Main-track derailment

Canadian Pacific Railway

Freight train 603-230

Mile 26.4, Maple Creek Subdivision

Antelope, Saskatchewan

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

The occurrence

On 03 October 2017, a Canadian Pacific Railway (CP) train crew (the crew) was ordered for 1830Footnote 1 in Swift Current, Saskatchewan (Figure 1). The crew was scheduled to operate freight train 603-230 (the train) westward on the Maple Creek Subdivision from Swift Current (Mile 0.0) to Medicine Hat, Alberta (Mile 147.4). The train departed at about 1905.

The train consisted of a head-end locomotive, 170 covered hopper cars loaded with potash, a mid-train remote control locomotive (85 cars behind the lead locomotive) and a remote control locomotive at the tail end of the train. This heavy unit train weighed about 24 201 tons and was 8210 feet long.

At about 2010, while proceeding at 48 mph, the train experienced a train-initiated emergency brake application at Mile 26.4 of the Maple Creek Subdivision. The lead locomotive came to a stop near the Antelope grain terminal at Mile 28.0. The crew made the required emergency radio call, and then inspected the train. It was determined that 37 cars had derailed: the 107th car to the 142nd car.

Before the emergency brake application, the crew had not observed any track or operating anomalies. The throttle had been in position 8 (maximum) since shortly after departing Swift Current. The train had previously traversed the wayside hot bearing and dragging equipment detector at Mile 10.5 of the Maple Creek Subdivision. No alarms had been noted at this location.

At the time of the occurrence, the sky was clear and the temperature was −6 °C.

Crew information

The crew consisted of a locomotive engineer and a conductor. Both crew members were qualified for their respective positions, met established fitness and rest requirements, and were familiar with the territory.

Subdivision and track information

The Maple Creek Subdivision is predominantly a single main track. Train movements are controlled by the centralized traffic control system, as authorized by the Canadian Rail Operating Rules, and are supervised by a rail traffic controller located in Calgary, Alberta. Train traffic was about 23 trains per day, with an annual tonnage of about 70 million gross tons (MGT).

In the vicinity of the derailment, the track was rated as Class 4, according to the Transport Canada–approved Rules Respecting Track Safety, also known as the Track Safety Rules (TSR). The authorized speed for freight trains in the area was 55 mph. There were no temporary slow orders in effect for the area of the derailment.

Between Mile 26 and Mile 27, the track was tangent with a one-degree left-hand curve near the point of derailment, on relatively flat grade. The rail consisted of 136‑pound continuous welded rail (CWR), manufactured by Sydney in 1996. The rail was set on 14‑inch double-shouldered tie plates, and secured with 7 spikes per tie plate. The ties were about 80% hardwood and 20% softwood, with an average of 3168 ties per mile. The ballast was crushed rock, in good condition, with 9-inch depth and 12-inch shoulders. The drainage was good in the vicinity of the occurrence. The track was in good condition.

Site examination and equipment information

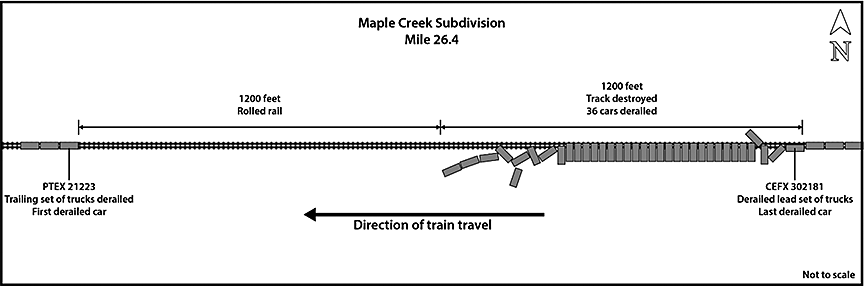

Leading up to the occurrence site, there were no wheel marks on the track infrastructure. The first derailed car (with the trailing set of trucks derailed) was PTEX 21223, the 107th car from the head end. The following 36 derailed cars came to rest in various positions on the right-of-way. The last of the derailed cars (with the lead set of trucks derailed) was CEFX 302181, the 142nd car from the head end (Figure 2).

Many of the derailed cars were breached and had released potash. About 2400 feet of track was destroyed or damaged, including about 1200 feet of rolled rail. There were no waterways in the vicinity, and there was no significant impact to the environment.

An examination of the head-end portion of the train was performed, up to and including the first derailed car. This car (the 107th) as well as the 105th and 106th, had impact marks on the treads of the wheels on the north side (Figure 3).

