Collision with terrain during landing

Endeavor Air (dba Delta Connection)

MHI RJ Aviation Group CL-600-2D24 (Regional Jet Series 900), N932XJ

Toronto/Lester B. Pearson International Airport (CYYZ), Ontario

This preliminary report, which provides information on the progress of the safety investigation, contains facts ascertained up to 20 March 2025, the date it was released. The information in the report may be incomplete or change in the course of the investigation, and new information may be obtained after this preliminary report is published.

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary of the occurrence

On 17 February 2025, the MHI RJ Aviation Group. CL-600-2D24 aircraft (CRJ-900LR) (registration N932XJ, serial number 15194) was operating as Endeavor Air flight EDV4819 from Minneapolis-Saint Paul International/Wold-Chamberlain Airport (KMSP), Minnesota, United States, to Toronto/Lester B. Pearson International Airport (CYYZ), Ontario. During the landing on Runway 23, the aircraft impacted the runway, the right wing detached, and a fire ensued. The aircraft overturned and slid down the runway inverted, coming to rest near the intersection of Runway 23 and Runway 15L. Aircraft rescue and fire fighting responded, and all passengers and crew evacuated.

Factual information

History of the flight

At 1247All times are Eastern Standard Time (Coordinated Universal Time minus 5 hours). on 17 February 2025, the MHI RJ Aviation Group. CL-600-2D24 aircraft (CRJ 900LR) operated by Endeavor Air (doing business as Delta Connection) departed Minneapolis-St. Paul International/Wold-Chamberlain Airport (KMSP), Minnesota, United States, on flight EDV4819, an instrument flight rules flight to Toronto/Lester B. Pearson International Airport (CYYZ), Ontario, with 2 flight crew members, 2 cabin crew members, and 76 passengers on board. The captain was seated in the left seat and was the pilot monitoring for the flight. The first officer was seated in the right seat and was the pilot flying (PF).

The flight proceeded uneventfully, and the crew received clearance for the instrument landing system approach to Runway 23 at CYYZ. The landing reference speed (VREF) for the approach was 139 knots. According to Endeavor Air’s CRJ700/900 Series Company Flight Manual, “Final approach is flown at VREF+5 knots. When operating in gusty wind conditions, increase VREF by 1/2 of the gust factor not to exceed 10 KIAS [knots indicated airspeed] (top of the bug).”Endeavor Air, CRJ 700/900 Series Company Flight Manual, Revision 11 TR 24-03 (16 June 2024, effective 01 July 2024), Chapter 7: Standard Profiles & Maneuvers, Section: Approach Speeds, p. 7-36. On the occurrence flight, the flight crew set the speed bug to VREF+5 knots, or 144 knots. Given the reported wind gusts, the approach was flown at 149 knots.

At 1412:01, the aircraft descended through 500 feet above ground level (AGL). The aircraft’s indicated airspeed was 150 knots, its ground speed was 121 knots, and the engine thrust was indicating approximately 64% N1.N1 is the engine’s low-pressure compressor rpm, displayed digitally on the top of the primary engine display information which indicates the current N1 in percent. The rate of descent was 720 fpm, and the localizer and glide slope were centred. Five seconds later, the PF disconnected the autopilot.

At 1412:26, while the aircraft was descending through 175 feet AGL, its indicated airspeed was 144 knots, with a ground speed of 121 knots, and a rate of descent of 672 fpm. The thrust remained at approximately 64% N1.

At 1412:30, while the aircraft was descending through 153 feet AGL, its indicated airspeed increased to 154 knots whereas the ground speed did not change appreciably, consistent with a performance-increasing wind gust. The PF pulled back the thrust levers, and as a result, over the following 5 seconds, N1 decreased from 64% to approximately 43%, where it remained until touchdown. The airspeed began to decrease.

At 1412:40 (3.6 seconds before touchdown), when the aircraft was at a height of 50 feet AGL, the indicated airspeed was 145 knots, and the ground speed was 112 knots. The rate of descent had increased to 1114 fpm. The enhanced ground proximity warning system (EGPWS) aural alert “fifty” sounded to indicate the aircraft was at 50 feet AGL, which is a standard callout.

