Main-track train derailment

Canadian Pacific Railway

Freight train 369-377

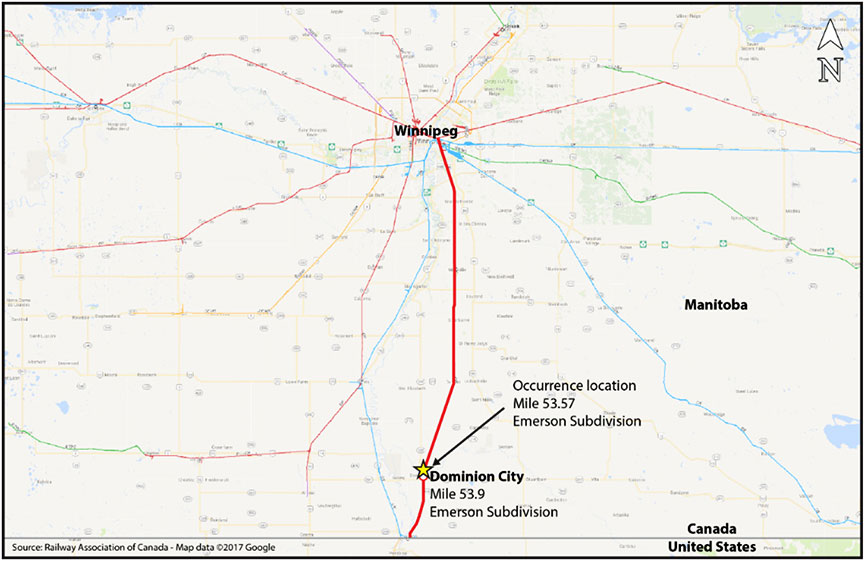

Mile 53.57, Emerson Subdivision

Dominion City, Manitoba

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

On 11 August 2017, at 1250 Central Daylight Time, Canadian Pacific Railway unit freight train 369-377 was proceeding northward at 40 mph on the Emerson Subdivision when it experienced a train-initiated emergency brake application. A subsequent inspection determined that 22 covered hopper cars loaded with corn had derailed while exiting a bridge (Mile 53.60) near the town of Dominion City, Manitoba. There were no injuries.

Le présent rapport est également disponible en français.

Factual information

On 11 August 2017, at 1212,Footnote 1 following a crew change at Noyes, North Dakota, United States, Canadian Pacific Railway (CP) unit freight train 369-377 (the train) departed northward for Winnipeg, Manitoba. The distributed power unit train was comprised of a head-end locomotive (CP 9585), 101 covered hopper cars loaded with corn, and a tail-end locomotive (CP 8646). The train was 5997 feet long and weighed 13 074 tons. The crew consisted of a locomotive engineer and a conductor. The crew members were qualified for their respective positions, were familiar with the territory, and met established fitness and rest standards.

The accident

At about 1240, while proceeding at 40 mph, the train crossed the CP bridge over the Roseau River (Mile 53.60 of the Emerson Subdivision), just north of Dominion City, Manitoba. Exiting the north end of the bridge, the train encountered a rough spot in the track. At 1241, a train-initiated emergency brake application occurred with the head end of the train near Mile 53.0.

