Main-track train derailment

Canadian Pacific RailwayFreight train 142-14

Mile 36.6, Winchester Subdivision

Saint-Polycarpe, Quebec

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

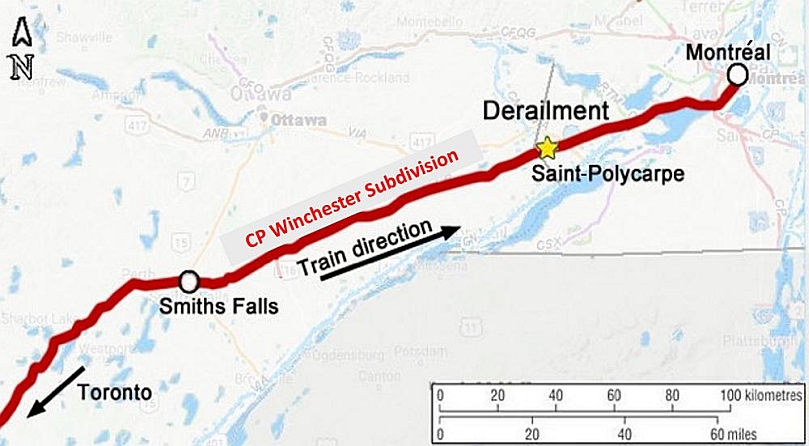

On 16 July 2018, at approximately 1845 Eastern Daylight Time, Canadian Pacific Railway (CP) freight train 142-14 experienced a train-initiated emergency brake application at Mile 36.6 on the south track of CP’s Winchester Subdivision, near Saint-Polycarpe, Quebec. An inspection determined that 22 cars had derailed. There were no injuries and there was no release of dangerous goods.

1.0 Factual Information

On 16 July 2018, at approximately 1110,Footnote 1 after receiving a mechanical pre-departure inspection,Footnote 2 Canadian Pacific Railway (CP) conventional freight train 142-14 departed eastward from CP’s Agincourt Yard in Toronto, Ontario, en route to Montréal, Quebec. The train consisted of 2 locomotives, 76 loaded cars, and 19 empty cars. It was 9405 feet long and weighed about 11 260 tons. The train received a pull-by inspection during a crew change at Smiths Falls, Ontario. No exceptions were reported. The train crew—a locomotive engineer and a conductor—were qualified for their respective positions and familiar with the territory, and they met fitness and rest standards.

1.1 The occurrence

At 1845, while proceeding eastward on the south track at Mile 35.82 of the CP Winchester Subdivision, the train experienced an unintended train-initiated emergency brake application near Saint-Polycarpe, Quebec (Figure 1). An inspection determined that 22 cars had derailed. There were no injuries and no release of dangerous goods.

