Table of contents

Rolling stock damage without derailment

Ottawa Light Rail Transit

The occurrence

On 02 July 2020, Ottawa Light Rail Transit Citadis Spirit light rail vehicle (LRV) 1113 motor bogie 3 was undergoing retrofit at the Alstom facility in Sorel-Tracy, Quebec. During the retrofit, Alstom personnel observed wheels with cracks on the outboard face of the wheel hub of wheels located in the L17 and R20 positions. After Alstom issued a safety alert, an inspection of each LRV wheel revealed similarly cracked wheels on 2 more OLRT LRVs, which were reported to the Transporation Safety Board of Canada (TSB) on 03 July.

The TSB opened a single class 3 investigation of the 3 incidents, which was subsequently reclassified as a class 5 investigation in November 2022 (see the rationale for the reclassification below).

Background

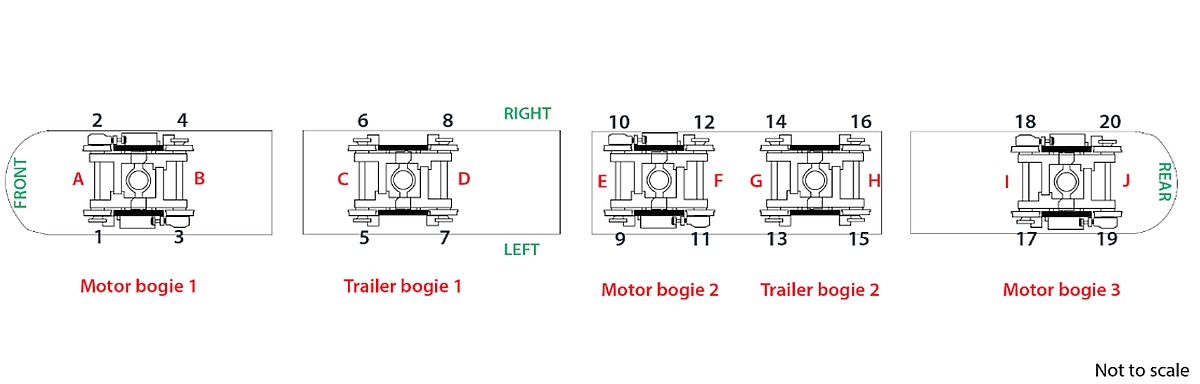

On 14 September 2019, Ottawa Light Rail Transit (OLRT) stage 1 commenced operation in Ottawa, Ontario. The vehicle selected for OLRT operations was the Citadis Spirit LRV, equipped with Iponam bogies, manufactured by Alstom. OLRT purchased 34 of the LRVs for stage 1 of its new light rail system (Figure 1). OLRT connects 2 LRVs together and operates the 2 LRVs as 1 train set.