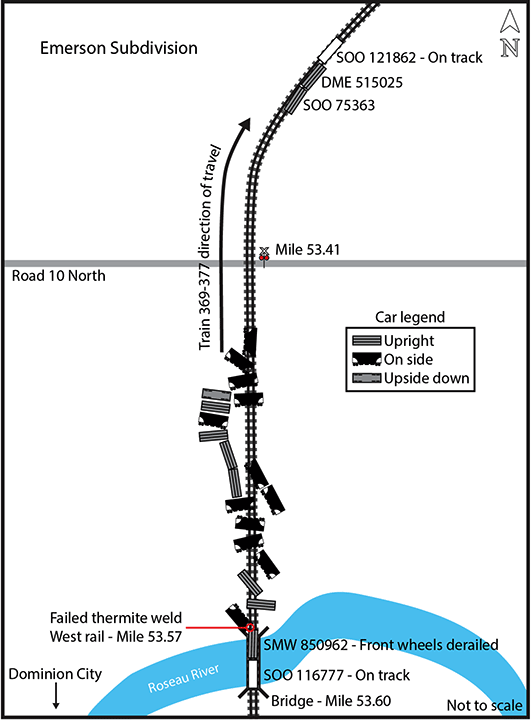

The subsequent inspection determined that 22 cars, the 58th to the 79th from the head end, had derailed just north of the CP bridge at Mile 53.57 of the Emerson Subdivision (Figure 1). Although some cars had released product, no product or rolling stock entered the waterway. There were no injuries.

At the time of the occurrence, the weather conditions were sunny and dry, with clear visibility and a temperature of 25 °C.

Site examination

The cars derailed at 2 locations, separated by about 600 feet (Figure 2).

The first 2 cars to derail were the 58th car (DME 515025) and the 59th car (SOO 75363) from the head end. Although remaining upright, these 2 cars had made it over the Road 10 North crossing (Mile 53.41) and had travelled about 3000 feet past the bridge in the derailed condition. The crossing sustained damage due to the derailed equipment.

The other 20 derailed cars were clustered together in various positions between the crossing and the north end of the bridge. Most of these cars had derailed to the west side of the track.

Based on a visual examination of the derailed cars, no pre-derailment equipment defects were present that could be considered causal to the derailment. As a result of the derailment, about 3000 feet of track was damaged or destroyed.