1.2 Site examination

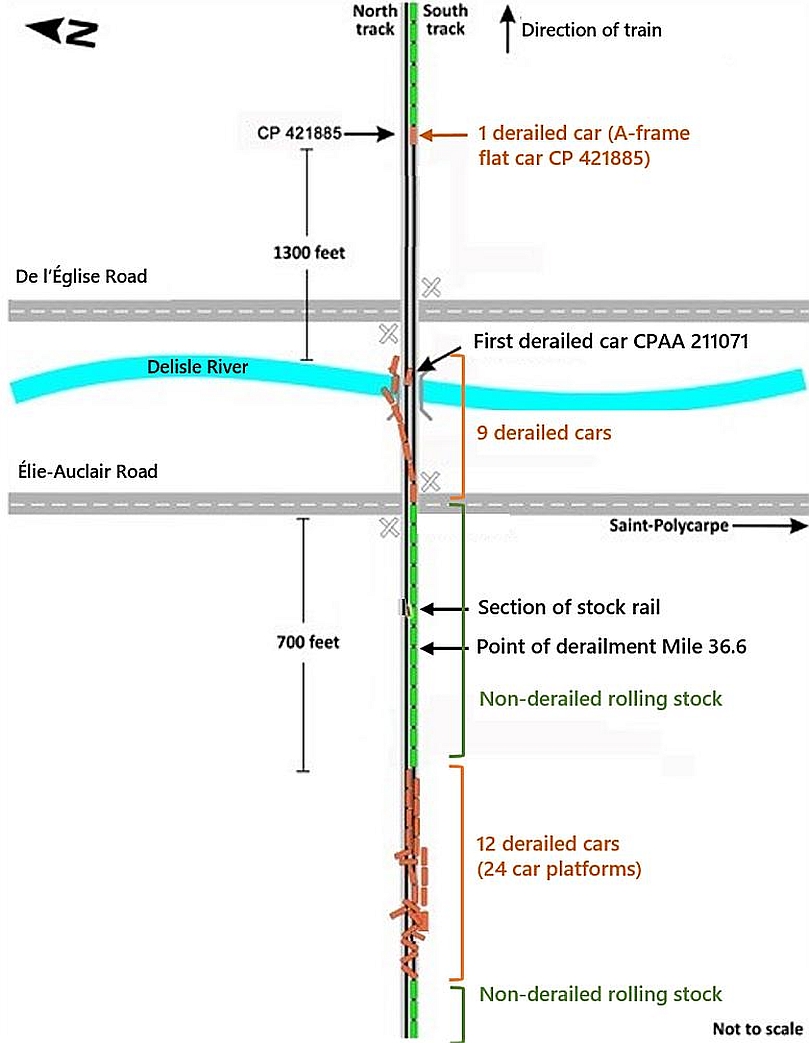

The 22 cars that had derailed came to rest at 3 separate locations (Figure 2). The 37th car, CP 421885, came to a stop about 1300 feet west of the 38th car and was still coupled to the head end of the train. Nine cars (38th to 46th) came to rest near the crossing (Figure 3). Twelve cars (60th to 71st), comprising 24 car platforms, came to rest about 700 feet west of the crossing (Figure 4).

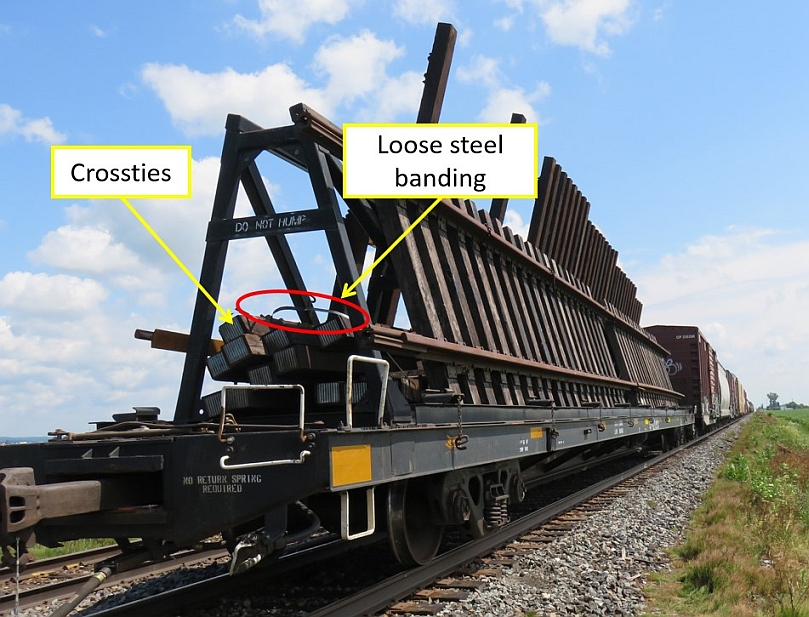

The first car that derailed, CP 421885, was a flat car equipped with a permanent A-frame structure (a type of car known as an A-frame flat carFootnote 3). It had been carrying pre-built track panels, stock rail, crossties, and associated supplies (Figure 5). The trailing truck (B-end) had derailed, and one of the 2 steel bands securing the crossties was broken. Some of the crossties had shifted laterally and fallen over. The stock rail was missing from the car. There were signs of abrasion and damage to the A-frame, lading, deck, and appurtenances of the car, as well as damage to the underside and trailing truck of the car. Track damage extended from just east of the Élie-Auclair Road crossing, where the track had been destroyed, eastward to where the trailing truck of CP 421885 stopped.

Approximately 1300 feet to the west of car CP 421885, the 38th car (loaded box car CPAA 211071) had come to rest on the east end of the ballast deck bridge over the Delisle River. The car had derailed upright, straddling the space between the north and south tracks, with both trucks lodged under the trailing end of the car.