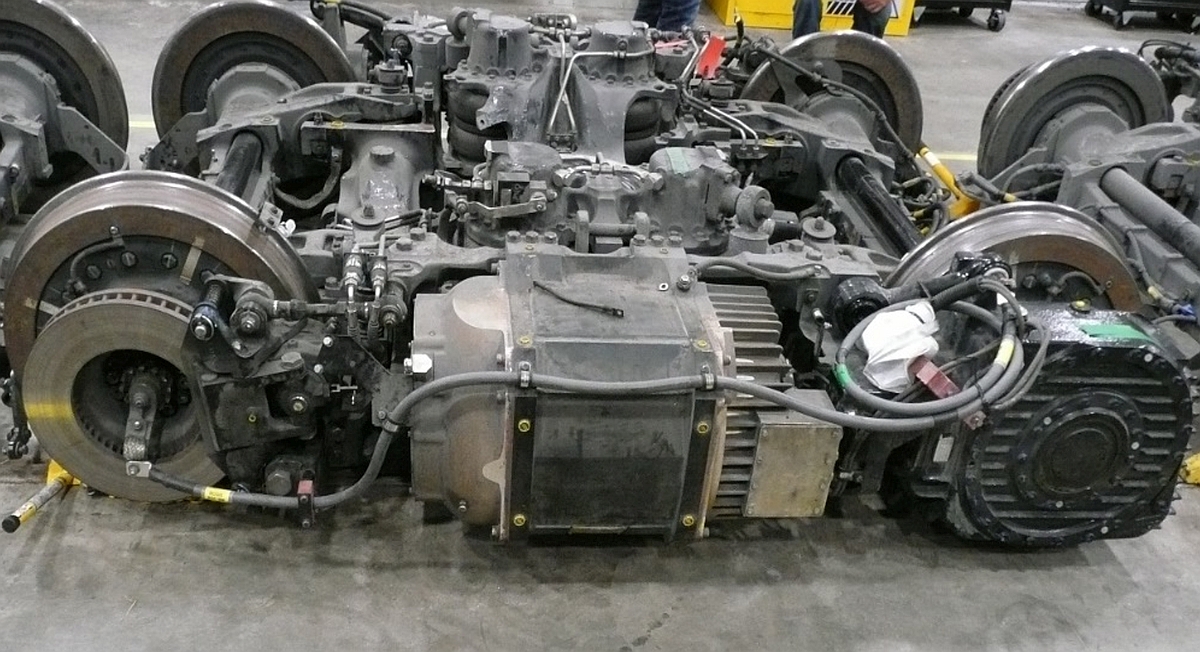

The final assembly of the LRVs was done at the OLRT shop, in Ottawa, where the LRV car bodies were mounted on Iponam bogies (Figure 2). Each LRV is equipped with 5 bogies in total which includes 3 motor bogies and 2 trailer bogies. Each bogie was equipped with 4 resilient wheel assemblies manufactured by Lucchini RS Group.