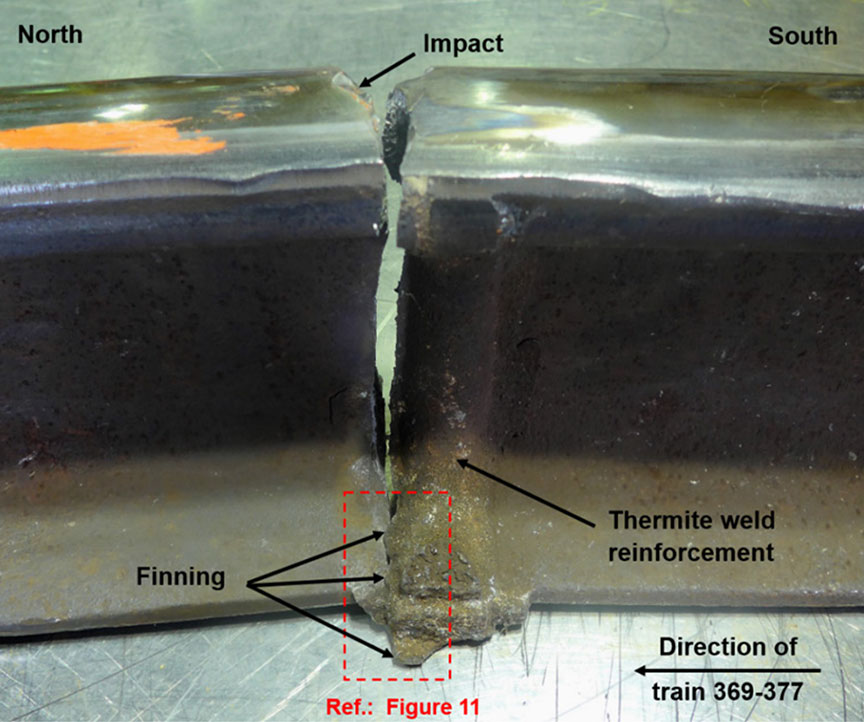

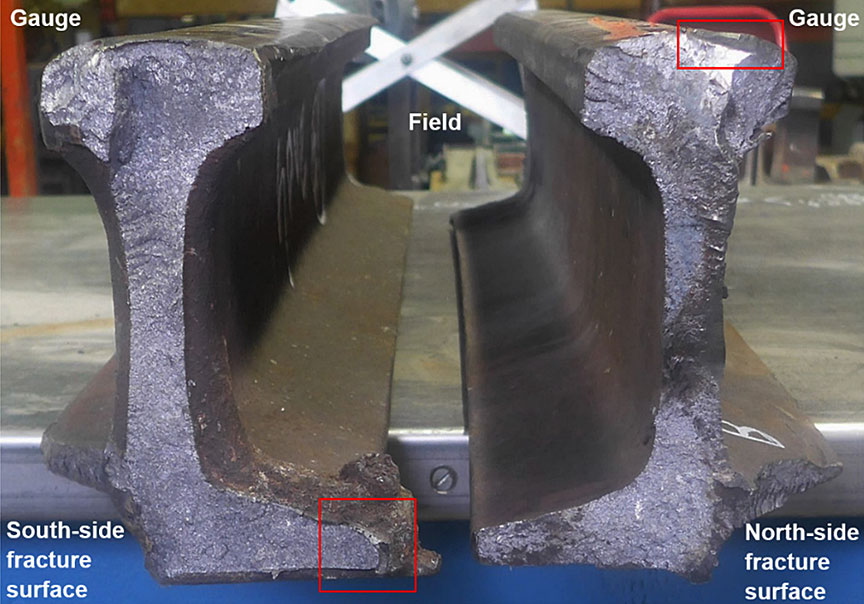

About 20 feet north of the bridge, a broken thermite weldFootnote 2 was observed in the west rail at Mile 53.57 (Figure 3 and Figure 4). The thermite weld had been installed on 30 October 2008.

Recorded information

Data from the locomotive event recorder was reviewed. For about 5 minutes prior to the train-initiated emergency brake application, the train speed was about 40 mph. Train speed was being controlled by throttle modulation.

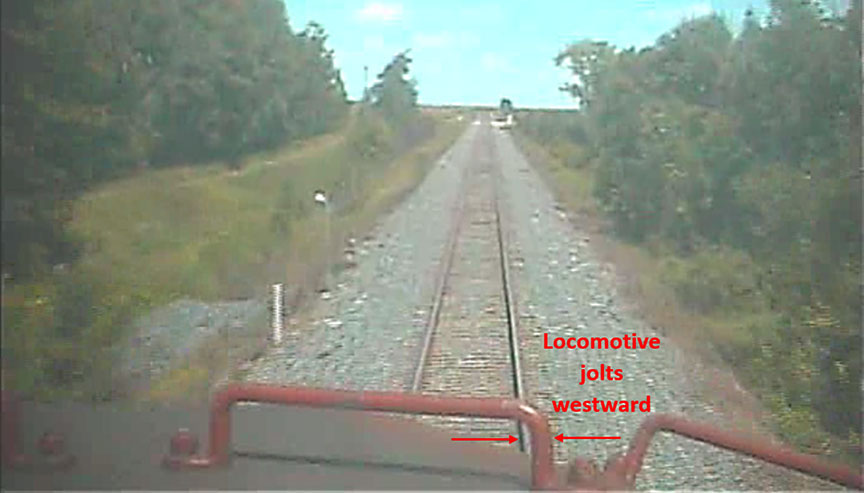

A review of the video recording from the forward-facing camera of the lead locomotive indicated that

- the thermite weld was located in the left (west) rail just beyond the guard railsFootnote 3 that extended off the north end of the bridge (Figure 5);

- a slight westward misalignment was present in the rail just north of the thermite weld (Figure 6); and

- the locomotive was jolted westward as it travelled over the misalignment location (Figure 7).

Subdivision and track information

The Emerson Subdivision is single main track that extends from the Winnipeg Terminal (Mile 4.0) to the border with the United States (Mile 64.1). Train movements on this subdivision are governed by the occupancy control system, as authorized by the Canadian Rail Operating Rules, and supervised by a rail traffic controller in Calgary, Alberta.

The track was classified as Class 3 track according to the Transport Canada–approved Rules Respecting Track Safety, also referred to as the Track Safety Rules (TSR). The maximum authorized timetable speed is 40 mph for freight trains. Rail traffic consisted of 2 freight trains a day (14 trains per week), with an annual tonnage of about 15.4 million gross tons.

