Striking of a mooring dolphin

Roll-on/roll-off ferry Apollo

Matane, Quebec

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Executive summary

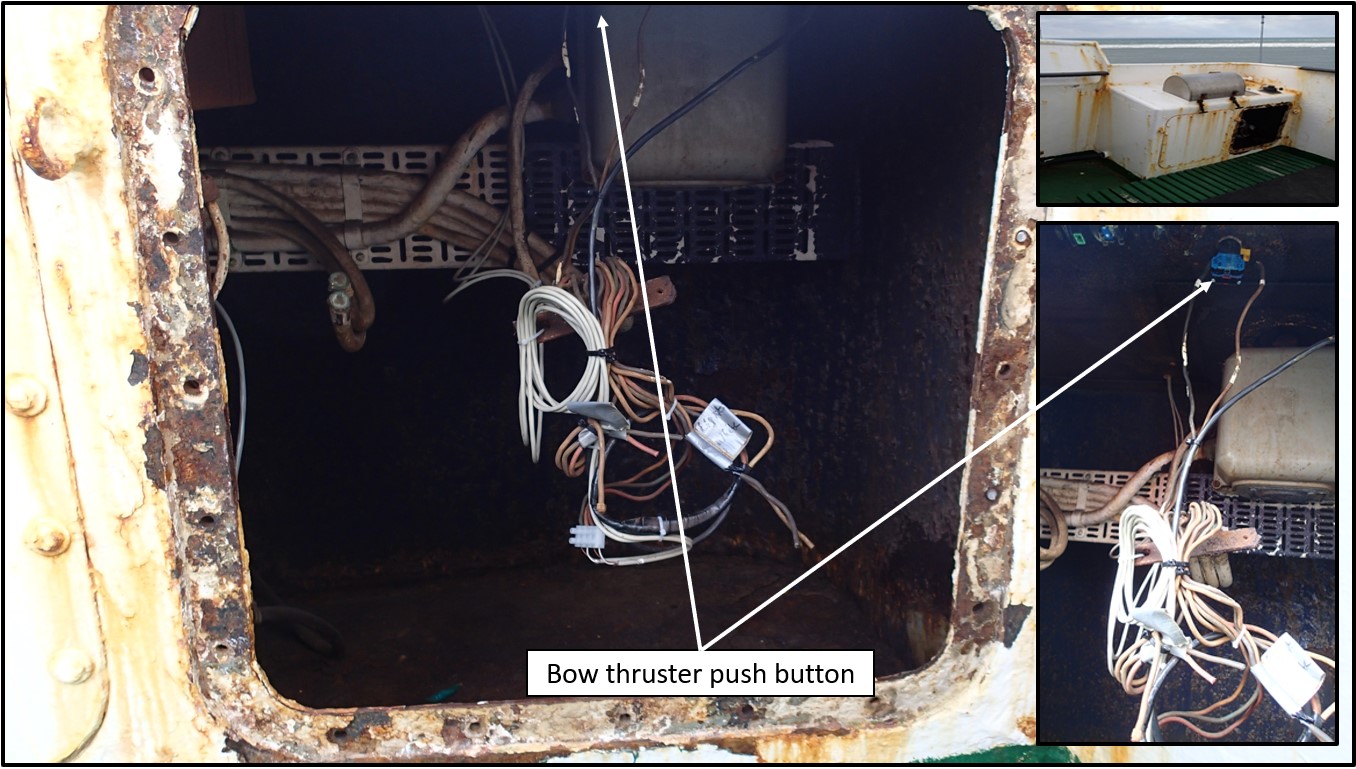

On 16 March 2019, the roll-on/roll-off ferry Apollo was making a routine crossing from Godbout, Quebec, to Matane, Quebec, with 94 people on board when it struck a mooring dolphin (a structure that extends the berthing capacity of a dock) during berthing. At the time of the occurrence, there were high winds and it was dark. During the berthing, the master had been attempting to manoeuvre the vessel from the starboard bridge wing console using the engine, rudder, and bow thruster. As the vessel entered the port of Matane, the master had pushed the button on the starboard bridge wing console to transfer control of the bow thruster from the bridge; however, the transfer did not initiate because of a broken electrical wire. This meant that the bow thruster did not respond to any of the master’s inputs made using the bow thruster controls while the vessel was in the port. The vessel sustained damage as a result of the striking and was removed from service. No pollution or injuries were reported.

The Apollo was an aging vessel that the Société des traversiers du Québec (STQ) had recently purchased to provide service on an essential ferry route after the regular vessel on that route was unexpectedly taken out of service. A pre-sale inspection was not conducted, and when the STQ received the vessel from the former owner, the STQ discovered it had a number of unsafe conditions that affected its seaworthiness. The STQ initially postponed the Apollo’s entry into service and began conducting repairs. However, under pressure to restore the ferry service and considering that the Apollo was a temporary vessel for short-term use, the STQ put the vessel into service while repairs were ongoing. A risk assessment was not conducted, which led to the Apollo being in service without adequate identification of hazards and an assessment of the associated risks.

The Apollo was a delegated vessel under the Transport Canada (TC) Delegated Statutory Inspection Program and had been inspected by a recognized organization before and after its purchase by the STQ. TC also inspected the vessel prior to the STQ putting it into service. These inspections did not identify a number of unsafe conditions present on the vessel and resulted in the recognized organization issuing the Apollo the certificates it required for entry into service. The investigation determined that if oversight of delegated vessels by TC and recognized organizations does not lead to the identification and timely resolution of unsafe conditions and regulatory contraventions, there is a risk to the safety of the vessel, its crew, its passengers, and the environment. As well, if TC oversight of recognized organizations carrying out work under the Delegated Statutory Inspection Program is ineffective, there is a risk that unseaworthy vessels will be certified and operated.

The investigation also looked at the vessel’s safety management system, bridge resource management training requirements, the design of the bow thruster’s status indicators on the vessel, and the availability of continuous maintenance records.

Following the occurrence, the TSB boarded the vessel and then notified TC of safety issues identified. TC inspected the vessel on 21 March 2019 and issued a restriction from sailing. The STQ conducted a risk assessment and internal investigation that resulted in several recommendations for safety action that the STQ subsequently implemented.

1.0 Factual information

1.1 Particulars of the vessel

| Name of the vessel | Apollo |

|---|---|

| International Maritime Organization number | 7006314 |

| Official number | 820777 |

| Port of registry | St. John’s, Newfoundland and Labrador |

| Flag | Canada |

| Type | Roll-on/roll-off ferry |

| Gross tonnage | 6609 |

| Length overall | 108.7 m |

| Draft | 4.59 m |

| Built | 1970, Germany |

| Propulsion | 2 medium-speed 4-stroke diesel engines (7330 kW in total) driving 2 variable-pitch propellers |

| Maximum complement | 270 |

| Complement at the time of the occurrence | 94 |

| Maximum vehicle capacity | 80 |

| Vehicles on board at the time of the occurrence | 43 |

| Registered owner and technical manager | Société des traversiers du Québec |

| Classification society / recognized organization | Bureau Veritas |

| Issuing authority for International Safety Management certification | Lloyd’s Register |

1.2 Description of the vessel

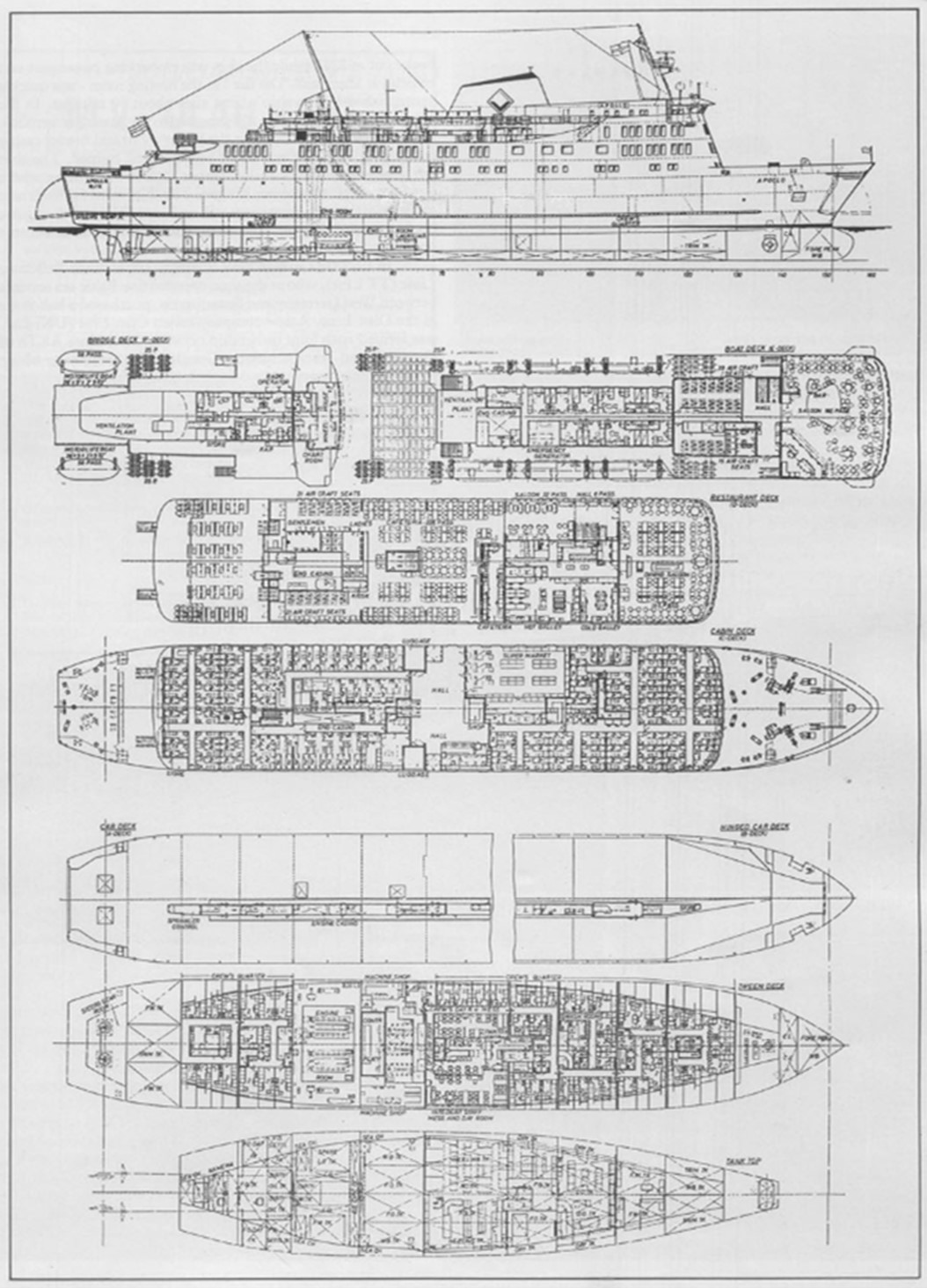

The Apollo was an ice-strengthenedFootnote 1 roll-on/roll-off ferry of steel construction (Figure 1). The vessel had 9 decks in total, including 1 vehicle deck accessible by ramps at the bow and stern (Appendix A). A bow visor could be raised and lowered to allow access to the vehicle deck. The vehicle deck extended fore to aft and had no transverse or longitudinal watertight bulkheads.Footnote 2 The vessel’s 2 anchors were located on either side of the bow, aft of the bow visor.

The vessel was originally designed to accommodate 1200 persons and had 222 passenger cabins. At the time of the occurrence, the cabins were no longer in use and had been locked to prevent passengers from entering them. Access points to the cabins had also been blocked off.

