Place du Centre

200 Promenade du Portage, 4th Floor

Gatineau QC K1A 1K8

17 April 2020

Letter addressed to:

Director General, Rail Safety

Transport Canada

14th Floor, Enterprise Building

427 Laurier Avenue

Ottawa, Ontario

K1A 0N5

Re :

Rail Safety Advisory Letter 617-04/20

Effectiveness of No. 1 brake test

On 04 February 2019, at approximately 0100 Mountain Standard Time, westward Canadian Pacific Railway (CP) loaded unit grain train 301-349 (the train) ran uncontrolled and derailed 99 grain cars and 2 locomotives at Mile 130.6 of the Laggan Subdivision, near Field, BC. The crew on board, consisting of a locomotive engineer, a conductor and a conductor trainee, were fatally injured. (TSB Occurrence No. R19C0015)

The train was a distributed power train with 1 lead, 1 mid, and 1 tail-end locomotive. It was handling 112 loads, weighed 14 418 tons, and was 6677 feet in length. Earlier on 03 February 2019, at 2148:21, the previous crew members had been unable to control train speed below 15 mph on the steep descending grade and had placed the train in emergency to bring it to a stop at Partridge, BC (Mile 128.7).

Train 301-349 received and passed a No. 1 brake testFootnote 1 on 3 February 2019 before departing Alyth Yard in Calgary, Alberta. The test, performed by qualified employees on a stationary train, verifies that the train air brake system is working as intended before the train departs.Footnote 2

In Canada, to pass the No. 1 brake test, the regulations require that at least 95% of air brakes be operativeFootnote 3 on trains departing designated safety inspection locations. The actual brake force or its effect is not physically measured.