A wooden crosstie fragment was jammed on the underside of the car, between the car’s centre beam and the lead bolster. Two new wooden crossties were found between the tracks, near the west end of the bridge. The end of one of the crossties had been damaged.

Eight tank cars (39th to 46th), of which 7 were loaded with dangerous goods,Footnote 4 had separated and come to rest on the north side of the track. Three of these cars slid off the bridge deck, destroying the north handrail and walkway of the bridge, and came to rest in the Delisle River. Of these 3 cars, two came to rest upside down on either bank of the river, and one was submerged in the river. None of the cars carrying dangerous goods had breached. A small quantity of vegetable oil, which was being carried in the 44th car, had leaked from a valve. There was no structural damage to the bridge deck.

Between the Delisle River and the Élie-Auclair Road crossing, approximately 250 feet of track was destroyed. Damage to the crossing surface was consistent with marks from derailed wheel sets. The next 13 cars (47th to 59th) had remained upright on the track.

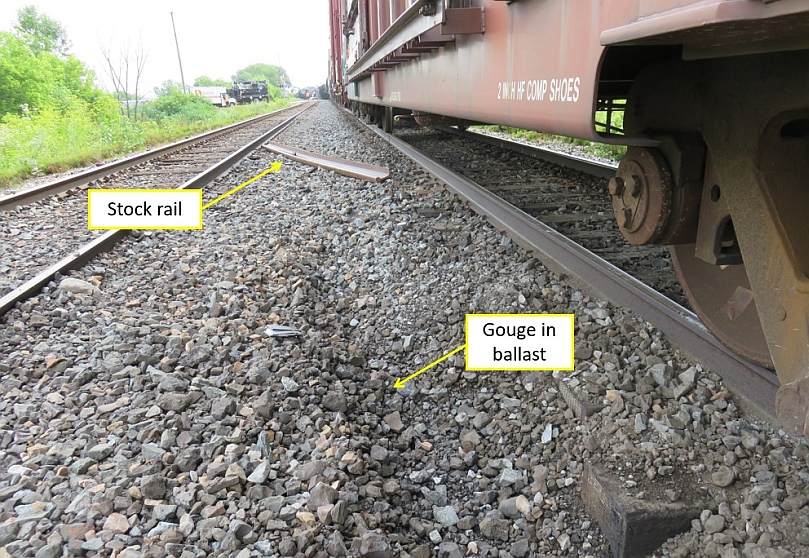

At Mile 36.6, approximately 400 feet west of the Élie-Auclair Road crossing on the south track, flange marks were present on the gauge side of the south rail and on the field side of the north rail. There were no marks on the head of the rail.

A 21-foot stock rail was lying between the north and south tracks (Figure 6), near a long gouge mark in the ballast. The gouge mark started approximately 60 feet east of the first flange marks.

Approximately 700 feet west of the crossing, another 12 derailed cars (60th to 71st) had come to rest. These cars, comprising 24 car platforms, consisted of 7 empty hopper cars, an articulated auto carrier car, and 4 multi-platform intermodal cars. The remaining 25 cars at the tail end of the train did not derail.

1.3 Subdivision and track information

The Winchester Subdivision is double main track, extending from Dorion, Quebec (Mile 18.9), to Smiths Falls, Ontario (Mile 123.8). Train movements on this subdivision are governed by the occupancy control system and automatic block signal (OCS/ABS) system rules , as authorized by the Canadian Rail Operating Rules, and are under the supervision of a rail traffic controller (RTC) located in Calgary, Alberta.

The track is classified as Class 4 track according to the Transport Canada–approved Rules Respecting Track Safety, also known as the Track Safety Rules (TSR). In the derailment area, the maximum authorized speed is 50 mph for freight trains. Rail traffic consisted of an average of 8 trains per day, with an annual tonnage of approximately 25 million gross tons.

1.4 Track inspection and maintenance

The TSR outline the minimum track maintenance standards and track inspection requirements. In addition to the TSR, CP has its own Red Book of Track & Structures Requirements (Red Book) outlining the company’s requirements, which meet or exceed TSR requirements.

CP’s most recent inspections in the vicinity of the occurrence were as follows:

- On 16 July 2018, the morning of the derailment, a visual track inspection was conducted by hi-rail. Loose joint bars were observed at Mile 30.5 and a loose bolt in a 4-hole joint bar was observed at Mile 36.8. These track conditions were repaired before the next train.