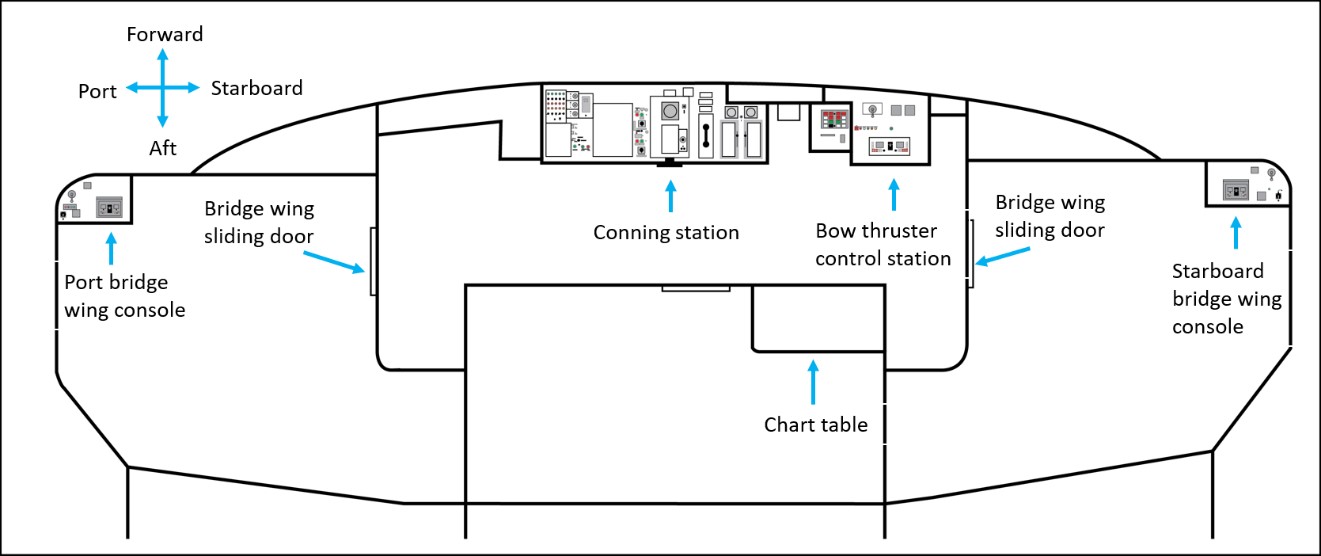

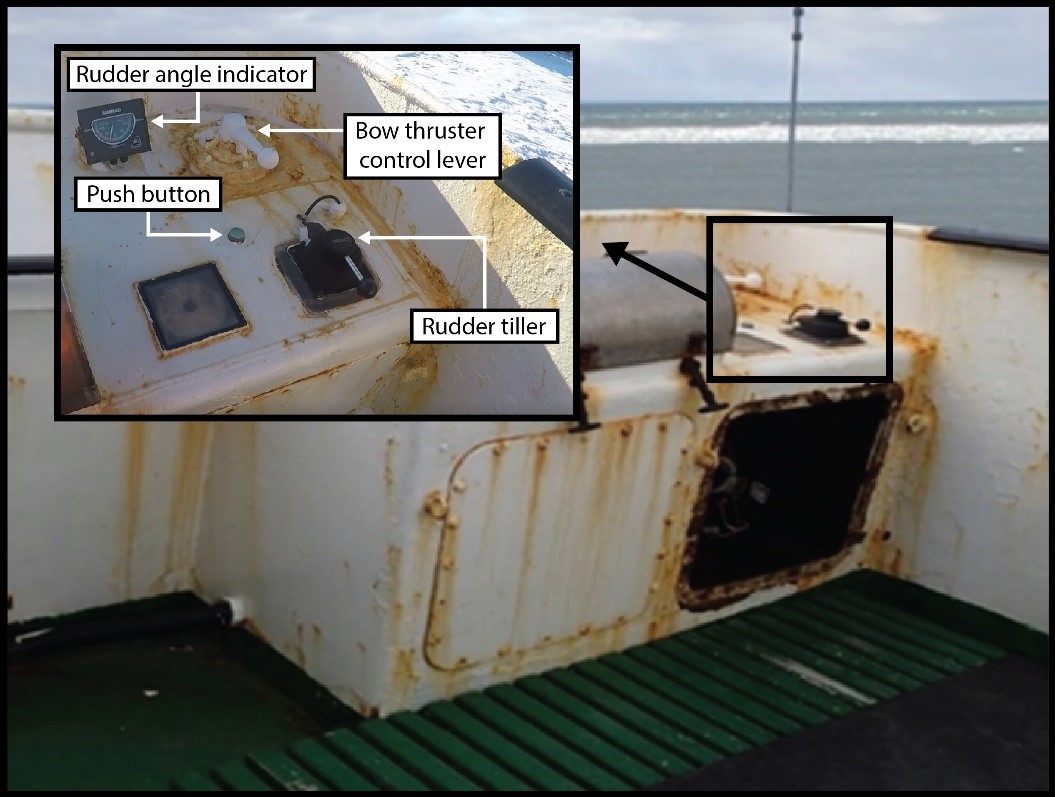

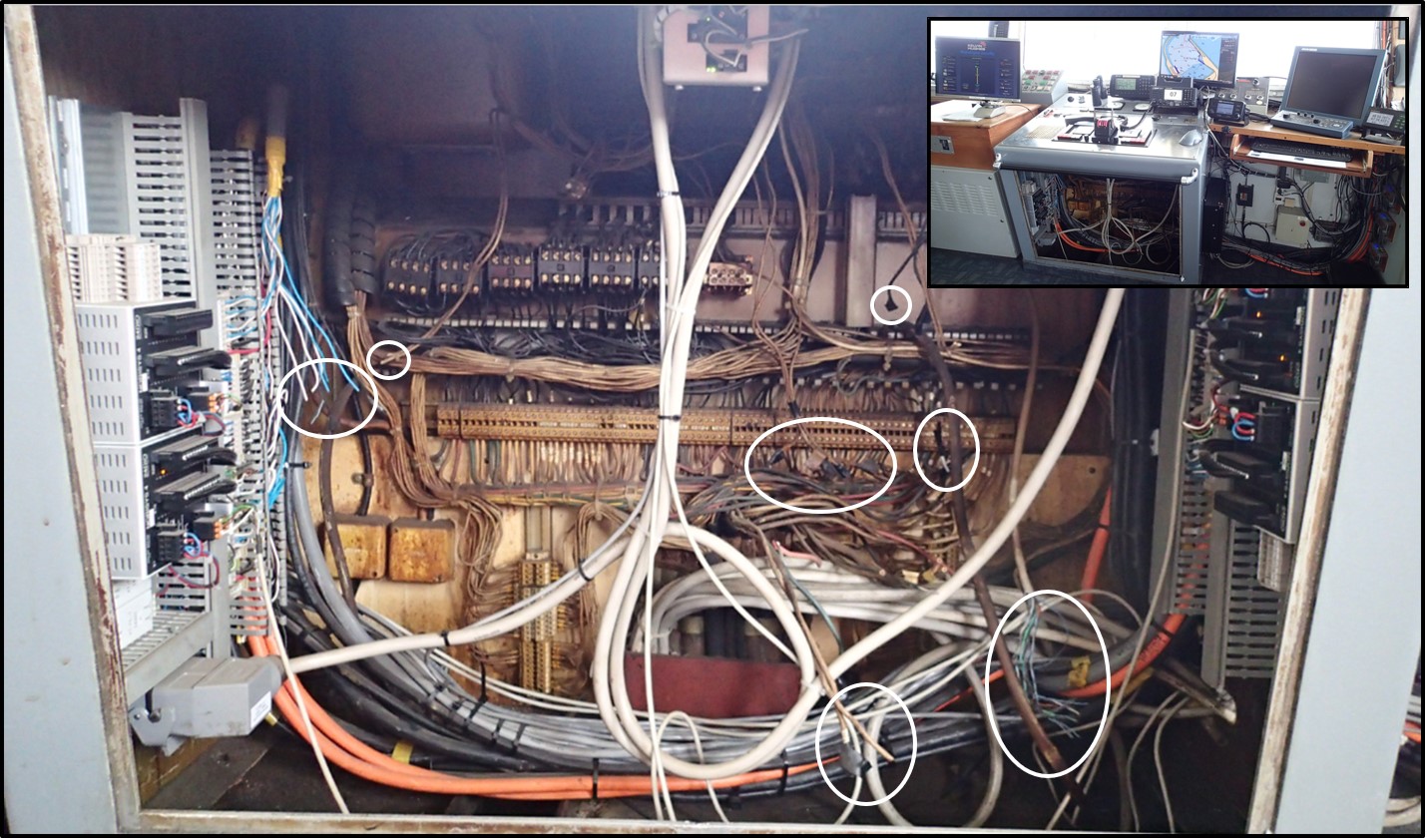

The bridge was enclosed and was equipped with navigational equipment that included a speed log, a GPS (global positioning system), an automatic identification system, and 3-cm and 10-cm radars with automatic radar plotting aid capability. The vessel also had paper charts and an electronic chart system. The main steering and propulsion control consoles were centrally located on the bridge, with additional consoles on the open bridge wings, which were used during berthing. The vessel was fitted with a bow thruster, controls for which were located on the bridge and the port and starboard bridge wing consoles (Figure 2).

The vessel was powered by 2 diesel engines: an 8-cylinder engine with a maximum continuous rating of 4000 kW on the port side and a 9-cylinder engine with a maximum continuous rating of 3330 kW on the starboard side. Both engines drove variable-pitch propellers via gearboxes. The vessel’s service speed was 20 knots. Steering was effected by means of 2 semi-balanced rudders.

The vessel’s electrical power was supplied by 3 generator sets. Each generator set consisted of a 500 kW diesel engine coupled to a 3-phase alternating current generator supplying electrical power to the main switchboard. The vessel also had an emergency switchboard as well as an emergency generator set, which was designed to start automatically if the main power failed and to supply power to essential systems.Footnote 3

1.3 Vessel’s service history

From the time the Apollo was constructed in 1970 until 2000, the vessel provided ferry service in northern Europe, sailing in the Baltic and North seas. In 2000, the Apollo was acquired by Labrador Marine Inc., a subsidiary company of Woodward Group of Companies (WGOC).Footnote 4 The Apollo was put into service providing a ferry connection between Blanc-Sablon, Quebec, and St. Barbe, Newfoundland and Labrador. On this route, the Apollo made an average of 2 round-trip crossings per day. The one-way crossing time was 2.5 hours, including loading and unloading. The Apollo remained on this route, providing service for vehicles and foot passengers, until it was sold to the Société des traversiers du Québec (STQ) in January 2019.

1.4 Société des traversiers du Québec

The STQ is a Crown corporation owned by the Government of Quebec, established in 1971. It oversees a network of 14 ferry routes, 9 of which are operated directly by the STQ and 5 of which are operated in partnership with private companies. At the time of the occurrence, the STQ had 21 vessels and approximately 700 employees. Over the course of a year, the STQ provides more than 108 000 crossings and transports nearly 4.7 million passengers and 2 million vehicles.Footnote 5 The STQ’s head office is located in Québec, Quebec. The STQ’s designated person ashore and the STQ director at each crossing report to the vice president of operations. The designated person ashore also has a direct link to the chairperson–chief executive officer, who reports directly to the provincial Minister of Transport.

1.4.1 Matane–Baie-Comeau–Godbout route

The STQ is responsible for providing ferry service on an essential routeFootnote 6 linking Matane, Baie-Comeau, and Godbout, Quebec. From 01 April 2018 to 31 March 2019, a total of 158 469 passengers and 76 022 vehicles were transported on this route.Footnote 7 This route provides an important socio-economic link between communities on either side of the St. Lawrence River, especially during the winter season, when other seasonal ferries in the area stop operations. During the winter season, the next nearest place where people can cross the St. Lawrence River, via a ferry crossing or bridge, is Québec—a detour of approximately 900 km.

Before the arrival of the Apollo, the STQ vessel assigned to this route was the roll-on/roll-off ferry F.-A.-Gauthier. The F.-A.-Gauthier had been purchased new by the STQ and had been providing service since July 2015. During this time, it had encountered ongoing problemsFootnote 8 that had led to service interruptions and had generated media coverage. On 17 December 2018, the F.-A.-Gauthier was removed from service for 2 days for maintenance. The maintenance was unexpectedly extended and, on 19 December, the F.-A.-Gauthier’s operations were ceased indefinitely. The STQ informed the public that all crossing reservations were cancelled.

Once the ferry service was halted, the STQ began to receive complaints from the public.Footnote 9 The unexpected service stoppage and the STQ’s management of the situation also received media coverage. The complaints and media coverage put pressure on the STQ to restore ferry service as soon as possible. The STQ initially used a temporary combination of vessels and airplanes to maintain service on the route (Table 2).

| Date range | Measure taken by the STQ |

|---|---|

| 21 December 2018 to 07 January 2019 | Airplane service between Baie-Comeau and Mont-Joli (except for 25 December 2018 and 01 January 2019) at reduced rates (less than the ferry walk-on rate) |

| 08 January 2019 to 31 January 2019 | CTMA Vacancier brought in to provide temporary ferry service |

| 01 February 2019 to 11 February 2019 | CTMA Voyageur brought in to provide temporary ferry service (priority given to transport trucks) |

| 12 February 2019 to 13 February 2019 | Airplane service between Baie-Comeau and Mont-Joli at reduced rates |

Approximately 1 week after the F.-A.-Gauthier was removed from service, the STQ began searching for a vessel to purchase for temporary use on the route, anticipating that the F.-A.-Gauthier would return at some point before the end of June 2019. The STQ considered 12 vessels, one of which was the Apollo. WGOC was in the process of replacing the Apollo with another vessel, as the Apollo was reaching the end of its service life.

The STQ approached WGOC about purchasing the Apollo, which was then operating between Blanc-Sablon and St. Barbe, providing similar services in similar environmental conditions. The Apollo held a class certificate issued by its classification society, Bureau Veritas (BV), and had all of the required Canadian certificates issued by BV, which was also acting as the recognized organization (RO)Footnote 10 for the Apollo under the authority of Transport Canada (TC). Of the 12 vessels that the STQ considered, the Apollo was the only one readily available that met some of the STQ’s criteria.

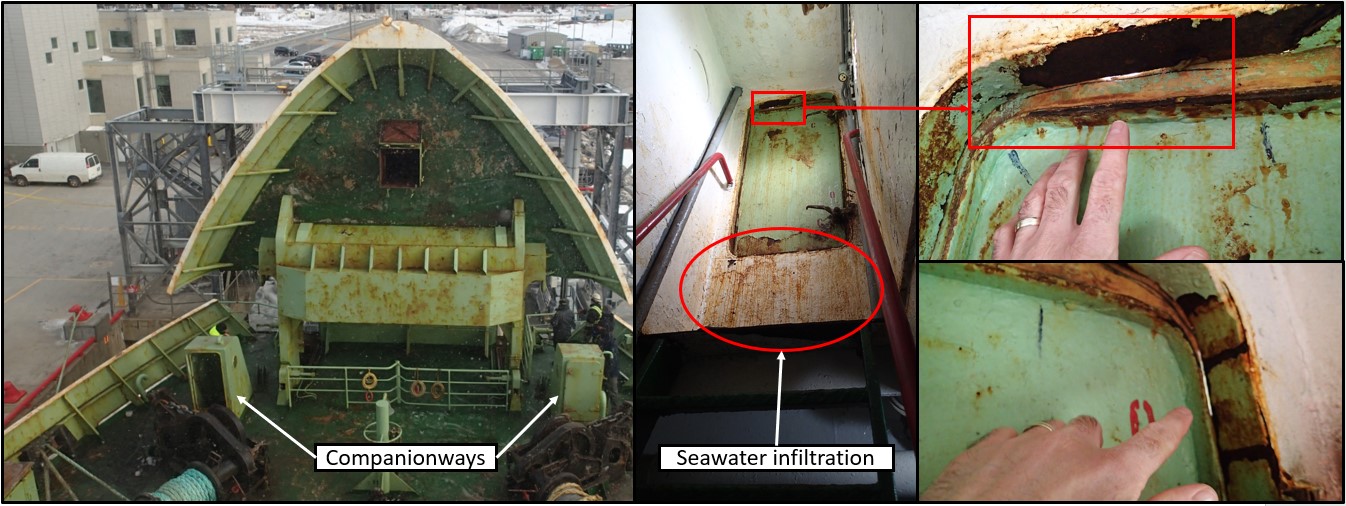

1.5 The Apollo’s entry into service with the Société des traversiers du Québec

After the sale agreement was concluded, 11 STQ crew members were sent to St. Barbe so that the Labrador Marine Inc. crew could help familiarize them with the vessel during its delivery voyage to Matane. The paperwork to transfer the vessel ownership in the TC Canadian Register of Vessels had not been completed, and WGOC was still responsible for the vessel during the delivery voyage. The STQ team boarded the Apollo on 21 January 2019 and identified a number of safety issues related to the vessel’s condition. The STQ team master raised his concerns about the Apollo’s seaworthiness to the WGOC master who had been assigned to the vessel for the delivery voyage, but the WGOC master had a different perception of the Apollo’s condition. The STQ team master then called the STQ superintendent of the shore maintenance team and conveyed his concerns.

On 22 January, senior officers on the STQ team, including the team’s master, had a conference call with STQ management, including the chairperson–chief executive officer and the vice president of operations. The senior officers expressed concerns about the state of the vessel, indicating that it was dangerous to operate and not seaworthy.Footnote 11 They pointed out that the vessel’s fire detection, monitoring, and extinguishing systems were unreliable. The STQ team masterFootnote 12 informed STQ management that the vessel was not safe to sail and that he would not take on the responsibility of sailing it once it arrived in Matane. The senior officers told STQ management that the vessel would need to undergo major repairs before sailing on a regular route across the St. Lawrence River. The senior officers recommended that the vessel’s purchase be cancelled because of its condition.

STQ management asked the team on board the vessel to prepare a list of observations about the vessel and provide it to the STQ management. The team did not prepare such a list but instead requested that STQ management contact an independent inspection firm to inspect the vessel before its departure. STQ management did not follow through on this request.

STQ management contacted WGOC to discuss the team’s concerns and inquire about the vessel’s condition. Following this conversation, a representative from WGOC met with the STQ team master and informed him that the sale had been agreed upon without a pre-sale inspection. The representative indicated that the STQ team was not permitted to access the vessel for the purpose of monitoring and verifying the vessel’s systems, and that their presence on board was for familiarization only.

The STQ team master contacted another STQ master who had many years of experience and expressed his concerns about the Apollo’s condition and the oversight being provided by the Apollo’s RO. A TC marine safety inspector (MSI) happened to be with the STQ master who received the call and and then explained the situation to the MSI. The MSI then called the STQ team master. The STQ team master informed the MSI of his concerns about the oversight of the vessel by the RO and the vessel’s overall condition, pointing out issues with life boats, leaking decks, storage of life jackets, leaking fire lines, and non-operational fire stations. The STQ team master also informed the MSI that he had a preliminary list of deficiencies to report. The MSI informed the master that he should address his concerns to the vessel’s RO and, if he was still dissatisfied, he should then contact TC. The master sent the preliminary list of deficiencies to a TC office on 22 January. He did not pursue the issue further, having raised the concerns with both STQ management and TC.

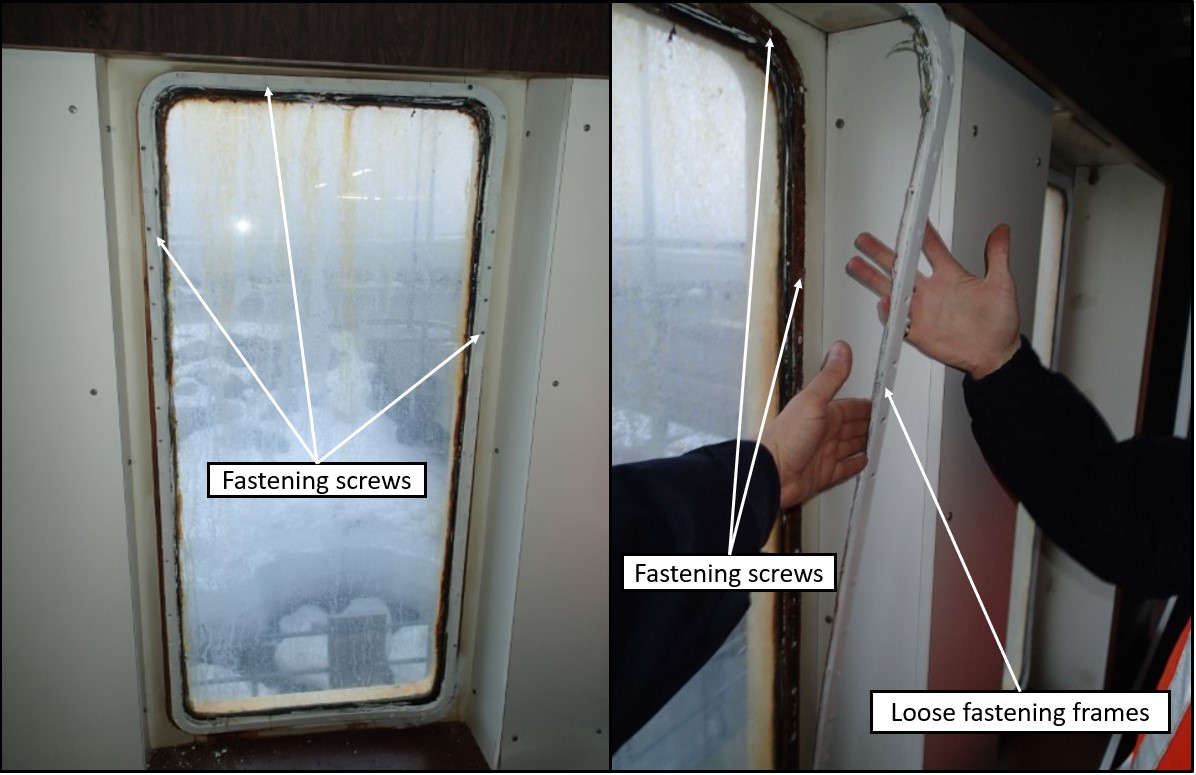

The Apollo departed St. Barbe for Matane on 25 January under the conduct of the Labrador Marine Inc. crew, with the STQ team on board for familiarization. The voyage was approximately 475 nautical miles (NM), mostly in the Gulf of St. Lawrence along the Lower North Shore of Quebec, which is sparsely populated by small communities. The voyage took 3 days, with the vessel arriving in Matane on 28 January. The STQ had planned that the Apollo would enter into service on 04 February, but, after the STQ identified repairs required on the vessel (Appendix B), it postponed the entry into service. The Apollo was assigned a crew, which, along with the shore maintenance team and contractors, began making repairs the next day. The repairs focused on getting the vessel’s firefighting systems, life-saving equipment, and critical equipment functioning. The crew’s involvement with the repairs reduced the time they spent on familiarization.

On 06 February, the vessel’s RO and TC concurrently inspected the vessel and identified a total of 19 deficiencies. On 10 February, after visiting the vessel and verifying the work done by the STQ to address the deficiencies identified, the RO issued an inspection certificateFootnote 13 under the Canada Shipping Act, 2001 (CSA 2001) for the Apollo, which allowed the vessel to begin providing ferry service. The Apollo made its first crossing on the Matane–Baie-Comeau–Godbout route on 14 February.Footnote 14

The ferry schedule was originally designed so that the Apollo would complete 2 round trips from Matane to either Godbout or Baie-Comeau each day. The one-way crossing time on either of these routes is approximately 3 hours, including loading and unloading. Repairs were still continuing when the Apollo entered into service. Because of concerns about the vessel’s condition, the crew requested that STQ management modify the schedule so that the Apollo could complete 2 round trips 4 days of the week, and 1 round trip on the remaining days, to allow more time for repairs. STQ management modified the schedule accordingly.