One second later (2.6 seconds before touchdown), the EGPWS alert “sink rate” sounded, indicating a high rate of descent. The aircraft’s indicated airspeed was 136 knots, its ground speed was 111 knots, and the rate of descent had remained at about 1100 fpm. The bank angle increased to a 4.7° right bank. The engine thrust was steady at approximately 43% N1.

At 1412:42 (1.6 seconds before touchdown), the aircraft’s indicated airspeed was 136 knots, and its ground speed was 111 knots. The aircraft was slightly below the glide slope, but on the visual segment of the approach and tracking the runway centreline. The rate of descent had increased to 1072 fpm, and the bank angle was 5.9° to the right.

Less than 1 second before touchdown, the aircraft’s indicated airspeed was 134 knots, and its ground speed was 111 knots. The bank angle was 7.1° to the right, and the pitch attitude was 1° nose up. The rate of descent was recorded as 1110 fpm.

At 1412:43.6, the right main landing gear (MLG) contacted the runway. The aircraft was in a 7.5° bank to the right with 1° of nose-up pitch and 3g vertical acceleration, at a rate of descent of approximately 1098 fpm (18.3 fps).

At touchdown, the following occurred: the side-stay that is attached to the right MLG fractured, the landing gear folded into the retracted position, the wing root fractured between the fuselage and the landing gear, and the wing detached from the fuselage, releasing a cloud of jet fuel, which caught fire. The exact sequence of these events is still to be determined by further examination of the fracture surfaces.

The aircraft then began to slide along the runway. The fuselage slid down Runway 23, rolling to the right until it became inverted. A large portion of the tail, including most of the vertical stabilizer and the entire horizontal stabilizer, became detached during the roll.

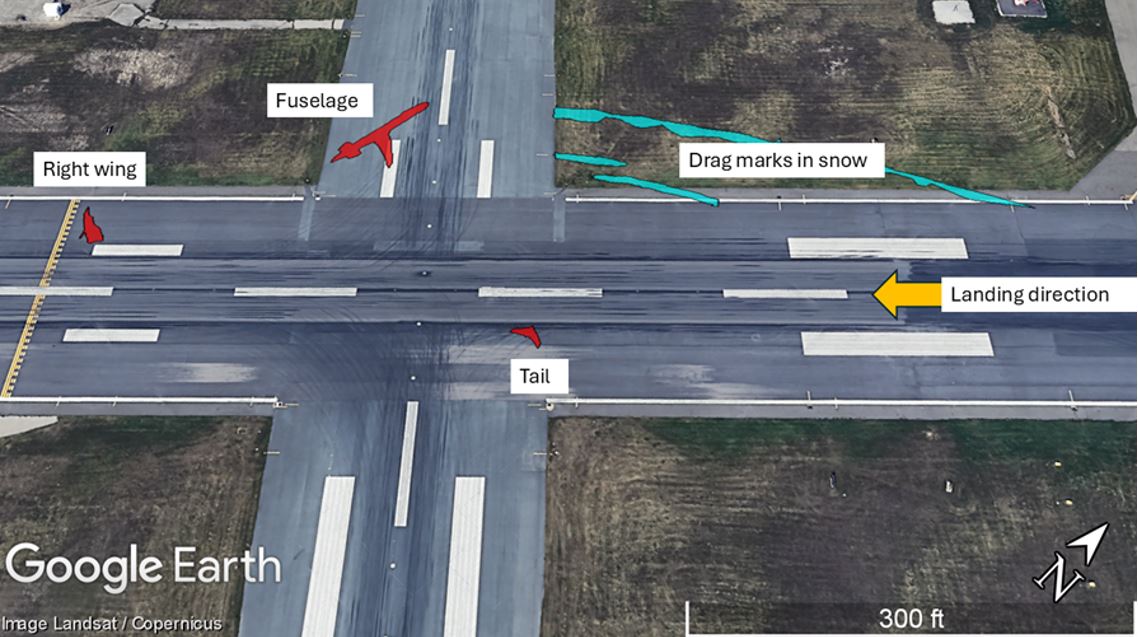

The aircraft went off the right side of the runway into the snow-covered grass area and came to a rest on Runway 15L, near the intersection with Runway 23, about 75 feet beyond the right edge of Runway 23 (Figure 1). The right wing, including the right MLG, became fully detached from the aircraft and slid approximately 215 feet further along Runway 23.

