Air brake system inspection and maintenance on grain hopper cars used in CP unit train operation

Place du Centre

4th Floor

200 Promenade du Portage

Gatineau, Quebec

K1A 1K8

11 April 2019

617-05-19

R19C0015

Ms. Brigitte Diogo (ASR)

Director General, Rail Safety

Transport Canada

14th Floor, Enterprise Building

427 Laurier Avenue

Ottawa, Ontario

K1A 0N5

Rail Safety Advisory Letter 617 05/19

Air brake system inspection and maintenance on grain hopper cars used in CP unit train operation

Dear Ms. Diogo:

On 4 February 2019, at approximately 2148 Mountain Standard Time, Canadian Pacific Railway (CP) loaded unit grain train 301-349, proceeding westward to Vancouver, British Columbia (BC), was brought to a stop at Partridge, BC (Mile 128.7) on the Laggan Subdivision, using an emergency brake application. The track grade at this location was about 2.2%. Subsequent to stopping, the crew performed the required job briefing with a supervisor and the decision was made to set retainer valves to the high-pressure position on 75% of the cars on the train (84 cars). No hand brakes were applied. After an extended period of about 2 hours 45 minutes, a relief crew arrived to replace the crew at Partridge, whose maximum hours of service had been reached. About 10 minutes later, the train began to move on its own. The relief crew had not yet recovered the air brake pressure from the emergency brake application. The crew members were in the process of securing the train to facilitate the safe release and recharge of the air brakes. The train gradually accelerated to a speed in excess of the maximum track speed, and then derailed. A total of 99 cars and 2 locomotives derailed between the Upper Spiral Tunnel and Lower Spiral Tunnel near Field, BC. The crew members on board, consisting of a locomotive engineer, a conductor and a conductor trainee, were fatally injured. At the time of the occurrence, the temperature was −28°C. (TSB Occurrence No. R19C0015)

Prior to the emergency stop, as the occurrence train began the descent on Field Hill and was proceeding through Partridge, the crew had not been able to keep the train at (or under) the maximum authorized speed of 15 mph using a progressive application of the air brakes and dynamic brakes. When the speed reached approximately 23 mph, and despite the heavy (> 20 psi) application of the air brakes in combination with full dynamic brakes, the locomotive engineer applied the air brakes in emergency, as required by CP's General Operating Instructions (GOIs), section 32.9, Uncontrolled Movements – Stop Required, which states:

Any movement descending a Heavy or Mountain grade that attains a speed 5 MPH above permissible speed is considered an uncontrolled movement and must be stopped immediately by whatever means available, including (if necessary) using an EMERGENCY brake application.

Subsequent to the accident, the TSB conducted air brake system testing on the 13 grain hopper cars that did not derail. It was determined that:

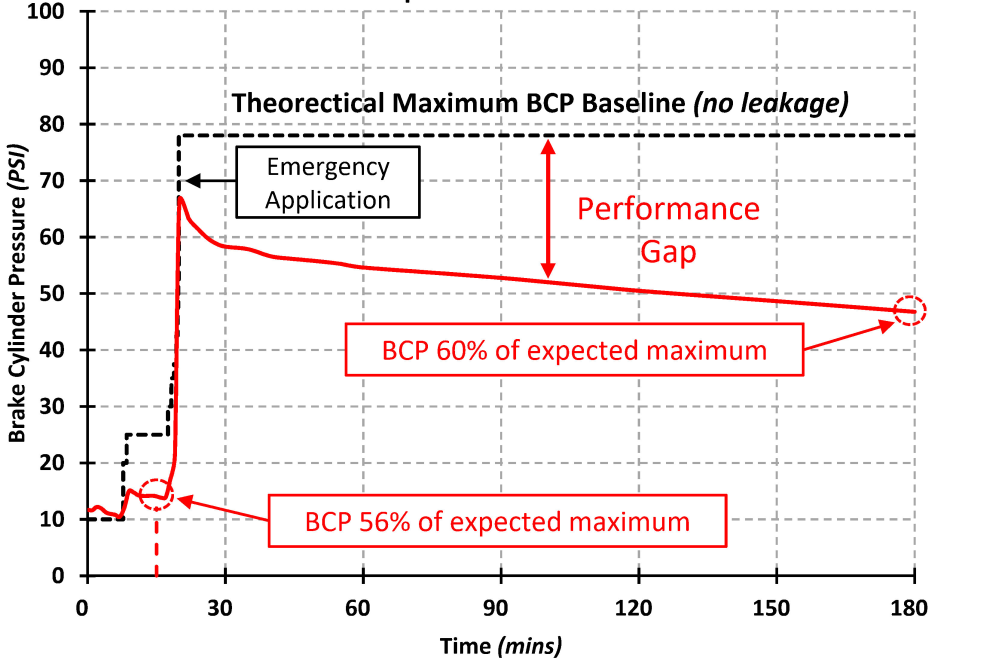

- The air brake system on these cars would not provide adequate braking effectiveness to ensure the safe operation of a loaded unit grain train in a situation where the air brakes are required to remain applied for an extended duration, such as while descending a steep grade. Annex A provides a summary of the test results, including a graph of the measured brake cylinder pressure (BCP) leakage (i.e., average BCP of the 13 cars plotted over the 3-hour test period).

- Relative to the expected maximum pressure during the series of service brake applications, BCP dropped to 56% in 15 minutes.

- Relative to the expected maximum pressure from the emergency brake application, BCP dropped to 60% at the end of the 3-hour test period.

As the 13 grain hopper cars represent about 11% of the 112 cars on the occurrence train, the test results generally represent the air brake performance on train 301-349 as it operated through Partridge and at the time of the occurrence.

Other observations relating to the air brake performance of the occurrence train include:

-

All 13 grain hopper cars failed additional testing utilizing an automated single car test device (ASCTD). The ambient temperatures during testing ranged between −21°C and −26°C.

(Note: Association of American Railroads (AAR) Field Manual Rule 3 and AAR Manual of Standards and Recommended Practices Section E, Specification S-486 and Specification S-4027 do not require that testing be performed at the coldest ambient temperatures to which the cars may be exposed. As such, test results obtained in a repair shop environment, or in moderate outdoor temperatures, may not reveal air brake performance issues that can develop during extreme cold operating temperatures.)

A properly functioning air brake system is of the utmost importance in mountain territory from a safety standpoint. For unit bulk commodity trains operating on Field Hill, CP has implemented a number of risk mitigation measures. With warmer ambient temperatures in the spring, this seasonal relief will help restore air brake efficiency. However, given the potential consequences when uncontrolled movements occur, particularly in mountain territory, Transport Canada may wish to review the efficacy of the inspection and maintenance procedures for grain hopper cars used in CP's unit grain train operations (and for other railways as applicable), and ensure that these cars can be operated safely at all times.

Yours sincerely,

Kirby Jang

Director

Investigations, Rail/Pipeline

Assistant Vice President, Safety & Sustainability - Canadian Pacific Railway

Senior Director, Operations and Regulatory Affairs - Railway Association of Canada

Appendices

Appendix A

Measured brake cylinderpressure (BCP) leakage

The 13 grain hopper cars recovered from the derailment site were tested between 8 and 10 February 2019 at Banff, Alberta. Outdoor testing was performed with the ambient temperature between −18°C and −24°C to replicate, as closely as possible, the conditions at the time of the occurrence. The tests were designed to duplicate the actual timing and sequencing of air brake applications that were used to “balance” the grade while train 301-349 was descending Field Hill, culminating in the application of the emergency brakes to stop the movement. Locomotive event recorder data retrieved from the occurrence train was used to develop the following air brake application script.

| Step: | Time: | Air Brake Reduction: | BPP (psi) |

|---|---|---|---|

| 1 | 00:00:00 | Min Red'n | 84 |

| 2 | 00:07:44 | - 8 PSI | 82 |

| 3 | 00:08:29 | - 10 PSI | 80 |

| 4 | 00:17:30 | - 12 PSI | 78 |

| 5 | 00:18:14 | - 14 PSI | 76 |

| 6 | 00:18:48 | - 15 PSI | 75 |

| 7 | 00:19:18 | - 17 PSI | 73 |

| 8 | 00:19:29 | - 19 PSI | 71 |

| 9 | 00:19:44 | - 21 PSI | 69 |

| 10 | 00:19:50 | EMERG | 0 |

Note: Units of time are hours, minutes, and seconds.

The following summary graph presents aggregated BCP test results. From the test measurements, the average BCP for the 13 hopper cars was calculated and plotted (in red) over a 3-hour timeframe. As reference, the expected theoretical maximum BCP baseline is shown as a dashed line.

Background information

R19C0015

Don Crawford, Regional Senior Investigator, TSB Calgary, Alberta

Robert LeBlanc, Regional Senior Investigator, TSB Edmonton, Alberta

Dan Holbrook,Manager, Head Office and Western Regional Operations, TSB Gatineau, QC