1.6 History of the voyage

On 16 March 2019, the crew was preparing the Apollo for the 1700Footnote 15 return trip from Godbout to Matane. In response to a request by the master, the chief engineer went to the starboard bridge wing console to look into replacing the button that was used to activate control of the bow thruster at that console. The plan was to replace the existing button in the next few days with one that would illuminate to indicate the operational status of the bow thruster. This would allow the master to have a visual indication of the bow thruster’s status while performing docking manoeuvres. The modification had been requested following instances in which the master had not realized that the bow thruster’s main breaker had tripped while he was using the bow thruster to manoeuvre the vessel near shore infrastructure. The chief engineer opened the console panel in order to identify the electrical circuit for the bow thruster, moving some of the electrical wires in the process. Once he was finished, the chief engineer secured the console panel back in place.

At 1658, the master took his position on the port bridge wing console in preparation for departure. A trainee master, the chief officer, and the helmsman were also on the bridge. The trainee master was on board for observation purposes only and was not actively involved in the vessel’s navigation. The chief officer was acting as the officer of the watch.

At 1702, the Apollo departed Godbout with 66 passengers and 43 vehicles on board. The Apollo’s minimum safe manning certificate required 15 crew members, but the vessel was sailing with 28 (a combination of crew, contractors, and members of the shore maintenance team), to assist with repairs.

At the time of departure, the wind was from the west at about 20 knots. The forecast for the crossing was westerly winds from 25 to 35 knots. At 1745, when the vessel was about midway through the crossing, the master reduced the vessel’s speed because the wind speeds had increased and the sea state had deteriorated. Once the Apollo was approximately 4 NM from Matane, the 3rd generator set was brought online. Switching on the 3rd generator set was an informal practice to address the fact that the Apollo’s 3 generator sets were operating at a reduced capacity. The practice of using all 3 generator sets was done to accommodate additional demand from the bow thruster and the deck equipment during docking manoeuvres.

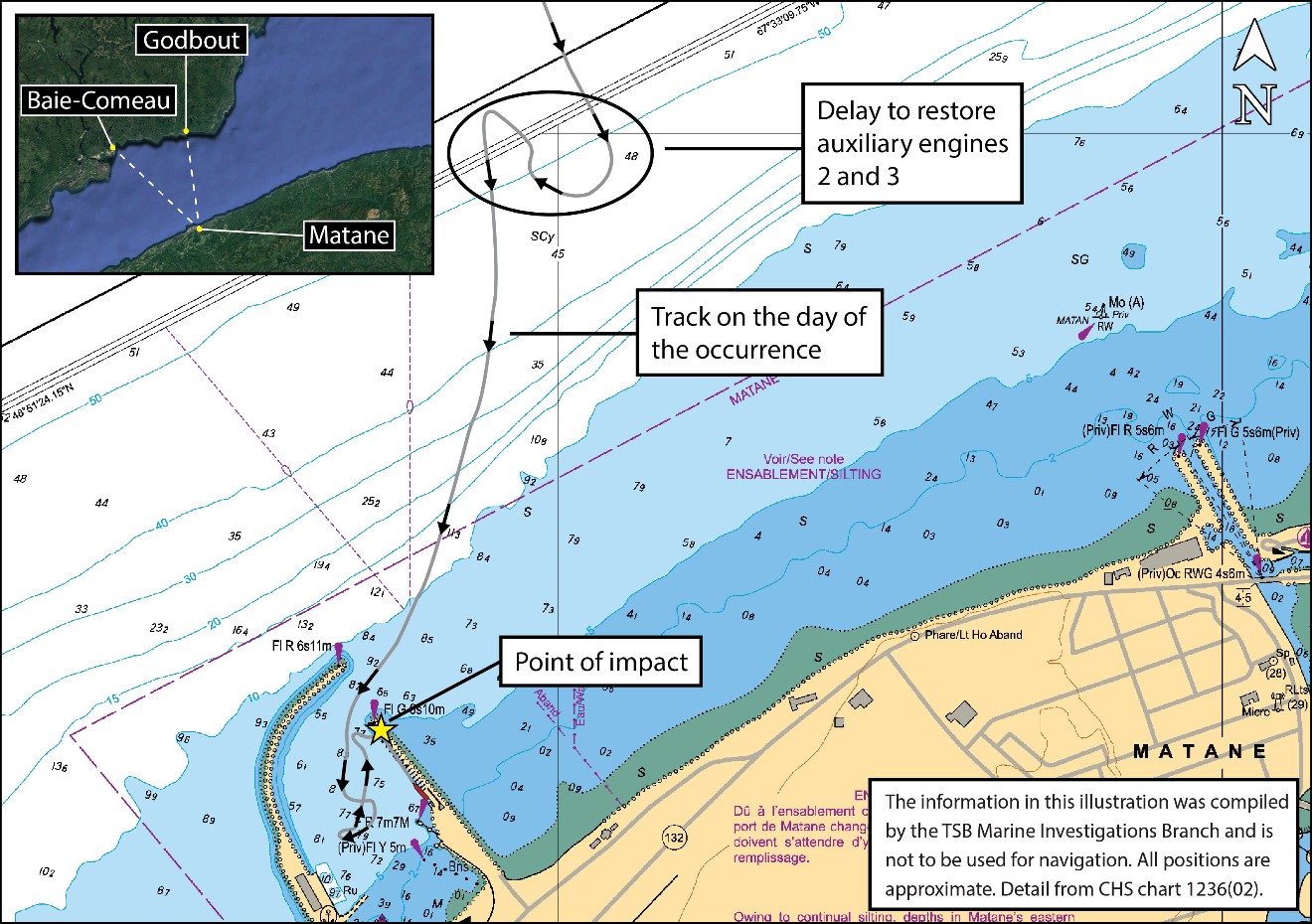

At 1903, the master called STQ personnel in Matane to inquire about the wind speed in the port. The master was informed that the wind speeds had increased beyond those originally forecast upon departure and were now between 35 and 40 knots. At 1908, the vessel was approximately 2 NM from Matane when the master received a call from the engine room crew. They informed him that 2 of the generator sets had shut down automatically when their overheat sensors had activated because of seaweed and debris blocking one of the strainers on a cooling line. The engine room crew had kept the 3rd generator set running by switching over to the other strainer on the cooling line. The engine room crew asked the master to give them some time to resolve the situation before proceeding to dock in Matane (Appendix D).

The master decreased the vessel’s speed to 2 knots and ordered a course alteration to bring the vessel windward to reduce its rolling motion while the engine room crew removed air locks in the generator sets’ cooling lines. By approximately 1928, the engine room crew had the generator sets running again, and the master decided to resume the voyage toward Matane. At this time, the engine room crew informed the master that the bow thruster had been activated and was ready for manoeuvring operations.

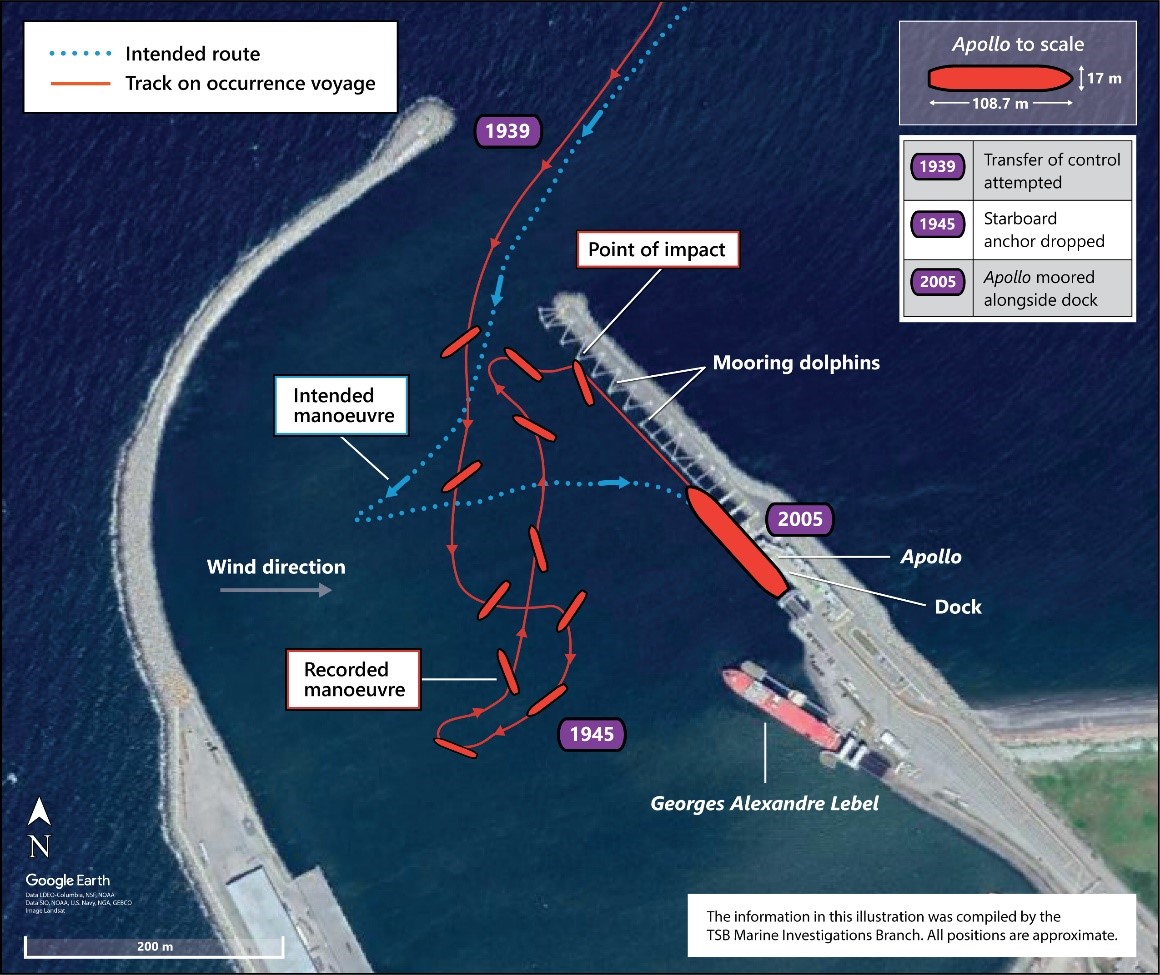

At approximately 1930, just before the vessel arrived in the port, the master communicated his intended docking manoeuvre to the bridge team. To mitigate the risk posed by the winds, the master had planned a docking manoeuvre that would make use of at least 1 anchor. He had the crew standing by to release 1 or both anchors if needed. The master intended to proceed into the port with the bow windward, drop the port anchor to create a pivot point if needed, and then back stern-first to the dock (Figure 3).

The master ordered the chief officer to the forecastle to prepare the anchors. The trainee master was asked to relay communication between the master and the forward and aft mooring teams.

At 1939, the Apollo entered the port of Matane. The master took conduct of the vessel from the starboard bridge wing console and pressed the button to transfer control of the bow thruster from the bridge to the starboard bridge wing console for docking. The wind was blowing from the west at 35 to 40 knots, and the wave height was about 0.5 m. As the Apollo proceeded past the outermost mooring dolphins,Footnote 16 the master used a combination of engine, rudder, and bow thruster controls to put the bow windward. The vessel’s response was minimal, and it continued on a transverse course under the influence of the wind.

Meanwhile, the mooring team was standing by on the forecastle ready to deploy the anchor during the docking operations. In the engine control room, the crew was closely monitoring the bow thruster’s ammeter for excess load consumption and the generator sets’ diesel engines for high temperatures. If either was observed, the crew was to notify the master, who could reduce thrust or stop using the bow thruster.Footnote 17

At approximately 1942, the master ordered the mooring team to drop the port anchor to create a pivot point for the vessel. Shortly after the anchor was dropped, the wind pushed the Apollo toward the rail ferry Georges Alexandre Lebel, which was moored nearby, bringingthe stern of the Apollo to within 45 m of the rail ferry’s bow (Figure 3). The master immediately ordered the mooring team to drop the starboard anchor to stop the Apollo from getting any closer. The starboard anchor was dropped at approximately 1945.

At 1948, in order to make a different approach, the master put both engines to full ahead with the rudders hard to starboard and moved the bow thruster controls to turn the vessel’s bow toward the mooring dolphins. The master managed to reposition the vessel for the new approach, and the crew was ordered to heave up the starboard anchor. At 1952, the master started approaching the mooring dolphins bow-first with the port anchor dragging on the sea bed.

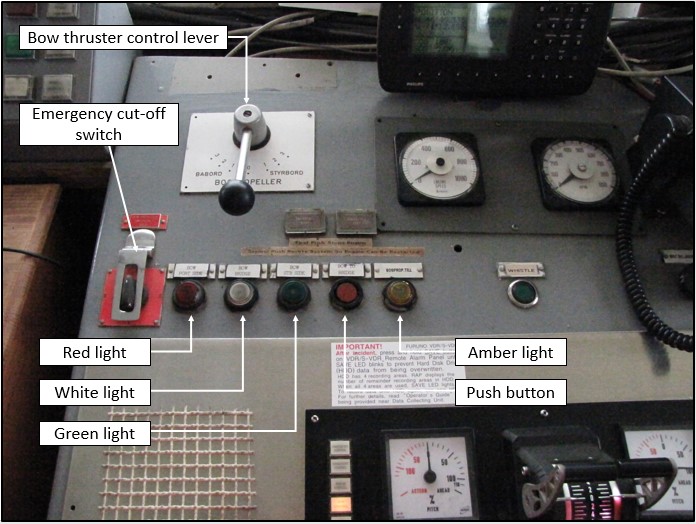

The engine room crew, still monitoring the bow thruster’s ammeter, noted that it showed no electrical consumption as the vessel was manoeuvring. The chief engineer called the bridge team and asked if the bow thruster was in use. The helmsman answered the call and, after noting that the white and amber indicator lights for the bow thruster on the bridge console were lit, provided an affirmative response. This light combination indicates that the bow thruster is activated and control is at the bridge console.

At 1954, the Apollo’s starboard side was brought alongside the mooring dolphins, but the stern swung toward them under the influence of the wind. The master throttled the engines full ahead and put the rudders hard to starboard, which, in combination with the strong wind, caused the vessel’s bow to swing toward the mooring dolphins. The master moved the bow thruster controls to counteract the movement of the vessel’s bow and turned the rudders hard to port, but the Apollo’s bow continued moving toward the mooring dolphins, striking one of them at 1955.

At 2005, the Apollo moored alongside the dock. The master ordered the crew to check the vessel for damage. After considering the damage, the crew determined that it was safe for the passengers and vehicles to disembark. There were no reported injuries.

Following the occurrence, the vessel’s electrician met with the master on the bridge to verify the operational state of the bow thruster. Based on the bow thruster’s ammeter readings in the engine control room, it was concluded that the bow thruster had not responded to any of the master’s inputs for the manoeuvres in the port.

1.7 Bow thruster

The Apollo’s bow thruster was a 478 kW tunnel-type unit with a fixed-blade propeller. The direction of thrust could be either port or starboard, and the thruster had 3 speed settings: slow (75%), half (90%), and full (100%).

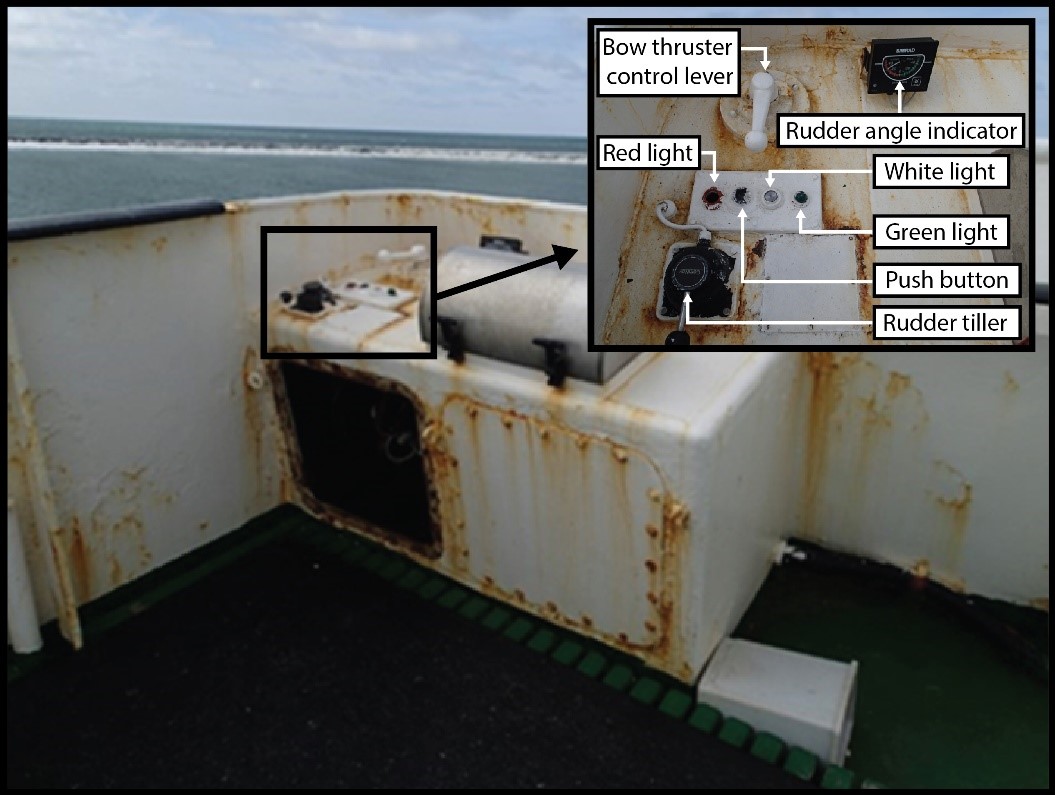

The bow thruster could be controlled from the bridge console, the port bridge wing console, or the starboard bridge wing console. Each console was fitted with a bow thruster control lever that controlled the speed and direction of thrust. Control was transferred among these 3 consoles by a button on each console. When the bow thruster was in use at 1 console, the controls at the other 2 consoles were locked out. There was also an emergency cut-off switch on the bridge console that could disable the bow thruster at all 3 consoles in case of emergency.

