Main-track derailment

Canadian Pacific Railway

Freight train 669-161

Mile 90.21, Sutherland Subdivision

Blucher, Saskatchewan

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

The occurrence

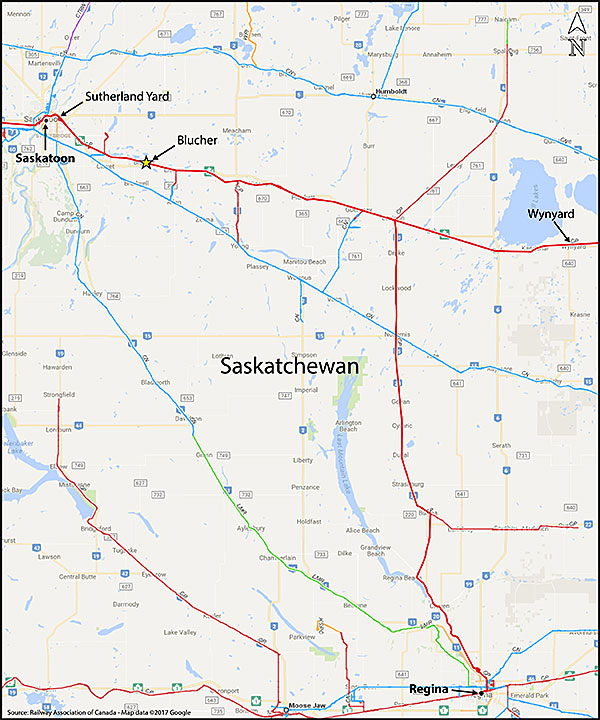

On 15 September 2017, a Canadian Pacific Railway (CP) train crew (the crew) was ordered at 0610Footnote 1 for Sutherland Yard in Saskatoon, Saskatchewan (Figure 1). The crew was scheduled to operate freight train 669‑161 (the train) eastward from Sutherland, Saskatchewan (Mile 109.70 of the Sutherland Subdivision), to Regina, Saskatchewan (Mile 0.0 of the Lanigan Subdivision).

The train consisted of 1 head-end locomotive, 130 covered hopper cars loaded with potash, and 1 remote-control locomotive at the tail end of the train. The train weighed about 18 550 tons and was 6250 feet long. The crew consisted of a locomotive engineer (LE) and a conductor who were qualified for their positions, met fitness and rest requirements, and were familiar with the territory.

At about 0630:00, a CP track foreman performed a visual inspection of track in the vicinity of the storage track at Blucher, Saskatchewan. The inspection was performed by hi-rail using a high-powered light bar as it was still dark at the time of the inspection. While inspecting the turnout at the west storage track switch at Blucher (Mile 90.20), the track supervisor reduced speed to between 5 and 10 mph to ensure a thorough inspection in the area of the switch. Shortly after the inspection, CP work train 9N14-14 traversed over this track and did not encounter any anomalies.

While en route, train 669-161 traversed the wayside hot bearing detector (HBD) at Mile 92.60, with no alarms. At 0755:23, the train was proceeding at 46.2 mph and was approximately 30 feet west of the west storage track switch at Blucher (Mile 90.20), when the crew felt the locomotive dip to the south side and heard a banging sound. The LE made a minimum brake application to slow the train. About 4 seconds later, a train-initiated emergency brake application occurred and the crew observed dust coming from under the train, behind the lead locomotive. The crew made an emergency call over the radio. After the train came to a stop, the conductor performed a walking inspection of the train and determined that 37 cars had derailed.

At the time of the derailment, the temperature was 6 °C.

Subdivision and track information

The CP Sutherland Subdivision is a single main track that extends from Wynyard, Saskatchewan (Mile 0.0), to Saskatoon (Mile 113.50). Train movements are controlled by the occupancy control system (OCS) as authorized by the Canadian Rail Operating Rules (CROR), and are supervised by a rail traffic controller located in Calgary, Alberta. OCS territory is non-signalled (i.e., dark territory). Train traffic consisted of about 10 trains per day with an annual average of 15 million gross ton-miles per mile. In the vicinity of the derailment, the track was rated as Class 4, according to the Transport Canada–approved Rules Respecting Track Safety, also known as the Track Safety Rules (TSR). The authorized speed for freight trains in the area was 45 mph.

The track was generally level and tangent. The track structure consisted of 115-pound continuous welded rail manufactured by Algoma in 1974. The rail was set into 14-inch double-shouldered tie plates, secured with 2 spikes per plate and box-anchored every other tie. The ties were a mix of moderate-condition softwood and good-condition hardwood, with 60 ties per 100 feet. The ballast consisted of a mix of crushed and round rock. The shoulders extended 12 inches beyond the end of the ties.

The storage track at Blucher is a non-main track that is 3500 feet long and runs adjacent to the main track. The storage track is used to store rail cars and as a set-off location for cars that trigger alarms for the HBD at Mile 92.60. Within 30 feet west of the west storage track switch points, there were 3 non-insulated rail joints in the main track (1 on the south rail and 2 on the north rail).

Site examination and equipment information

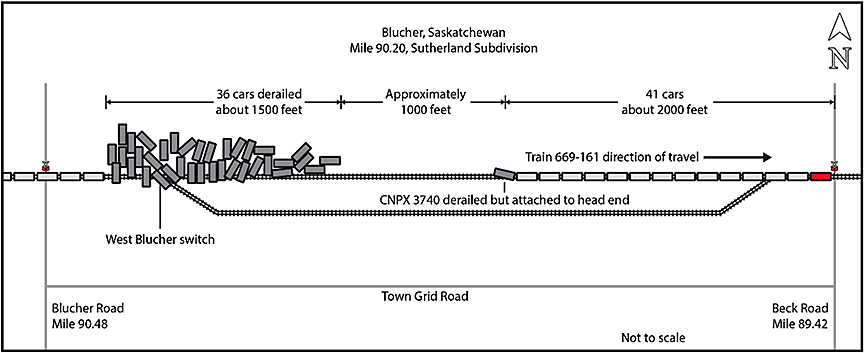

No wheel marks were present on the track infrastructure leading up to the derailed cars near the west storage track switch. The lead locomotive came to a stop near the Beck Road crossing (Mile 89.40). The first derailed car was the 41st car from the head end (CNPX 3740). The car remained attached to the head-end portion of the train and was missing its trailing truck. The truck had become dislodged during the derailment and was later located in the vicinity of the west storage track switch. The following 36 derailed cars (42nd to 77th cars from the head end) came to rest in various positions adjacent to the storage track, within a distance of about 1500 feet (Figure 2). Many of the derailed cars were breached and had released potash. About 2500 feet of track was damaged or destroyed.

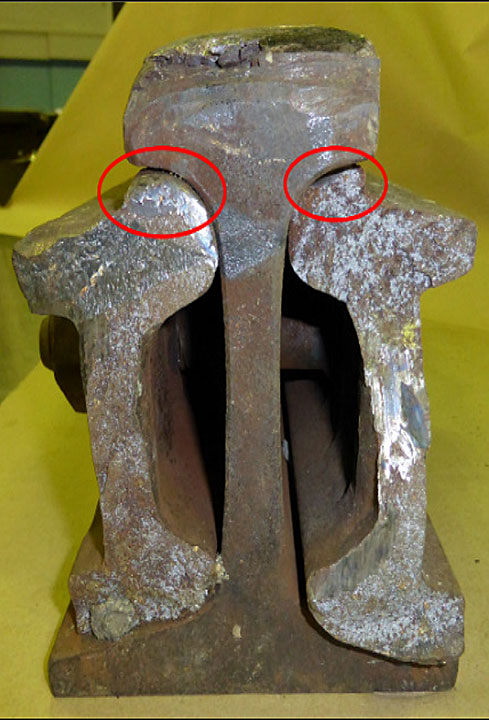

During site restoration, half of a rail joint was recovered; the other half could not be located. The recovered portion of the joint had rail-end batter on the east-end rail head and fatigue cracking in the joint bars (Figure 3). It was determined that the joint was likely located in the south rail, about 30 feet west of the west storage track switch, near Mile 90.21.

An inspection of the head-end portion of the train was performed. Impact marks were present on the south-side wheel treads of lead locomotive CEFX 1049 and several of the head-end cars. A rail impact mark was also present on the fuel tank of CEFX 1049, but the tank was not breached. The impact marks observed were consistent with that of equipment sustaining an impact with a rail end. Many of the covered hopper cars also had contact marks on their side body bearings from the wheel trucks, likely from heavy rocking of the cars as they traversed the rail at the point of derailment.

The damage observed on site suggests that the south rail joint near Mile 90.21 initially failed beneath the lead locomotive and the 41st to 77th cars from the head end subsequently derailed.

Examination of rail joint

Both joint bars from the recovered portion of the joint displayed fatigue fractures that extended from the upper fishing surface on the top of both joint bars (i.e., the mating surface between the top of the joint bars and the underside of the rail head). Fatigue cracking had propagated vertically downward for up to about 10% of the cross-sectional area of both joint bars (figure 4 and figure 5). Once the fatigue fractures reached a critical size, the remaining joint bar cross-sectional area could no longer support the load, sustained an overstress rupture, and failed under the train.

Track inspection and maintenance

The TSR outline the minimum maintenance standards and related track inspection requirements. In addition to the TSR, CP had its Red Book of Track and Structures Requirements (Red Book), the guidance in which meets or exceeds the TSR requirements. All required track inspections had been performed in accordance with the TSR and CP's Red Book.

Over the previous 12 months, 3 track geometry inspections had been conducted in the vicinity of the occurrence (in October 2016, April 2017, and May 2017). In all 3 inspections, a CP priority defectFootnote 2 S22-SR (S22) and some minor alignment conditions were recorded in the area of the joint and switch. A CP S22 priority defect occurs when the measured vertical displacement or midpoint of a 22-foot cord strung along the top of the rail in Class 4 track exceeds 0.625 inches. While the TSR contain standards for surface defects,Footnote 3 there is no S22 defect equivalent.

S22 defects are commonly associated with excessive joint deflection, which can result in higher-than-usual wheel impacts, leading to rail or joint failure. When these defects occur at rail joints, these defects are normally indicative of deteriorating joint support that should be restored. Delays in restoring joint support can result in cracks developing in the joint bars.

During track geometry inspections, high-definition machine vision photos of all rail joints are taken to help identify joint bar cracks and other defects. For the 3 joints in the vicinity of the west storage track switch, no defects were noted during the 3 inspections. However, due to the presence of the S22 defects, the location was being monitored during regular track inspections. Between October 2016 and May 2017, the S22 defect in the south joint deteriorated from 0.75 inches to 1 inch, which exceeded CP's S22 priority defect criteria. For a priority S22 defect, CP guidance requires the location to be monitored and then repaired as soon as practicable. CP has no near-urgent criteria or urgent criteria for an S22 defect.

Rail cracks within joints (i.e., bolt hole cracks) are hidden from view during a visual inspection. Rail flaw testing (ultrasonic or induction) is another means of identifying rail cracks within rail joints. At this location, the most recent ultrasonic test had been conducted on 24 August 2017, with no defects noted.

On 02 and 03 August 2017, the main track and storage track had been resurfaced using a ballast regulatorFootnote 4 and a track tamper.Footnote 5 During the surfacing operation, the regulator re-distributed the existing ballast and no additional ballast was added. On 13 September 2017, a CP locomotive equipped with a vehicle–track interaction deviceFootnote 6 inspected the track in the vicinity of the point of derailment; no defects were noted.

Other similar occurrences

Since 2014, the TSB has conducted 4 other similar investigationsFootnote 7 involving low spots in the track that were identified as either conditions, such as a localized surface collapse (LSC), or track geometry priority surface defects that required monitoring. In each occurrence, the track eventually failed before being repaired or becoming an urgent defect.

Safety messages

Although track low spots identified as either conditions (e.g., LSC) or track geometry priority surface defects are monitored in accordance with company standards, joint bars with undetected fatigue cracks may remain in service and subsequently fail under a passing train.

This concludes the TSB's limited-scope investigation into this occurrence. The Board authorized the release of this investigation brief on 08 January 2018. It was officially released on 11 January 2018.