In the vicinity of the derailment, the track was tangent and oriented in a north–south direction. The track structure consisted of 115-pound continuous welded rail made up of various vintages of rail manufactured by Algoma between 1966 and 1975. The rail was secured on 11-inch double-shouldered tie plates with 2 spikes per plate and with every tie box-anchored. The ties consisted of treated softwood that were in fair condition, with about 61 ties per 100 feet. Although defective ties had been marked for replacement, the TSR minimum requirement for non-defective ties was met (i.e., at least 12 non-defective ties per 39‑foot rail section). The subgrade consisted of mixed ballast, which was fouled. The shoulders extended 12 inches beyond the end of the ties.

Bridge information

The bridge was in good condition. It had 9 spans and was 277 feet long. There were four 15‑foot timber spans on timber piles at each end. The middle span in the bridge consisted of a 157-foot open-deck steel through-truss span on concrete piers.

Guard rails had been installed inboard and parallel to the regular rail running along the bridge deck and extended just beyond each end of the bridge. Transition areas at the end of bridges that contain guard rails can be problematicFootnote 4 during surfacing or other maintenance work.

Track inspections

The TSR outline the minimum track maintenance standards and track inspection requirements. In addition to the TSR, CP has its own Red Book of Track & Structures Requirements (Red Book), with these requirements meeting or exceeding those of the TSR.

For Class 3 track with 15 million gross tons of traffic annually, the TSR require that

- track must be visually inspectedFootnote 5 twice weekly, with no more than 3 days between inspections in a week;

- ultrasonic rail flaw inspection must be conducted on the rails a minimum of once per year; and

- track must be inspected twice annually by a track geometry car.

In the vicinity of the occurrence, CP had been conducting inspections in accordance with the TSR and the Red Book:

- The most recent visual track inspection was conducted by hi-rail on the morning of the derailment, with no defects noted.

- The most recent rail flaw ultrasonic test was performed on 14 July 2017, with no defects noted.

- The three most recent track geometry inspections had been conducted on 16 November 2016, on 29 March 2017, and on 10 July 2017.

During each of the track geometry inspections, geometry irregularities had been detected just off the north side of the bridge in the vicinity of the thermite weld (Mile 53.57):

- The 16 November 2016 geometry test identified a TSR non-compliance/CP urgentFootnote 6 defect for narrow gauge,Footnote 7 a CP priorityFootnote 8 S22 defect (1¼ inches), and a CP priority R31 defect (1½ inches) in the east rail.Footnote 9

- The 29 March 2017 geometry test identified a CP priority S22 defect (1⅛ inches) in both the east rail and the west rail.

- The 10 July 2017 geometry test (1 month prior to the occurrence) identified TSR non-compliance/CP urgent defects for narrow gauge, a CP priority R31 defect (1½ inches) in the east rail, and a CP priority R31 defect (1¾ inches) in the west rail.

CP had been monitoring the priority defects in accordance with its Red Book requirements.

When alignment deviations are present in the track, wheels on the rolling stock tend to kick outward, placing additional stress on the rail and ties. Alignment deviations are often accompanied by gauge and cross-level deviations or defects.Footnote 10

For Class 3 track, a CP priority R31 defect occurs when the runoff in the surface of the rail, measured over 31 feet of rail at the end of the raise, exceeds 1½ inches. The R31 surface defect can cause freight car suspension springs to unload rapidly, which can result in wheel unloading and subsequent higher-than-usual wheel impacts on the rail.

A CP priority S22 defect occurs in Class 3 track when the measured vertical displacement at the midpoint of a 22-foot chord exceeds 1 inch. CP S22 defects are associated with excessive rail or joint deflection. Since rail generally flexes on each side of a rail joint (or weld), a 22-foot chord is used to identify locations where a single wheel would respond to a sudden impact when it encounters a track surface anomaly (low spot). CP S22 defects are known to cause higher-than-usual wheel impacts that can result in rail or track failure. When these defects occur, they usually indicate deteriorating support that should be restored. Consequently, delays in restoring the support can result in even higher-than-usual loading due to wheel impacts.

