliary reservoir leakage and lead to an unintended release of a service brake application.

For the Luscar occurrence, the NYAB tests determined that the unintentional release of the brakes was likely the result of the same type of failure and leakage of the DB-10 service portions that was the subject of the AAR Circular in 2013.

With respect to the DB-20 emergency portions, the NYAB tests established that the failure mechanism was not the same as the failure mechanism for the service portions. For the emergency portions, the failure was related to a deformed K-ring inside the vent valve, which resulted in excessive leakage during extreme cold temperatures and the failure to propagate the emergency brake application command. The setting and deformation of the K-ring rubber had likely occurred when the coal cars were in storage for an extended period of time prior to being delivered to CN. With the permanent deformations, the intended performance of the K-ring, particularly during cold temperatures, was negatively affected.

Given the potential consequences of a loss of braking function due to brake valve failure, Transport Canada may wish to alert railways and car owners of the need to examine the brake valve functionality of cars that have been in long term storage, particularly if the cars are to be used in cold weather service.

Original signed by

Kirby Jang

Director

Investigation Operations, Rail/Pipeline

Cc.

- Canadian National Railway

- Canadian National

- Association of American Railroads

- New York Air Brake

- Railway Association of Canada

Background information

Occurrence No.

R18E0007

Contacts

Dan Holbrook, Manager, Head Office and Western Regional Operations - Rail, Head Office, Gatineau, Quebec

Don Crawford, Regional Senior Investigator, Calgary Regional Office, Alberta