- On 05 July 2018, a track geometry inspection was performed. No urgent or near-urgent defects were identified.

- On 15 June 2018, a rail flaw ultrasonic test was conducted, and no defects were noted.

1.5 Recorded information

1.5.1 Locomotive event recorder

The data from the locomotive event recorder (LER) of lead locomotive CP 9735 was corrected for time and distance. According to the LER data, at 1845:45, the train experienced a train-initiated emergency brake application while travelling at 37.5 mph in throttle 1. The lead locomotive was at Mile 35.82 of the CP Winchester Subdivision. About 42 seconds after the emergency brake application, after having travelled another 1236 feet, the head end of the train came to a stop at Mile 35.59. There were no train handling anomalies.Footnote 5

1.5.2 Locomotive forward-facing video

Following this occurrence, the TSB requested video recordings from forward-facing cameras installed on locomotives from the occurrence train and the last westbound train that passed the occurrence train before the derailment.Footnote 6 CP indicated that no video was recorded by the occurrence train.Footnote 7 The video from the westbound train had been overwritten and was not available to the investigation.

In two other TSB investigations of CP occurrences since 2016, the video recording from at least one forward-facing camera was incomplete or unrecoverable.Footnote 8

1.6 Loading and securement of rail cars

1.6.1 General rules for the loading and securement of rail cars

In Canada, rail cars must be loaded in accordance with the requirements set forth in the Transport Canada–approved Railway Freight Car Inspection and Safety RulesFootnote 9 (Freight Car Safety Rules). According to these rules, the loading of open top rail cars must comply with the applicable rules of the Association of American Railroads (AAR) or the applicable circulars of the Railway Association of Canada (RAC).

Specifically, the requirements for the securement of commodities loaded on open top rail cars, trailers, and containers for safe and reliable transport by rail are contained in the AAR Open Top Loading Rules ManualFootnote 10 and the RAC Circular No. M-1, entitled Car Loading Rules.Footnote 11,