Track maintenance

In the vicinity of the occurrence, to repair the urgent narrow gauge defects following each of the 3 track geometry tests, track maintenance personnel had to remove spikes, shift the rail and tie plates, plug the spike holes in the ties with wooden plugs, and then replace and regauge the rail. When this type of repair is repeated multiple times at the same location, spike hole enlargement, also known as spike kill,Footnote 11 can occur. Spike kill is known to reduce the lateral strength of the rail.

On 26 April 2017, a CP surfacing crew resurfaced the main line track from Mile 53.5 to Mile 53.6 and from Mile 53.7 to Mile 53.8 of the Emerson Subdivision.

On 20 July 2017, 2600 feet was resurfacedFootnote 12 between Mile 42.0 and Mile 63.0. However, the specific locations where the surfacing occurred were not identified.

Wheel impacts under normal operating conditions

Freight cars are typically equipped with 8 wheels (4 wheel-set assemblies, each of which contains 2 wheels). For a loaded freight car with a gross rail load capacity of 263 000 pounds, such as the covered hopper cars involved in this occurrence, each wheel carries 32 875 pounds.

If a wheel traverses a track surface anomaly, it imparts a higher-than-usual impact on the track running surface. These higher-than-usual wheel impacts can result in greater deflection, particularly in areas where track surface and alignment conditions are present.

Thermite welds

The joining of 2 rails without the use of a mechanical joint (joint bars and fasteners) is achieved by welding the rail ends together. There are currently 2 methods of welding rail ends: thermite and flash butt welding.

Thermite welding has three main components: the crucible, where a chemical reaction takes place; the charge that forms the filler metal; and the moulds that surround the rail ends. The process employs an exothermic reaction of a thermite composition to heat the metal, and requires no external source of heat or current. When the charge is melted, a self-tapping thimble at the bottom of the crucible allows molten steel to flow into the moulds, fusing the rail ends and forming a weld. The moulds are removed and the weld is shaped by hot chiselling and grinding to produce a smooth joint.

Some common defects associated with thermite welds are

- porosity,

- lack of fusion,

- internal shrinkage cavities, and

- finning.

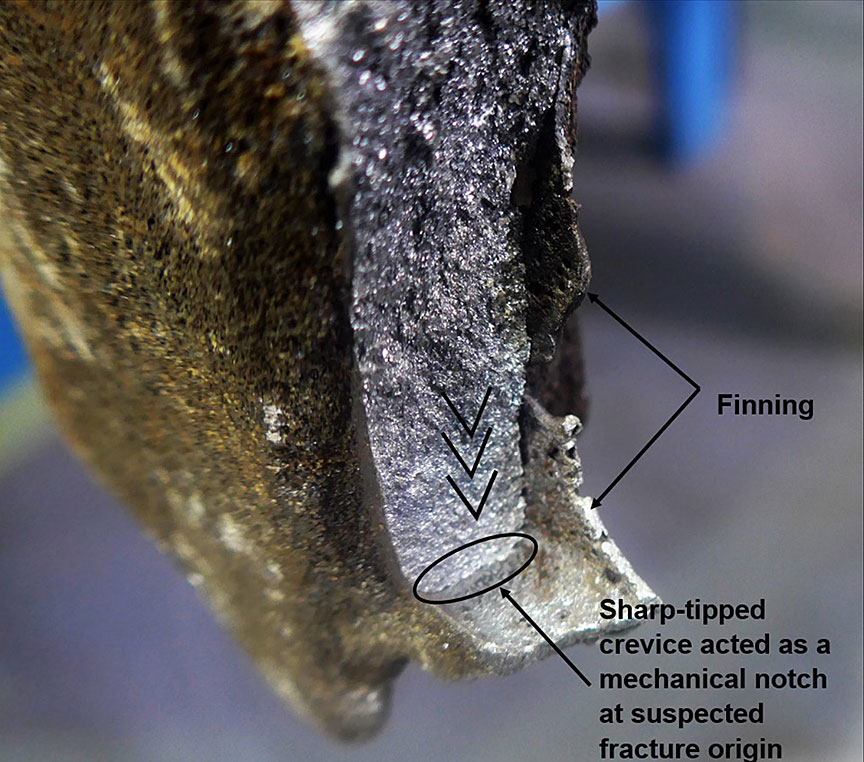

Finning is caused by the leakage of molten metal between the moulds and the rail surfaces. A refractory paste is generally used to seal the moulds to the contour of the rail. However, if the paste is applied improperly or there is an insufficient amount, a leak can occur. The leak is usually minimal. The molten metal may not fuse completely with the rail due to scale and rust on the rail surfaces. The lack of fusion creates a sharp-tipped crevice that can become a stress riser. Fins should be removed from the surfaces of the rails.

