Sinking with loss of life

Fishing vessel Arctic Fox II

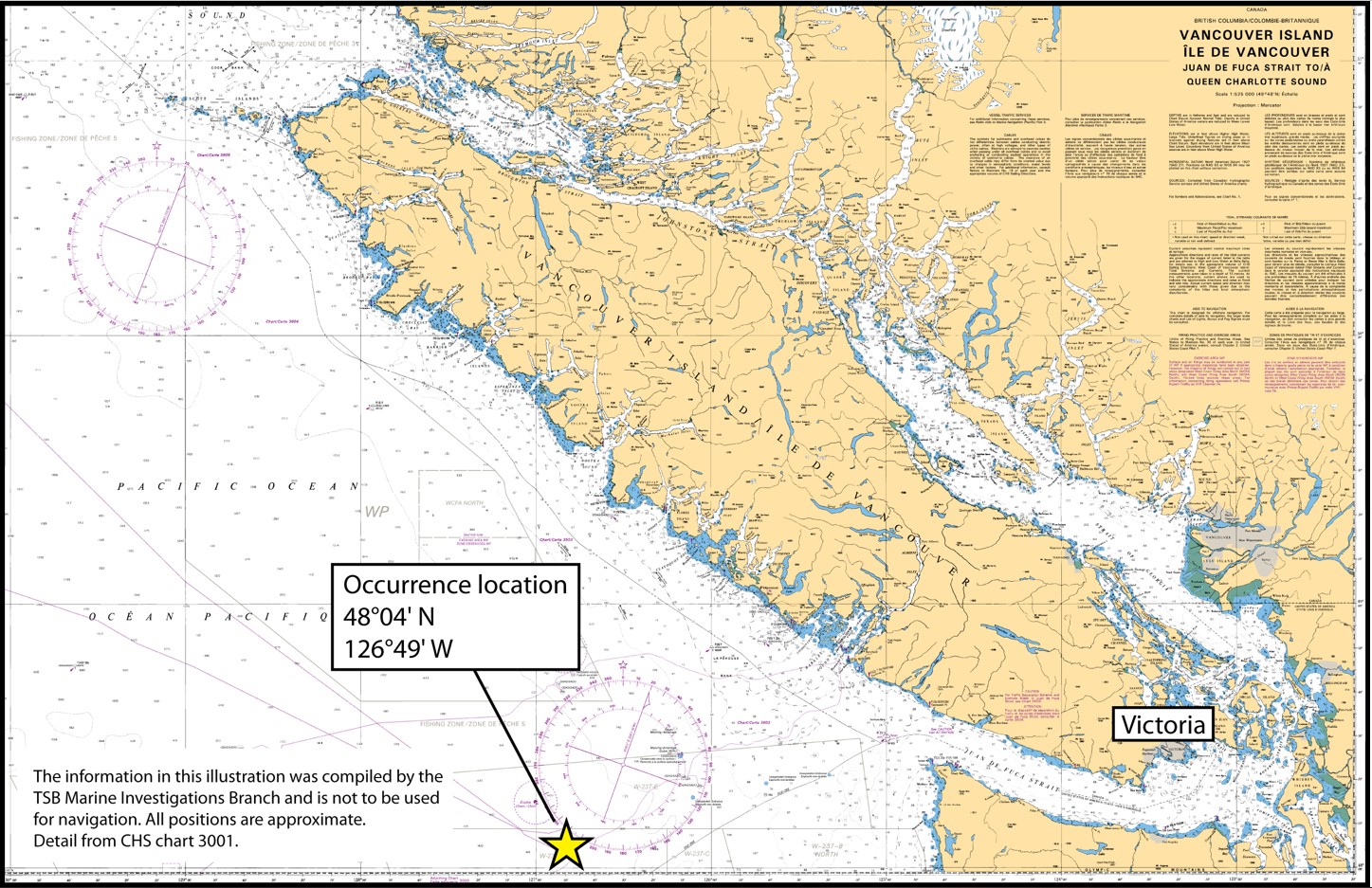

77 nautical miles west-southwest of Bamfield, British Columbia

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

On 11 August 2020, the fishing vessel Arctic Fox II, with 3 crew members on board, reported taking on water. The crew abandoned the vessel approximately 77 nautical miles west-southwest of Bamfield, Vancouver Island, British Columbia. The United States Coast Guard and the Canadian Coast Guard initiated search and rescue operations. The one surviving crew member was located in the vessel’s life raft, and the bodies of the master and the other crew member were recovered from the water. The vessel sank on 13 August and was not recovered.

1.0 Factual information

1.1 Particulars of the vessel

| Name of vessel | Arctic Fox II |

|---|---|

| Transport Canada official number | 371702 |

| Fisheries and Oceans Canada vessel registration number | 25125 |

| Port of registry | Victoria, BC |

| Flag | Canada |

| Type | Fishing |

| Gross tonnage | 61.67 |

| Length (registered) | 20.12 m |

| Built | 1947, J & G Forbes & Co Boat Builders, Sandhaven, Scotland |

| Propulsion | Diesel engine (149 kW) driving a fixed-pitch propeller |

| Crew | 3 |

| Registered owner | Teague Fishing Corporation, Shawnigan Lake, BC |

1.2 Description of the vessel

The Arctic Fox II (Figure 1) was a carvel-planked wooden vessel. The hull was a full displacement design that featured a nearly plumb bow, rounded bilges, a tapered stern, and steel hull stabilizers. The forward main deck had a forepeak access hatch and 3 fish-hold hatches. The aft main deck was partially covered and housed a centre-mounted fish-cleaning table, 2 hydraulic fishing-line haulers, and a ladder to access the upper deck. The upper portion of the deckhouse contained the bridge, the master’s cabin, and an aft upper deck where the life raft was stored. The lower portion of the deckhouse contained 2 crew cabins, the galley, and a settee, and provided access to the engine room.

The bridge was equipped with 4 marine very high frequency digital selective calling (VHF-DSC) radiotelephones, a satellite phone, an autopilot, a global positioning system, an automatic identification system receiver, 2 radars, and a non-operable bridge navigational watch alarm system. One portable Canadian-registered emergency position-indicating radio beacon (EPIRB) was also on the bridge and a fixed United States (U.S.)–registered EPIRB, fitted with a hydrostatic release unit (HRU),Footnote 1 was attached to the top of the deckhouse.

The area below the main deck was divided into 3 compartments: the forepeak, which housed components for the refrigerated fish holds and two 20 mm automatic bilge pumps; the cargo compartment, containing 3 insulated fibreglass fish holds; and an engine room compartment equipped with the main engine, 2 generators, and tanks for consumables. The engine room compartment also contained the steering gear and lazarette, 7 through-hull fittings, 1 forward bilge alarm, 2 engine or auxiliary engine-driven pumps (50 mm and 38 mm) capable of pumping all compartments, and three 20 mm automatic bilge pumps. The vessel carried a 4 kW electric portable pump that was stowed on deck.

1.3 History of the voyage

On 08 August 2020, at approximately 0900,Footnote 2 the Arctic Fox II departed Victoria, British Columbia (BC), for the tuna fishing grounds off Vancouver Island. The vessel’s master and 2 crew members (crew member 1 and crew member 2) were on board.

During the 20-hour transit to the fishing grounds, the master showed the crew members the location of the vessel’s immersion suits and had both of them try on a suit to ensure it fit. Both crew members partially donned a suit, zipping it up to the neck without putting the hood on. The master was relieved of the watch by crew member 2 once during the evening hours. Crew member 1 experienced motion sickness most of that time and remained in his cabin.

On the morning of 09 August, the vessel arrived at the fishing grounds and began to troll for tuna.Footnote 3 The master remained on watch in the wheelhouse most of the day while crew member 2 was on deck hauling in the tuna and placing it in the hold. Although crew member 1 continued to experience motion sickness, he was able to periodically help on deck. The catch was minimal, which allowed crew member 1 to mostly remain in his cabin throughout the day. The fishing continued until dark, at which point the master and crew members 1 and 2 retired to their cabins and remained there overnight. During this period, the vessel drifted with no one on watch.Footnote 4

On 10 August, trolling for tuna began around sunrise. The master remained on watch in the wheelhouse while crew member 2 handled the catch and crew member 1, still ill, remained in his cabin the majority of the time. Later in the day, crew member 1 requested that the master take him back to port as he was too ill to remain on board. The master agreed and, near sunset, set a course for Ucluelet, BC. The master used a satellite phone to update the vessel owner, explaining that the vessel was heading to Ucluelet in adverse weather conditions to drop off crew member 1, hire a new crew member, and return to the fishing grounds.

On 11 August, in the early hours of the morning, water began accumulating aft in the engine room. The master left the wheelhouse unattended and placed the additional portable pump in the engine room, but the water ingress continued and the vessel began to sink. He then ordered the crew members to prepare to abandon the vessel, returned to the wheelhouse and, at 0158, broadcast a Mayday call indicating the vessel was in approximate position 48°04′ N and 126°49′ W, had developed a problem, and might need assistance (Figure 2).

The crew members mustered in the wheelhouse as the master communicated with Marine Communications and Traffic Services (MCTS) Prince Rupert, indicating that he might be able to address the water ingress, but might also need a tow to Ucluelet. At approximately 0203, MCTS contacted the United States Coast Guard (USCG) Seattle and the Joint Rescue Coordination Centre (JRCC) Victoria to inform them of the situation. At 0205, MCTS began attempts to follow up with the Arctic Fox II. The master did not respond. At approximately 0212, MCTS broadcast a Mayday relay. Following the broadcast, the USCG took the lead in the search and rescue.

At 0220, the master communicated again with MCTS. He informed MCTS that the vessel’s main engine had been shut off and that he and the crew members were abandoning the vessel. MCTS reminded the master to have all crew members completely do up their immersion suits, and to take a portable radio with him. At 0224, the USCG dispatched an airplane and a helicopter to initiate the search for the crew.

At this point, the vessel was drifting and rolling in the prevailing sea conditions and sinking by the stern; waves landed on deck, making it difficult for the master and crew members to maintain their balance as they partially donned their immersion suits. The master gave the portable EPIRB and the portable satellite radio to crew member 2, then they all began the process of deploying the life raft overboard. During this process, the life raft’s painter line was untied from the vessel, and both the life raft and its painter line went into the sea. The life raft drifted away from the vessel and the master immediately jumped into the water.

When the master surfaced he called out for assistance. Crew member 1 jumped into the water and attempted to help the master, but the master told crew member 1 to retrieve the painter line and pull it to inflate the life raft. Crew member 1 swam toward the life raft and found the painter line. Crew member 1 then pulled the painter line, inflating the life raft. The life raft inflated upside down; crew member 1 managed to right the life raft and get inside, where he turned on his immersion suit’s light. Crew member 1 called out to the master, encouraging him to swim to the life raft; however, the master did not respond or use his immersion suit whistle, and his immersion suit light was not visible.

At approximately 0230, the vessel’s stern was submerged and crew member 2 had made his way to the aft upper deck and activated the portable EPIRB. With his immersion suit still partially donned, and the suit light on, crew member 2 jumped into the water on the opposite side of the vessel from crew member 1 and the life raft. Crew member 1 then blew the whistle on his immersion suit and called out to crew member 2. Crew member 2 responded to crew member 1 but did not reach the life raft.

At 0237, JRCC was notified that a signal had been received from the portable EPIRB. Shortly afterward, when the fixed EPIRB became submerged, the HRU activated. At 0243, the USCG received a signal from the Arctic Fox II’s EPIRB from a position that was 1.7 nautical miles (NM) from the location given during the initial Mayday call. At approximately 0330, JRCC added air resources to the search.

At 0436, the USCG rescued crew member 1 from the life raft. At 0939, the bodies of the master and crew member 2 were recovered wearing partially donned immersion suits that had filled with water. The cause of death for each was determined to be drowning.

The Arctic Fox II continued to float with its bow visible until 13 August, when it sank completely.

1.4 Environmental conditions

At the time of the occurrence, the USCG reported scattered clouds with a visibility of 10 NM. The winds were from the southeast at 25 knots, and there was a 2.4 m southwest sea. The air temperature was 14 °C, and the sea temperature was 14 °C.

1.5 Personnel certification, experience, and training

The master of the Arctic Fox II held an expired Fishing Master, Fourth Class certificate of competency issued in 2001 under the now-repealed Marine Certification Regulations. He had also obtained a restricted radiotelephone operator certificate and a marine emergency duties (MED) A1 training certificate. At the time it was issued, the master’s Fishing Master, Fourth Class certificate of competency did not require any vessel stability education or a marine medical exam. Vessel stability education and medical certificates have been required by Transport Canada (TC) since 2007. The MED A1 training did not cover how to train new crew members in terms of procedures, drills, and familiarization.

The master had approximately 50 years of commercial fishing experience as a crew member, master, and owner; during this period, he and his crew successfully abandoned 2 vessels Footnote 5 after they took on water and sank.

Most Canadian tuna fishing vessels retain experienced crew members by increase income opportunities: for example, engaging in salmon trolling earlier in the summer. This can make experienced crew members difficult to find for vessels like the Arctic Fox II that participate in only one fishery, making income more uncertain.

Crew members 1 and 2 responded to a job advertisement for experienced crew members for a tuna fishing operation. They were hired by the master to join the Arctic Fox II with no commercial marine experience and no emergency training.

Seafarers are required to take emergency duties training.Footnote 6 However, they are not required to take these formal courses immediately upon hire; the courses may be delayed until the seafarer has acquired 6 months of sea time.

1.5.1 Marine medical certificates

Seafarers who hold a certificate of competency are also required to hold a valid marine medical certificate from TC.Footnote 7 To obtain a marine medical certificate, a seafarer must have their level of fitness determined by a marine medical examiner, taking into account the requirements of the position and the level of risk for the master, crew members, and passengers.Footnote 8 Marine medical examiners calculate a seafarer’s level of risk for incapacitation, among other things, using certain methods.Footnote 9 For example, the Framingham risk scoring system estimates the 10-year cardiovascular disease risk by considering 6 key factors: age, blood lipids, blood pressure, diabetes, smoking, and family medical history. Other factors considered include alcohol intake, obesity, and gender. All of these factors are known to increase the risk of a cardiac event and thus incapacitation. After the seafarer has been examined by a marine medical examiner, limitations may be applied to their certificate, including limitations related to duty, medication, time, and voyage class. The investigation determined that the master of the Arctic Fox II had multiple health conditions that were cardiac event risk factors and under the management of his personal physician, but not assessed by a marine medical examiner.

Finding: Other

The master’s medical conditions, which could have led to limitations that affected the validity of his marine medical certificate, were unknown to TC. Moreover, his certificate of competency had expired.

1.6 Emergency preparedness

1.6.1 Responsibilities of authorized representatives and masters

Authorized representatives (ARs) Footnote 10 are required by regulation to provide vessel masters with written procedures that must be followed before crew members can undertake any duties. The procedures must include familiarization with shipboard equipment, operational instructions, and assigned duties. Footnote 11 In addition, ARs must provide masters with procedures on how to safely operate the vessel and deal with emergencies. Footnote 12 These procedures must at a minimum familiarize crew members with Footnote 13

- the location of safety equipment and how to use it;

- measures to be taken to protect persons on board; and

- measures to be taken to maintain watertight integrity.

Masters must determine whether crew members can perform their assigned duties effectively. They must also ensure that crew members are trained on these procedures and keep a record of training and drills. Footnote 14

In BC, similar requirements exist for documentation, instructions, and procedures under provincial regulations. Footnote 15

The owner and AR of the Arctic Fox II listed on the vessel registration was Teague Fishing Corporation. The owner of and contact person for Teague Fishing Corporation is a fish harvester with extensive experience in commercial fishing. He was unsure of all of his owner responsibilities under provincial requirements and his AR responsibilities under TC requirements. The owner assumed that the responsibilities he was aware of were being met by the master. When the Arctic Fox II was not at sea, the master fulfilled the role of ship’s husband. Footnote 16 There was no understanding between the owner and the master about who was to meet the AR responsibilities, and the owner, as AR, did not oversee the master to ensure these responsibilities were being carried out.

The investigation found no indication that the master had received training on how to conduct an emergency drill. Footnote 17 Similarly, there was no record of formal emergency procedures, drills, familiarization, or training having been provided to the crew members on board the vessel during the occurrence voyage, or to any previous crew members who had sailed on the vessel.

1.6.2 Life-saving appliances

When at sea, crew members risk ending up in the water and experiencing the effects of cold water immersion, such as cold water shock, cold incapacitation, and hypothermia.

Fishing vessels are required to carry life-saving equipment in case of emergencies such as cold water immersion.Footnote 18 The Arctic Fox II was equipped with the following required life-saving equipment:

- Standard lifejackets

- Personal flotation devices (PFDs) (neither crew member wore a PFD while working on deck)

- Immersion suits

- A life ring

- A serviced, 6-person life raft

- 1 EPIRB

The vessel was also equipped with an additional EPIRB.

1.6.2.1 Acquiring knowledge and skills

When physically performing a task such as donning life-saving equipment, a crew receives training to learn the associated motor actions for that task.Footnote 19 With practice, motor actions create motor memories and the crew develops skills.Footnote 20 Enabling crew to understand how and when to coordinate these skills as a team, such as when deploying a life raft, optimizes the probability that they will be able to respond in the most effective and efficient manner.

During an emergency, the crew will typically have time pressures and a potential or imminent threat to life, both of which can increase workload and stress conditions. These conditions in turn reduce mental capacity.Footnote 21 For this reason, it is important that the crew has practised an emergency task so they can perform it automatically. When emergency duties training and practice are not initially and recurrently provided, performance may deviate from procedures or be substandard, either as a result of insufficient skill, skill fade, or learned adaptations that have a detrimental effect on safety.

The master had last participated in MED training in 2001. The crew members had not yet had any MED training.

1.6.2.2 Immersion suits

Immersion suits are designed to prevent, or at least slow down, the effects of immersion in cold water by keeping the wearer dry. Immersion suits may also prevent drowning by providing buoyancy to keep the wearer afloat.

When an immersion suit is not fully donned it will not provide thermal protection as water will be able to enter the suit. If immersion suits are not correctly donned and air becomes trapped in the suit’s legs and feet, the legs and feet balloon and float to the surface, which may cause the wearer’s head to become submerged. Some immersion suits have straps around the ankles that, when used, can reduce air pooling in the feet. Ideally, immersion suits provide a flotation angle of about 45°.Footnote 22 To achieve this angle, some immersion suits have an inflatable bladder positioned behind the wearer’s head to counteract the suit’s natural buoyancy and keep the wearer’s mouth out of the water.

The immersion suits carried on the Arctic Fox II were universally sized for adults with a weight of 50 to 150 kg and a height of 150 to 190 cm; to accommodate this size range, the suits are long and the hands and feet are large. The bulkiness of the suits’ hands limits manual dexterity. Each suit on the Arctic Fox II had an inflatable bladder around the torso (known as a high-rider ring), a whistle, a light, reflective tape, and ankle straps.

Following the occurrence, the immersion suits worn by the crew of the Arctic Fox II were inspected. Each suit met U.S. design requirements and was serviceable.Footnote 23

While travelling to the fishing grounds, as was his practice, the master provided crew members with informal instructions on how to don the immersion suits, and showed the crew members the location of the whistle, the light, and the inflatable bladder for the high-rider ring on each suit. When crew member 1 entered the water, his suit was partially donned (the hood was pulled over his head but the zipper was not zipped over his face), the high-rider ring of his suit was not inflated, and the ankle straps were not secured. The suits on the bodies of the master and crew member 2 had also been only partially donned.

1.6.2.3 Life rafts

Life rafts are designed to provide a crew with a primary means of staying out of the water while awaiting rescue. Instructions for deployment are displayed on them. To make manual deployment easier, a life raft is required to be stowed in a location where it can be lifted from its cradle and dropped directly into the water by 2 crew members.Footnote 24,Footnote 25

As required, the Arctic Fox II’s life raft cradle was accessible from the aft upper deck (Figure 3) and the painter line was secured to the vessel.

The instructions for manual deployment written on the life raft read:

- Check painter line is secured to strong point.

- Launch life raft container.

- Heave on painter line until life raft inflates.

No other deployment instructions or procedures were available to the master and crew. During the process of deploying the life raft, the painter line was untied from the vessel; the master and crew member 2 then passed the life raft to crew member 1, who was on the aft main deck. The master went to the aft main deck and assisted crew member 1 with dropping the life raft overboard; at this point, their hold on the painter line was lost.

After entering the water, crew member 1 managed to pull the painter line, and the raft inflated upside down. Crew member 1 had not received any formal instruction on how to right a life raft, but with informal knowledge acquired from television programs, he entered the water and was eventually able to right the life raft.

1.7 Fatigue and crew work/rest schedule

Fatigue can lead to impairments in general cognitive functioning, problem solving, decision making, memory, attention, vigilance, and reaction time. When a person is fatigued, it takes them longer to perceive, interpret, understand, and react to normal and emergency events. Footnote 26

Fatigue is widespread in the fishing industry due to many factors, including increased crew workload, unsafe operating practices, and adverse weather conditions. When a less experienced crew member is on board, the workloads of others increase, as do levels of fatigue. Footnote 27 The risks of human performance impairments from fatigue increase when there is an insufficient awareness of fatigue and its effects. Crew members on fishing vessels with a gross tonnage (GT) of less than 100 are not required to take fatigue management training, which teaches participants to identify the various risk factors for fatigue and strategies to manage fatigue.

Certain risk factors can be examined to determine the likelihood that a crew member was fatigued at the time of an occurrence: acute sleep disruption, chronic sleep disruption, continuous wakefulness, circadian rhythm effects, sleep disorders, medical or psychological conditions, and illnesses or drugs that could lead to fatigue. Restorative sleep is required to address these risk factors; for sleep to be restorative, it should occur at night in a period of at least 7, and up to 9, continuous hours. Footnote 28

As well as fatigue, an individual who has been awakened may experience sleep inertia, which is a period of confusion and decreased alertness that can reduce decision-making performance for up to 30 minutes. Sleep inertia impairs the essential cognitive abilities of vigilance and alertness necessary for rational decision making. Footnote 29 Sleep inertia is influenced by many fatigue factors, particularly the sleep-stage the person is in before awakening and prior sleep deprivation. Footnote 30

The investigation could obtain only a partial crew work/rest schedule for this occurrence. During the overnight transit to the fishing grounds, the 2 crew members were in their cabins while the master was on watch, with the exception of an approximately 4-hour period where crew member 2 relieved the master of the watch. When the vessel arrived at the fishing grounds the next morning, the master and crew worked until about sunset, retired to their cabins, and woke the next morning about 1 hour before the start of fishing operations at sunrise. They continued to work until sunset; the crew then retired to their cabins while the master took the helm to travel to Ucluelet. Crew member 1 had poor-quality sleep during the 3 days at sea due to motion sickness.

At the time of the occurrence, the master had likely been awake continuously for 22 hours. More than 22 hours of continuous wakefulness is considered the point at which fatigue causes almost all aspects of human performance to decline. Crew members 1 and 2 were awoken, which may have initiated a period of sleep inertia. In addition, the crew was preparing to abandon the vessel during a circadian low, Footnote 31 a time when human performance is at its lowest.

There are no work/rest requirements for fishing vessels of less than 100 GT, such as the Arctic Fox II. The province of BC does not have work/rest requirements specific to the fishing industry. Provincial occupational health and safety regulations require all employees to declare physical or mental impairment such as fatigue, and individuals must not be assigned activities if any impairment is observed.

1.8 Vessel

1.8.1 Registration and licensing

The Arctic Fox II arrived in Canada in 1977. It was first registered with TC in 1984 when it began fishing operations. TC’s vessel registration history indicates that the vessel was purchased by Teague Fishing Corporation in 2008, and that the corporation was appointed as the AR. In 2012, the vessel was registered in the U.S. because of a change in ownership. In 2018, the current owner became the owner of the Arctic Fox II again, and it was re-registered with TC. Footnote 32 It was issued a Fisheries and Oceans Canada (DFO) fishing licence for tuna in June 2020.

1.8.2 History and modifications

The vessel had been operating for 74 years. Before 2004, the vessel had been used in several fisheries and other commercial operations, and it had undergone a number of major modifications that affected its stability, including

- replacing the main engine;

- replacing and enlarging the superstructure;

- converting the fish holds from dry-pack holds to watertight freezer holds;

- adding trolling poles;

- enlarging the size of the rudder;

- adding a partial shelter on the aft main deck;

- adding steel stabilizers (also known as batwings) to the hull;

- encasing the keel in steel; and

- rebuilding the galley following a fire.

TCFootnote 33 and WorkSafeBCFootnote 34,Footnote 35 guidelines remind fish harvesters that the accumulation of weight over the life of the vessel will increase its lightship weight, which decreases its freeboard and affects the vessel’s stability.Footnote 36 This increase in lightship weight may be attributed to several factors. Some factors are specific to the vessel, such as the addition of a new superstructure, batwings, and trolling poles; the accumulation of equipment and spare gear stowed in the void spaces; and the absorption of water by the fish-hold insulation material. Other factors are more general, such as the added weight of materials used for repairs, the accumulation of stores and crew effects, sedimentation in tanks, corrosion, and the buildup of coatings. Increased lightship weight and decreased freeboard render a vessel more vulnerable to the additional forces acting on it while at sea.

There is no U.S. or Canadian record that the Arctic Fox II had undergone a full stability assessment. In 1993, the previous owner of the Arctic Fox II noted the low freeboard at the vessel’s stern while tuna fishing. The owner contacted a UK marine engineering company that was involved in the vessel’s original construction to enquire about adding a full shelter deck to the vessel to address the low freeboard. A company representative conducted a roll period test, which provides a limited measure of vessel stability. The results did not meet the minimum UK stability requirements, which include a measurement of freeboard. The owner did not add the shelter deck, noting concerns over the test results. The current owner was not aware of the vessel’s roll period test results.

1.8.3 Seaworthiness and stability requirements

For many fish harvesters, experiencing a vessel’s movements in a variety of operating conditions is the sole indication of whether a vessel is in seaworthy condition and has adequate stability. However, this is not the same as measuring the vessel’s ability to right itself, which can be done only by performing a stability assessment.

One factor used in a stability assessment is buoyancy, which is affected by the watertightness of the hull and the vessel’s freeboard. With or without a formal stability assessment, fish harvesters must carry out safe work practices that are necessary for ensuring that seaworthinessFootnote 37,Footnote 38 and adequate vessel stability are maintained.Footnote 39 These safe work practices include maintaining the vessel,Footnote 40,Footnote 41 securing deck openings, and maintaining freeboard. Additional safe work practices include recording vessel modifications and addressing the effects of adding, removing, or rearranging gear and equipment to accommodate multiple fisheries. A record of maintenance must be kept, and written safety procedures must be established to familiarize persons on board with the vessel’s characteristics, including stability, and with the measures that must be taken to maintain watertightness and prevent flooding of the interior spaces of the hull.Footnote 42,Footnote 43

The owner of the Arctic Fox II deferred these responsibilities to the master. The master was compensated for the roles of ship’s husband and master with a share of the landed catch, while the owner paid for the services and materials used for preventive and periodic maintenance of the vessel and equipment.

Shipyard invoices since 2016 indicate that the master periodically arranged to maintain the vessel’s hull by having it painted, having sections recaulked as needed, and by having the zincsFootnote 44 replaced. There were no shipyard records of any inspections done on through-hull fittings, engine room piping or pumps, or the vessel’s structural hull integrity. The owner determined that the vessel’s seaworthiness was adequate based on the fact that the master, who was given the responsibility for maintaining the vessel in a seaworthy condition, had never indicated otherwise. Although the owner was in possession of documents detailing the vessel’s history and modifications, he was aware of only some of the modifications made to the vessel and past changes in the vessel’s operations. There are no records to indicate that the effects of any modifications on the vessel’s stability were assessed, or that the stability was within acceptable limits for its intended purpose, as was required by regulation.Footnote 45

1.8.4 External evaluations

1.8.4.1 Examinations

While the Arctic Fox II operated as a U.S.-registered vessel (2012 to 2018), it underwent 3 mandatory dockside safety examinations. These USCG examinations ensured the vessel was carrying the required documentation and life-saving equipment. All 3 examinations noted that the vessel carried the required life raft, EPIRB, and immersion suits; however, they also noted that the crew did not wear PFDs on deck.

1.8.4.2 Transport Canada inspections

As a fishing vessel of greater than 15 GT, the Arctic Fox II was required to be certified by TC and carry a TC certificate of inspection indicating that it was inspected for compliance with applicable regulations while it was registered in Canada (1984 to 2012, and 2018 to 2020). This certificate is required to be renewed every 4 years.

A review of records from TC indicated that the Arctic Fox II was first inspected in June 2004. The vessel was inspected again in June 2008 and was issued a near coastal voyage, Class 1 safety certificate. There are no other records of TC safety certificates being issued to the vessel after 2008. TC had neither identified the absence of an inspection in 2018 nor followed up with the AR about the fact that the vessel was overdue for an inspection.

Finding: Other

TC had not evaluated the need for voyage limitations because the vessel had not been inspected for certification purposes.

The owner was aware of the requirement for a TC vessel inspection and assumed that the master, as ship’s husband, was arranging for the required vessel inspections. The owner did not receive an invoice from any shipyard or from TC for an inspection service, and never questioned the master or performed any checks to ensure that the Arctic Fox II was carrying the required Canadian maritime documents, such as a vessel safety certificate or a safe manning document.

Teague Fishing Corporation, the AR, owned another vessel similar to the Arctic Fox II, of which the owner of Teague Fishing Corporation served as the master from 1977 to 2020. This other vessel was of greater than 15 GT and was required to carry Canadian maritime documents, similar to the Arctic Fox II. TC has no record of this vessel ever having been issued any Canadian maritime documents.

Although TC’s national vessel registration office sends registration reminders, TC’s regional marine safety offices do not send out reminders for vessel inspections. While some TC regional offices had routinely done this in the past for vessel owners, the practice of sending reminders ended when the Canada Shipping Act, 2001 (CSA 2001) came into force in 2007; the CSA 2001 places the responsibility of having inspections performed to obtain Canadian maritime documents on the AR.Footnote 46

1.8.4.3 Surveys

Most vessel owners choose to obtain insurance to protect against loss. In most cases, insurance underwriters require a vessel survey before providing a policy. The principal function of this survey is to determine the condition of a vessel, its suitability for the intended purpose, as well as its current and replacement value. A vessel survey often states that its sole purpose is to assist in determining a vessel’s qualification for insurance coverage, and should not be used for other purposes.

The owner arranged for an insurance survey of the Arctic Fox II in 2018 and another in 2020. The surveys were conducted when the Arctic Fox II was afloat, and no opinion was given as to the condition of the underwater hull. The surveys also indicated that neither the vessel’s equipment nor machinery were tested, and no determination of stability characteristics or inherent structural integrity was made.

The 2018 survey recommended that the engine room fire extinguisher and wiring connections be replaced and that these recommendations be addressed by the AR within 30 days. The 2020 survey contained the 2018 recommendations as well as a recommendation to replace the deteriorated hose clamps on the generator. Both surveys indicated that the vessel was in satisfactory condition for its intended operation, provided the recommendations were addressed. The owner considered these surveys to be a measure of vessel seaworthiness.

1.8.5 Crewing

A safe manning document specifies a vessel’s minimum required complement and the minimum certification requirements for each crew member to safely navigate the vessel and respond to an emergency on its intended voyage.Footnote 47 The safe manning document may also specify the voyage areas permitted, watch arrangements, and work/rest requirements. It is issued to a vessel by TC in accordance with the requirements of the Marine Personnel Regulations,Footnote 48 following a TC evaluation of the vessel and its intended operation and voyage location. The AR of a vessel must ensure that the requirements specified in the document are met.

The evaluation does not consider crew qualifications or the number of crew members required to safely carry out other vessel operations, such as fishing. Furthermore, the evaluation is not a substitute for using professional judgment and following appropriate general seamanship practices to ensure that there are a sufficient number of competent crew members on board a vessel.

Although a safe manning document was required by regulation, there is no record of the Arctic Fox II having been assessed for or issued one. Without a safe manning document, the master may have been unaware of the regulatory requirements associated with the safe navigation and operation of the vessel. Navigational watch requirementsFootnote 49 are such that during hours of darkness, a minimum of 2 people must be on watch and 1 must have the appropriate certification.

In the fishing industry, all of those working on board are typically compensated by sharing the value of the landed catch, which means the proceeds of the catch are divided by the number of crew members on board. Thus, the desire to optimize income in the difficult economy of many fisheries may lead operators to reduce crew.Footnote 50

Finding: Other

The Arctic Fox II’s manning level and the experience and certification of the crew on the occurrence voyage were such that the navigational watch requirements could not be met.

1.9 Fishing context and safety

The commercial fishing industry in Canada is complex and diverse, and operates in hazardous environments. Economic and market conditions, crew availability issues, and confusing and overlapping regulatory systems influence the priorities, choices, and decisions that ARs and masters face as they attempt to make a living and operate safely.

The hazards facing fish harvesters while their vessels are at sea are well known, systemic, and persistent. Evaluating risks associated with hazards involves assessing the probability of that hazard occurring and the severity of any consequences. The ability to see and detect risk depends particularly on a person’s own understanding and tolerance of risk.Footnote 51 Many factors influence individual risk perception and tolerance, including pressure to accept risk, personal experience, the approval of others, and confidence in their own risk mitigation (e.g., the availability of life-saving and distress alerting equipment, certificates and surveys, training, and drills).

To reduce the risk of loss, hazards in fishing operations must be consciously and regularly identified, and the associated risks must be mitigated to a point that is reasonably practicable. Within the safety limits defined by the minimum regulatory requirements, this point is determined by the AR and the master.

The TSB’s Safety Issues Investigation into Fishing Safety in Canada (safety issue investigation [SII] on fishing safety),Footnote 52 a comprehensive national review of safety issues in the fishing industry, revealed a complex relationship and interdependency among these issues. This investigation determined that the safety of fish harvesters will continue to be compromised until the complex relationship and interdependency among safety issues is recognized and addressed by the fishing community.

The SII on fishing safety identified 10 significant safety issues that are interconnected and that require attention, including the following issues found in the occurrence involving the Arctic Fox II:

- Stability (vessel seaworthiness)

- Work practices that do not include vessel familiarization

- Training that is not regularly reinforced with emergency drills

- Fatigue due to an insufficient crewing

Other significant safety issues identified in this SII on fishing safety were also evident in this occurrence but not analyzed (see Appendix A).

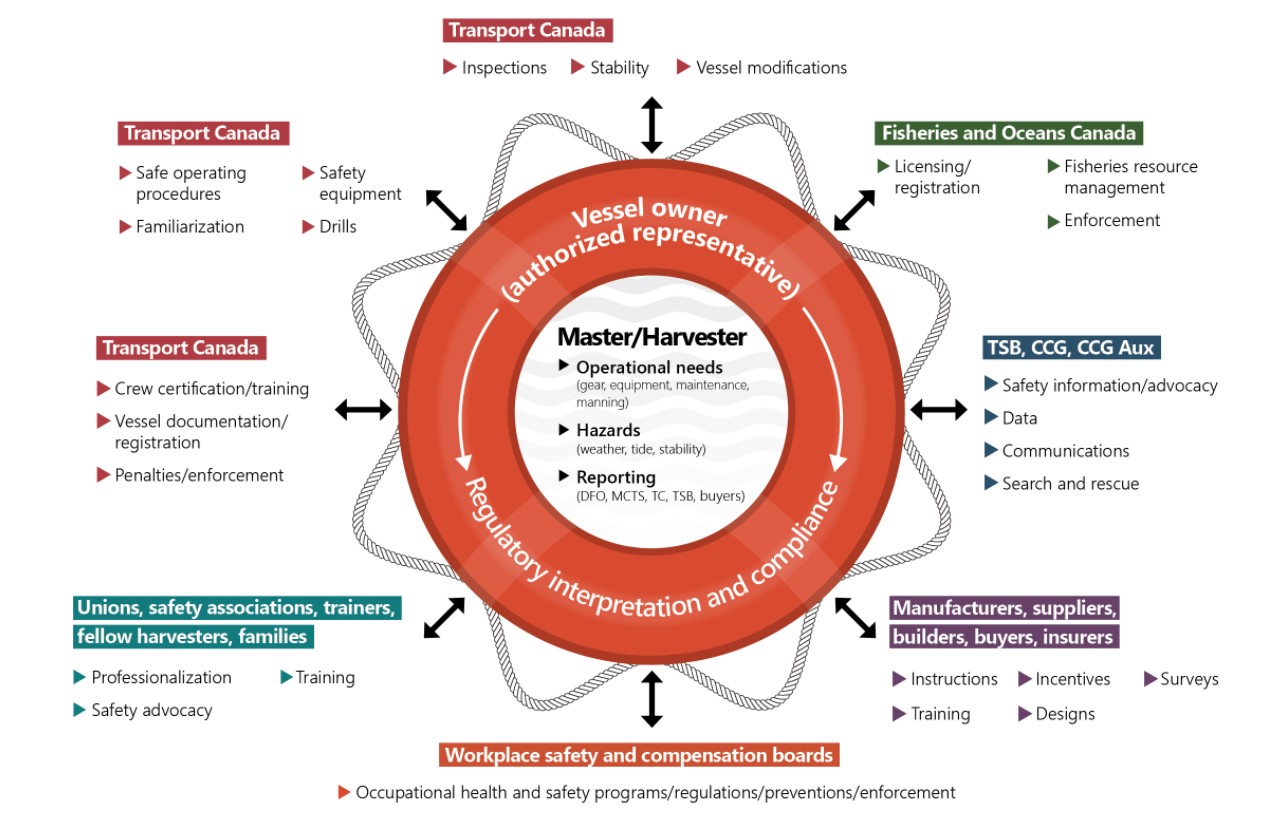

Success in reducing exposure to hazards relies on the partnership between the fishing industry and government agencies, where masters, ARs, and regulators work together to continuously identify systemic hazards and ensure that the associated risks are being mitigated proactively (Figure 4).

1.9.1 Authorized representative, master, and crew

Regardless of regulations, before a fishing season begins, ARs (usually an owner), masters, and crew typically prepare the vessel for its intended operations. While at sea, masters make sure that the vessel, its machinery, and equipment are functional and maintained in working order; additionally, they are ultimately responsible for their own safety, the safety of the crew, and the safety of the vessel. Crew members often assist the master by reporting when they become aware of a hazardous condition or situation during fishing operations.

Often, ARs, masters, and crews identify hazards and mitigate risks only for hazards that are directly related to the business of fishing and those that they perceive to affect fishing safety. For example, they may consider the risks of being injured by equipment, but not the risks associated with navigational hazards or operating outside stability limits. ARs, masters, and crews also have an obligation to meet the minimum safety requirements detailed in the regulations, but ARs are not required to have a formal safety management system for their vessels.

1.9.2 Safety advocates

There are safety advocates in each region of the country, such as safety associations, fishing associations, professional certification boards, sector councils, and alliances of industry participants. Some of these organizations collaborate with fish harvesters to promote safety, offer training to fish harvesters, supply safety information, and provide a forum for industry and regulator representatives to discuss safety. These organizations work independently of regulators; their primary interest lies in improving safety within fishing operations. For other organizations, the main focus is on advocating for fish harvesters by promoting their economic interests. Safety advocacy groups in BC, Nova Scotia, Quebec, and Newfoundland and Labrador represent the majority of fish harvesters and have extensive knowledge of the hazards and significant safety issues. The investigation determined that safety information from these safety advocates reaches about one-third of fish harvesters.

1.9.3 Regulators

Regulators play an important role in identifying hazards and mitigating associated risks to improve fishing safety; their role is to directly or indirectly aid in protecting life and property.

1.9.3.1 Transport Canada

Under the CSA 2001, TC is the federal department responsible for the regulatory program that oversees the safety of all vessels and marine personnel; this responsibility includes the development of regulations and standards for vessels and crews. TC is also responsible for enforcing those regulations and standards. TC defines oversight as

[a]ctivities that support the systematic promotion, monitoring, or enforcement with Transport Canada requirements governing safety or security and that contribute to departmental strategic outcomes. Footnote 53

1.9.3.2 Fisheries and Oceans Canada

Under the Fisheries Act,Footnote 54 DFO is primarily responsible for protecting Canadian fisheries resources. Over the years, DFO has recognized that the actions fish harvesters take to meet the requirements of the Fisheries Act regarding fishery resource management are negatively affecting fishing safety. For example, trip and quota limits as well as time and area restrictions affect operational decisions, and vessels are being built to stay within the length restrictions specified for vessel licences.Footnote 55,Footnote 56 While DFO does not have a fishing safety policy, it does acknowledge that it has a role to play in incorporating safety into the development of fishery management plans and policies.

In 2011, an initiative was started in the DFO Pacific region in which DFO asks to see a valid TC registration for the fishing vessel before issuing a licence; no other validation of compliance with safety regulations is needed. In 2018, a new regional initiative was started in the DFO Arctic region where DFO requests confirmation of TC vessel registration as part of licensing requirements.

DFO’s enforcement does not extend to any safety infractions under the CSA 2001Footnote 57 or the Fishing Vessel Safety Regulations (FVSR).

1.9.3.3 WorkSafeBC

WorkSafeBC establishes, implements, and enforces provincial occupational health and safety regulations, which cover marine operations, including fishing.Footnote 58 With regard to fishing operations, WorkSafeBC is specifically concerned with the business of fishing.

1.10 Regulatory oversight of fishing safety

Hazards can be managed in a variety of ways. One important way is by promoting behaviours that are expected to manage hazards successfully, and monitoring those behaviours to determine if they are improving safety. Inherent within these behaviours is the ability to identify hazards. Some of the mechanisms for promoting and monitoring behaviours that identify hazards and mitigate associated risks are minimum legal and regulatory requirements, oversight, and enforcement mechanisms.

1.10.1 Legal and regulatory requirements

Canadian marine legislation and regulations specify requirements that ARs and masters must meet to establish a minimum level of safety and function as defences to manage hazards. Regulations applicable to fishing vessels are developed to optimize the reliability of equipment and the dependability of operators, as well as to prevent accidents or minimize loss and injury as a consequence of accidents.Footnote 59

The CSA 2001, which is applicable to all vessels, including fishing vessels, places responsibility for vessel safety on the ARs. As well, the SII on fishing safety found that a broader aim of the FVSR was to encourage fish harvesters (ARs and masters) to take greater responsibility for keeping their own operations safe. TC also changed its vessel inspection system to one that depends on ARs to ensure that regulations are understood and complied with through self-monitoring. These inspection program changes were part of a transition from a regime focused on mandatory inspection for the purpose of certification to one that factors in risk and takes a self-monitoring approach, while TC monitors regulatory compliance. The SII on fishing safety also noted that this transition would take time and would require close monitoring by TC. All commercial vessels, including fishing vessels, that are powered with a motor of 7.5 kW (10 hp) or more and owned by qualified persons,Footnote 60 must be registered with TC, and the registration information must be complete.Footnote 61 The ARs of these vessels need to be knowledgeable about their responsibilities under the CSA 2001Footnote 62 and applicable regulations, such as thosepertaining to vessel registration, safe work practices, watchkeeping practices, safe crewing, and vessel seaworthiness. They must also ensure that these regulations are complied with.

Maintaining vessel seaworthiness is a required condition of a vessel’s insurance policy when the Marine Insurance ActFootnote 63 applies. The Act requires the insured party to enter the agreement for vessel insurance in good faith, and to guarantee vessel seaworthiness and compliance with applicable acts and regulations.

Vessel masters are ultimately responsible for their own safety, the safety of the crew, and the safety of the vessel.Footnote 64 In addition to identifying hazards, fulfilling this responsibility involves taking reasonable measures to protect the vessel and persons on board from those hazards,Footnote 65,Footnote 66 and ensuring that safety regulations are followed.Footnote 67 Masters must ensure that the vessel, its machinery, and equipment are properly maintained and function safely; that safety procedures are established and responsibilities are assigned; and that crews are trained in and understand safe work. Masters must also regularly conduct emergency drills, including drills for abandoning the vessel, and must maintain records of those drills.Footnote 68,Footnote 69

Crew members are required to assist the master by reporting to the master when they become aware of an unsafe or harmful condition or situation (hazards).Footnote 70

Although formal hazard identification and risk assessment is required in other marine sectors as part of a safety management system, it is not required for fishing vessels.

1.10.2 Oversight and enforcement mechanisms

Under its Marine Safety and Security Program,Footnote 71 TC has a number of means to oversee and enforce safety regulations related to fishing vessels. TC relies primarily on a vessel’s AR and master to ensure regulatory compliance. TC’s primary regulatory oversight mechanism is through the vessel certification regime, which includes vessel inspections, such as

- annual inspections for vessels that are 24 m in length or above, a function that has been delegated to TC-approved classification societies;

- quadrennial inspections of vessels of between 15 and 100 GT conducted by TC marine safety inspectors;

- risk-based inspections of vessels of any size; and

- inspections performed under a concentrated inspection campaign (CIC).

It is the responsibility of ARs, masters, and crews to be informed of all applicable regulations and standards involved in meeting the requirements under the regime. These inspections assist in determining whether ARs are in compliance with regulations, such as maintaining their vessels in a seaworthy condition.

At the end of 2020, TC reported approximately 4000 fishing vessels that were required to be inspected for certification every 4 years. From 2016 to 2019, for a variety of reasons, the ARs of approximately one third (1200 vessels) of this group of vessels did not arrange for inspections as required by regulation, and so approximately 650 fishing vessels were inspected per year, which is a small percentage of the Canadian fishing fleet. Footnote 72

A TC vessel inspection consists of an examination of a vessel’s hull and watertight integrity. It includes removing and inspecting the through-hull fittings, cutlass bearing, internal piping, and raw water intake piping; testing the machinery and pumps; and performing an overall check on a vessel’s seaworthiness. Such an inspection also ensures that a vessel is carrying the correct number and types of serviceable life-saving equipment as well as the required written safety procedures. TC records the condition of each vessel inspected. Vessel inspections provide TC inspectors with an opportunity to mitigate risks by discussing with the AR what corrective actions are required to be compliant, if any, and the vessel’s AR is responsible for addressing these deficiencies and notifying TC. Even when vessels are inspected, not all factors that affect seaworthiness are identified in every case.Footnote 73 For example, the Arctic Fox II had been inspected twice by TC in 2004 and 2008, but the vessel’s modifications and changes in operation were not noted, and the effects on the vessel’s stability were unknown.

These inspections also give inspectors an opportunity to educate ARs and masters about regulatory requirements and their safety responsibilities, and to increase their awareness of hazards. For example, inspectors may explain how modifications can affect vessel stability.

A CIC is a planned, risk-based oversight activity that addresses specific areas of safety concerns encountered by inspectors, described in accident reports, or received as feedback from marine industry stakeholders. Inspections may also be conducted under this campaign when new regulations have recently come into force. The first domestic CIC, which applied to all TC-registered vessels, was conducted in 2012; since then, CICs have been conducted every 2 years. According to the report from the 2018 campaign,Footnote 74 83 vessels were inspected nationwide as part of that CIC, of which 21 were fishing vessels of over 15 GT. These 21 vessels were already required to undergo regular TC inspections. In summer 2021, TC began its fourth national CIC, which targeted small fishing vessels of the same size as the Arctic Fox II. This CIC focused on items such as life-saving and firefighting equipment, ensuring proper procedures were in place for crew safety, and ensuring adequate vessel stability. The campaign involved 101 vessels, 83% of which were certified vessels that required inspections and 62% of which were found to have safety deficiencies. Footnote 75 The campaign also noted that

- the largest categories of deficiencies were the absence of procedures, records, drills, and maintenance of lifesaving equipment;

- 28% of fishing vessel crews could not demonstrate their knowledge of procedures;

- 41% of fishing vessel crews did not conduct drills on safety procedures;

- 79% of vessels did not have up-to-date Canadian maritime documents; and

- 80% of vessels had overdue deficiency notices from previous inspections.

When a violation of safety regulations is identified in BC, usually through accident reports, regulatory investigations or a vessel inspection, TC and WorkSafeBC can issue one or more of the following to ARs or masters using a scaled approach: written or verbal warnings, notices of violation, notices of corrective action, monetary penalties, and detention or stop-work orders.

According to TC’s website,Footnote 76 TC issues an average of 10 administrative monetary penalties per year to all types of vessels across the country, including fishing vessels.Footnote 77 TC and WorkSafeBC have issued penalties for non-compliances such as failure to ensure that

- PFDs are worn;

- safe work procedures are available;

- a hazard assessment is conducted;

- major vessel modifications do not adversely affect its stability;

- the vessel is maintained in seaworthy condition;

- the vessel is inspected by the regulator;

- inexperienced crew members receive a health and safety orientation before beginning work;

- crew members are provided with the information, instruction, training, and supervision necessary to ensure their health and safety; and

- the master and crew members are certified, as required.

Following the occurrence involving the Arctic Fox II, TC conducted a regulatory investigation and issued administrative monetary penalties to the owners for a total of $20 000. The penalties were for failing to ensure that the Arctic Fox II and its machinery and equipment had been inspected for the purpose of obtaining the vessel inspection certificate and for failing to provide the master with written instructions on appropriate procedures to be followed for familiarizing crew with shipboard equipment and instructions for safe watchkeeping and emergencies.

As well, it was determined that the AR’s other vessel had never been inspected as required. TC detained the vessel until the regulatory investigation was completed.

Under its Marine Initiative,Footnote 78 WorkSafeBC has a marine team comprising approximately 4 full-time equivalent positions. The members of WorkSafeBC’s marine team have experience in the fishing industry, and conduct at-sea and dockside inspections that assess compliance with occupational health and safety requirements. About half the marine team’s time is spent at sea conducting inspections of inshore fishery vessels. WorkSafeBC statistics indicate that commercial fishing continues to have one of the highest fatality rates per capita of all the industries in BC; the goal of the Marine Initiative is to reduce the number of work-related deaths in BC’s fishing industry.

1.10.3 Known issues

TC faces a number of high-level known issues in implementing and conducting oversight of the fishing industry with finite resources.

In 2019, TC published a report of the oversight activities under its Marine Safety and Security Program. In the report, TC indicated that 90% of the program’s budget was slated for planned certification activities, such as updating vessel registration and safety certificates. This portion of the budget also covered accident and incident monitoring and follow-up for all potential infractions of the CSA 2001 and all applicable regulations, leaving only a small portion for risk-based oversight activities such as CICs.Footnote 79

TC may not always be aware of vessels that are operating as fishing vessels if the vessels are registered only with DFO and not with TC. Under the CSA 2001, it is the AR’s responsibility to obtain the vessel’s Canadian maritime documents, which include a vessel registration certificate. Previous TSB investigations have determined that ARs are often unaware of or neglect this responsibility.Footnote 80

Following the TSB’s investigation into the loss of the fishing vessel Sarah Anne, where the investigation identified approximately 4000 vessels that were registered with DFO but not with TC, the Board recommended that

the Department of Fisheries and Oceans require that any Canadian vessel that is used to commercially harvest marine resources have a current and accurate Transport Canada registration.

TSB Recommendation M22-01

1.11 Education and awareness

Education about hazards and risks, and awareness of the regulations and their purpose represent one step in operating safely. However, regulations are often difficult to understand, and fish harvesters are sometimes frustrated by the absence of consistency in their application, and may comply with regulations only to obtain certification. Footnote 81

Under its Marine Safety and Security Program, TC has mechanisms in place for targeted education and awareness activities. For example, from 2016 to 2018, TC ran campaigns to make the fishing industry aware of the new FVSR prior to those regulations coming into force. TC also conducts tests, sets training standards, and approves training providers. TC manages a web portal that provides fish harvesters with safety information in the form of technical publications Footnote 82 and Ship Safety Bulletins. TC also encourages compliance through the voluntary Small Vessel Compliance Program Footnote 83 for vessels of less than 15 GT; there is a specific component of the program for fishing vessels. Nationally, TC issued to fishing vessels 1130 notices of participation for the Small Vessel Compliance Program between 2017, when the program began, and April 2021. Lastly, TC supports and encourages education and awareness campaigns by provincial safety advocates.

WorkSafeBC has guidance material such as safety bulletins, a manual, and guidelines to regulations. This material is available in print and online via WorkSafeBC’s web portal. The manual is entitled Gearing Up for Safety: Safe Work Practices for Commercial Fishing in British Columbia, and addresses many common safety and health hazards in the commercial fishing industry. It emphasizes emergency preparedness, safe operating procedures, safety equipment, and gear-specific hazards. To encourage the industry to adopt safe behaviours and attitudes, WorkSafeBC relies on education and awareness initiatives provided by safety advocacy groups, such as Fish Safe. Footnote 84 Both the master and the owner of the Arctic Fox II had learned about Fish Safe just before the occurrence.

Representatives of safety advocacy groups have knowledge of the fishing industry, its context, and the hazards and safety issues that are present. In some regions, these representatives are also fish harvesters. Safety advocates provide harvesters with tools to take ownership of safety, such as information on the use of life-saving equipment, emergency drills, and compliance with minimum safety requirements. This material is generally available both in print and online. In some regions, safety advocates run programs that allow for one-on-one interaction with fish harvesters, giving representatives an opportunity to support harvesters in meeting their safety responsibilities. The programs take place in the form of dock walks, Footnote 85 vessel visits, Footnote 86 on-board person overboard drills, and assisting harvesters in identifying hazards and developing vessel-specific safety procedures.

1.12 Active recommendations

Following an occurrence on 05 September 2015 in which the large fishing vessel Caledonian suddenly capsized 20 NM west of Nootka Sound, BC, and 3 crew members died,Footnote 87 the Board recommended that

the Department of Transport require that all small fishing vessels undergo a stability assessment and establish standards to ensure that the stability information is adequate and readily available to the crew.

TSB Recommendation M16-03

In the case of the Arctic Fox II, the vessel modifications were not assessed for effects on stability. Stability factors have played a significant role in numerous fishing vessel accidents since 1990.

Since issuing Recommendation M16-03, the TSB has followed up annually with TC on action being taken to address it. TC’s last response was assessed in March 2022. As part of the response, TC's proposed actions include promoting the voluntary use of the stability notice templates and carrying out a review of stability information during inspections. However, these actions can only take place if vessels have had their stability assessed, which is not the case for the majority of small fishing vessels. While the onus for compliance does fall to a vessel’s AR, TSB investigations have demonstrated that not all ARs are aware of or are effectively carrying out this responsibility.

In March 2022, this response was assessed as Unsatisfactory.Footnote 88

1.13 Previous occurrences

The TSB has investigated several occurrences involving small fishing vessels in which issues related to vessel seaworthiness, non-use of PFDs, and unsafe vessel operations were identified, in addition to not taking ownership of safety responsibilities.Footnote 89

1.14 TSB Watchlist

The TSB Watchlist identifies the key safety issues that need to be addressed to make Canada’s transportation system even safer.

Commercial fishing safety is a Watchlist 2022 issue. Following the initiation of the TSB’s SII on fishing safety in 2009, the Board placed commercial fishing safety on the Watchlist in 2010. Since then, there continues to be a disproportionately large number of fatalities within the fishing industry. Footnote 90 From 2018 to 2020, there were 45 fish harvester fatalities, which is the highest fatality count for a 3-year period in over 20 years. This occurrence involving the Arctic Fox IIdemonstrates the continued need for the coordinated regulatory oversight of commercial fisheries to support ARs and masters in taking ownership of their safety responsibilities.

ACTIONS REQUIRED Commercial fishing safety will remain on the Watchlist until there are sufficient indications that a sound safety culture has taken root throughout the industry and in fishing communities across the country, namely:

|

Fatigue management in rail, marine and air transportation is a Watchlist 2022 issue.

In the fishing industry, approximately 95% of fishing vessels do not have any applicable work/rest provisions under the Marine Personnel Regulations. Given that fishing operations are not conducive to obtaining proper restorative sleep, fish harvesters need a greater awareness of the risks associated with fatigue, and effective strategies to mitigate its risks. This occurrence demonstrates the continued need for fatigue education and awareness training, and for ARs to implement fatigue management plans on board their vessels.

ACTIONS REQUIRED Fatigue management will remain on the Watchlist for the marine transportation sector until the following actions are taken:

|

Regulatory surveillance is a Watchlist 2022 issue.

The investigation determined that, as of December 2019 in BC, there were 614 fishing vessels that required a vessel inspection for certification before beginning operations. Of these fishing vessels, 291 did not have the required safety certificate to begin operations and approximately 25% of them (78 vessels), including the Arctic Fox II, were actively fishing. The level of seaworthiness and compliance with applicable safety regulations of these vessels has therefore not been assessed. As a result, TC also misses opportunities to provide oversight and support and to influence the behaviour of the ARs, masters, and crews of these vessels. This demonstrates the continued need for effective surveillance and monitoring of the commercial vessel inspection process.

ACTIONS REQUIRED Regulatory surveillance will remain on the Watchlist for the marine transportation sector until TC provides more oversight of the commercial vessel inspection process by demonstrating that its surveillance and monitoring are effective in ensuring that authorized representatives and recognized organizations are ensuring compliance with regulatory requirements. Additionally, TC demonstrates an increase in proactive surveillance. |

Safety management is a Watchlist 2022 issue.

Fishing vessels are exempt from regulations regarding safety management systems; however, section 106 of the CSA 2001 and subsection 3.16 of the FVSR do require fishing vessels to have written safety procedures. The investigation determined that the AR of the Arctic Fox II did not provide the master with procedures on how to safely operate the vessel and deal with emergencies.

ACTIONS REQUIRED Safety management will remain on the Watchlist for the marine transportation sector until:

|

2.0 Analysis

The investigation could not determine the exact cause of water ingress on the Arctic Fox II. The analysis will focus on the underlying causes and contributing factors of this occurrence, specifically fish harvesters’ perception of risk, vessel crewing, crew training, fatigue, and vessel seaworthiness. The analysis will also examine the effectiveness of TC’s oversight and the reliance on authorized representatives (ARs) and masters to monitor their own operations for regulatory compliance in the commercial fishing industry.

2.1 Fish harvesters’ perception of risk

The TSB has determined that some fish harvesters consider fishing to be a dangerous occupation where accidents are inevitable regardless of the precautions they take.Footnote 91 Many owners and masters do not fully understand the level of risk they face and therefore see little benefit to identifying hazards and mitigating the associated risks. As a result, they often take or accept risks to a greater degree than is acceptable to regulators, safety advocates, and crew members. Fish harvesters’ overall perception of risk is also influenced by the following factors:

- There are economic pressures to go fishing. These pressures often outweigh any mitigation of risks that would limit opportunities to maximize fish harvesters’ catch, such as waiting for better weather conditions for fishing operations.

- Fish harvesters have more confidence in their own skills, actions, and experience than in the regulatory defences, emergency duties training, and stability booklets.

- Previous accident-free years reinforce fish harvesters’ belief in the safety and success of their operation and, as a result, they continue to underestimate the actual risks involved and behave accordingly.

- Fish harvesters may overestimate the level of risk mitigation that life-saving equipment actually provides, especially if the equipment is not always well-maintained and its use is not always practised.

- Certificates, licenses, and vessel surveys from governments, associations, and insurers may be perceived more broadly as overall approval of fish harvesters’ capacity to operate safely.

In this occurrence, the master’s and owner’s perception of risk was affected by the following factors:

- The vessel was registered with TC and licensed by DFO, equipped with approved life-saving and distress alerting equipment, had been surveyed for insurance purposes, and was insured.

- The master was experienced, had taken training as part of TC certification, and had taken TC-approved MED training in the past.

- The master, as ship’s husband, conducted preventive maintenance on the vessel periodically to be ready to operate in a single, limited-time fishery, which was also the only opportunity to earn income.

- The master and owner had completed successful trips in the past with inexperienced crew members. As well, economic pressures played a role in the decision to not delay the trip until sufficiently experienced crew members were available.

- Finally, the master had survived 2 previous vessel abandonments.

Finding as to causes and contributing factors

When the master departed for the fishing grounds on the occurrence voyage, both he and the owner perceived that the risks of the planned fishing operation had been addressed sufficiently. Their perceptions of risk were likely influenced by economic incentives, approvals and certificates, and many successful voyages.

2.2 Vessel crewing

The master and the owner attempted to hire an experienced crew; however, given the short fishing season (the vessel operates in only one fishery), and the uncertainty of income, only inexperienced people applied. As the master’s and owner’s earnings were tied to the catch, the master accepted departing with an inexperienced crew rather than missing the season.

The inexperienced crew members had limited knowledge and understanding of fishing operations and how to maintain compliance with safety regulations; therefore, they had limited ability to identify hazards or hazardous situations related to the operation of the vessel.

During the water ingress emergency, the master attempted to maintain a bridge watch, locate and stop the ingress of water, de-water the vessel, and communicate with search and rescue authorities by himself, in addition to preparing the life raft and crew members to abandon the vessel. Because the master had chosen to manage all of these tasks himself, the inexperienced crew members were entirely dependent on him to manage the emergency situation. At one point, the master did not communicate with search and rescue authorities for more than 20 minutes while he was trying to manage multiple tasks. This delay in communication delayed the decision to deploy search and rescue resources.

Finding as to causes and contributing factors

The master managed the water ingress and related safety-critical tasks unassisted. As a result, essential emergency actions were delayed, which both contributed to the deteriorating seaworthiness of the vessel and impacted the survivability of the crew.

2.3 Crew training

When the vessel departed, it was operated by an experienced master and 2 inexperienced crew members. Economic and market conditions and the unavailability of experienced crew members contributed to the necessity of hiring inexperienced crew members.

The master last participated in marine emergency duties (MED) training in 2001. Recurrent MED training is not required, nor is there any required training for masters on how to train new crew members in terms of procedures, drills, and familiarization. With the absence of recurrent training, the informal instructions the master gave to new crew members on board the Arctic Fox II were the only emergency practice sessions in which the master participated. In this occurrence, these informal instructions meant that the necessary information was not conveyed to crew members, resulting in crew members improperly donning their immersion suits before entering the water and not deploying the life raft as intended. The master had not recently practised any formal emergency procedures, such as walking through the procedure for deploying the life raft, or practising the complete donning of an immersion suit. The limited nature of the informal instructions affected the quality and quantity of the knowledge and skills that were transferred to new crew members.

Before fishing operations began, the inexperienced crew members were briefly familiarized with emergency procedures specific to the Arctic Fox II, although they were not given any emergency-related training or information on any procedures for vessel abandonment or responding to persons overboard. This brief familiarization did not provide sufficient information to the crew members. Therefore, the crew members were unfamiliar with the proper donning of an immersion suit, including the importance of zipping it up fully, securing the ankle straps to prevent air from entering the boots, and filling the inflatable bladder. They were also unfamiliar with the procedure for deploying a life raft, particularly the importance of keeping the painter line secured to the vessel and placing the life raft directly in the water from its secured position on the aft upper deck.

Finding as to causes and contributing factors

The master and crew were unfamiliar with the instructions for deploying the life raft and, in their efforts to deploy the raft, its painter line was disconnected from the vessel and went overboard. This prompted the master to enter the water with his immersion suit only partially zipped and with ankle straps unsecured. Consequently, the master was exposed to the elements and eventually drowned.

The master’s action to retrieve the painter line effectively created a person overboard situation during an emergency abandonment procedure.

Finding as to causes and contributing factors

The familiarization that the crew members received was insufficient for them to acquire the knowledge or skills necessary for successfully abandoning the vessel or for retrieving a person overboard, and the crew’s response to these emergencies was guided only by their limited experience.

Without any guidance or procedures for vessel abandonment or persons overboard, crew member 1 jumped into the water without any discussion or plan, and with an improperly donned immersion suit. Additionally, later on during the emergency situation, crew member 2 jumped overboard on the vessel side opposite from where the liferaft was rather from on the same side.

Finding as to causes and contributing factors

Crew member 2 jumped into the water with his immersion suit only partially zipped and with ankle straps unsecured. Consequently, he was exposed to the elements and eventually drowned.

2.4 Fatigue

To manage fatigue effectively, navigational watch requirements and manning levels for fishing operations must be considered. Navigational watch requirements for commercial vessels stipulate that a certified person must be on watch at all times, and that during the hours of darkness there must be 2 people on watch. Tuna fishing operations occur during daylight hours. To safely conduct tuna fishing operations and manage fatigue while complying with the applicable regulations, the Arctic Fox II was required to have a crew of at least 4 people, of which 2 were required to be certified.

In this occurrence, the vessel’s crewing made it impossible to meet the navigational watch requirements, given that only the master was certified. The master’s attempts to manage fatigue led to non-compliances with regulations: an inexperienced crew member was allowed to stand watch alone and the vessel allowed to drift at night with no one on watch.

These attempts to manage fatigue led to unsafe work practices, such as the master remaining awake for approximately 57 of the 67 hours he was at sea and being continuously awake for about 22 hours immediately before his Mayday call.

The master and crew members also experienced acute disruptions to their sleep and sleeping patterns during the fishing operations. At the time of the emergency, the crew members had been woken from sleep, and their performance was likely affected by sleep inertia. Finally, they prepared to abandon the vessel during a circadian low.

Finding: Other

The investigation determined that 4 fatigue risk factors (acute sleep disruption, continuous wakefulness, circadian rhythm effects, and multiple health conditions) and sleep inertia were present to a sufficient degree that the master and the crew were likely experiencing the effects of sleep-related fatigue at the time of the occurrence.

Fatigue has been identified in previous TSB reports as a contributing factor to accidents, and fish harvesters have confirmed that fatigue risk factors are widespread in the commercial fishing industry. The presence of fatigue risk factors demonstrates that fatigue persists as an issue within the commercial fishing industry.

2.5 Vessel seaworthiness and monitoring for regulatory compliance

Maintaining vessel seaworthiness is a responsibility that is crucial to the safety of a vessel, its crew, and the environment. Maintaining vessel seaworthiness requires specific knowledge and skills, and involves making sure that vessel modifications are assessed for effects on stability, that weight creep is monitored, and that watertight integrity and adequate freeboard are maintained. The effects of these stability factors change over a vessel’s lifespan, so it is especially important to monitor the seaworthiness of older vessels.

Safety regulations are defences in place to ensure that known hazards within the industry are addressed; these regulations specify the minimum safety requirements that must be met. TC and, in the province of BC, WorkSafeBC, are responsible for oversight and enforcement of safety regulations for fishing vessels. However, the regulations regarding vessel seaworthiness are subject to interpretation, leaving ARs and masters to determine whether a vessel is sufficiently seaworthy for its intended voyage. TC and WorkSafeBC provide regulatory guidance for maintaining vessel seaworthiness, although this information and the regulatory requirements are not always known or necessarily understood by ARs and masters.