Laboratory examination of broken rail

Five pieces of rail were recovered from the occurrence site for detailed examination. However, their exact locations in the track before the derailment are unknown.

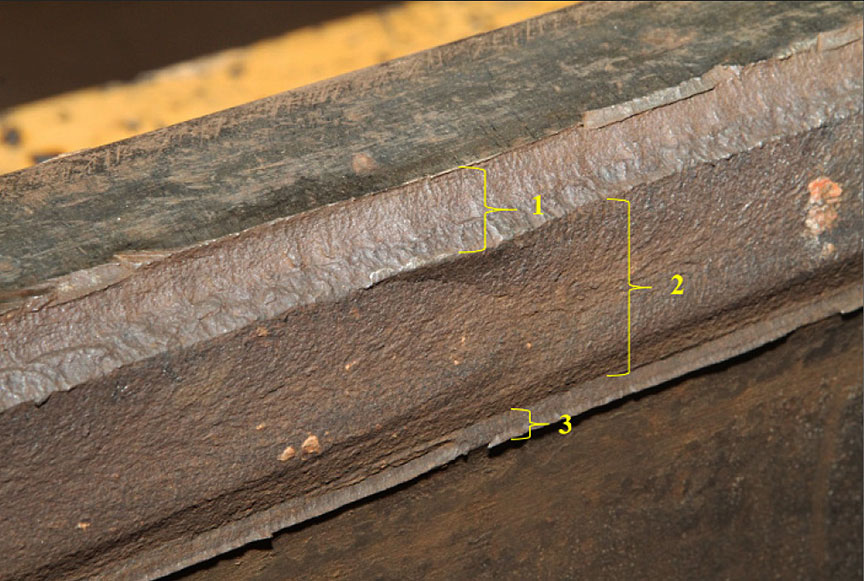

The laboratory examination determined that most of the fractures in the rail were due to overstress as a result of the derailment. However, the gauge side of the rail head was missing on one of the rails. There were indications of a vertical split head (VSH) on this rail. The approximately 2-inch-wide fracture was relatively uniform with a ½-inch band of fatigue cracking along the top edge (zone 1), a ⅛-inch band of fatigue/shear along the bottom edge (zone 3), and an overstress rupture along the 1⅜-inch centre portion (zone 2) (Figure 4). The fatigue cracking along the top of the fracture surface indicated that the overstress portion had been partially separated for an extended period of time. The pre-existing VSH on this rail section had likely progressed to a complete separation during the derailment sequence. Shelling was also present on the running surface at one end of the same rail section (Figure 5), but the VSH fracture passed by the shelling.

Track inspection and maintenance

The TSR outline the minimum maintenance standards and related track inspection requirements. In addition to the TSR, CP had developed its Red Book of Track and Structures Requirements (Red Book), providing further guidance that meets or exceeds the TSR requirements.

In the vicinity of the occurrence, the required track inspections were being performed in accordance with the TSR and with CP's Red Book.

Over the previous 2 years, rail flaw detection (RFD) testing had been conducted 11 times in the vicinity of the derailment. During these tests, no defects had been reported at or near the occurrence site. The most recent RFD testing had occurred on 17 August 2017.

One of the benefits of rail grinding is to remove the rail surface conditions on the rail head that are known to inhibit the transmission of ultrasonic signals during RFD testing. CP targets 2 rail grinding programs per year on the Maple Creek Subdivision (i.e., once every 40 MGT). Before the occurrence, CP had completed a grinding program on the subdivision in July 2017, and 2 grinding programs in 2016.

From the 2017 RFD tests, only 2 SSC (shelling, spalling, corrugation) defects were detected on the Maple Creek Subdivision. Based on these results, CP believed that the rail surface condition was not a significant factor on this subdivision.

Forward-facing camera

The lead locomotive in this occurrence was equipped with a forward-facing camera. Based on a review of this recording, no track anomalies were evident as the lead locomotive passed over the occurrence site.

Safety messages

It was not possible to determine precisely the role of the recovered rail sections in the derailment, as their exact location (pre-derailment) was unknown. Nonetheless, the VSH and the shelling on one of the rail sections showed that there were pre-existing conditions in the rail.

Marks that were present on the north wheel treads of the 105th car to the 107th car indicated that these wheels had hit a broken rail. The rail had likely broken when the head-end portion of the train passed over it.

This concludes the TSB's limited-scope investigation into this occurrence. The Board authorized the release of this investigation report on . It was officially released on 28 March 2018.