Once the aircraft came to a stop, an evacuation began. All occupants evacuated the aircraft. At the time of writing this preliminary report, it has been confirmed that 21 of the 80 occupants were injured; 2 of those occupants were reported to have serious injuries.In the Transportation Safety Board Regulations (SOR/2014-37), a serious injury is defined as follows: “(a) a fracture of any bone, except simple fractures of fingers, toes or the nose; (b) lacerations that cause severe hemorrhage or nerve, muscle or tendon damage; (c) an injury to an internal organ; (d) second or third degree burns, or any burns affecting more than 5% of the body surface; (e) a verified exposure to infectious substances or injurious radiation; or (f) an injury that is likely to require hospitalization.”

Personnel information

The captain has worked for Endeavor Air since October 2007. He holds an airline transport pilot certificate issued by the U.S. Federal Aviation Administration (FAA). He is employed as a flight crew member and a simulator instructor. At the time of the occurrence, he had accumulated about 3570 hours total flight time, including 764 hours on the aircraft type. On the day of the occurrence, the captain began his day at KMSP, and the occurrence flight was his 1st flight of day and his 1st flight in 7 days. In the previous 7 days, the captain had worked 3 days as an instructor. He had flown 3.5 hours in the previous 30 days.

The first officer has worked for Endeavor Air since January 2024. She holds an airline transport pilot certificate issued by the FAA. At the time of the occurrence, she had accumulated 1422.3 hours total flight time, including 418.7 hours on the aircraft type. The first officer was on day 5 of a 5-day work cycle. On the day of the occurrence, she had begun the day in Cleveland, Ohio, United States, with a flight that departed for KMSP at 0819. Upon arrival at KMSP, the first officer had 1 hour and 48 minutes until her next flight. Over the previous 30 days, she had conducted 3 round-trip flights into and out of CYYZ, not including the occurrence flight. She had flown 56.3 hours in the previous 30 days.

The flight attendant seated in the forward section of the aircraft had 3 years of experience, all of them with Endeavor Air.

The flight attendant in the rear section had 11 years of experience, including 5 years with Endeavor Air.

Aircraft information

The aircraft was a CL-600-2D24 (Regional Jet Series 900) manufactured by Bombardier Inc. in 2008 and registered to Delta Air Lines, Inc. on 31 December 2009. It was issued a transport category airworthiness certificate. It was configured with 2 flight crew seats, 1 cockpit observer seat, 3 flight attendant seats, and 76 passenger seats.

At the time of the occurrence, the aircraft was being operated within its allowable weight-and-balance limitations. The occurrence landing weight was approximately 73 000 pounds, and there was about 6000 pounds of fuel remaining at the time of landing.

Manufacturer | Bombardier Inc.* |

|---|---|

Type, model, and registration | CL-600-2D24, CRJ 900LR, N932XJ |

Year of manufacture | 2008 |

Serial number | 15194 |

Certificate of airworthiness | 24 September 2008 |

Total airframe time | 35 335 hours |

Engine type (number of engines) | CF34-8C5 (2) |

Maximum allowable take-off weight | 84 500 lb (38 329 kg) |

* MHI RJ Aviation Group currently holds the type certificate for the aircraft type.