The bow thruster is an essential piece of equipment during docking in Matane because of the confined nature of the port. The bow thruster increases manoeuvrability of the vessel and assists in the avoidance of hazards (other vessels, ice, etc.). In the Matane port, the practice was to dock the Apollo stern-first with its starboard side to the dock, so the bow thruster was operated from the starboard bridge wing console. In Baie-Comeau and Godbout, the practice was to dock bow-first with the vessel’s port side to the dock, so the bow thruster was operated from the port bridge wing console.

The Apollo’s masters had an informal practice of testing the bow thruster from the bridge wing consoles before using it and of confirming that it was operational from the noise and visible thrust in the water that it produced. On occasion, the masters had used another method to verify that the bow thruster was operational, which was to call the engine room and have the engineers verify the bow thruster’s electrical consumption using the ammeter.

Before the occurrence, the last time the master had successfully used the bow thruster controls from the starboard bridge wing console was upon departure from Matane on the morning of the occurrence. On the occurrence voyage, the bow thruster’s operational status could not be confirmed from the noise it produced or visible thrust in the water because of the environmental noise from the wind and waves. The master did not confirm its operational status using the ammeter in the engine room.

1.7.1 Bow thruster power supply

To power the bow thruster’s electric motor, at least 2 of the 3 generator sets had to be online. For safety reasons, there was an interlocking arrangement to prevent the bow thruster motor from coming online if fewer generator sets were in operation. At slow speed, the bow thruster used 400 A, at half speed, 600 A, and at full speed, 800 A.

Upon purchasing the Apollo, the STQ had identified problems with the fuel injectors on the generator sets’ diesel engines and had ordered replacement fuel injectors, but they had not yet been delivered at the time of the occurrence. The problems with the fuel injectors meant that the Apollo’s 3 generator sets were unable to operate at more than approximately 50% of their rated power because their auxiliary diesel engines overheated for demands in the range of 280 kW. This meant that at slow speed the bow thruster’s operational time was unlimited; however, at half speed it was a few minutes and, at full speed it was about 20 seconds. The bridge crew and engine room crew were aware of the reduced operational time of the bow thruster.

1.8 Damage to the vessel

The Apollo was damaged where the bow visor and the hull connect (figures 4 and 5). The shell plating was pushed in and dented over about 1 m, which resulted in a gap between the bow visor and the hull about 0.3 m wide at its maximum. There was also structural buckling around this area. The STQ permanently removed the Apollo from service on 19 March 2019 as a result of the damage caused by the striking.

1.9 Environmental conditions

At 1658 on 16 March 2019 in Godbout, around the time of the Apollo’s departure, the winds were from the west at about 20 knots. The forecast for the crossing was westerly winds at 25 to 35 knots. The recorded air temperature was around −4 °C.

An entry in the vessel’s logbook at 1800 indicated that the wind speeds corresponded to Beaufort wind scale categories of F8 and F9. F8 wind speeds are between 34 and 40 knots, and F9 wind speeds are between 41 and 47 knots.

At around 1940, in the port of Matane, the winds were westerly at 35 to 40 knots, and the wave height was about 0.5 m. The sky was clear, it was dark, and the visibility was about 10 NM.

1.10 Personnel certification and experience

The master held a Master Mariner certificate of competency issued in January 2018. He had started working for the STQ in May 2018 as a chief officer on the F.-A.-Gauthier and had undergone training on that vessel to become a master. In February 2019, he was promoted to the rank of master and was assigned to the Apollo. At the time of the occurrence, he had sailed for approximately 1 week as master on the Apollo. As part of his familiarization on the Apollo, he had spent 15 hours dedicated to manoeuvring the vessel. Before joining the STQ, he had worked as a chief officer on various chemical/products tankers. He had 12 years of experience at sea.

The trainee master held a Master, Near Coastal certificate of competency issued in February 2007. Before joining the STQ in January 2019, he had worked as a second officer and third officer for various companies. He had 40 years of experience at sea.

The chief officer held a Watchkeeping Mate, Near Coastal certificate of competency issued in November 2007. He had joined the STQ in 2015 and had become a chief officer in March 2019. He had 21 years of experience at sea.

The chief engineer held a First Class Engineer certificate of competency issued in January 2012. Before joining the STQ in April 2018, he had held a position as chief engineer for 17 years.

The helmsman held a Bridge Watchman certificate of competency issued in February 2000. He had joined the STQ in 2010 and had 31 years of experience at sea.

The STQ team master who was on board the Apollo for familiarization purposes during its delivery voyage held a Master, Near Coastal certificate of competency issued in February 2016. He had joined the STQ in January 2015 as a second officer and relief chief officer. He was promoted to the rank of master on the F.-A.-Gauthier in November 2016. Before joining the STQ, he had worked as a navigation officer on various vessels. He had 10 years of experience at sea.

1.10.1 Fatigue

The investigation determined that fatigue was not a factor in this occurrence.

1.11 Vessel management

Under the CSA 2001, every vessel must have an authorized representative (AR), who is responsible for acting with respect to all matters related to a vessel that are not otherwise assigned to any other person. Specifically, the AR shall

- ensure that the vessel and its machinery and equipment meet the requirements of the regulations made under this Part;

- develop procedures for the safe operation of the vessel and for dealing with emergencies; and

- ensure that the crew and passengers receive safety training.Footnote 18

As well, with respect to the vessel’s Canadian maritime documents (CMDs),Footnote 19 the AR shall ensure that

- the vessel and its machinery and equipment are inspected for the purpose of obtaining all of the Canadian maritime documents that are required under this Part; and

- every term or condition attached to a Canadian maritime document issued in respect of the vessel or its machinery or equipment is met.Footnote 20

At the time of the occurrence, the AR for the Apollo was the STQ.

1.11.1 Master’s responsibilities for safety of persons

Under the CSA 2001, the master of a vessel shall take all reasonable steps to ensure the safety of the vessel and the persons who are on board. If the master is informed of a hazard, the master shall take all reasonable measures to protect the vessel and persons on board. If it is not feasible to eliminate the hazard, the master of a Canadian vessel shall notify the AR.Footnote 21

1.12 Vessel classification

Vessel classification is a fee-based service that ensures adherence to a set of rules for construction and inspection established by a classification society. The rules lay out standards for the structural strength of the vessel’s hull and its appendages, as well as the suitability of the propulsion and steering systems, power generation, and other vessel features and auxiliary systems. A vessel that meets class requirements is provided with a certificate of classification and is noted in the classification society’s Register of Ships.

Once a vessel is classed, vessel owners or ARs invite classification surveyors on board annually to verify the vessel’s compliance with class rules. Classification surveyors may also be invited on board for specific requests. When surveyors board for specific requests, the scope of their work is limited to that requested by the vessel owner or AR. The classification society has the right to refuse or withdraw from class any vessel that does not continue to meet class requirements.

The Apollo had been classed by BV from its construction until the time it was taken out of service in 2019. Its last inspection for endorsement of its class certificate was on 05 April 2018.

1.13 Delegated Statutory Inspection Program

Through the Delegated Statutory Inspection Program (DSIP), TC delegates authority to selected classification societies to complete inspections required under section 16 of the CSA 2001 and to deliver certain CMDsFootnote 22 to vessels enrolled in the program. Many other flag states have similar programs.

The DSIP was implemented in 2001. It was originally an optional program for classed vessels and was intended to allow TC to allocate inspection and oversight resources to higher-risk vessels. In 2014, the DSIP became mandatory for all Canadian vessels of 24 m in length and above. As of March 2021, a total of 699 vessels were registered in the DSIP.

There are currently 7 ROs in Canada authorized under the DSIP. All of the ROs are international classification societies that carry out similar duties for other flag states. The ROs are accountable to TC for work done on TC’s behalf, and are required to notify TC immediately if they become aware of a major deficiencyFootnote 23 or safety-related issue on a delegated vessel.

One of the 7 ROs authorized under the DSIP is BV, which has been carrying out DSIP work for TC since 2003. The Apollo was first enrolled in the DSIP, with BV as its RO, in 2014. At the time of the occurrence, the Apollo held valid CMDs issued by BV.

1.13.1 Transport Canada’s monitoring of recognized organizations

Although ROs are authorized to carry out DSIP work, TC maintains responsibility for overseeing the performance of ROs in a variety of ways, including oversight visits to RO offices as well as compliance inspections on board delegated vessels.Footnote 24

TC’s role in monitoring ROs is explained in the DSIP policy Footnote 25 and the DSIP work instructions. Footnote 26 The DSIP policy states that TC will monitor the RO’s performance at various points throughout the life of a vessel.

TC also has a work instruction for inspection of existing delegated vessels. Footnote 27 This document provides details on assigning responsibility for certain deficiencies to ROs. TC refers to these as “RO-related deficiencies.” The document explains that, while it is unreasonable to expect ROs to identify every deficiency at every survey, “if there are deficiencies that have a significant impact on the safety or environmental performance of the vessel that an RO should have noted, within reason, then that deficiency should be attributed to the RO.” Footnote 28

The document sets out guidance for determining RO responsibility, as follows:

1. The deficiency is structural (e.g., corrosion, cracking)

a) It is a serious structural deficiency including corrosion, wastage, cracking and buckling, unless it is clear that the deficiency has occurred since the last survey conducted by the RO

2. The deficiency is related to non-structural (e.g., fire main, rails) or equipment

a) It is a serious deficiency in equipment or non-structural fittings (such as fire main, air pipes, cargo hatches, rails, masts, etc.) AND it is less than 90 days since the last survey conducted by the RO

b) It is a serious deficiency in equipment or non-structural fittings which clearly would have existed at the time of the last survey

c) It is a serious deficiency associated with out-of-date equipment which was out-of-date at the time of the last survey

d) Missing approval or endorsement of Plans and Manuals, if required to comply with the provisions for issuance of statutory certificates [CMDs] which clearly would have existed at the time of the last survey

3. The deficiency is a major non-conformity where there is clear evidence of a lack of effective and systematic implementation of a requirement of the ISM [International Safety Management] Code AND there is clear evidence that it existed at the last audit conducted by the RO. It may also include operational drills and operational control and there is clear supporting evidence of failure. Footnote 29

The document indicates that if TC records an RO-related deficiency, the DSIP liaison officer (DSIPLO) will inform the RO of the deficiency. Footnote 30 It also indicates that the DSIP program officer Footnote 31 should be copied on the communication in order to ensure that a national record of oversight activities is maintained. Finally, the document indicates that the DSIP program officer is responsible for communications related to the oversight of RO activities. The DSIP work instructions state that the DSIP program officer is responsible for maintaining a record of non-conformities to be discussed with the RO during an oversight review. Footnote 32

An authorization agreement Footnote 33 between TC and the RO specifies that TC is responsible for monitoring the RO’s work and may undertake audits at any time and for any reason. One reason for an audit is to respond to adverse reports. The DSIP procedure states that TC “may remove a vessel from DSIP at any time based on the performance of the AR or the RO […].” Footnote 34

1.13.2 Periodic and occasional inspections

The RO carries out periodic inspections of delegated vessels, typically consisting of annual, quadrennial, and quinquennial inspections to verify the vessel’s compliance with the CSA 2001 and its regulations. The RO also conducts occasional inspections on an as-needed basis, for example, to verify a certain piece of machinery or to inspect a vessel before issuing a transit certificate.Footnote 35

Annual inspections are conducted while the vessel is afloat and involve checking the vessel’s structure, watertight integrity, main and auxiliary engines, steering, communications equipment, power distribution systems, life-saving equipment, firefighting equipment, and paperwork, among other things. The vessel’s CMDs are delivered after the RO has confirmed that the vessel meets regulations.

In addition to annual inspections, vessels must also undergo quadrennial or quinquennial inspections, conducted while the vessel is in dry dock, to verify the hull’s condition and perform thickness measurements. These inspections also verify the condition of the vessel’s sea chests, valves, rudders, and propellers, among other things. The Apollo’s inspection history dating back to 2014 is detailed in Appendix E.

Before leaving St. Barbe, the Apollo underwent an occasional inspection in order to obtain a transit certificate. The inspection report noted that the port-side ceiling plates in the engine room were corroded through. BV issued the vessel a transit certificateFootnote 36 for 1 direct voyage without passengers from either St. Barbe or Blanc-Sablon to either Matane or Baie-Comeau with the delivery crew on board.

1.13.3 Change of owner or authorized representative for a delegated vessel

When a delegated vessel undergoes a change of owner or AR, the vessel must reapply to the DSIP. The process for doing so is outlined in the 2016 DSIP work instructions. The rescinding owner or AR is required to notify the RO and TC of the change. The receiving owner or AR is required to submit a form to TC entitled “Notice of Participation in the Delegated Statutory Inspection Program.” TC reviews the form to determine if the enrolment conditions are met. If the enrolment conditions are not met or the form is incomplete, TC advises the new owner or AR and, if necessary, a handover inspection is scheduled. The RO then issues new CMDs to the vessel and TC notifies the new owner or AR and the RO that the delegation process is complete. TC may prioritize vessels that are changing owner or AR for inspections, with vessel history and the new owner or AR being factors in this prioritization.Footnote 37

The STQ followed the process to reapply the Apollo to the DSIP. TC did not require the Apollo to undergo a discretionary handover inspection.

1.13.4 Compliance inspections

TC carries out compliance inspections to verify whether the AR has maintained the vessel in accordance with the CSA 2001 and its regulations. These inspections can be announced or unannounced. At the time of the occurrence, TC had a target of inspecting 25% of delegated vessels every year.Footnote 38,Footnote 39 TC is responsible for dealing with non-compliance in an effective, timely, and nationally consistent manner. Footnote 40 TC may also use compliance inspections to verify the RO’s performance in fulfilling its responsibilities under the authorization agreement between TC and the RO.

TC uses a risk-based approach to target delegated vessels for compliance inspections. TC indicates that this approach is taken “to balance the need for oversight of the entire fleet with the need to pay special attention to the vessels that are most likely to be substandard.”Footnote 41 At the time of the occurrence, TC’s risk matrix tool used to evaluate every delegated vessel was based on 17 criteria, and provided an overall risk score of high (35+), medium (15 to 34), or low (0 to 14).Footnote 42 The Apollo’s risk had been evaluated as medium (16, 17, and 17) in each of the 3 years leading up to the occurrence. The risk scores were used to provide TC regions with a proposed list of vessels to be monitored throughout the year. The risk scores also provided guidance for responding to unplanned inspections following adverse reports or incidents.Footnote 43

Passenger vessels and older vessels are targeted for more frequent compliance inspections. The vessel’s inspection history is also considered in targeting vessels, which is why TC indicates that it is important for the vessel’s file to be kept up to date.Footnote 44 As well, vessels may be targeted as a result of other factors, such as if there has been a marine casualty or an adverse report from a crew member, or if TC becomes aware of a specific issue on board the vessel.

Compliance inspections are conducted using a sampling process that is intended to be sufficiently broad and deep to satisfy MSIs that the vessel has the required certification and does not pose a risk to safety, health, or the environment. MSIs must also be satisfied that the crew is proficient in the safe operation of the vessel.

An MSI will typically begin a compliance inspection by checking the vessel’s documentation and crew certificates with the master. Next, the MSI will conduct a walk-through of the vessel to check its overall condition, in accordance with work instructions for an initial inspection. This involves checking the vessel’s hull, structure, machinery spaces, and life-saving and firefighting equipment, among other things. If the review of the vessel’s documentation and the walk-through do not reveal any areas of concern, the inspection typically ends at that point.Footnote 45

If the MSI identifies clear groundsFootnote 46 that the vessel, equipment, or crew do not meet regulatory requirements, the MSI begins a more detailed inspection of the areas of concern. The work instructions provide specific examples of when a more detailed inspection must be carried out: if there is serious hull or structural deterioration on the vessel or if the vessel has been the subject of a report or complaint by the master, a crew member, or any person or organization with a legitimate interest. The work instructions set out the guidelines for a more detailed inspection.Footnote 47 The MSI may request that the crew perform one or more safety drills (e.g., a fire or boat drill), or may request that the crew test the life-saving or firefighting equipment (e.g., deploy the lifeboats or start the emergency fire pump).

Once the MSI has completed a compliance inspection, the MSI provides the master with a copy of the inspection report and, if applicable, a copy of the deficiency notice. If deficiencies have been found, the MSI uses professional judgment to determine whether further compliance action is needed, based on the nature and severity of the deficiencies. The MSI records the inspection results in TC’s Ship Inspection Reporting System (SIRS)Footnote 48 and informs the RO of the inspection results through the DSIPLO.

If the conditions on board a vessel are found to be significantly substandard, the MSI may suspend the inspection until the vessel’s AR has taken steps to ensure that the vessel complies with regulatory requirements, or the MSI may detain the vessel. The MSI may also pursue compliance and enforcement action, such as administrative monetary penalties. TC then coordinates with the RO to ensure that any deficiencies are appropriately rectified.

1.13.4.1 Compliance inspections on the Apollo

TC had conducted compliance inspections of the Apollo while the vessel was operating in the Atlantic region in 2015 and 2016. Each of these inspections was carried out by a team of 2 MSIs in Newfoundland and Labrador while the vessel was managed by WGOC. The areas of inspection included the vessel’s navigation bridge, accommodation and galley, vehicle deck, deck and forecastle, passenger spaces, engine spaces, and steering gear room. Operational control tests were carried out on the emergency fire pump, the emergency generator set, and the emergency steering. Additionally, fire drills and abandon-vessel drills were performed. During the compliance inspections in 2015 and 2016, the MSIs found no deficiencies.

On 29 January 2019, the day after the Apollo arrived in Matane, 3 MSIs attended the vessel to conduct a compliance inspection. Two BV surveyors (Surveyor 1 and Surveyor 2) also attended the vessel to conduct a change of owner inspection in order to issue the vessel its new CMDs.

The crew informed TC and BV that the remaining paperwork for the transfer of ownership in the TC Canadian Register of Vessels had not yet been completed. The crew pointed out to the MSIs that there were problems with the fire detection, monitoring, and extinguishing systems (e.g., one of the isolating valves on the fire main was blanked, some of the fire hydrants were not functional, various pipes were leaking, and the main fire pump had no pressure). The inspections were postponed and the crew was informed that the master and chief engineer were responsible for keeping the vessel from sailing if it was judged not seaworthy.

On 06 February, 2 new MSIs boarded the vessel to conduct the compliance inspection. Surveyor 1 also returned to conduct the change of owner inspection. The compliance inspection was completed in 2 days, and the change of owner inspection was completed in 1 day. TC issued the vessel a deficiency notice that included 19 deficiencies identified by TC and BV (Table 3).

| Deficiency | Deficiency code | MSI notes |

|---|---|---|

| Registration – changes to vessels | C0003 | The total propulsive power has not been adjusted on the registration certificate after 1 of the 2 propulsion engines was replaced about 8 years ago. The current power output is 7330 kW, but the registration certificate indicates 6660 kW. |

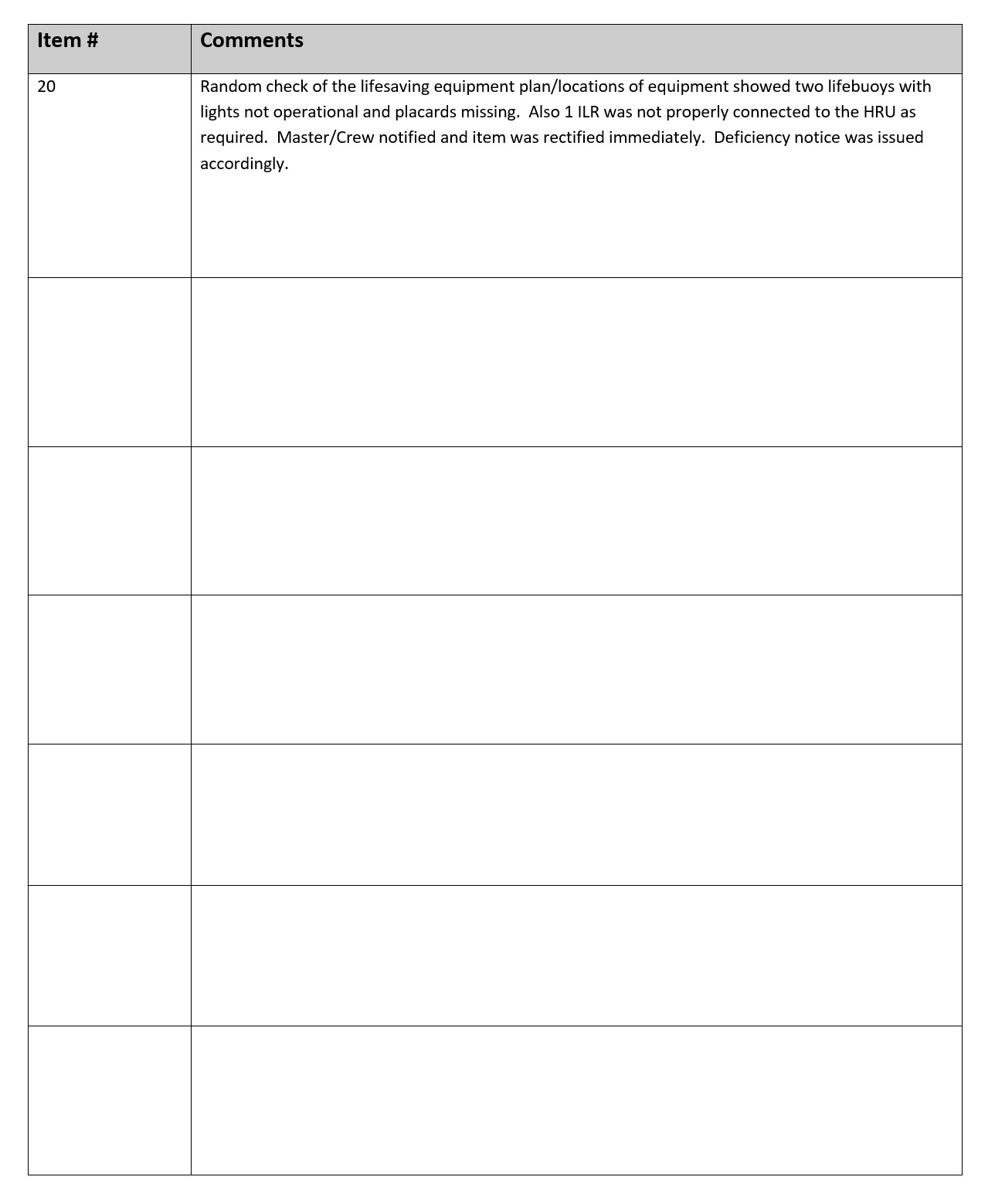

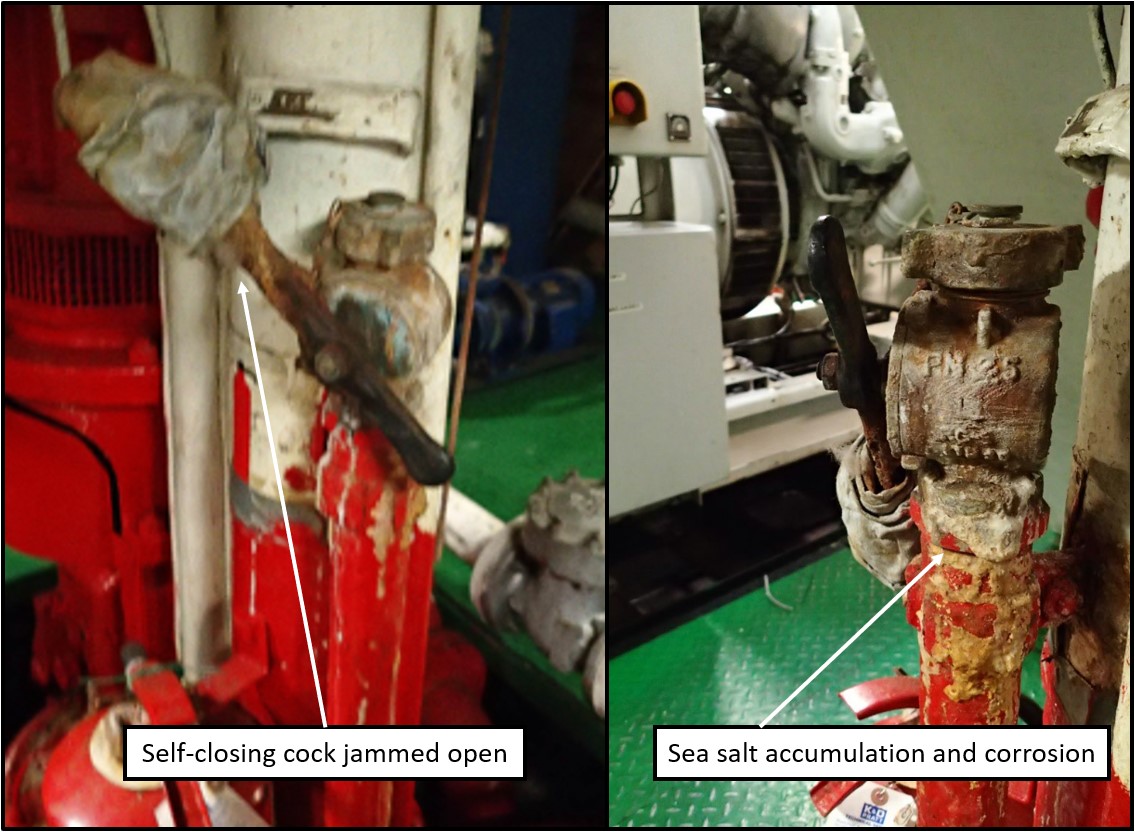

| Double-bottom (void space, tank, and others) | 02163 | The sounding pipes in the auxiliary engine rooms for water ballast tanks No. 22 and 25 are corroded and the valves are jammed open. |

| Doors | 03107 | The aft starboard access door on deck 5 does not close tightly. The handle is missing and the door structure is holed. The door must be repaired for fire integrity. |

| Scuppers, inlets, and discharges | 03112 | The car deck drains require cleaning. |

| Fire divisions – decks, bulkheads, and penetrations | 07103 | There are communication cables passing through fire partitions. The holes must be sealed with a high-temperature-resistant sealant. |

| Fire doors / openings in fire divisions | 07105 | Four fire-resistant doors are not closing or their indicators are not indicating that the doors are closed. Doors must be made functional. |

| Firefighting equipment and appliances | 07110 | The hydrants at fire stations No. 2 and 9 are non-functional. Stations must be made functional. |

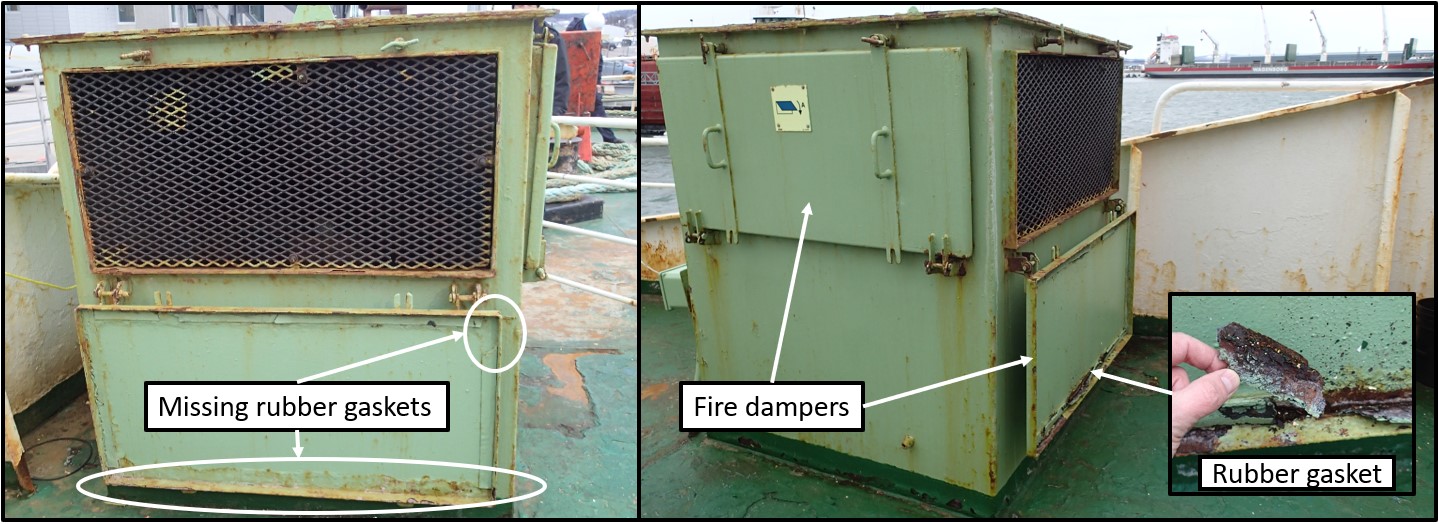

| Fire dampers | 07115 | The damper handle on the mushroom ventilator on the exterior port-side deck is broken. |

| Means of escape | 07120 | Several emergency exit lights are burned out. |

| Emergency fire pump | 07161 | The emergency fire pump has insufficient pressure. |

| Fixed fire extinguishing installation (water, foam, steam) | 07163 | The sprinkler control room for the cargo decks needs to be cleaned and emptied of large equipment. |

| Warning notices | 09217 | All of the safety signs are in English only. All signs, instructions, safety equipment, and emergency equipment are to be bilingual (English/French). |

| Emergency steering position communications – compass reading | 10163 | The vessel’s phone number directory is not available in some locations (e.g., emergency steering gear). |

| Rescue boats | 11104 | The rescue boats’ outboard motors are not operational. |

| Launching arrangements for survival craft | 11112 | The instructions to launch the life rafts are specific to the crane, but the instructions for the hooks, life rafts, and rescue boats are not up to date. |

| Launching arrangements for survival craft | 11112 | There is no operational poster for the rescue boat crane to indicate that the electric winch should not be operated when the crank lever is engaged. |

| Bilge pumps and pumping arrangement | 13104 | The bilge and ballast pump (piston pump) is not functional. |

| Cleanliness of main engine room | 13161 | The engine room bilges need cleaning to remove oil accumulation. |

| Propulsion and auxiliary machinery | 13675 | Public access to the boiler room needs to be restricted. |

Surveyor 1 withheld the vessel’s Canadian Passenger Ship Safety Certificate. The 19 deficiencies identified were recorded in SIRS, but none were reported to TC management as being RO-related.

On 10 February, Surveyor 2 returned to the vessel and, after verifying the work done by the STQ to address the deficiencies identified, issued the Apollo a Canadian Passenger Ship Safety Certificate.Footnote 49 This certificate was signed by Surveyor 2 on behalf of Surveyor 1.

1.13.5 Delegated Statutory Inspection Program training

TC provides training on the DSIP to MSIs and RO surveyors. The training for RO surveyors was first offered in 2015 and covers the following:

- An overview of TC’s organizational structure, the CSA 2001, and the Canadian regulatory regime, with a focus on certain regulations

- An explanation of the DSIP agreement between the Minister of Transport and the ROs

- An overview of DSIP and associated work instructions

- An explanation of TC oversight of delegated vessels and ROs

- A description of the certification process for classed and non-classed vessels

- Overviews of safety management system (SMS) instructions and audits for conformity with the ISM Code

- An explanation of the role of the Marine Technical Review Board (MTRB)

- An overview of Flagstatenets and Ship Safety Bulletins Footnote 50

- A description of TC’s regulatory regime for the Arctic and the International Code for Ships Operating in Polar Waters

Surveyor 1 had taken this training before the occurrence, and Surveyor 2 had not.

TC began offering formal DSIP training for MSIs in January 2019. The training is online and is 3 hours in duration. Once MSIs have completed this training, their managers are responsible for ensuring that the MSIs have the proficiencies needed to complete their various tasks. This may involve individual on-the-job training adapted to specific MSIs. To assist in inspections on delegated vessels, MSIs are provided with work instructions that outline the items that must be verified. Footnote 51 TC management relies largely on the marine experience of MSIs for the inspections to be carried out in accordance with the work instructions.

Before January 2019, DSIP training for MSIs was provided on the job rather than through formal training. None of the MSIs involved in the Apollo inspections had taken the formal DSIP training.

1.14 Persons and organizations authorized to conduct inspections

The CSA 2001 sets out the authorized persons and organizations that have the power to conduct inspections. It states that both MSIs and ROs may board any vessel at any reasonable time to carry out an inspection for the purpose of ensuring compliance. Footnote 52

1.14.1 Bureau Veritas surveyors

In Canada, BV has 4 offices, located in Halifax, Nova Scotia; Québec, Quebec; Montréal, Quebec; and Vancouver, British Columbia. Two surveyors in Canada are qualified to inspect passenger vessels. The decision regarding which surveyor to select for a survey is made on a case-by-case basis, depending on the surveyor’s qualifications and availability.

Surveyor 1 had a background in naval architecture and, before joining BV in Canada, had worked abroad. He had acquired 24 years of experience as a naval architect and, later, as a marine surveyor for various classification societies. He had joined BV in Canada as a senior marine surveyor in October 2014 and was one of the 2 BV surveyors in Canada who were qualified to inspect passenger vessels. Since 2014, Surveyor 1 had conducted 17 of 22 inspections on the Apollo, both those required for classification and those required under the DSIP.

Surveyor 2 had 6 years of experience working for a naval consultant, a classification society, and a privately owned company. He had joined BV in September 2018, and was being mentored by Surveyor 1. The first time that Surveyor 2 was on board the Apollo was when it arrived in Matane.

1.14.2 Transport Canada marine safety inspectors

Of the 2 MSIs involved in the Apollo’s 2019 compliance inspection, the first had a background in naval architecture and had 10 years of experience as a naval architect in various shipyards before joining TC in 2000. The second had a background in marine engineering and had 25 years of seagoing experience before joining TC in 2015.

The Apollo’s 2015 and 2016 compliance inspections were conducted by a different team of 2 MSIs. The lead MSI had 30 years of experience with TC as of 2019. The other team member had 18.5 years of experience as of 2019.

1.15 Transport Canada internal review

In fiscal year 2012–13, TC carried out an internal review of its management policies, practices, and processes related to inspectors and their managers in the air, surface, and marine transportation modes. Footnote 53 The review was prompted by a number of internal and external audits and reviews that indicated gaps and weaknesses in the processes and tools used by inspectors and their managers. These included weaknesses in regulatory oversight practices (e.g., inspections not conducted in accordance with established methods), weaknesses in managerial oversight, and an absence of functioning quality assurance programs.

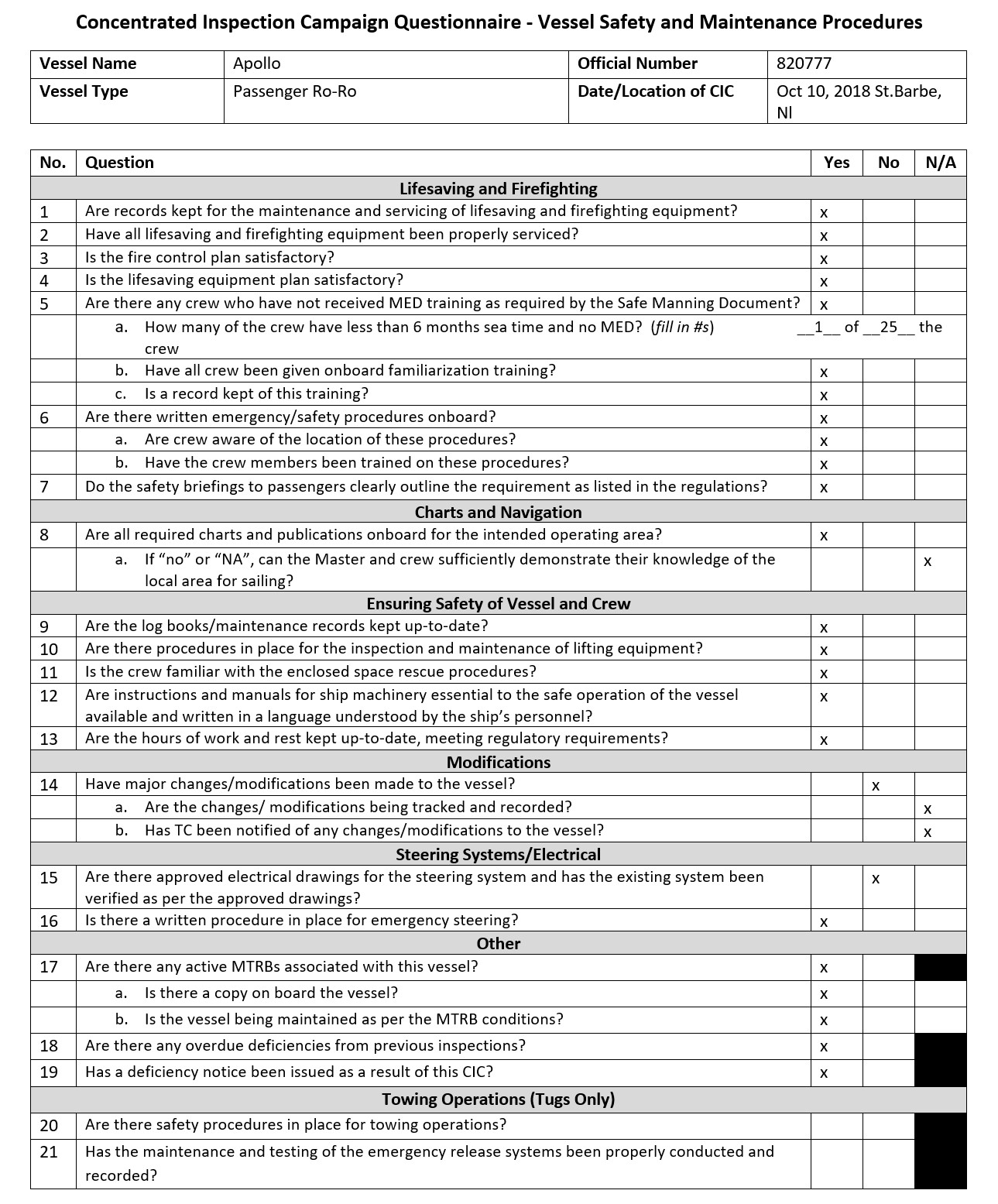

1.16 Concentrated inspection campaigns

TC conducts concentrated inspection campaigns (CICs) that involve checking specific areas of safety on selected vessels. CICs focus on areas in which MSIs or surveyors have observed a high number of deficiencies, or in which new regulatory or convention requirements have recently come into effect. CICs are typically conducted biennially, and may be conducted in conjunction with compliance inspections.

The Apollo had been selected for CIC inspections in 2015 and 2018. The 2015 CIC inspection was conducted in conjunction with the Apollo’s compliance inspection that year, whereas the 2018 CIC inspection was not conducted in conjunction with a compliance inspection. Footnote 54 The 2015 CIC focused on fire and boat drills and life-saving equipment; the 2018 CIC focused on vessel safety and maintenance procedures.

The checklist for the 2018 CIC prompted the MSIs to verify a number of items, including the following:

- Check that all of the life-saving and firefighting equipment has been properly serviced (which entails a walk-through of the vessel).

- Check that the condition of the vessel meets the fire control plan (e.g., all fire-detection and suppression equipment is marked, and equipment is in the correct locations).

- Check that the life-saving equipment is located on the vessel, per the life-saving equipment plan.

The guidance provided to MSIs conducting the 2018 CIC also included a section on compliance and enforcement, which reminded MSIs of their powers to detain vessels under section 222 of the CSA 2001. The guidance included examples of deficiencies considered serious enough to warrant a detention. These included

- expired or defective life-saving and firefighting equipment;

- non-operational survival craft;

- deficiencies that significantly affect seaworthiness;

- too many passengers on board;

- expired or invalid (e.g., outside approved voyage classification) certificates;

- means of freeing water from the deck that are not satisfactory or not operational; and

- closing devices, hatch closing arrangements, and watertight doors that are missing, substantially deteriorated, or defective.

During the Apollo’s CIC inspection on 10 October 2018, the MSIs found 3 minor deficiencies: 2 non-operational lifebuoy lights, missing identification placards, and a hydrostatic release unit that was not properly tied to the inflatable life raft. The full inspection results are in Appendix F.

The deficiencies were not recorded in SIRS, which is used to record inspection results. The CIC procedures did not guide MSIs to save CIC inspection data in SIRS, although deficiencies identified during CICs form part of the vessel’s inspection history and may require follow-up at a subsequent compliance inspection. Footnote 55

1.17 Vessel detention

Under the CSA 2001, there are 2 types of vessel detentions: optional and mandatory. An optional detention may be enacted if the MSI “believes on reasonable grounds that a contravention of a relevant provision has been committed by or in respect of a vessel or that the vessel is not seaworthy[…].”Footnote 56 A mandatory detention occurs when

the contravention is a contravention of section 110 (too many passengers) or the inspector also believes on reasonable grounds that the vessel is unsafe, that it is unfit to carry passengers or crew members or that its machinery or equipment is defective in any way so as to expose persons on board to serious danger.Footnote 57

TC relies on MSIs to use their professional judgment in determining reasonable grounds for a detention. There are various factors that are taken into account when a decision is made to detain a vessel, including the severity of any deficiencies identified, as well as the immediate safety risk related to these deficiencies. In some cases, a single deficiency can result in a vessel being detained. When a detention of either type is issued, the vessel must remain at the dock until the detention is rescinded. A detention can be issued only by TC, and TC MSIs must board the vessel and review corrective actions before rescinding it.

1.18 Vessel seaworthiness

A vessel is seaworthy when it is in sufficient condition to safely carry out its intended operations, taking into consideration a range of factors that include the vessel’s structural integrity, stability, and watertight integrity; the condition of both routine and emergency equipment and systems; and the state of on-board documentation. A valid inspection certificate confirms that a vessel complies with the CSA 2001 and its regulations and thereby attests to the vessel’s seaworthiness at the time the certificate is issued.