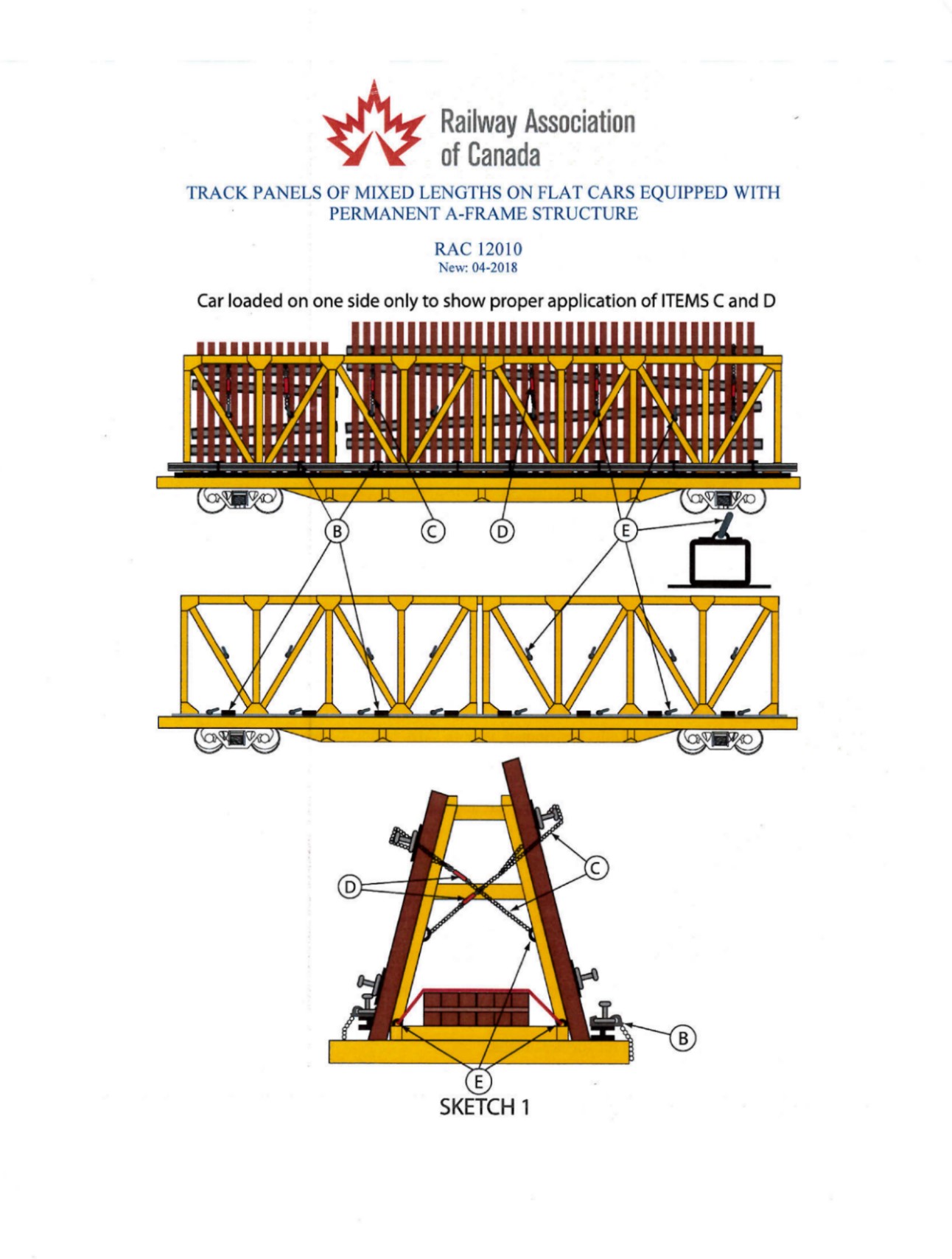

The AAR and RAC documents contain general rules that are applicable to all open top loading, as well as approved load design and securement patterns for specific commodities. These generally consist of figures and sketches that illustrate how different types of commodities and equipment must be loaded and secured as well as indicating specific hardware and restraints to be used.

Rail cars loaded according to these standards are accepted for unrestricted transportation and can be interchanged between railway companies across Canada, the U.S., and Mexico.

1.6.2 Rules for the loading and securement of A-frame flat cars

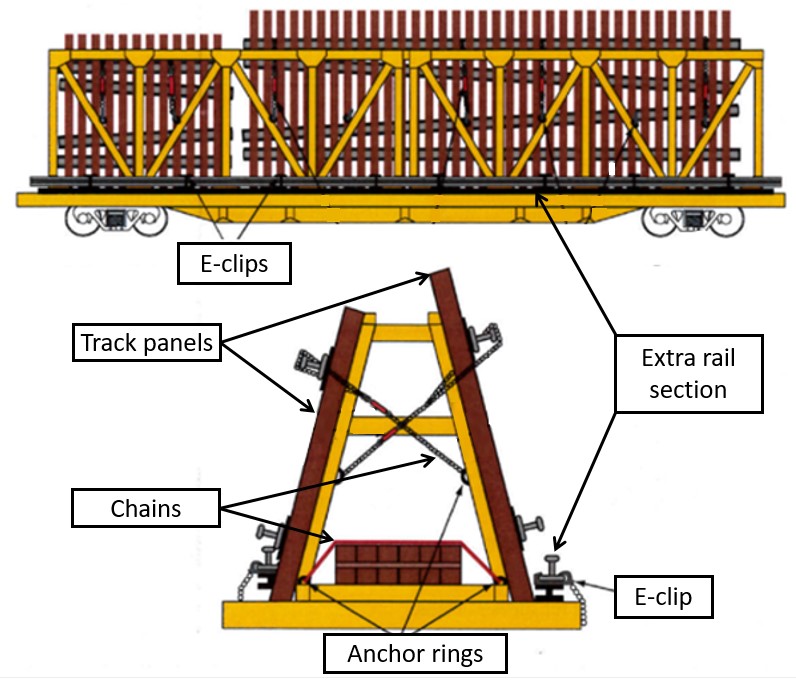

A-frame flat cars are special-purpose cars used by railway companies to transport maintenance-of-way materials, including pre-built track panels, stock rails, and crossties. Specific company loading and securement practices incorporate the general rules of the AAR and RAC.Footnote 12