Weather

The aerodrome routine meteorological report for CYYZ issued at 1400 indicated the following:

- Winds from 270° true (T) at 28 knots, gusting to 35 knots

- Visibility 6 statute miles (SM) in blowing snow

- Runway visual range for Runway 24L variable between 3000 feet and more than 6000 feet with an upward trend

- Broken ceiling at 3400 feet AGL

- Temperature −9 °C and dew point −14 °C

- Altimeter setting 29.93 inches of mercury

- Remarks indicated cumulus clouds at 6 oktas

Following the occurrence, a special aerodrome routine meteorological report for CYYZ issued at 1432 indicated the following:

- Winds from 270°T at 20 knots, gusting to 32 knots

- Visibility 6 SM in blowing snow

- Runway visual range for Runway 24L variable between 2600 feet and more than 6000 feet with a downward trend

- Broken ceiling at 3000 feet AGL

- Temperature −8 °C and dew point −13 °C

- Altimeter setting 29.94 inches of mercury

- Remarks indicated cumulus clouds at 5 oktas

The aerodrome forecast for CYYZ issued at 1240 and valid from 1300 on 17 February 2025 until 1900 on 18 February 2025 indicated the following:

- Winds from 270°T at 25 knots, gusting to 35 knots

- Visibility 3 SM in light snow showers and blowing snow

- Broken ceiling at 3000 feet AGL

- Between 1300 and 1600, a temporary (TEMPO) condition of 6 SM visibility due to blowing snow

- Between 1300 and 1600, a 40% probability (PROB40) of 1½ SM visibility due to light snow showers and blowing snow

The runway had recently been plowed to a width of 160 feet; the full runway width is 200 feet.

Company information

Endeavor Air is a wholly owned subsidiary of Delta Air Lines, Inc. headquartered in Minneapolis, Minnesota, United States. It has hub operations in Atlanta (Georgia), Cincinnati (Ohio), Detroit (Michigan), Minneapolis, New York (New York), and Raleigh-Durham (North Carolina), and it has 11 maintenance bases across the network. It is the world's largest operator of CRJ-900 aircraft, with 139 regional jets. Flying as Delta Connection, Endeavor Air operates 700 daily flights to over 126 cities in the United States, Canada, and the Caribbean. Endeavor Air has over 1800 flight crew members and 1600 cabin crew members.

Company landing standard operating procedures

The flight operations manual indicates to initiate the flare between 30 and 20 feet AGL by increasing pitch attitude as needed to slow the descent rate while continuing to reduce thrust to idle. At 20 feet, back pressure on the control column is to be maintained as necessary to hold a constant pitch angle. In addition, the manual states that the pitch attitude at touchdown should be between 3° and 8°, depending on the landing reference speed (VREF) of the aircraft. If the pitch attitude exceeds 11°, there is a risk of a tail strike.Endeavor Air, CRJ 700/900 Series Company Flight Manual, Revision 11 TR 24-03 (16 June 2024, effective 01 July 2024), Chapter 7: Standard Profiles & Maneuvers, Section: Aircraft Geometry Considerations for Takeoff, p. 7-17. Also, a hard landing is defined as “[a] landing at a vertical descent rate greater than 600 ft/min when the aircraft's gross weight is less than or equal to MLW [maximum landing weight].”Ibid., Section: Hard/Overweight Landing, p. 7-73.

Wreckage information

The initial impact point was about 420 feet past the Runway 23 threshold, where the right MLG struck the runway surface. The aircraft came to rest inverted on Runway 15L, approximately 1800 feet beyond the threshold and about 75 feet to the right of the runway edge, near the intersection of Runway 23 and Runway 15L.

A large portion of the tail section was found on the runway, to the left of the centreline, about 1680 feet from the threshold and 235 feet from the main wreckage. The right wing came to a rest on Runway 23 about 215 feet beyond the main wreckage (figures 2 and 3).