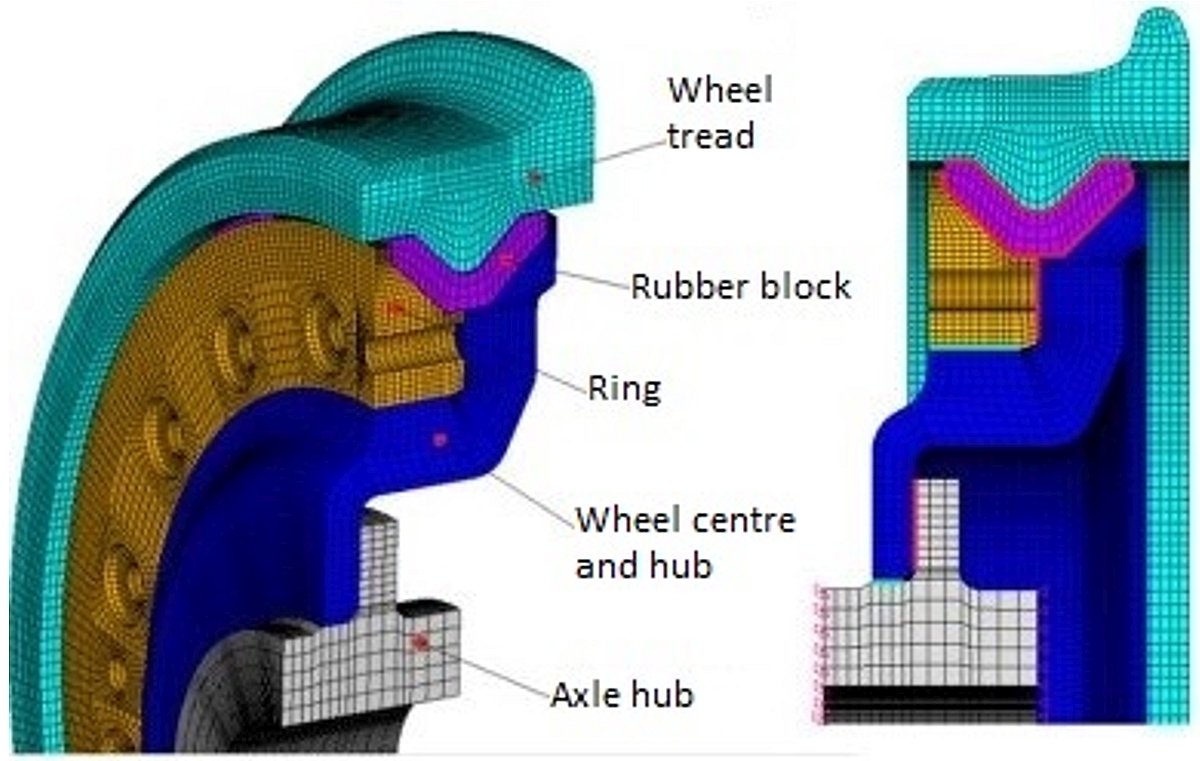

Each Lucchini resilient wheel is manufactured and assembled in a European plant. Groups of 4 assembled wheels are packaged together in wooden crates and then shipped to customers all over the world for installation. The resilient wheels are fundamentally different from cast steel freight car wheels. Each resilient wheel consists of a steel wheel tread, a rubber block, a steel ring and a steel wheel centre with an integrated wheel hub. The components are bolted together to build the wheel (Figure 3).

Each wheel hub contains 12 large holes, one for each of the 12 axle lug bolts. Similar to an automobile, the LRV resilient wheel assemblies are mounted and secured to bogie axle hubs with lug nuts. During installation, each of the 12 lug nuts seat against the outboard face of the wheel centre and are applied to the axle hub lug bolts with 400 foot-pounds of torque. Resilient wheels reportedly have an estimated service life of about 330 000 km.

In addition to the 12 lug bolt holes, each wheel hub contains 3 smaller threaded holes for the installation of jacking screws, and connections for 4 grounding cables. In order to remove a wheel from the axle, the lug nuts are removed, and the jacking screws are applied to push against the axle hub in order to separate the wheel hub from the axle hub interface. The view of 1 jacking screw on each wheel is usually obscured by 1 of the 4 grounding cables (Figure 4).

After approximately 100 000 km of service, Alstom proactively determined that a bogie retrofit program was required for the OLRT LRV fleet in order to address some maintenance issues.

The initial and subsequent incidents

During the retrofit of LRV 1113 motor bogie 3 (BM3) at the Alstom facility in Sorel-Tracy, Quebec, on 02 July 2020, Alstom personnel observed wheels with cracks on the outboard face of the wheel hub of wheels located in the L17 and R20 positions (Figures 5 and 6).

The incident was reported to the TSB and, due to the potential for a serious adverse outcome (i.e., broken wheel and derailment), the TSB initiated a Class 3 investigation.

Alstom issued a safety alert and, in conjunction with OLRT, implemented a daily inspection of each LRV wheel before the LRV was permitted to enter service. The daily inspections identified additional resilient wheels with cracks observed in the outboard surface of the wheel hub.

The TSB laboratory performed a detailed examination of four bogies and 46 wheel assemblies. The examinations determined that:

- The wheel centres’ material composition, microstructure and mechanical properties met specification requirements.

- All wheel centre cracks observed were adjacent to protruding jacking screw locations.

- It is likely, that the driving force for the initiation and propagation of the radial cracks in the wheel centres were related to the stresses generated as a result of the jacking screws protruding beyond the inboard surface of the wheel centre.

- The location of the cracked wheels and the rate of cracking progression (high cycle, low stress, no catastrophic failures) all suggest that these wheels failed under normal service stress applied to wheels that were installed over protruding jacking screws.

Subsequently, on 02 November 2020, the TSB issued Rail Safety Advisory 08-20: Cracked wheels on Ottawa Light Rail Transit vehicles. The RSA identified that all of the resilient wheels for the OLRT LRVs were shipped to Alstom with jacking screws already installed in the wheels. This was a change in process and was the first time that resilient wheels were shipped to Alstom with jacking screws installed.