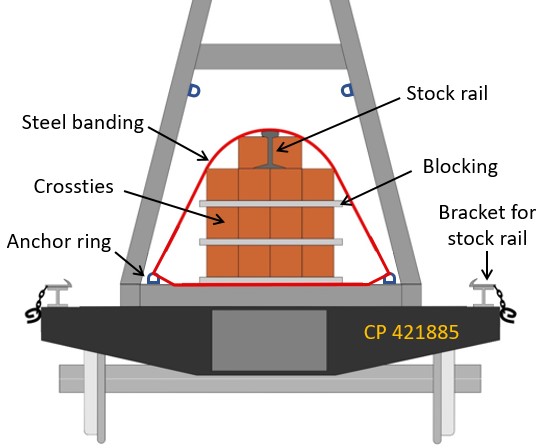

Starting in early 2018, CP began using pre-built track panels and related components from suppliers that are not located on the CP network. As a result, A-frame flat cars carrying these materials began to be interchanged among multiple railway networks. To aid in the safe interchange of these cars, CP developed a specific set of instructions and illustrations based on the company’s long-standing loading and securement practice for A-frame flat cars. CP then submitted this new set of instructions and illustrations to the RAC for consideration as a new circular. As a result, in April 2018, the RAC issued Circular RAC 12010 (Appendix A), which contained new instructions for securing pre-built track panels, rail sections, and related material onto A-frame flat cars (Figure 7).Footnote 13

The AAR was then requested to approve similar instructions. Subsequently, in June 2018, the AAR issued Circular letter C-13155, which amended the Open Top Loading Rules Manual by including new instructions for securing pre-built track panels, rail sections, and related material onto A-frame flat cars.Footnote 14

These new instructions included figures and sketches illustrating the approved securement patterns. The guidance notes for these instructions indicated the following:

- Chains must be used when securing track panels and additional material.

- Anchor rings must be used to secure additional material under the A-frame.

- When extra rail sections are carried in the mounting brackets, they must be secured using e-clips, with all e-clips applied.

1.6.3 Canadian Pacific Railway’s practice for the loading and securement of A-frame flat cars

1.6.3.1 Before May 2018

Before May 2018, all track panels and related materials transported on A-frame flat cars were loaded and secured at Weston Shops, in Winnipeg, Manitoba,Footnote 15 in accordance with an undocumented CP in-house practice. This method had been developed many years earlier, when the A-frame cars were first placed into service, based on AAR’s Open Top Loading Rules Manual. Personnel performing the loading and securement work received on-the-job (verbal) instructions during their job-specific training.

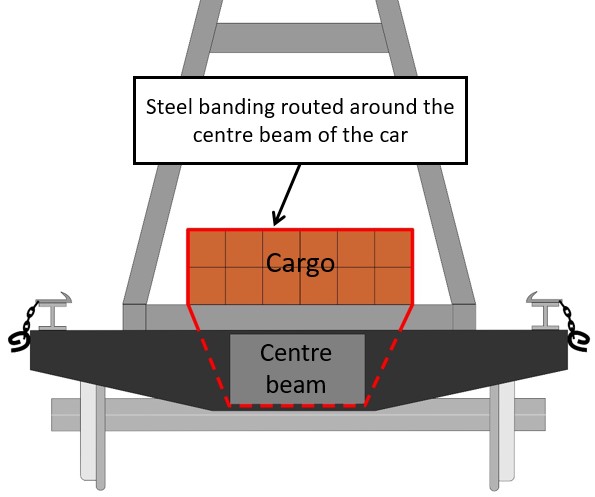

The following was CP’s in-house practice:

- Track panels were secured to the A-frame using chains or cables.

- Material loaded on the car deck beneath the A-frame was secured using steel banding routed through the car deck and around the centre beam.

- When stock rails were transported, they were normally placed on and secured to the brackets on the side of the car using e-clips (Figure 8).

- If stock rails were loaded with other materials on the car deck, they were secured where they were placed.

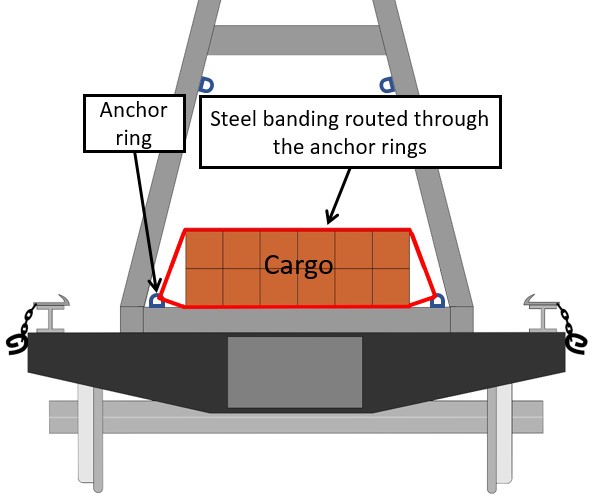

1.6.3.2 Following issuance of Circular RAC 12010 (May 2018)

In May 2018, following the issuance of Circular RAC 12010, CP personnel involved in the loading and securement of track panels and related material onto A-frame flat cars were verbally advised to use anchor rings when securing material beneath the A-frame. With the exception of the use of anchor rings, CP considered the securement method documented in Circular RAC 12010 to adequately reflect its existing long-standing practices. As a result, no specific analysis of the use of anchor rings was performed. No additional details, instructions, documentation, procedures, or training related to the new circular were provided to personnel. Consequently, personnel modified their securement practice related to cargo under the A-frame by routing the steel banding through the anchor rings instead of around the centre beam (Figure 9), and no chains were used.

1.6.4 Securement practice at Canadian Pacific Railway’s Weston Shops

According to CP’s securement practices at Weston Shops, A-frame cars were loaded at one location, then moved to a second location for securement by securement specialists.

The securement specialists were informed by email when a load was ready to be secured, at which point they secured it and reported when the work was completed.

Once a car was loaded and secured, it was inspected by a CP supervisor, whose role was to verify that the work had been done correctly.

1.6.5 Loading and securement of car CP 421885

On 05 July 2018, car CP 421885 was loaded at CP’s Weston Shops approximately 2400 kilometres (1500 miles) west of the derailment location. The track materials—consisting of pre-built switch panels, 14 crossties, and a 21-foot-long stock rail weighing approximately 950 pounds—were loaded as follows:

- The crossties were stacked and blocked but not bundled together.

- The stock rail was loaded on top of the stacked crossties, instead of being loaded on the mounting bracket on the side of the car. The investigation could not determine why the stock rail had not been loaded onto the mounting bracket on the side of the car, as per CP practice.

- The stacked and blocked crossties, with the stock rail on top, were placed on the car deck under the A-frame of the car.

- The pre-built switch panels were loaded onto the A-frame.

As per CP’s securement practice, updated in May 2018, the track materials were secured to the A-frame as follows:

- The track panels were secured to the A-frame using chains. The load under the A-frame, consisting of the stack of 14 crossties and the stock rail on top, was secured using 2 loops of steel banding routed through the anchor rings (Figure 10).

Once the car was loaded and secured, a CP supervisor inspected the car to verify that the work had been completed correctly, as was the practice at Weston Shops. Although the assigned supervisor had not been formally trained on the specifics of the Open Top Loading Rules Manual in effect at the time of the occurrence, he had 8 years of on-the-job experience with CP’s securement practices, on which the RAC Circular was based.

Once inspected, the car was then marshalled onto CP train 420-13, which was destined for Toronto. On 16 July 2018, in Toronto, the car was marshalled onto CP train 142-14, destined for Montréal.

1.7 Procedures and training related to the loading and securement of A-frame flat cars

1.7.1 Procedures and training

A procedure is a step-by-step set of instructions for performing a particular task. Procedures should take into account the knowledge level of the workers who are expected to perform the task.

The level of detail, clarity, format, and arrangement of the steps should enable the worker to consistently achieve the desired result without deviating from the procedure. Well-written procedures reduce the risk of human errors and promote standardized results.

Operating procedures that are used both as a training aid and as a hard-copy job aid require detailed task descriptions that a task analysis can provide. Task analysis should be the basis of most system design work. Equipment design, procedure development, and training should be integrated, as a matter of policy.

1.7.2 Loading and securement of A-frame flat cars

When Circular RAC 12010 came into effect in April 2018, CP’s implementation of the circular was limited to providing verbal instructions to personnel to use anchor rings when securing cargo under the A-frame. Weston Shops personnel had been consulted in the drafting of the circular and believed that it documented existing loading and securement practices, with the exception of the requirement to use anchor rings.