Landing gear

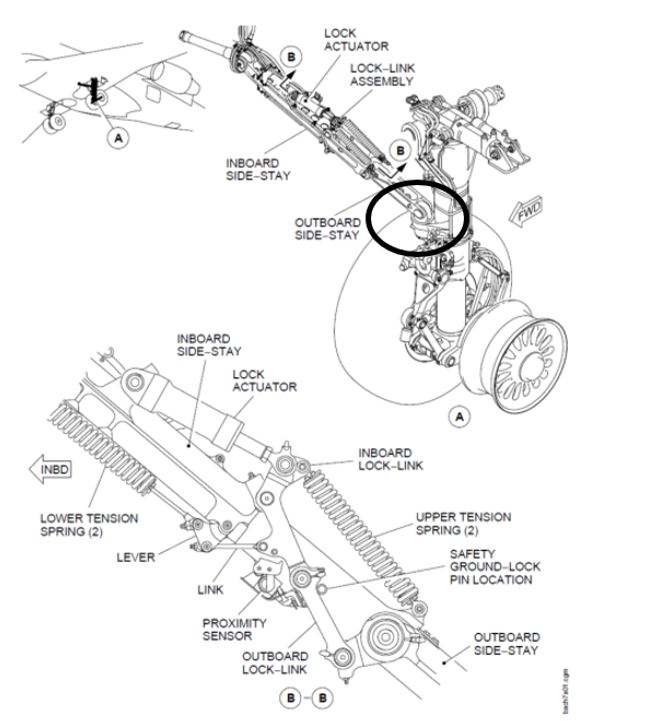

The MLG consists of 2 MLG assemblies mounted on the underside of the wing that retract inward into wheel bays. Each MLG assembly incorporates a shock absorber and twin wheels.

A folding side-stay is attached to the wing rear spar and to the shock strut and locks the MLG in the extended position. An uplock assembly located in the fuselage structure (above the side-stay) provides a mechanical means of locking the MLG in the retracted position. The uplock assembly releases the MLG from the up-and-locked position through hydraulic pressure for normal extension, or mechanically when the gear alternate extension system is used. A retract actuator is fitted to each of the MLG assemblies to extend and retract the MLG. A lock actuator unlocks the MLG from the down-and-locked position for retraction of the gear.

The right MLG was found with the severed right wing. There was minor damage to the right MLG tires; however, no flat spots or major damage was observed. The right MLG tire wear and pressure and nitrogen strut pressure were found within the aircraft maintenance manual limits. There was no damage to the left MLG or nose landing gear.

There was minor damage to the right MLG strut; marks on the lower portion of the right MLG strut outer cylinder showed evidence of the strut bottoming out.