Prior to the OLRT LRV build, Lucchini resilient wheels were shipped with plastic plugs or silicone installed in the jacking screw holes to protect the threads. The plugs were removed only when there was a need to use jacking screws to remove a wheel. It appears that the change in process was implemented with no requirement for the wheel manufacturer (Lucchini), the LRV builder (Alstom), or the personnel installing the wheels on the bogies to examine the rear surface of the wheel hub to ensure that none of the jacking screws protruded or otherwise interfered with the mating surface of the axle hub.

Alstom and the TSB examined all of the new Alstom resilient wheel stock and identified that 116 of the 185 new wheels examined (62.7%) had 1 or more jacking screws protruding from the rear surface of the wheel hub.

The TSB noted that despite ongoing daily inspections, some wheel hub cracks may go undetected and the development of cracks in the area of jacking screws installed in the hub of resilient wheels may be more prevalent than initially thought. Therefore, the RSA suggested that OLRT and Alstom expedite the removal of all Lucchini resilient wheels that were originally installed on the OLRT LRV fleet and that were equipped with jacking screws.

Safety action taken

Since the incident, TSB staff have continued to follow-up with OLRT and Alstom to verify the status of the removal/repair of all Lucchini resilient wheels that were originally installed on the OLRT LRV fleet and that were equipped with jacking screws.

In the year since the TSB issued RSA 08-20, OLRT and Alstom fully addressed the safety deficiency identified by the TSB. All OLRT LRVs with wheel sets that were originally equipped with jacking screws had the jacking screws removed, the wheels and axle hubs were inspected, and any damaged wheel or axle hub components were replaced before being returned to service.

OLRT have confirmed that since December 2021, OLRT LRV wheels operating in commuter service were no longer equipped with jacking screws installed, nor will they be in the future.

Rationale for reclassifying R20H0079 to a class 5 investigation

Over a 2-day period in July 2020, the TSB received 3 occurrence reports (R20H0079 on 02 July, R20H0080 on 03 July, and R20H0081 on 03 July) related to cracked wheels detected on 3 OLRT LRVs.

At the time, the scope of the issue and its cause were unknown, and since all of the cracked wheels observed appeared to be similar, the TSB decided to conduct a single class 3 investigation (R20H0079) for all 3 occurrences.

Following the TSB’s investigation and issuance of Rail Safety Advisory Letter 617-08/20 on 02 November 2020, the OLRT and Alstom took safety action to mitigate the risk of cracked wheels due to the jacking screws, and no new safety issues related to this occurrence were identified. Consequently, occurrence R20H0079 was reclassified from a class 3 investigation to a class 5 investigation, and the investigation was closed.

Safety Communications

Media materials

Investigation notice

TSB launches investigation into wheel cracks on Ottawa Light Rail Transit vehicles

Gatineau, Québec, 10 July 2020 — The Transportation Safety Board of Canada (TSB) is conducting a class 3 investigation after cracks were found on a total of four wheels on three separate Ottawa Light Rail Transit (OLRT) vehicles during maintenance and inspection activities.

Investigation information

Download high-resolution photos from the TSB Flickr page.

Class of investigation

This is a class 5 investigation. Class 5 investigations are limited to collecting data, which are then stored in the modal database. If TSB investigators deployed to the occurrence site, a short description of the occurrence is posted to the TSB website once the investigation has been completed. These investigations are generally completed within 90 days. For more information, see the Policy on Occurrence Classification.

TSB investigation process

There are 3 phases to a TSB investigation

- Field phase: a team of investigators examines the occurrence site and wreckage, interviews witnesses and collects pertinent information.

- Examination and analysis phase: the TSB reviews pertinent records, tests components of the wreckage in the lab, determines the sequence of events and identifies safety deficiencies. When safety deficiencies are suspected or confirmed, the TSB advises the appropriate authority without waiting until publication of the final report.

- Report phase: a confidential draft report is approved by the Board and sent to persons and corporations who are directly concerned by the report. They then have the opportunity to dispute or correct information they believe to be incorrect. The Board considers all representations before approving the final report, which is subsequently released to the public.

For more information, see our Investigation process page.

The TSB is an independent agency that investigates air, marine, pipeline, and rail transportation occurrences. Its sole aim is the advancement of transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability.