Crossing collision

Canadian National Railway Company

Track unit CN461-18

Mile 90.61, Joliette Subdivision

Saint-Norbert, Quebec

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

On 18 August 2016, at approximately 0330 Eastern Daylight Time, Canadian National Railway Company (CN) track unit CN461-18 was travelling northward at approximately 16 mph (26 km/h) on the CN Joliette Subdivision. At the Highway 347 public grade crossing, at Mile 90.61, near the municipality of Saint Norbert, Quebec, the track unit collided with an eastbound tractor-trailer. Two employees on board the track unit and both occupants of the tractor-trailer sustained minor injuries. Approximately 600 L of diesel fuel and hydraulic fluid were released from the track unit and the tractor trailer.

Le présent rapport est également disponible en français.

Factual information

The accident

On 18 August 2016, at approximately 0305,Footnote 1 a convoy of 15 track units (TUs)Footnote 2 working as a rail replacement production crew left the work site at Mile 95.95 of the Canadian National Railway Company (CN) Joliette Subdivision, travelling north. TU CN461‑18, consisting of a multi-crane pulling a tool car, was the 8th TU in the convoy.

At approximately 0330, the multi-crane was travelling at approximately 16 mph (26 km/h) as it approached the Highway 347 public grade crossing, at Mile 90.61, near the municipality of Saint‑Norbert, Quebec (Figure 1). The crossing warning device was not activated. The multi‑crane operator saw that a CN flag-person was positioned east of the crossing. The flag‑person signalled to the multi-crane operator to proceed, then walked through the crossing and stood on the road.

The operator saw that the flag-person was trying to stop a road vehicle approaching from the west by waving his white headlamp at the vehicle while continuing to indicate to the multi‑crane operator to move forward. Following the flag‑person's instructions, the operator continued moving without slowing down. Then, after passing a farm building on the western side of the track, the operator saw the headlights of a tractor-trailer that was approaching the crossing. When the driver of the tractor‑trailer saw the flag-person signalling for the driver to stop and the multi-crane approaching the entrance to the crossing, the driver, unable to stop, veered into the opposite lane. The multi-crane entered the crossing, struck the tractor‑trailer, and derailed.

The multi‑crane operator and a mechanic who was on board the tool car, as well as the driver and passenger of the tractor‑trailer, sustained minor injuries.

The temperature was 20 °C and the sky was overcast. It had rained earlier that night.

Occurrence site information

In the area of the collision, the track runs north-south,Footnote 3 past fields and agricultural facilities. The track is tangent over a long distance and intersects Highway 347 at an angle of approximately 90°. Highway 347 is a 2‑lane road with a maximum authorized speed of 90 km/h (55 mph) and an average traffic density of 3000 vehicles per day.

In 2000, CN modified the warning device at this grade crossing by adding gates and cantilevered flashing lights. In 2001, the Ministère des Transports, de la Mobilité durable et de l'Électrification des transports du Québec (Quebec Ministry of Transport, Sustainable Mobility and Transportation Electrification) installed advance warning signs (Figure 2).Footnote 4 These signs are located approximately 700 feet (213 m) from the crossing at both approach roads.

A farm building and a mill were situated on either side of the track. The farm building, covering an area of about 4000 square feet (371 m2), bordered the track over a distance of about 100 feet (30.5 m) in the southwest quadrant, approximately 70 feet (21 m) from the highway and 45 feet (14 m) from the track.

An examination of sight distances found that road vehicles coming from the west and travelling at the authorized speed became visible to an observer located in the southeast quadrant of the crossing 17 seconds before they entered the crossing, meaning at a distance of approximately 1400 feet (427 m).

Site examination

The multi-crane remained upright and came to rest at an angle of approximately 45° from the track centreline (Figure 3), obstructing the crossing for several hours. The guide wheels derailed and dug grooves into the asphalt surface of the roadway.

The multi-crane was substantially damaged. The windows on either side of the cabin were shattered. The multi-crane boom locking mechanism was broken and the boom was turned approximately 30°. The devices on the tip of the boom and attached to the front of the multi‑crane were destroyed (Figure 4).

The tractor‑trailer, which had been loaded with sand, came to rest on the roadway approximately 150 feet (46 m) east of the crossing. The tractor and trailer were still attached and had jackknifed (Figure 5). The tractor was significantly damaged. The front of the cab had impact marks above the passenger door. The roof and part of the rear of the cab had been torn off and launched into the ditch.

The trailer was substantially damaged. The front was dented, and the side panels of the dump body and several reinforcing ribs were torn off. The articulating arm of the tarp covering the dump body was broken off.

The track and the crossing sustained minor damage. Two flashing lights in the northeast quadrant of the warning system were shorn off.

Release

The fuel tank on the right side of the tractor‑trailer was punctured and released all of its contents. Diesel fuel and oils from the multi-crane spilled onto the grade crossing and spread to the gravel road leading to the mill. Approximately 600 L of petroleum products were released onto the ground and were contained with absorbent material.

Track information

The Joliette Subdivision is a single main track running from Garneau Yard, at Mile 40.1, to Pointe-aux-Trembles, Quebec, at Mile 127.8. Train movements are controlled by the occupancy control system as authorized by the Canadian Rail Operating Rules (CROR) and supervised by a rail traffic controller located in Montréal, Quebec. Traffic on the subdivision consists of approximately 5 freight trains and 1 passenger train per day.

In the vicinity of the accident site, the track is a Class 4 track according to the Transport Canada–approved Rules Respecting Track Safety, also known as the Track Safety Rules (TSR). The maximum authorized speed on the Joliette Subdivision between miles 87.5 and 101.0 is 60 mph (97 km/h) for passenger trains and 50 mph (81 km/h) for freight trains.

Inspections of the accident site area were conducted in accordance with the provisions of the TSR and did not reveal any defects requiring immediate correction.

The following inspections were performed:

- The last regular inspection was conducted on board a hi-rail vehicle on 16 August 2016.

- The most recent internal rail defect testing was conducted on 19 July 2016.

- A track geometry inspection was conducted with a track evaluation car on 29 July 2016.

The crossing warning system was inspected regularly. CN conducted the most recent weekly inspection, which consists of verifying the flashing lights, the bell, and the movement of the gates, on 11 August 2016; no defects were noted.

Convoy route

During the work shift that began at 1830 on 17 August 2016, rail replacement work was carried out by CN Engineering Services. Once this work was completed, the crew was to move all work equipment and specialized equipment to Joffre Station, near Charny, Quebec, for their next assignment. This move was to be completed over 2 nights, with the first leg from Joliette, Quebec, to Garneau Yard, and the second leg from Garneau Yard to Charny.

The distance between the work site and Charny was approximately 150 miles (244 km) by rail. The convoy had to cross approximately 100 public grade crossings equipped with warning devices. When a convoy is moving, flag-persons must ensure that TUs can cross safely. Crossings requiring manual protection by a flag-person had been identified by the foreman in charge through an assessment of local traffic and visibility conditions.

Flag-person

The flag-person posted at the Highway 347 crossing had started working for the company in March 2015 as a trackman for regional production crews. His work as a production crew trackman includes all activities related to track maintenance, and acting as a flag-person to provide track protection for TUs at grade crossings, which he had done on several previous occasions.

The flag-person met fitness and rest standards and was qualified for his position. The flag‑person normally obtained approximately 8 hours of sleep the day before his shifts, and had no trouble sleeping. He was off duty on 12 and 13 August 2016, and returned to work on 14 August. His 8-hour shift started at 1830. The night of the accident, his task as trackman was to provide assistance at all steps related to replacing sections of rail, as well as other related duties.

The flag-person was familiar with the Joliette Subdivision, but he was not familiar with the particularities of the grade crossings in the area. Once the work was completed, he was responsible for protecting the Highway 347 crossing. He was wearing his personal protective equipment,Footnote 5 as per company requirements, and had a white headlamp (Figure 6).

White headlamps worn by workers during night work produce a luminosity of approximately 200 lumens.Footnote 6 Depending on the type of headlights installed on a road vehicle, the light they produce can range from 1200 to 1600 lumens for a halogen headlight to 3200 lumens for xenon headlights. Therefore, the visual conspicuityFootnote 7 of the truck's headlights was greater than that of the white headlamp used by the flag‑person.

A vehicle at the head of the convoy dropped off the flag-person at the Highway 347 grade crossing. The flag‑person stood to the east of the crossing and allowed the first 7 TUs to pass. He then signalled to the multi-crane to proceed after ensuring that no road vehicle was visible. When the multi-crane was approximately 400 feet (122 m) from the crossing, the flag‑person saw the lights of a road vehicle approaching from the west. He walked toward the centre of the crossing and signalled using his white headlamp (moving it up and down) to try to stop the vehicle, while continuing to indicate to the multi-crane operator to advance. When the flag-person realized that the road vehicle was not slowing down, he jumped into the ditch to protect himself.

Multi-crane operator

The multi-crane operator began working for the company in June 1983 as a trackman. He became an equipment and roadway machine operator in the early 1990s. He met fitness and rest standards, was qualified for his position, and was familiar with the territory.

The operator was off duty on 12 and 13 August 2016, and reported for work on 14 August. His 9-hour shift began at 1730. The night of the accident, his role as the crane operator was to lift various loads, including sections of rail.

Multi-crane

The multi-crane is a hi-rail TU used for handling rails and ties. It weighs approximately 65 000 pounds (30 000 kg). An examination of the multi-crane's mechanical records found no defect requiring repair. The multi-crane underwent daily inspections as well as planned inspections every 50, 200, and 1500 hours in service. The following inspections were performed:

- The last daily inspection was conducted on 16 August 2016. All fluid levels and the brakes were checked.

- The most recent 50-hour inspection was conducted on 08 August 2016.

- The most recent 200-hour inspection was conducted on 02 August 2016.

- The most recent 1500-hour inspection was conducted on 08 December 2015.

Several rail braking tests are recorded in the multi-crane's logbook. They indicate that, at a speed of approximately 15 mph (24 km/h), the vehicle requires about 75 feet (23 m) to come to a complete stop.

After leaving the work site at Mile 95.95, with all of its headlights and additional lights on, the multi-crane passed through 9 grade crossings, including 3 without a flag‑person. At these 3 crossings, the crane operator came to a complete stop and looked both ways before proceeding through the crossings. In addition, at each stop, the operator advised the vehicle behind him, to avoid collisions between the hi-rail vehicles.

As indicated in section 10.5 of CN's General Engineering Instructions (GEI),Footnote 8 TUs with damaged or defective insulation must be repaired immediately. Hi-rail TUs are electrically insulated so as not to activate railway signals or crossing warning devices. All specialized track work equipment has these same characteristics.

Tractor‑trailer driver

The driver of the tractor-trailer met fitness and rest standards and was qualified for his position. He had approximately 30 years of experience driving heavy vehicles. His shift had begun at approximately 0200. He had had more than 48 hours of rest since his last assignment. He had loaded his truck at a sandpit about 40 km from the crossing and was to unload it at a concrete plant in Laval, Quebec. The driver was familiar with the area and often took this route.

Tractor‑trailer

The tractor-trailer consisted of a tractor and a dump trailer loaded with sand. Its combined gross weight was approximately 58 000 kg (127 800 pounds). The tractor was a 2003 Kenworth model and the trailer was a 2006 Stargate. Both were equipped with antilock braking systems. They were registered in the province of Quebec and had passed their most recent annual safety inspections. The tractor and trailer were examined by road vehicle inspectors. No pre-existing mechanical defect was found.

According to a study by the U.S. National Highway Traffic Safety Administration,Footnote 9 the average braking distance for a tractor-trailer similar to the one in this accident, travelling at 55 mph (90 km/h), is approximately 300 feet (91 m). With an average reaction time of 2.5 seconds, the stopping distance for this vehicle is approximately 500 feet (152 m).

Grade crossing safety measures

The GEI have established practices aimed at implementing methods and instructions enabling railway personnel to safely perform manual protection at grade crossings. CN recommends 3 methods of passing through a grade crossing for TUs and other types of insulated equipment:

- Stop at the crossing and ensure that there are no conflicting movements before proceeding through the crossing.

- Activate the crossing's existing warning system.

- Use a flag-person.

The GEI indicate that the TU operators must give the right of way to road vehicles, except when the crossing is protected either by an activated warning system or by a flag‑person in accordance with guidelines on manual protection at crossings.Footnote 10 The GEI do not specify that the flag-person must give the right of way to road vehicles over railway TUs.

Signalling equipment

The GEI state that, to carry out the planned activity during daytime hours at a crossing requiring protection, each flag-person must have an approved handheld "STOP/SLOW" paddle, an approved high-visibility reflective vest, the required personal protective equipment, and an effective means of communicating with a flag-person outside his or her field of vision. The instructions specify that "[d]uring the hours of darkness, or in other conditions of poor visibility, […] each flag-person is to be provided with a working flashlight which may be fitted with a red signalling baton or a lit red fusee."Footnote 11 All traffic control equipment, including signs and personal protective equipment, must be clean and in good condition.

At the time of the accident, the flag-person was wearing only his personal protective equipment and white headlamp. Other flag-persons posted at other crossings had similar equipment. None of the flag-persons had a key to activate the warning system for the crossing for which they were providing manual protection.

Signalling procedure

Flag-persons must warn road users or signal for them to slow down at night by facing them head‑on, holding up the "STOP/SLOW" paddle in their right hand with arm extended, and waving up and down, from shoulder height, a flashlight with a red signalling baton in their left hand.

In addition, the GEI, as well as the Railway Association of Canada's Circular 13, Recommended Practices for Manual Protection of Highway/Railway Grade Crossings, state in part that flag‑persons must stand in a safe position on the side of the road for which they are responsible and have an unobstructed view of approaching traffic. The flag‑person must make all the necessary traffic control motions and signals in a precise and deliberate fashion so that their meaning is clearly understood. The flag-person must provide road users with a message that is consistent with those that they encounter in other roadway flagging situations.Footnote 12

The investigation determined that the hand signals used by the flag-persons at grade crossings did not comply with the procedure described above.

Engineering personnel training

New Engineering employees receive training on the rules, general instructions, and procedures related to their work. From March 2015 to July 2016, the occurrence flag‑person took 44 courses, including an introduction to the GEI and safe operation for TUs, which specifically addressed manual protection at crossings. The GEI are not covered in detail, but each employee receives a copy of the GEI to consult as necessary.

Oversight

CN has developed instructions and training to manage risks related to grade crossing safety. The company uses efficiency testing to ensure that its personnel (and others) use the required equipment and correctly apply procedures for manual protection at grade crossings. These efficiency tests are an oversight measure for the control mechanisms put in place to manage the risks associated with passing through a grade crossing. In the year preceding the accident, the Eastern Region production crews had been subject to 4 checks related to the instructions for manual protection at crossings. No efficiency test on manual protection at crossings was entered into the railway company's database for the occurrence flag-person.

Alertness during the night shift

A factor that could have increased the risk of fatigue (Appendix A) at the time of the accident was the period of work from 0000 to 0600. Almost all functions of the body are regulated by circadian rhythms. Their major effect is programming humans to be awake during the day and asleep at night, with 2 periods of sleepiness. The main period of sleepiness generally occurs between 0300 and 0500, and the secondary period of sleepiness in the afternoon. Regardless of an individual's motivation or the situation, it can be difficult to remain alert, and cognitive performance can be reduced, during these periods.

TSB statistics

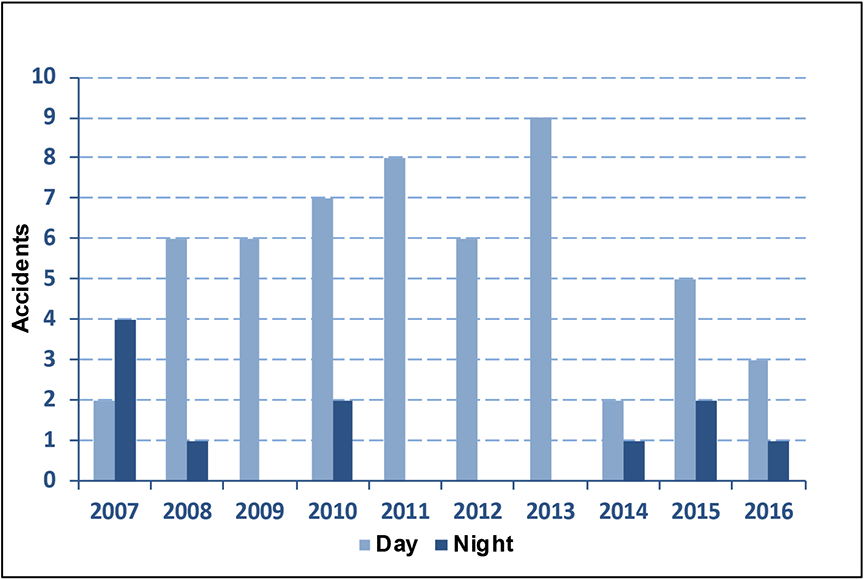

According to the TSB's railway occurrence database, from 2007 to 2016, there were 65 occurrences involving a TU at a grade crossing. Of those, 39 happened at grade crossings with warning devices and 28 involved insulated TUs that could not activate grade crossing warning devices. During that same period, 11 accidents occurred at night (Figure 7). As well, 2 accidents occurred while a flag‑person was protecting the crossing and the warning device was not activated.

Analysis

Because the condition of the crossing and the occurrence vehicles did not contribute to the accident, the analysis will focus on the signalling procedures for manual protection of a convoy of track units (TUs), as well as the management of the associated risks.

The accident

When the multi-crane was approximately 400 feet (122 m) from the crossing, the flag-person instructed the multi-crane operator to proceed through the crossing. The flag-person subsequently noticed the lights of a road vehicle approaching from the west. Given that the headlights of the tractor‑trailer would have become visible approximately 1400 feet (427 m) from the crossing, there would have been sufficient time for the flag-person to stop the multi‑crane.

However, the flag-person's reaction was to pursue his original plan to let the multi-crane proceed instead of giving the right of way to the road vehicle. The flag-person positioned himself on the west side of the crossing, pointing his white headlamp toward the road to try to warn the tractor‑trailer driver, instead of signalling for the multi-crane operator to stop. The right of way was given to the TU travelling on the track rather than to the road vehicle; therefore, the multi‑crane operator, having received the flag-person's permission to proceed, did not slow down.

Just after passing the farm building that was beside the track and obstructing his view of the southwest quadrant, the operator saw the headlights of the tractor‑trailer as it moved. At that point, the multi-crane was approximately 70 feet (21 m) from the crossing, which was less than the required stopping distance. By the time the operator realized that the tractor‑trailer was still approaching, the multi-crane was no longer capable of stopping before the crossing; it entered the crossing and struck the front of the tractor‑trailer.

Right of way according to the General Engineering Instructions

The General Engineering Instructions (GEI) instruct TU operators to give the right of way to road vehicles, except when the crossing is protected either by an activated warning device or by a flag‑person. However, the GEI do not specify that a flag‑person posted at a crossing must also give the right of way to road vehicles when providing protection for a convoy. If the GEI do not specify that a flag-person must give the right of way to road vehicles, there may be confusion regarding the actions that the flag‑person is to take, thereby increasing the risk of an accident.

Non-activated advance warning sign and crossing warning device

Road vehicle drivers are continually forming mental models, i.e., internal structures that allow individuals to describe, explain, and predict events and situations occurring in their environments. They are developed based on several factors, including experience, knowledge, perception and comprehension of external cues in the work environment.

Because drivers generally do not encounter any trains at grade crossings, each experience with one of these crossings reinforces their perception that the presence of a train is unlikely. A literature review by Yeh and MulterFootnote 13 determined that drivers who are familiar with a crossing are less likely to look for a train at the crossing or to reduce their speed when approaching it than drivers who are unfamiliar with it. At protected crossings, activated warning devices provide visual and aural stimuli that alert drivers while reinforcing their perception that the activated systems are associated with the presence of a train and, therefore, that non‑activated systems would indicate the absence of a train or rolling stock on the track.

For road vehicles approaching from the west on Highway 347, the flashing lights of the advance warning sign, when activated, are visible from a distance that is sufficient to warn vehicles of a train at the grade crossing. However, on the night of the occurrence, neither the advance warning sign nor the crossing warning device was activated, because the multi‑crane was electrically insulated and the flag‑person had not manually activated the warning device. Given that the advance warning sign and the crossing warning device had not been activated, the tractor‑trailer driver was expecting the crossing to be clear and therefore did not prepare to stop the vehicle at the crossing.

Headlamp conspicuity

Once a mental model has been established, it is difficult to change. For a person's mental model to be modified, the existing model must be superseded by another, with the new information being sufficiently compelling to result in an update of the mental model. In the case of a crossing that has non‑activated warning devices and is occupied by rolling stock, the stimuli must be sufficiently compelling to alter motorists' existing mental model and make them aware of the imminent danger so that they can take appropriate action.

Given that the tractor‑trailer driver was travelling on a familiar segment of road, and given that the flashing lights of the advance warning sign and the crossing warning device were not activated, his attention was not focussed specifically on the crossing. As a result, he did not notice the flag-person signalling for him to stop in time. In addition, the visual conspicuity of the truck's headlights was greater than that of the white headlamp used by the flag-person, making the headlamp more difficult to detect. Regardless, the personal protective equipment and the white headlamp used by the flag-person did not constitute stimuli that were sufficiently compelling to alert the driver and make him aware of the abnormal situation at the grade crossing.

Moreover, the building beside the road, and the vegetation surrounding the southwest quadrant, limited the tractor‑trailer driver's sightline toward the south and prevented him from seeing all of the multi-crane's lights as it approached the track. By the time the tractor‑trailer driver saw the flag-person signalling for him to stop, the tractor‑trailer was too close to be able to stop before the crossing, and the multi-crane's boom struck the tractor‑trailer as it entered the crossing.

Hand‑signalling procedures

Interviews with a sample of Engineering employees who acted as flag-persons revealed that the hand signals used by flag-persons at crossings were not in compliance with the procedure set out in the GEI and varied from one flag‑person to another. In addition, the GEI specify that flag-persons must give all necessary traffic control signals in a precise and deliberate fashion so that their meaning is clearly understood. Furthermore, flag-persons must provide road users with message that is consistent with those that they encounter in other roadway flagging situations. If employees do not apply the hand‑signalling procedures for grade crossings in accordance with the GEI, this can lead to misinterpretation, thereby increasing the risk of collisions.

Equipment for flag-persons

According to the GEI, a flag-person must have several pieces of equipment to perform manual protection at grade crossings. The equipment (a flashlight with a red signalling baton or red fusee and an approved handheld "STOP/SLOW" paddle) required by the GEI to attract motorists' attention may not correspond with drivers' expectations for indications that the crossing is occupied by rolling stock. However, a flag-person using the equipment required by the GEI would have been more conspicuous and would have been more likely to attract the tractor‑trailer driver's attention in time and avoid the collision.

The flag-person posted at the Highway 347 crossing did not have the equipment required by the GEI, nor did he have a radio to communicate with the operators in the convoy. Furthermore, none of the other flag-persons possessed all of the equipment required by the GEI. Adaptations to rules and procedures can happen over time; these adaptations then become accepted practices. If the equipment necessary for grade crossing signalling is not used, procedures cannot be carried out as prescribed, thereby increasing the risk of an accident.

Efficiency tests

During their training, new employees take several courses, including courses on manual protection at grade crossings. Although these topics are not covered in detail, each employee receives a copy of the GEI to consult as necessary. However, some deficiencies in the application of the GEI were noted. The equipment necessary for manual protection at grade crossings was not always used. The hand signals used by flag-persons at crossings differed from the procedure set out in the GEI and varied from one flag-person to another. As well, there may be some confusion in the GEI regarding giving the right of way to road vehicles.

The railway company has implemented control measures to manage the risks associated with the passage of TUs through grade crossings. Efficiency testing is a means of oversight to verify and validate risk control and mitigation measures. For tasks related to manual protection at crossings, these tests can confirm whether employees understand and execute instructions as prescribed. In addition, these tests can verify whether teams are using all the equipment required to safely carry out their duties.

In the year preceding the accident, the Eastern Region production crews had been subject to 4 checks related to the instructions for manual protection at crossings. However, the occurrence flag-person was never subject to efficiency testing on manual protection at crossings, and few tests related to manual protection at crossings were conducted for any of the production crews. As a result, the deficiencies related to the application of the GEI were not identified or corrected. If efficiency tests are not conducted often enough to verify and validate control measures at crossings protected by flag-persons, safety deficiencies will not be identified, increasing the risk to the public.

Lowered alertness during the night shift

The grade crossing protection took place approximately 9 hours after the beginning of the flag-person's shift, during a period generally associated with low alertness and diminished cognitive performance, between 0300 and 0500. Although he was expecting little to no road traffic at that time of the night, the flag-person did notice a road vehicle, which indicates a certain level of alertness. In addition, the fact that the flag-person gave the right of way to the railway vehicle rather than to the road vehicle can be attributed to a reaction of continuing the original plan and not necessarily to a diminished cognitive performance. Therefore, the fact that the flag-person was working at night during a period generally associated with impaired performance did not affect his performance.

Assessment of type of protection

The route between the work site and Charny, Quebec, includes about 100 public grade crossings equipped with warning devices. The foreman in charge determines which crossings require manual protection by a flag-person based on a brief assessment of local traffic and visibility conditions. Although the conditions and particularities of each crossing are not necessarily known or taken into account as part of this assessment, this approach is sufficient for most situations. If advance warning signs with flashing lights are not activated when a grade crossing is occupied, the defence provided by the advance warning sign is negated, which can increase the risk of an accident.

Findings

Findings as to causes and contributing factors

- The right of way was given to the track unit travelling on the track rather than to the road vehicle; therefore, the multi-crane operator did not slow down as he had received the flag-person's permission to proceed through the crossing.

- By the time the operator realized that the truck was still approaching, the multi-crane was no longer capable of stopping before the crossing, it entered the crossing, and struck the front of the truck.

- Given that the advanced warning road sign and the crossing warning system were not activated, the truck driver was expecting the crossing to be clear and therefore did not prepare to stop his truck at the crossing.

- The personal protective equipment and the white headlamp that the flag-person was using did not constitute cues that were sufficiently compelling to alert the driver and make him aware of the unusual situation at the crossing.

- By the time the driver saw the flag-person who was signalling for him to stop, the truck was too close to be stopped before the crossing, and it was struck by the multi-crane's boom when it entered the crossing.

Findings as to risks

- If the General Engineering Instructions do not specify that a flag-person must give the right of way to road vehicles, the flag-person could be confused regarding the actions to take, thereby increasing the risk of accidents.

- If employees do not comply with the manual signalling procedures at crossings set out in the General Engineering Instructions, this can lead to misinterpretation, increasing the risk of collisions.

- If the equipment necessary for signalling at crossings is not used, procedures cannot be carried out as intended, increasing the risk of accidents.

- If efficiency tests are not carried out at a frequency that is sufficient to verify and validate control measures at crossings that are protected by flag-persons, safety deficiencies will not be identified, increasing the risks for the public.

- If advanced warning road signs with flashing lights are not activated when a crossing is occupied, the means of defense provided by the advanced warning sign is nullified, which can increase the risk of accidents.

Other findings

- A flag-person using the equipment required by the General Engineering Instructions would have been more conspicuous and would have been more likely to attract the truck driver's attention in time to avoid the collision.

Safety action

Safety action taken

Canadian National Railway Company

Following the accident, the Canadian National Railway Company (CN) published a safety bulletin entitled "Proper flagging procedures for operating work equipment machinery over roadway crossings at grade."Footnote 14

The bulletin states that, when traffic is heavy, when visibility is poor, or in other specific circumstances, certain conditions must be met before protecting a crossing with a flag‑person.

In particular, the flag-person must have the following items:

- a key or tool to access the crossing warning devices;

- a reflectorized handheld Stop paddle;

- a radio to communicate with equipment operators and to ensure clear understanding of instructions; and

- a flashlight with a red signalling baton for protection at night.

The bulletin also states that, if such items are not available from suppliers, they must be purchased from a local business as soon as possible. In addition, if the items are not available immediately, the flag-person must stop the rolling stock and confirm that the crossing is clear before authorizing the rolling stock to proceed through the crossing. Some situations may require more than one flag-person. High-risk situations must be discussed during the briefing.

As well, even when a flag-person is present, the equipment operator must take all necessary precautions to ensure that the crossing is clear. Before carrying out their duties, flag-persons must have a clear understanding of the rules to be followed in the flagging procedures for flag-persons for track units passing through crossings, in order to improve safety at railway crossings.

CN also distributed Safety Flash 2016-20, Crossing Collision, to all of its Engineering Services personnel. The document describes the facts of the accident and specifies the guidelines to prevent such an accident from recurring.

This report concludes the Transportation Safety Board of Canada's investigation into this occurrence. The Board authorized the release of this report on . It was officially released on .

Appendices

Appendix A – Factors related to the risk of fatigue

The following factorsFootnote 15 can increase the risk of fatigue:

- total length of the work shift exceeding 14-16 hours;

- continuous hours of wakefulness beyond 19 hours;

- working between the hours of 0000 and 0600;

- obtaining less than 6 hours of continuous sleep in a 24-hour period;

- rest periods that do not permit reasonable recuperative times (less than 8 hours);

- continuous work beyond 64 hours in a 7-day period (without a rest period);

- less than 2 consecutive nights of recuperative sleep;

- continuous work for over 5 hours without at least a 30-minute break;

- undiagnosed or untreated medical conditions (e.g., sleep apnea) that may affect fatigue;

- differences in ability to sleep and respond to conditions (e.g., age, hardiness);

- quality of sleep.