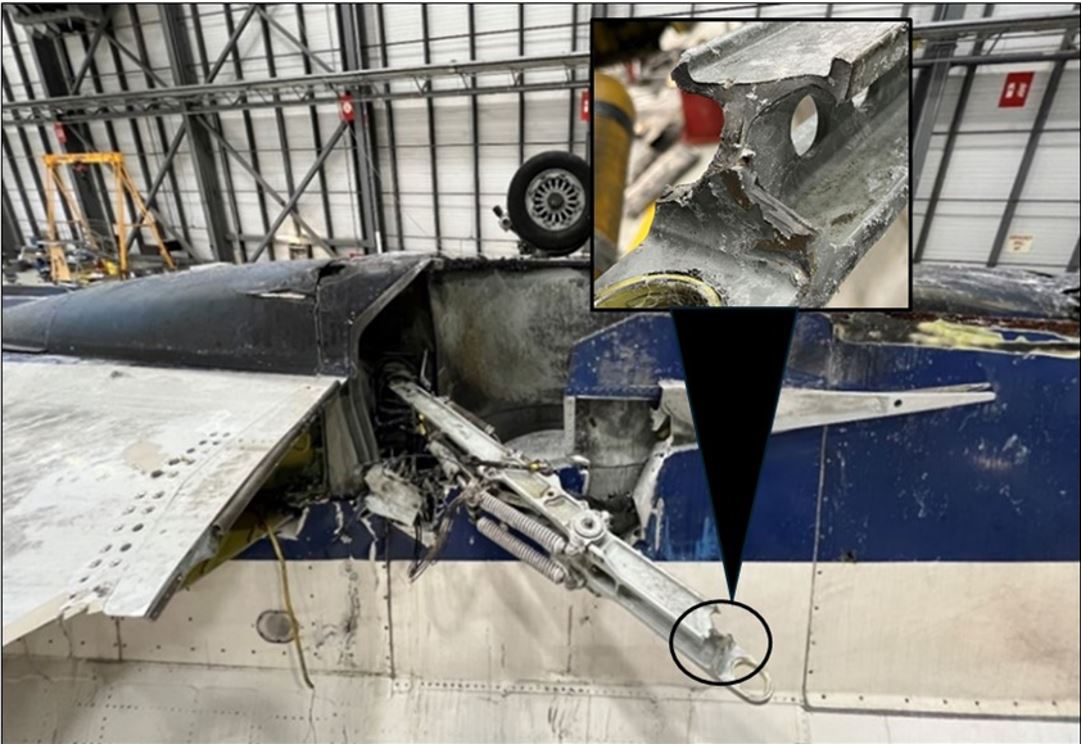

The right MLG outboard side-stay (Figure 4) locks the landing gear in place and prevents the landing gear from collapsing during normal operations.

During the occurrence, the right MLG outboard side-stay fractured at the connection to the landing gear strut; the landing gear then folded inward. The side-stay remained in the down-and-locked position (Figure 5).

Various other components of the landing gear strut and side-stay attachment fittings were found scattered along the runway.

The MLG shock struts on this aircraft are designed to absorb the energy of a 720 fpm (12 fps) descent velocity at the maximum landing weight.

The right MLG strut and side-stay were shipped to and quarantined at the landing gear manufacturer for further TSB examination. During the MLG strut removal, the installation pins were moving freely at the landing gear trunnion attachments.

Flight controls

The flaps and slats were fully deployed at the time of the occurrence. The flap jackscrew threads were measured to be 10 inches for both the left and right inboard flap actuators (4 locations), which corresponds to 45° of flaps. Based on measurements taken from the left slat, the slats were in a 25° position.

The flight control cables from the flight deck to the severed locations were examined and showed to be continuous. Rudder, elevator, and aileron control was validated for the fuselage portion; no faults were found. The flight control components in the vertical stabilizer section were severely damaged because of the accident sequence, but no pre-existing damage was found. The aileron controls for the right wing were torn from the aircraft structure in the MLG bay area when the right wing detached. Aileron control was validated to the centering mechanism located on the aft MLG bay wall.

The elevators’ power control units and mechanism were verified, and no faults were found in the horizontal stabilizer area. The elevator autopilot servo was removed and sent to the TSB Engineering Laboratory, in Ottawa, Ontario. No corrosion was found on the cables; however, the body and cables were severed during the accident sequence.

The flight data recorder data did not contain any caution or warning messages pertaining to the flight controls.