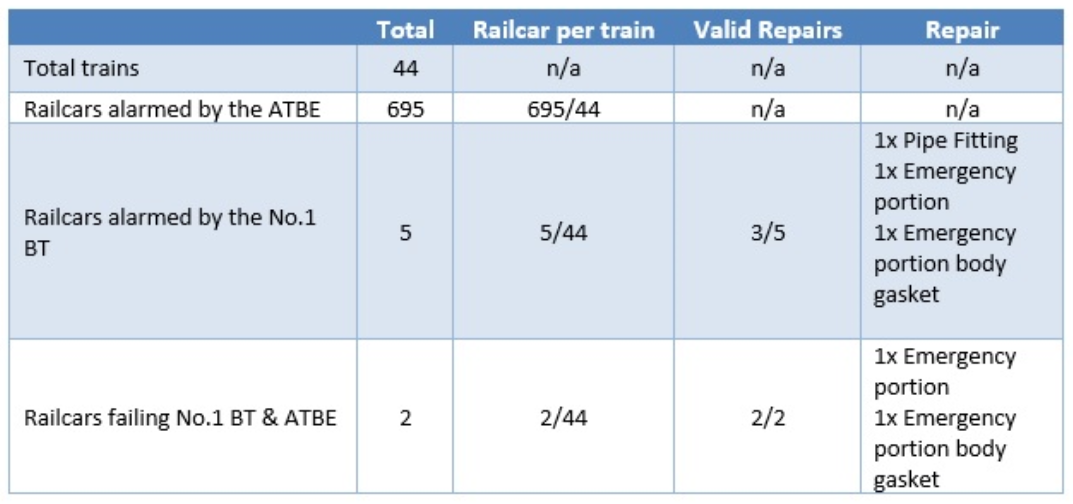

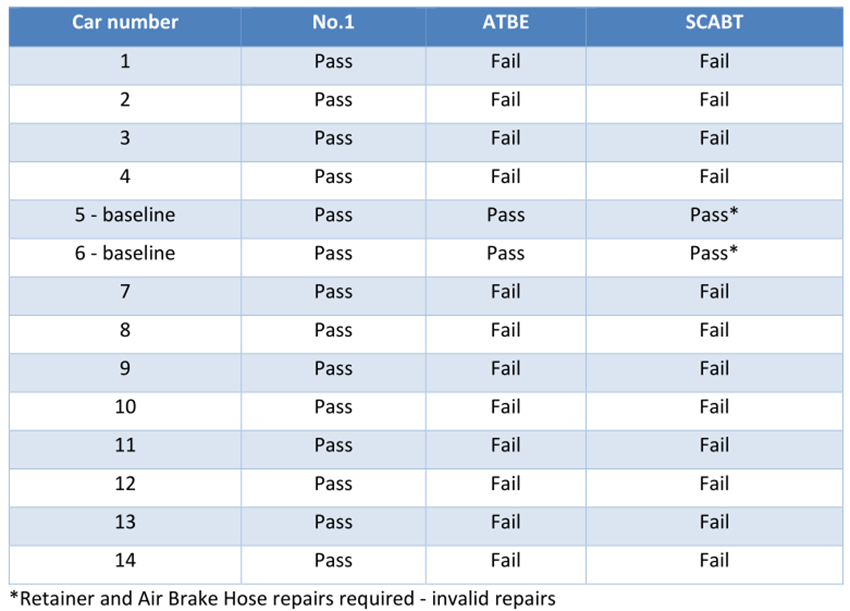

In 2015, Transport Canada, the National Research Council (NRC) and CP initiated a joint research project on Automated Train Brake Effectiveness (ATBE) to assess ATBE as an alternative or in combination with the manual brake test currently regulated in Canada.Footnote 4 The ATBE research examined wheel temperature data from a series of cold wheel detectors located at the bottom of long descending grades where prolonged air brake applications are required to control train speed. In 2016, preliminary research results documented a high frequency of unit grain cars with cold wheels under braking (Annex A, Figure 1). Subsequently, researchers conducted a comparison of ATBE data and No. 1 brake test results on a sample of 44 grain trains. ATBE testing identified 695 cars with ineffective brakes while the No. 1 brake test identified 5 cars; a 139:1 ratio (Annex A, Figure 2). A random sampling of 14 of the cars identified by the ATBE testing were sent for a single car air brake testFootnote 5 (SCABT) and inspection. All of the cars in the sample that were identified with ineffective brakes by the ATBE method failed the SCABT. All cars that failed the SCABT were subsequently determined to have defects that required repairs (Annex A, Figure 3).

At CP, when employees notice a hazard, they are encouraged to fill out a hazard notification and send a copy to the Health and Safety Committee. A review of CP’s Health and Safety Committee hazard notifications submitted prior to the accident revealed multiple instances where train crews operating loaded unit grain trains westward descending Field Hill in winter operating conditions experienced difficulty controlling train speed. These hazard notifications document air brake performance issues on unit grain trains that had successfully passed a No. 1 brake test.

The ATBE test results and the hazard notifications of train braking anomalies on Field Hill both suggest that the No. 1 brake test does not reliably identify ineffective brakes in rail cars. Given this information, Transport Canada is advised that an alternate approach to determining the effectiveness of freight car air brakes is required to ensure that departing trains have sufficient effective brakes to operate safely.

The TSB would appreciate being advised of TC’s position on this issue, and what action, if any, will be taken in this regard. Upon completion of the investigation into occurrence R19C0015, the Board will release its investigation report.

Yours sincerely,

Original signed by

Paul Treboutat

Director,

Investigations, Rail/Pipeline

CC.

- Assistant Vice President, Safety & Sustainability

Canadian Pacific Railway - Senior Director, Operations and Regulatory Affairs

Railway Association of Canada

Annex A - Key results from Automated Train Brake Effectiveness research project, 2015–2018

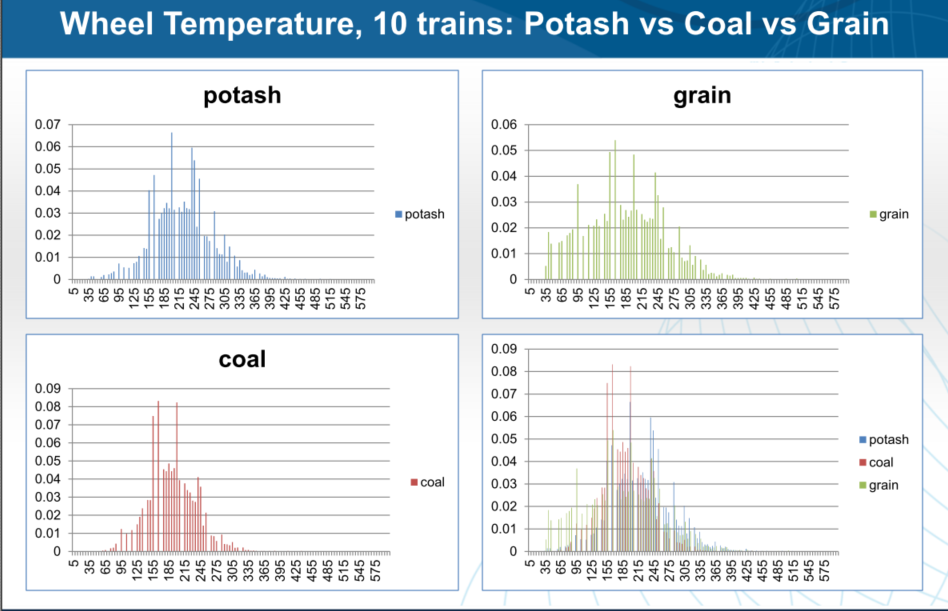

Figure 1 is a plot of wheel temperature data presented to the TC-NRC-CP Automated Train Brake Effectiveness (ATBE) research project steering committee in July 2016.Footnote 6 The data collected for 10 coal, potash and grain unit trains document that warm and cold wheels, consistent with poor or ineffective brakes, occur more frequently in grain cars. In fact, the CP ATBE test guidelines for identifying ineffective brakes in its coal cars (< 70 °F and < 3 standard deviations from mean) could not identify ineffective brakes in the grain cars because the grain trains displayed a wider range of wheel temperatures (i.e., more cooler wheels).

* The horizontal axes denote temperature in °F (Fahrenheit). The vertical axes denote the ratio of the total number of wheels in each temperature range (5-degree increments) divided by the total number of wheels.

Figure 2 captures the results of 2017 follow-up research comparing the detection rate of the No. 1 brake test with ATBE cold wheel (CW) alarms on 44 grain trains.Footnote 7 To trigger a CW alarm, the grain cars must meet the following conditions:

- train average wheel temperature ≥ 155 °F (68 °C),

- wheel ≤ 70 °F (21 °C), and

- standard deviation ≤ 1.5 – varies depending on measured temperature distribution.Footnote 8

The subsequent testing of a random sample of these grain cars is included in Figure 3.

Background information

Occurrence No.

- R19C0015