Laboratory examination of the rail and the broken thermite weld

At CP's Test Department in Winnipeg, TSB investigators and CP personnel jointly examined the rail and the broken thermite weld. The following was determined.

- The rail's chemical composition, hardness, and internal structure were typical for plain carbon steel rails manufactured in the 1960s and 1970s.

- There was no indication of any original material defects and/or manufacturing defects in the rail that could have caused or contributed to the failure.

- A macro-etched cross-section of the thermite weld found the weldment to be sound and homogenous, with no visual internal deficiencies.

The underside of the rail showed irregular tie spacing. The crib adjacent to the thermite weld had no tie contact for at least 19 inches (Figure 8).

The break at the thermite weld was vertical and generally flat, and corresponded to the north edge of the thermite weld reinforcement (Figure 9).

The running surface of the rail on the north-side fracture surface exhibited impact marks that were consistent with the train's direction of travel, indicating that the north side of the break had been exposed and was impacted by 1 or more wheel treads (Figure 10).

The fracture surfaces revealed a V-shaped chevron pattern, typical of a brittle failure. The chevrons pointed back to and identified a fracture origin on the field side of the fractured thermite weld at the outside surface of the rail base flange.

The fracture origin displayed an original thermite weld manufacturing process anomaly known as "finning." A sharp-tipped crevice had formed and acted as a mechanical notch at the suspected fracture origin (Figure 11). There was no indication of fatigue failure.

Other similar occurrences involving track surface anomalies

Since 2014, the TSB has conducted 5 other investigationsFootnote 13 involving track surface anomalies that had been identified as track geometry priority surface defects requiring monitoring. In each occurrence, the rail or its components eventually failed before being repaired or becoming an urgent defect.

Analysis

There were no mechanical or train-handling issues that contributed to the occurrence. The analysis will focus on the track geometry and track maintenance conditions that led to the thermite weld failure.

The occurrence

With the train travelling at about 40 mph, the lead locomotive exited the north end of the bridge over the Roseau River and encountered a rough spot in the track. Just beyond the guard rails that extended off the north end of the bridge, the location coincided with a thermite weld (Mile 53.57) and a slight westward misalignment in the left (west) rail.

About a minute later, a train-initiated emergency brake application occurred. Subsequent inspection revealed that 22 cars, the 58th to the 79th from the head end, had derailed just as the train exited the north end of the bridge. Site examination identified a broken thermite weld in the west rail, about 20 feet north of the bridge. The train derailed when the thermite weld located in the west rail at Mile 53.57 failed under the train.

Track geometry and maintenance

The thermite weld had been in service for about 9 years. The weld was generally sound and there was no indication of fatigue on any of the fracture surfaces. Other factors were present that contributed to the thermite weld failure.

Since at least November 2016, the area near the initial point of derailment contained a number of track geometry anomalies and/or conditions, including the following:

- Reccurring non-compliance with narrow gauge thresholds in the Track Safety Rules (TSR): The repairs of this recurring track defect likely "spike-killed" the ties, reducing the lateral strength of the rail.

- A westward track alignment deviation: An alignment deviation in the rail can cause wheels on rolling stock to kick outward, placing additional stress on the ties and the rail, particularly at the toe of the base of the rail on the field side (west).

- A Canadian Pacific Railway (CP) S22 priority surface defect in the west rail: S22 defects are known to cause high wheel impacts that can result in rail or track failure. When these defects occur, they usually indicate deteriorating support that should be restored. Delays in restoring the support can result in even higher-than-usual loading due to wheel impacts.