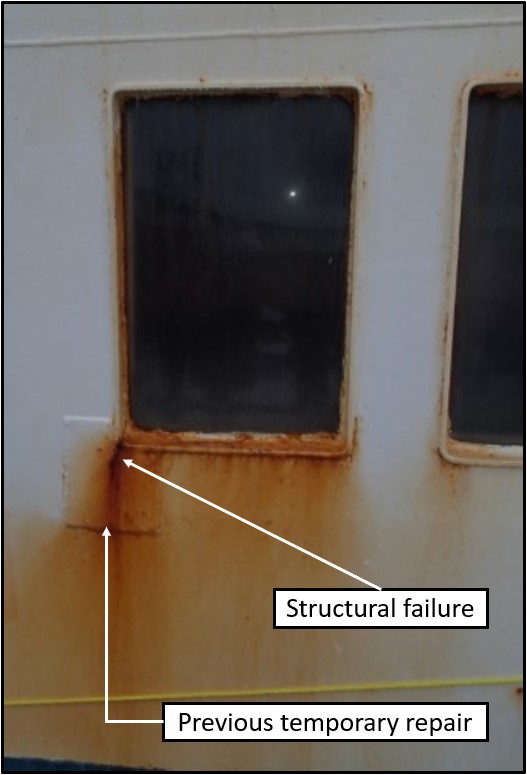

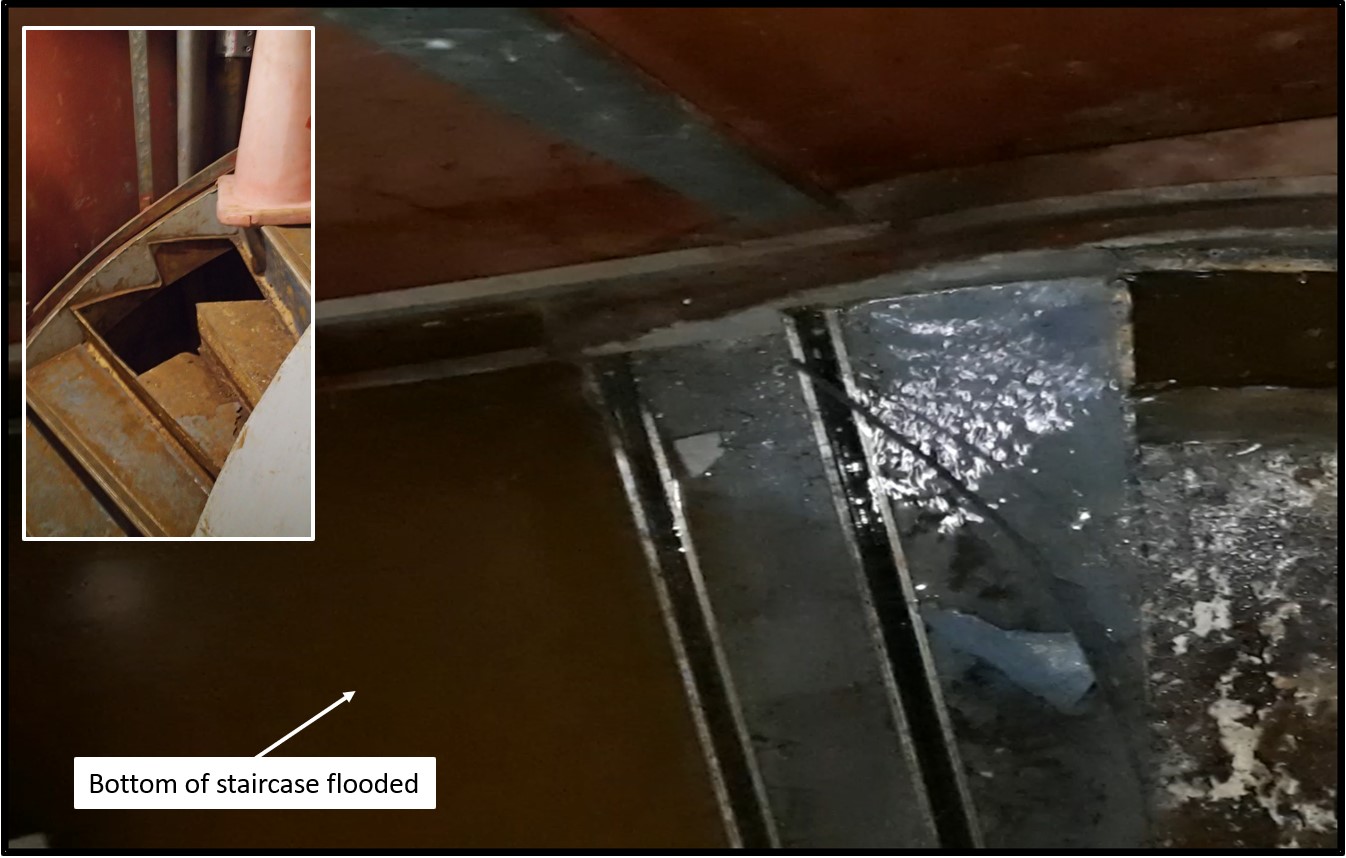

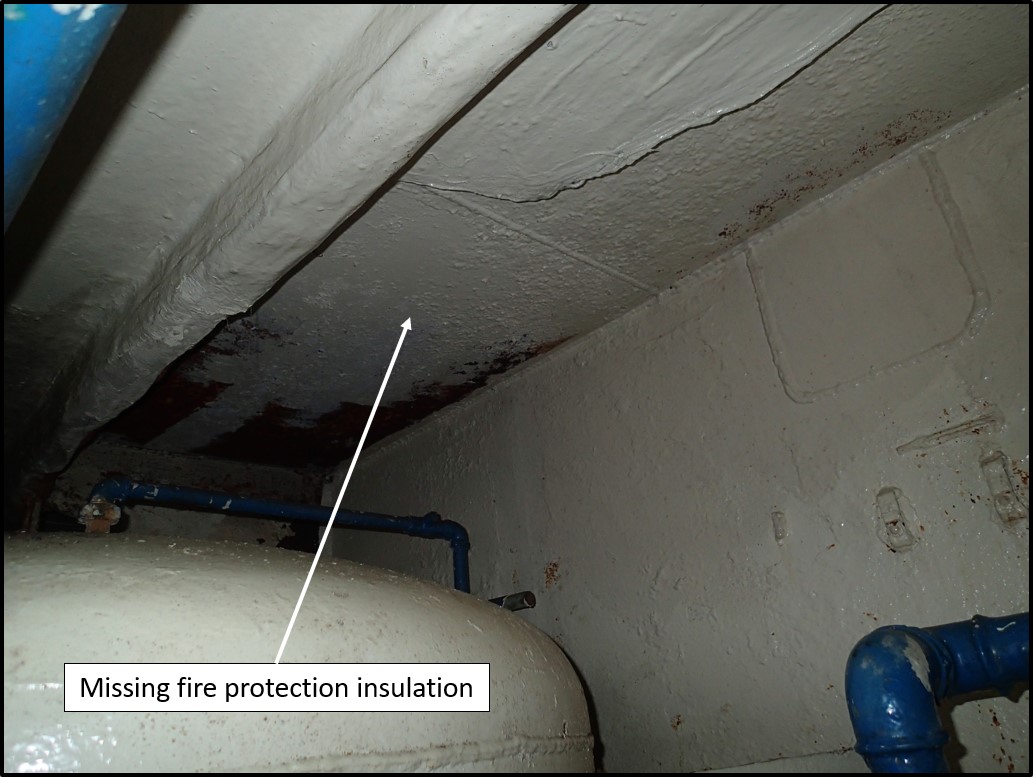

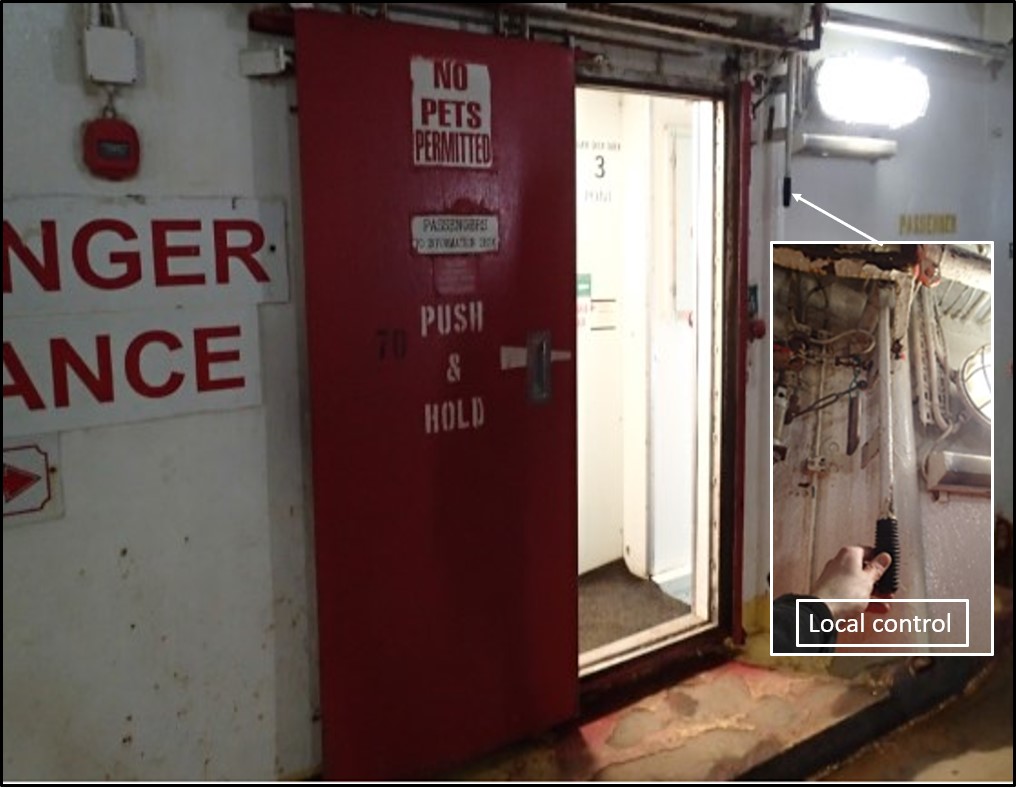

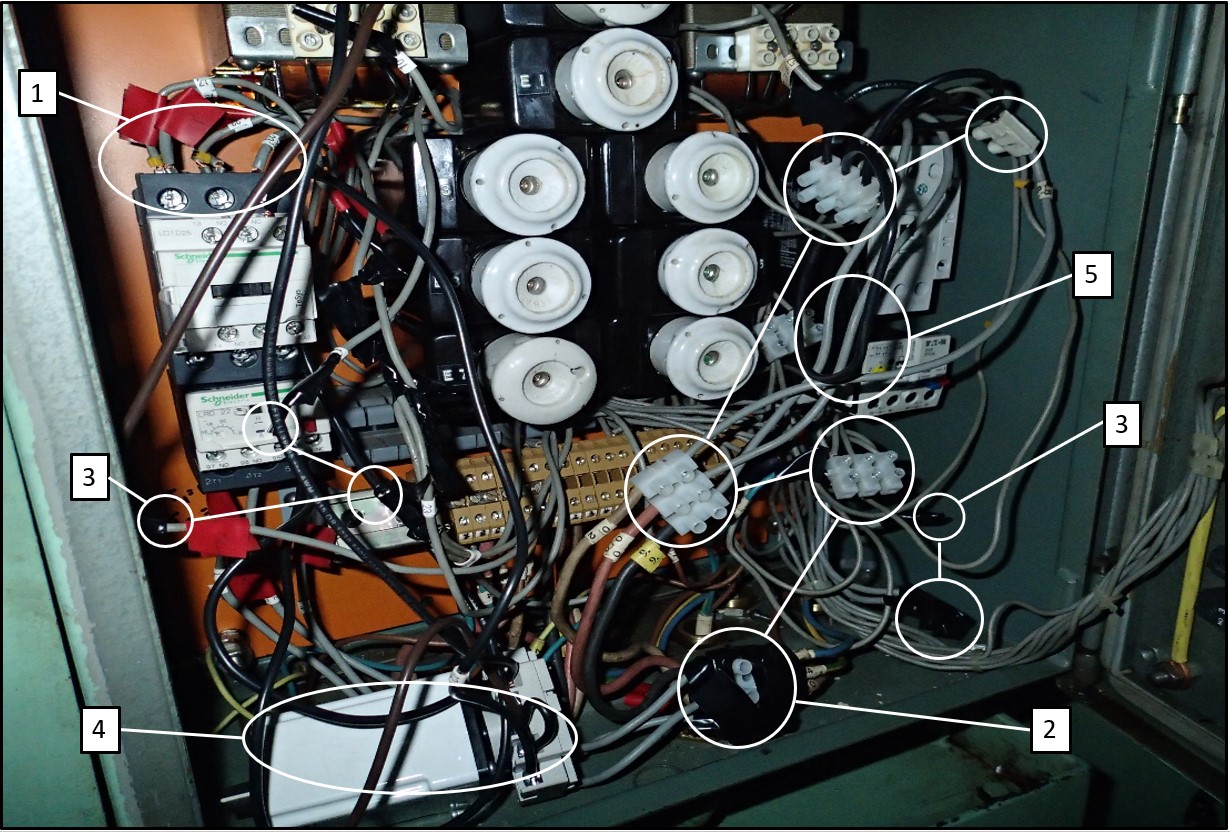

TSB investigators boarded the Apollo a day after the occurrence and collected data that provided information about the vessel’s seaworthiness. The following issues were noted:

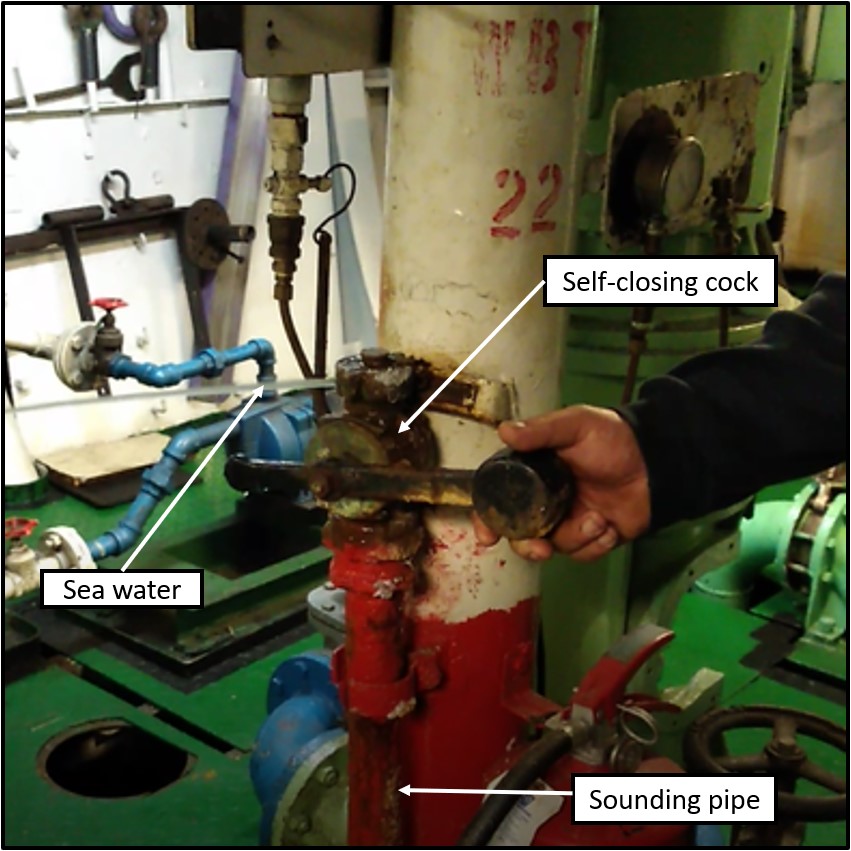

- One of the scuppers had rusted through at the car deck level, creating a breach 15 cm wide that exposed the car deck to the elements. The scupper was located approximately 4 m below the vessel’s downflooding point (Figure 6).

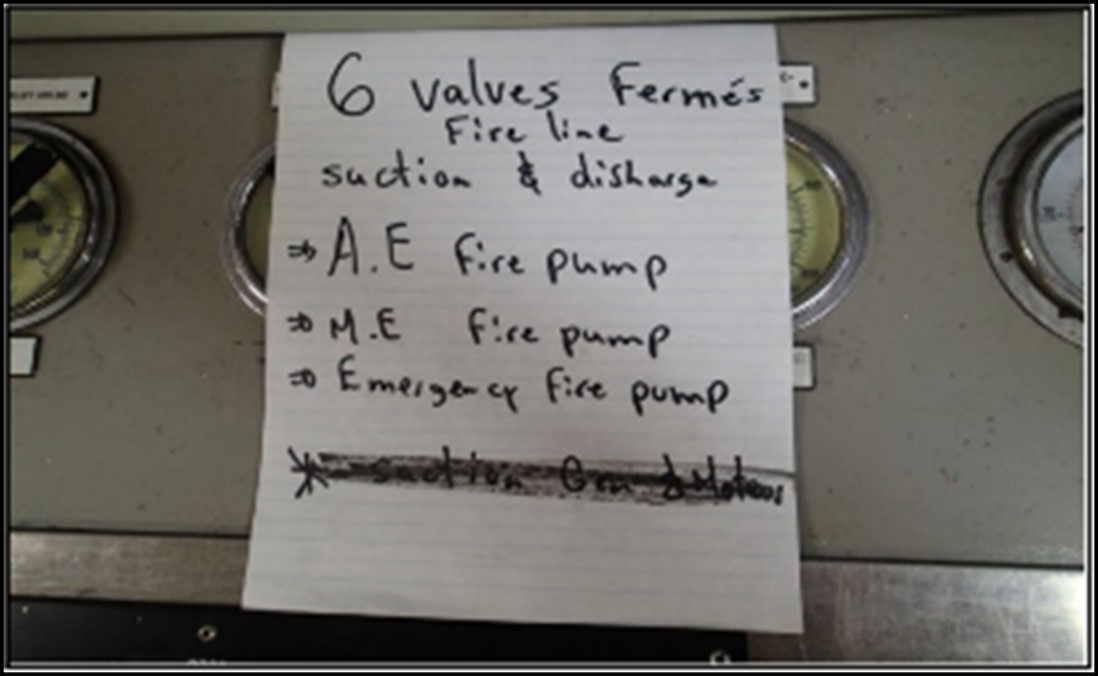

- The suction and discharge valves for the main and emergency fire pumps were being kept closed to avoid sea water ingress in different compartments from the fire main, which had corroded in various places throughout the vessel. A notice to the effect that the 6 valves were to be kept closed was posted in the engine control room (Figure 7). The main fire pumps had a remote control start located on the car deck, but to remotely start and operate the pumps, the valves needed to be open.

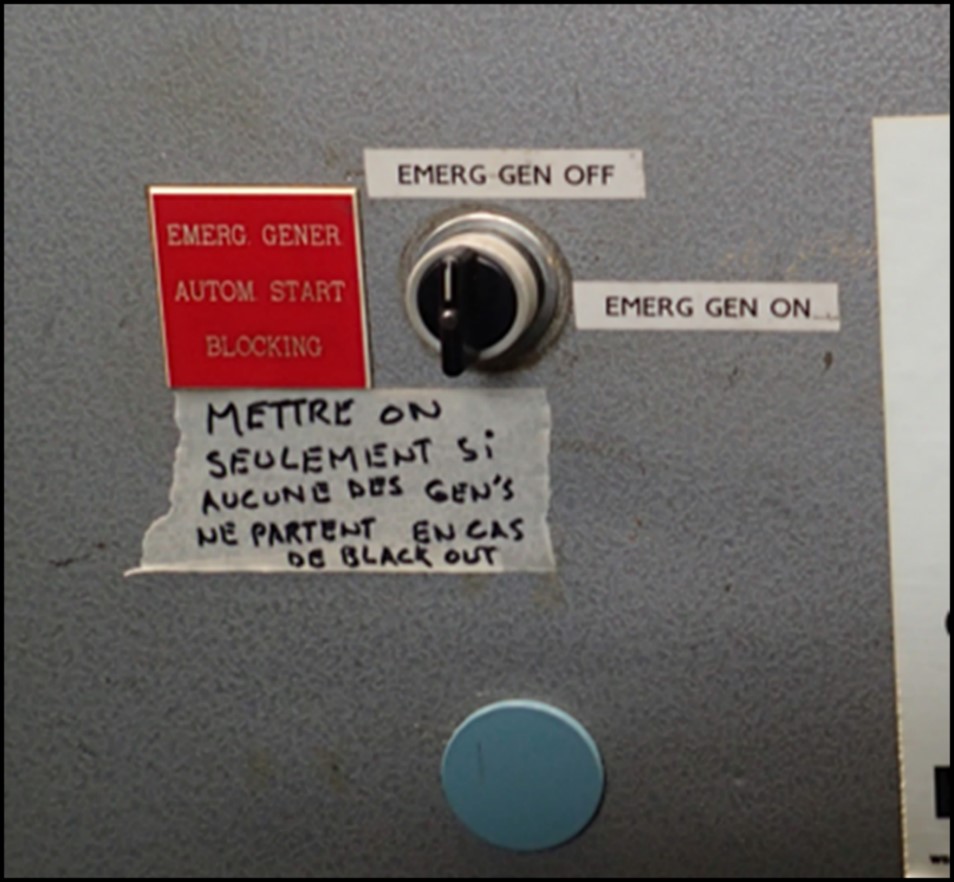

- The switch for the emergency generator set’s automatic start was kept in the “OFF” position, and a note handwritten on masking tape next to the switch stated “METTRE ON SEULEMENT SI AUCUNE DES GEN’S NE PARTENT EN CAS DE BLACK OUT” ([translation] “Turn switch on only if no main generator starts in case of a blackout”) (Figure 8).

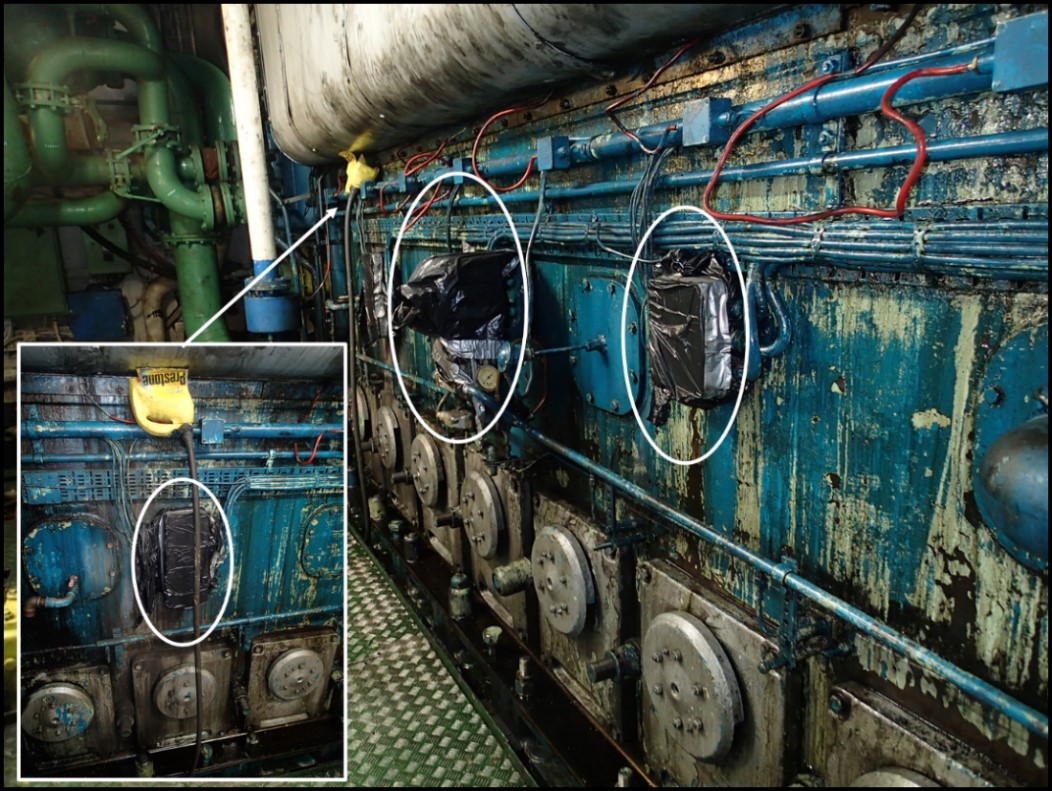

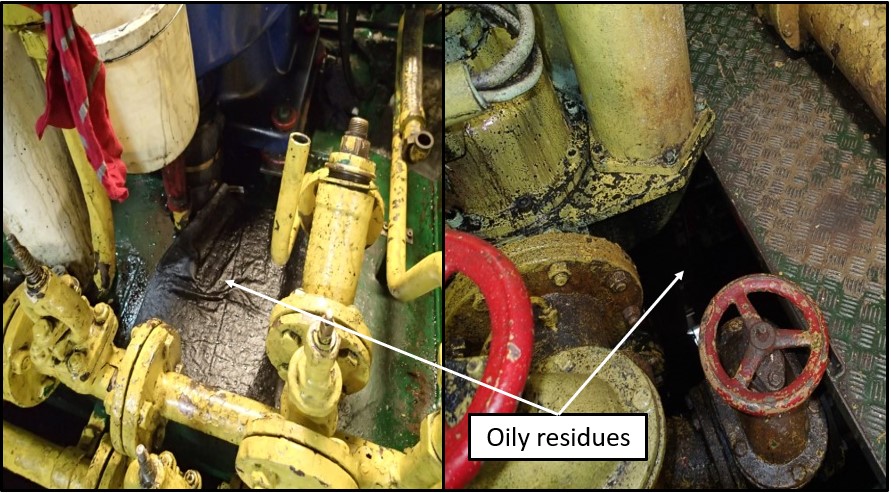

- The starboard main engine was streaked with oily residue, and a number of electrical components had been covered with plastic bags to protect them from oil and water leaks. An empty plastic container with a hose attached to it had been affixed to one side of the engine to redirect leaking oil into the bilges (Figure 9).