Wings

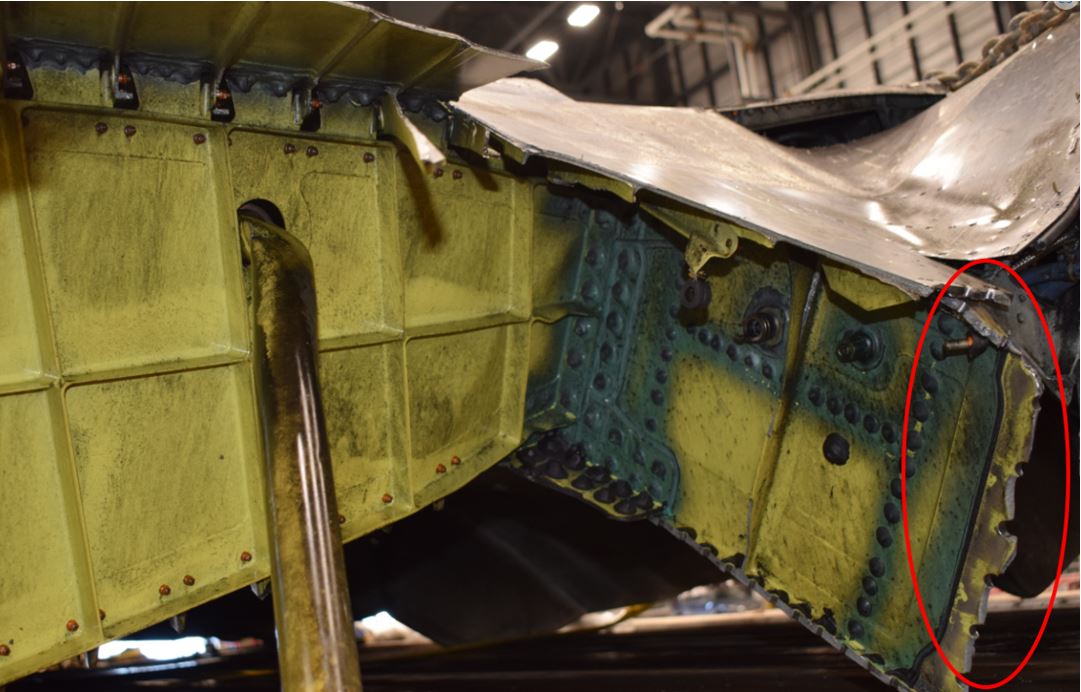

The right wing separated from the fuselage, and the left wing was severely damaged but remained attached to the fuselage. The right-wing main spar fractured at the fastener location to the fuselage, and the main spar was also bent significantly downward from the accident sequence (Figure 6). In addition, there was substantial damage to the right wing in the area surrounding the landing gear.

The fuel tank is integrated into the wing. As a result, when the right wing broke off, fuel spilled out of the wing and ignited. There was significant fire damage to the wing, and the right-wing fuel balance pipe, which is located inside the right wing, had a damaged sidewall that was deformed outwards (Figure 7).

The right wing, sections of the left wing, and the wing box structure (to which the wings are attached) will undergo further examination at the TSB Engineering Laboratory.

Engines

The No. 1 and No. 2 engine fans and low-pressure turbines were found still free to rotate; the left-engine forward mount had fractured during the accident sequence. No abnormalities were found with the engines.

Before the occurrence, the right engine integrated engine-driven generator had been disconnected and a minimum equipment list deferral was in effect for the repair. The auxiliary power unit was running during the entire occurrence flight to provide an additional power source, per the minimum equipment list. This was the only deferred item in the journey log.

Emergency locator transmitter

Although the emergency locator transmitter was armed, it did not activate during the accident sequence. The transmitter and applicable components have been sent to the TSB Engineering Laboratory for further analysis.

Recorded data

The flight data recorder and cockpit voice recorder were removed from the wreckage and sent to the TSB Engineering Laboratory for download and analysis. Both recorders captured the approach and impact.

Subsequently, the following components were recovered and also sent to the TSB Engineering Laboratory for non-volatile memory recovery and analysis:

- The cockpit voice recorder G-switch

- The radio altimeter components including the antennas

- Two spoiler stabilizer control units

- Two flaps/slats control units

- The stall protection computer

- The central maintenance computer

- The EGPWS

- The proximity sensor electronic unit

- The quick access recorder

Emergency response and evacuation

The aircraft came to rest inverted; as a result, passengers were hanging upside down in their seats, suspended by their safety belts, and many of the carry-on baggage and other items ended up on the aircraft ceiling (Figure 8). Some passengers had difficulty releasing the buckles on their safety belts due to being inverted. Some of the injuries sustained by the passengers occurred when they unbuckled their safety belts and fell to the ceiling. The TSB is not aware of any safety belt or seat failures occurring during the accident.

The crew and the passengers began evacuating; however, the deformation of the forward fuselage coupled with the flight attendant jump seat position prevented the flight deck door from opening after the accident. As a result, the pilots used the escape hatch on the cockpit ceiling (which was upside down) to evacuate. The hatch opening was close to the ground, which impeded the evacuation; however, with help from a passenger, the pilots were able to egress (Figure 9).