- A CP R31 priority surface defect value of 1¾ inches in the west rail: This surface defect can cause freight car suspension springs to unload rapidly, which can result in wheel unloading and subsequent wheel impact on the rail.

- Irregular tie spacing: The crib adjacent to the thermite weld in the west rail had no tie contact for at least 19 inches, resulting in greater vertical deflection of the rail at this location.

Due to the presence of multiple persistent, recurring geometry defects and track conditions, the rail in the vicinity of the failed thermite weld had been experiencing higher stresses during normal train operations. In particular, with the passing of each wheel on the train, the toe of the rail base on the field side of the west rail was placed in tension due to the track alignment deviation at this location.

Failed thermite weld

The thermite weld fracture surfaces exhibited features typical of brittle transverse fracture, indicating that the thermite weld had failed suddenly under the train. The fracture surfaces displayed a V-shaped chevron pattern, which pointed back to and identified the fracture origin at the toe of the rail base, on the field side of the west rail.

The fracture origin displayed an anomaly referred to as "finning", which occurred when the thermite weld was installed in October 2008. During the thermite weld process, finning occurred at the toe of the rail base when molten metal leaked from the mould and did not fuse with the rail, resulting in a sharp-tipped crevice (mechanical notch) that acted as a stress riser. With repeated tensile forces due to normal train operations, the finning at the toe of the rail base on the west rail's field side became the nucleation site for the propagation of the brittle transverse fracture, leading to the failure of the thermite weld.

Track surface conditions and priority surface defects

Since 2014, the TSB has conducted 5 other investigationsFootnote 14 involving track surface anomalies that were identified as conditions, such as a localized surface collapse, or track geometry priority surface defects that required monitoring. In each occurrence, the rail or its components eventually failed before being repaired or becoming an urgent defect that required immediate attention.

If track geometry priority defects are not identified, monitored, and mitigated in a timely manner, further track structure degradation can occur, increasing the risk of derailments.

In this occurrence, a number of track geometry tests over 2 years identified CP priority track surface defects (R31 and/or S22) in the east rail and the west rail near the derailment site. About a month prior to the occurrence, a track geometry inspection recorded an R31 priority defect value of 1¾ inches in the west rail at Mile 53.57.

CP monitored the priority defects in accordance with its Red Book requirements. However, the thermite weld failed before the priority defects reached a level that required immediate repair. Despite the monitoring of track geometry priority defects in accordance with company standards, the thermite weld failed under the passing train before priority defects were repaired.

Findings

Findings as to causes and contributing factors

- The train derailed when the thermite weld located in the west rail at Mile 53.57 failed under the train.

- In October 2008, during the thermite welding process, finning had occurred at the toe of the rail base when molten metal leaked from the mould and did not fuse with the rail, resulting in a sharp-tipped crevice (mechanical notch) that acted as a stress riser.

- Due to the presence of multiple persistent, recurring geometry defects and track conditions, the rail in the vicinity of the thermite weld had been experiencing higher stresses during normal train operations.

- With the passing of each wheel on the train, the toe of the rail base on the field side of west rail was placed in tension due to the track alignment deviation at this location.

- With repeated tensile forces due to normal train operations, the finning at the toe of the rail base became the nucleation site for the propagation of the brittle transverse fracture, leading to the failure of the thermite weld.

Findings as to risk

- If track geometry priority defects are not identified, monitored, and mitigated in a timely manner, further track structure degradation can occur, increasing the risk of derailments.

Other findings

- Despite the monitoring of track geometry priority defects in accordance with company standards, the thermite weld failed under the passing train before priority defects were repaired.

Safety action

Safety action taken

Canadian Pacific Railway

Following the accident, Canadian Pacific Railway installed 5022 feet of 136-pound continuous welded rail between Mile 52.9 and Mile 53.8, and 568 ties between Mile 53.0 and Mile 54.0.

This report concludes the Transportation Safety Board of Canada's investigation into this occurrence. The Board authorized the release of this report on 04 July 2018. It was officially released on 24 July 2018.