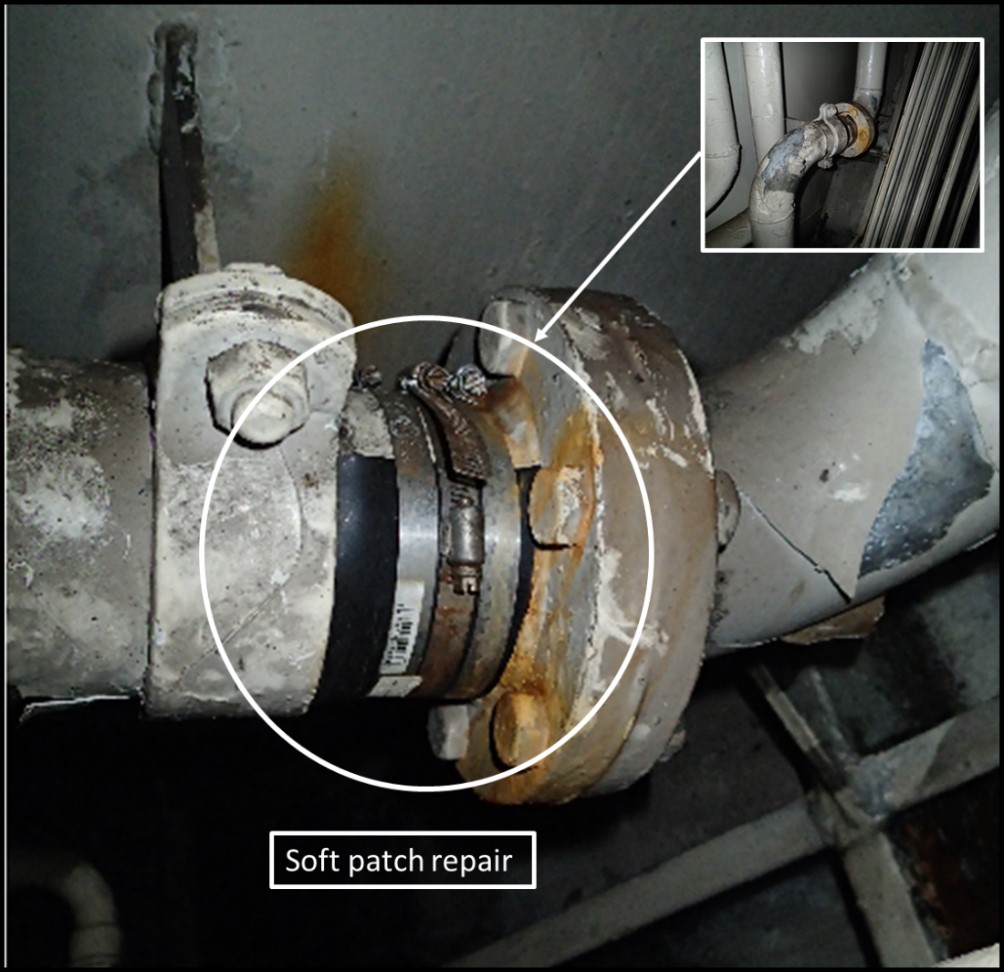

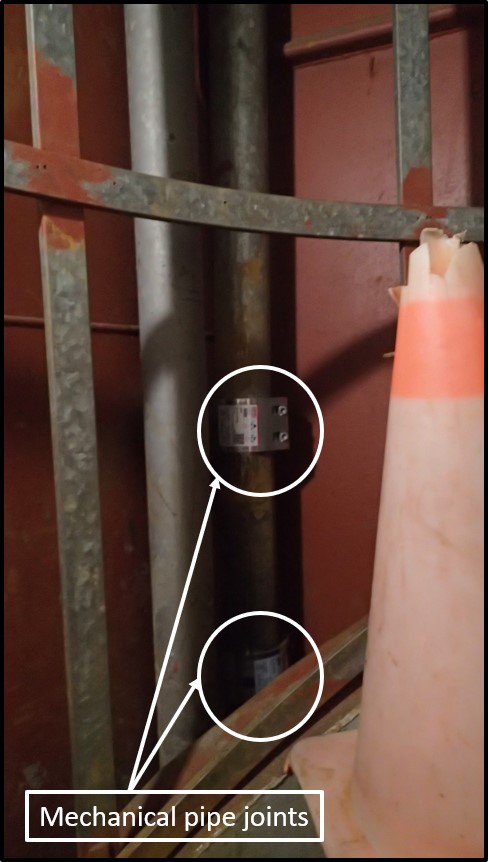

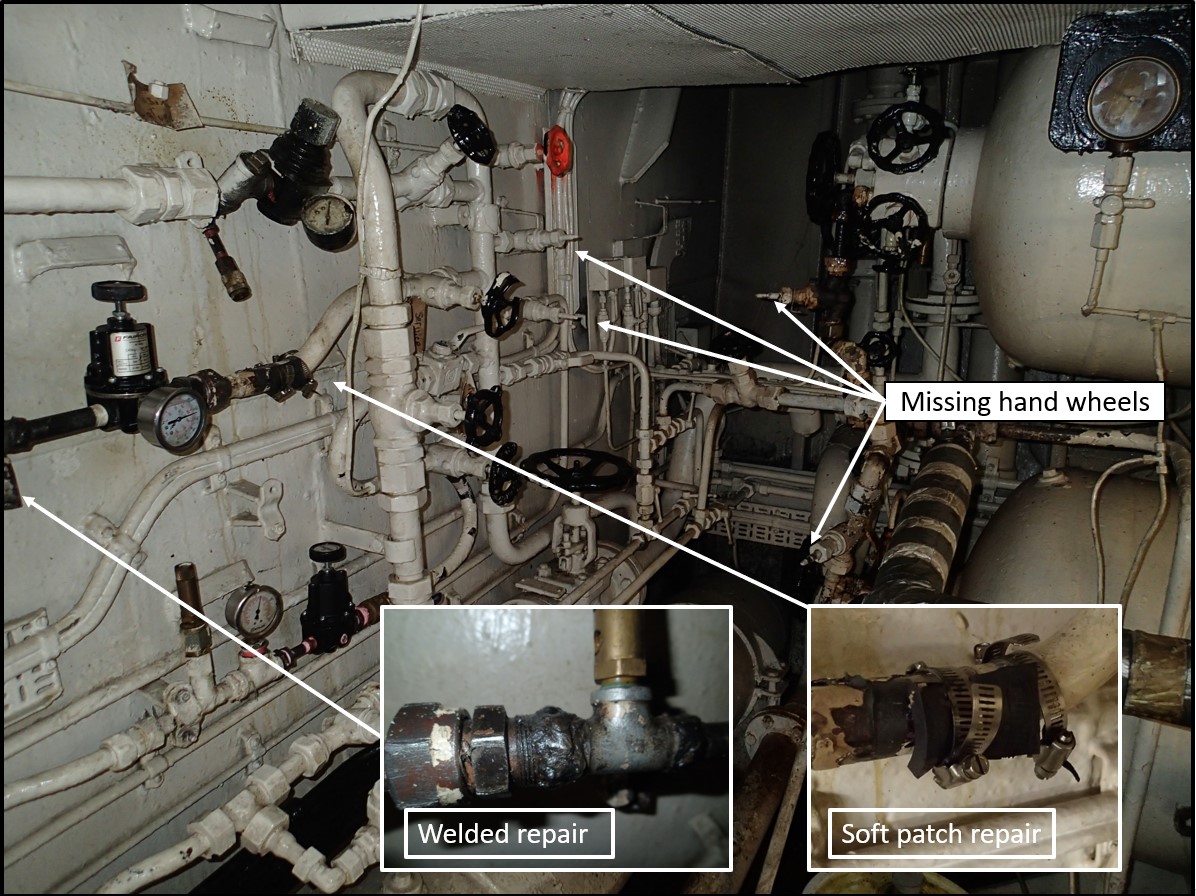

- Soft patch repairs had been made on pressurized sea water lines in the engine room and adjacent watertight compartments (Figure 10).

The data collected during the TSB’s visit to the vessel also identified other issues related to the vessel’s watertight integrity; fire detection, monitoring, and extinguishing systems; main and auxiliary machinery; electrical components; and deck and navigational equipment (Appendix G).

1.19 Load line and conditions of assignment

An International Load Line certificate assigns a vessel’s minimum freeboard, and certifies that the vessel complies with the International Convention on Load Lines, 1966 and that the appropriate load lines have been marked on the vessel’s hull.Footnote 58 Minimum freeboard is assigned with the assumption that the vessel is completely enclosed and is weathertight and watertight. Means of protection and closure for openings in the vessel’s envelope (hatchways, machinery space openings, openings in the superstructure deck, ventilators, cargo doors, air pipes, scuppers, side scuttles, inlets, and discharges) are identified as “conditions of assignment.” These conditions of assignment must be maintained in compliance with the International Convention on Load Lines, 1966 in order for the vessel’s minimum freeboard and load lines to remain valid.Footnote 59 The AR of a vessel that holds an International Load Line certificate must ensure that the vessel is maintained in accordance with the requirements of the convention at all times.

The certificate is valid for 5 years and must be endorsed annually. After a certificate is issued to a delegated vessel, the RO carries out annual inspections within 3 months before or after the anniversary of the certificate’s date of issue. The inspections verify that the vessel’s hull and superstructure have not been altered in a way that affects the position of the load lines. During these annual inspections, the RO is required to verify that the vessel’s conditions of assignment have been maintained. The RO must also verify the state of guard rails, freeing ports, and means of access to crew quarters. The conditions of assignment are recorded in a document that specifically describes each item and its location. For some vessels, this document is supplemented by drawings that show the location of every item on the decks concerned. The document must be kept on board and made available to the RO or TC during the endorsement or renewal of the certificate. The Apollo’s conditions-of-assignment document was available on board, but it referred to a drawing that could not be located. Neither BV nor TC had copies of this drawing in their records.

At the time of the occurrence, the Apollo held a valid International Load Line certificate. The certificate was originally issued by BV when the vessel was constructed, and BV had renewed and endorsed the certificate since that time. The last annual inspection had been on 06 April 2018. The certificate was due for renewal on 22 March 2019.

1.20 Marine Technical Review Board

The MTRB was established under the CSA 2001 and authorizes TC to review applications from Canadian ARs for exemptions to regulatory requirements for individual vessels (e.g., substituting certain safety requirements for equivalent ones or obtaining an exemption from a requirement that is not safety-related). Footnote 60 Any regulatory exemptions or substitutions must be in the public interest and must not jeopardize safety or the environment. Substitutions must result in a level of safety that is equivalent to or greater than the original requirement. For vessels in the DSIP, the RO typically applies to the MTRB on behalf of the vessel’s AR. The responsibilities of the MTRB have not been delegated to ROs under the DSIP.

When an application is made, the MTRB convenes a panel that normally includes the TC director and manager responsible for the regulation to which the application relates, and the director of the region in which the vessel operates. Decisions are made based on the information in the application. When making a decision, the MTRB panel must be confident that the proposed substitution does not pose any additional risk to safety or the environment. A decision made by the MTRB has the same legal authority as the regulatory requirement that the decision replaces.

In early January 2019, WGOC made a request to the MTRB to delay the Apollo’s mandatory 5-year dry-docking date Footnote 61 by 5 months. The delay of the dry-docking date was one of the STQ’s conditions for purchasing the Apollo. BV was responsible for both making the request on behalf of WGOC and providing the MTRB with inspection information about the vessel’s condition.

The resulting MTRB decision granted a 5-month postponement of the vessel’s dry-docking date, until 29 June 2019, and required an in-water survey to be completed before 30 January 2019. An in-water survey is different from a dry-dock inspection, which is conducted by an MSI or RO surveyor when the vessel is out of the water and allows for a close examination of the vessel’s hull and appendages below the waterline. Drydocking provides an opportunity for certain repairs that cannot be done when the vessel is afloat, such as an overhaul of isolating valves on the ship side and bottom plating (those used for fire pumps, sea chests, etc.). An in-water survey is conducted by a diver who uses a video camera to provide footage of the vessel’s hull to an MSI or RO surveyor. An in-water survey provides a general overview of the vessel’s plating and appendages, but does not allow for repairs to isolating valves located below the waterline. In-water surveys also do not provide the same opportunities as a dry-dock inspection when it comes to close examination of a vessel’s hull, and footage clarity can be affected by various factors (e.g. particulate matter in the water or light conditions).

Before the occurrence, the Apollo had last undergone a dry-dock inspection on 30 January 2016. The Apollo underwent an in-water survey and an internal examination of the shell plating and framing in way of the ice belt on 23 January 2019. At this time, the forepeak, the bow thruster compartment, the machinery space, and the steering gear compartment were also examined internally.

1.21 Safety management system

The main objectives of the International Safety Management Code(ISM Code) are to ensure the safe operation of the vessel, to prevent injury or loss of life, and to avoid damage to property and the environment.Footnote 62 Chapter IX of the International Convention for the Safety of Life at Sea, 1974 (SOLAS Convention) requires certain vessel operators to comply with the ISM Code and develop an SMS. In Canada, these operators include

- passenger ships, including passenger high-speed craft, operating on international voyages;

- oil tankers, chemical tankers, gas carriers, bulk carriers, and cargo high-speed craft of 500 gross tonnage and above operating on international voyages; and

- other cargo ships and mobile offshore drilling units of 500 gross tonnage and above operating on international voyages.

An SMS involves individuals at all levels of an organization and promotes a logical approach to hazard identification, risk assessment, and risk mitigation. An SMS includes procedures, plans, instructions, and checklists that have been developed by the vessel owner or AR in conjunction with their masters and crew. Operators for whom the ISM Code does not apply may choose to voluntarily adopt an SMS. The Apollo was not required to have an SMS, but the STQ was in the process of voluntarily implementing SMS on the vessel at the time of the occurrence.

Vessel operators that are required to have an SMS must go through an audit by a third party (an RO or a classification society) to ensure that their SMS meets the requirements of the ISM Code and that the company and the vessel are operating in accordance with the SMS. Both the company and its vessels must obtain certificates to indicate compliance (the company is issued a document of compliance [DOC] and the vessel is issued a safety management certificate [SMC]).

Companies that voluntarily implement an SMS may opt to have their SMS audited by a third party. The standard set out in the ISM Code against which the audits are carried out remains the same for companies and vessels required to have an SMS and those complying voluntarily. Upon verifying that the voluntary SMS meets the requirements of the ISM Code and that the company and the vessel are operating in accordance with the SMS, the third party will issue the company a DOC and the vessel an SMC. At the time of the occurrence, the STQ had been issued a DOC for the safe operation of an “other cargo ship,” and was in the process of obtaining an SMC for the Apollo.

During an audit carried out in order to issue a DOC or an SMC, the third party can issue major non-conformities, non-conformities, or observations. Major non-conformities are deviations that pose a serious threat to the safety of personnel, the vessel, or the environment, and require immediate correction. Non-conformities are situations in which objective evidence indicates non-fulfillment of a specific requirement from any applicable regulation. Observations are statements of fact that are substantiated by objective evidence.

When a non-conformity is issued, the company is given a 3-month period to resolve it. Non-conformities that are not resolved within 3 months may lead to major non-conformities. Observations do not have specific time limits for resolution, but may lead to a non-conformity if left unresolved over a period of time. For vessel operators that are required to have an SMS, when a major non-conformity is issued, the vessel is prohibited from sailing and must undergo another audit before sailing again. This does not apply for vessel operators that are not required to have an SMS because their SMS is voluntary.

When a company in possession of a DOC adds a newly acquired vessel to its fleet, the company can apply for an interim safety management certificate (ISMC) for this vessel. An ISMC is a temporary certificate that allows 6 months for an SMS to be implemented on board the vessel and an internal verification of the SMS to be conducted. To be eligible for an ISMC, the vessel must hold an inspection certificate and all other required CMDs. The Apollo had been issued an ISMC for a “passenger ship.” The vessel types on an ISMC and DOC must match, but, on the certificates issued to the Apollo, they did not match.

During an audit in order to issue an ISMC, the third party checks the vessel’s compliance with mandatory rules and regulations,Footnote 63 does a walk-through of the vessel, meets with the crew members, and checks that

- the company has a valid DOC and the vessel type listed on the ISMC matches that listed on the DOC,

- the company’s SMS includes the key elements of the ISM CodeFootnote 64 and has been assessed by a third party,

- the company has planned for an internal verification of the SMS,

- the master and officers are familiar with the SMS and its implementation on board,

- essential shipboard instructions are provided before sailing to allow the new crew to become familiar with the specific shipboard equipment and operations, and

- relevant information is provided in the crew’s working language.Footnote 65

Once the audit is complete, the third party determines whether the vessel complies with the ISM Code. If the vessel does not comply (i.e., if the audit identified non-conformities or major non-conformities), the ISMC must be withheld. The third party can issue an ISMC when there have been observations.

Passenger vessels that are not subject to the SOLAS Convention and that are operating on domestic voyages are not currently required to have an SMS, although TC encourages companies operating these types of vessels to have an SMS. TC does not carry out oversight of a voluntary SMS, so any external oversight of a voluntary SMS is done at the company’s own initiative through a contractual agreement with a third party.Footnote 66

WGOC had an SMS for one of its other shipping companies that operates tankers. Some parts of this SMS were applicable to Labrador Marine Inc., but they were not specific to the Apollo. The Apollo had not been issued an SMC while operating under WGOC.

1.21.1 Risk assessment under the International Safety Management Code

One of the objectives of the ISM Code is that the “[s]afety management objectives of the company should […] assess all identified risks to its ships, personnel and the environment and establish appropriate safeguards[…].”Footnote 67 The International Association of Classification Societies has created a guidance document to assist with interpreting the ISM Code, which states the following:

Although it is not often referred to as such, the development and implementation of a documented safety management system is an exercise in risk management. The drafting or amendment of written procedures involves looking at the company's activities and operations identifying what could go wrong, and deciding what should be done to try to prevent it. The documented procedures are the means by which the controls are applied.Footnote 68

The results of a risk assessment must be documented so that there is evidence of the decision-making process being applied. Risk should be reduced to a level that is as low as reasonably practicable. This level is achieved when all reasonable mitigating measures for identified hazards are in place. Essential shipboard instructions, which cover emergencies, inspections, and maintenance, are evidence that hazard identification and risk assessment processes have been conducted and that mitigation measures are in place. Risk assessments must be updated, as required, with new or infrequent activities specifically triggering a risk assessment.Footnote 69

1.21.2 Société des traversiers du Québec’s safety management system