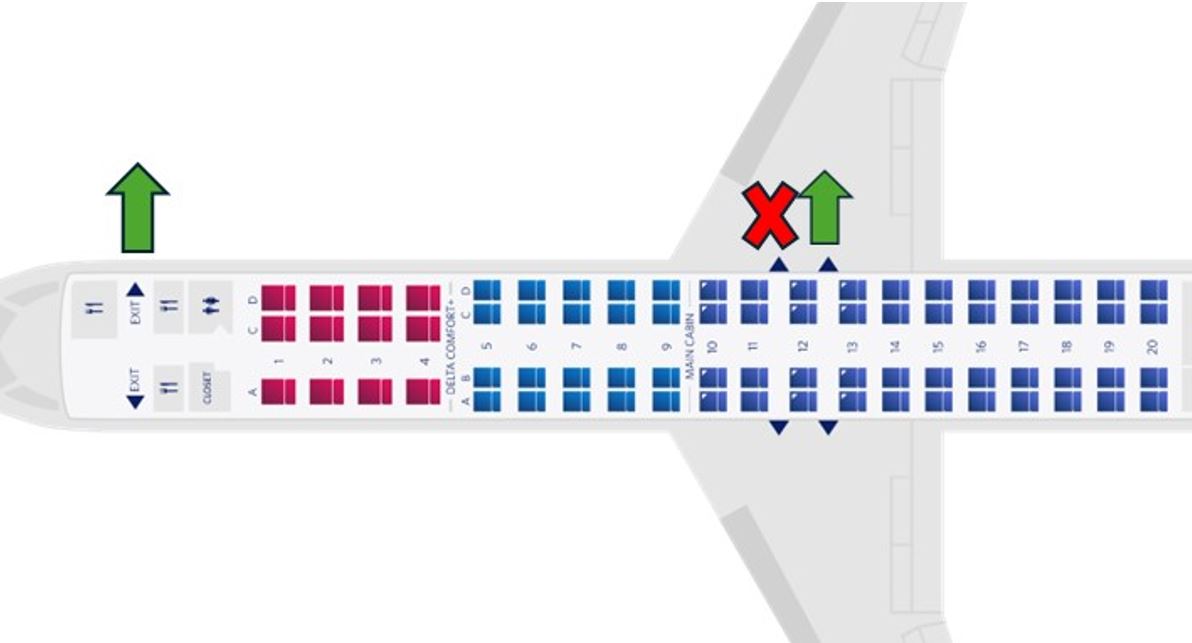

Aircraft rescue and fire fighting (ARFF) personnel arrived approximately 5 minutes after the accident. A passenger attempted to utilize the forward emergency overwing exit located on the starboard side of the fuselage at seat 12D; however, because fuel was flowing over that exit door, most rear-fuselage occupants evacuated via the overwing exit door at seat 13D (Figure 10), some of whom got covered in fuel. Several passengers exiting through the same exit were also sprayed by fire retardant foam from the ARFF vehicle.

The lavatory door, which became unhinged during the accident sequence, blocked visibility looking aft for the forward flight attendant before being removed entirely by a passenger.

After the passengers and crew evacuated, ARFF personnel entered the fuselage. Shortly thereafter, an explosion occurred outside the aircraft in the area of the left wing root. The cause of this explosion has yet to be determined.

Although some passengers had evacuated with their carry-on baggage, much of the carry-on baggage was left on board. Another company pilot and cabin crew member, who were repositioning as passengers on the flight, assisted with the evacuation in the aft of the cabin.

Areas of investigation

The following is a list of the current areas of focus for this investigation. This list is not exhaustive and may be expanded over the course of the investigation.

- Metallurgical examination of the wing structure

- Certification (landing gear and wing structure)

- Evacuation / egress procedures

- Flight deck door structure and design

- Landing techniques, hard landings, and pilot training

- Cabin obstructions and impediments once inverted

- Flight deck secondary egress route

- Organizational and management factors

- Flight attendant training

- Coordination in emergencies

- ARFF and emergency medical technician actions after accident

Other organizations assisting in the investigation

- Transport Canada

- NAV CANADA

- U.S. National Transportation Safety Board

- FAA

- Delta Air Lines, Inc.

- Endeavor Air

- MHI RJ Aviation Group

- GE Aerospace

- Air Line Pilots Association

- Collins Aerospace

- Association of Flight Attendants-CWA