No task analysis was carried out, and no specific written procedure was developed for the loading and securement of A-frame flat cars. Furthermore, no specific training on the new instructions was provided to personnel involved in the loading and securement of A-frame flat cars.

1.8 Inspections of car CP 421885

En route from Winnipeg, car CP 421885 had received at least 9 trackside/pull-by visual inspections. These inspections, performed in accordance with Canadian Rail Operating Rules Rule 110,Footnote 16 were focused on identifying and reporting dangerous conditions to the train crew to ensure that such conditions, including shifted loads, are addressed before the train proceeds further. Following each of the trackside/pull-by inspections, no exceptions were reported for car CP 421885. Footnote 17

On 15 July 2018, train 420-13 was inspected by a certified car inspector when it arrived in Toronto. During this inspection, a high flange condition was identified on another A-frame car, CP 421892, which was coupled to the leading end of car CP 421885. Car CP 421892 was bad-ordered and subsequently removed from train 420-13. No exceptions were reported for car CP 421885 (Figure 11).

1.8.1 Observations from yard cameras

The TSB reviewed video recordings from various yard cameras documenting the journey of car CP 421885 from the time it was loaded at CP’s Weston Shops in Winnipeg on 12 July 2018 (Table 1).

| Location | Date and time* | Observations |

|---|---|---|

| Winnipeg Terminal, Manitoba | 12 July 2018, 1314 |

|

| White River, Ontario** (Train 420-13) | 14 July 2018, 0545 |

|

| Cartier, Ontario (Train 420-13) | 14 July 2018, 1655 |

|

| Sudbury, Ontario (Train 420-13) | 14 July 2018, 1750 |

|

| MacTier, Ontario (Train 420-13) | 14 July 2018, 2345 |

|

| Toronto, Ontario (Arrival – Train 420-13) | 15 July 2018, 0714 |

|

| Toronto, Ontario (Departure – Train 142-14) | 16 July 2018, 0906 |

|

* All times are converted to Eastern Daylight Time.

** White River is located approximately 670 miles east of Winnipeg.

1.9 Other shifted load events

About 2 months earlier, in May 2018, a shifted load had been identified on an A-frame flat car (CP 421895) during an inbound certified car inspection at CP’s Alyth Yard in Calgary, Alberta. The car was carrying a stock rail, pre-built switch panels, crossties, and associated components. The stack of crossties, which had been secured with nylon strapping, had shifted over the end of the platform. The stock rail, which had been secured to the mounting brackets on the side of the car, had not shifted. In that situation, the yard staff re-secured the load, and the car was allowed to continue to its destination.

Following that event, supervisors verbally instructed the CP inspectors at Alyth Yard to keep an eye out for similar cars for possible shifted loads. However, no system-wide bulletin or formal alert was issued, and no further follow-up was conducted.

For the 5-year period between 2014 and 2018, 13 occurrences (including this accident) during train operations and/or switching that were reported to the TSB involved load-related conditionsFootnote 18 for non-bulk materials (Appendix B). This accident was the only occurrence reported to the TSB during this period that involved an A-frame flat car.

1.10 Site management during response activities

1.10.1 Site security during response activities

When dealing with dangerous goods in an emergency response situation, industry best practice is to establish a formalized incident command structure to manage the response.

CP employs an incident command system to mobilize and use resources effectively if there is a derailment. For a major event, involving various authorities, a unified command is established to allow organizations with different functional mandates to work together effectively.Footnote 19

Under CP’s incident command system / unified command structure, the on-scene response coordinator assigns a site safety officer whose duties include

- creating a site safety plan with associated access routes, hot zones, and hazards; and

- controlling a hot zone access point and accounting for all personnel in and out.

In addition, CP Police Service officers are assigned to provide effective site security. This includes

- controlling and dispersing crowds in the emergency site,

- sealing off the emergency area,

- establishing road blocks and controlling traffic,

- consulting with the on-scene response coordinator on security needs, and

- ensuring adequate records are maintained.

1.10.2 Establishing and maintaining exclusion zones for workers following the derailment

In this occurrence, CP set up an incident command trailer as a dedicated command post on the road south of the derailment, north of the town of Saint-Polycarpe. A CP Police Service officer set up barriers at the north and south road approaches to the derailment site and monitored the south approach. A sign-in sheet was established to keep track of staff or other officials on site.

The derailment occurred in a rural area near a number of communities. After an assessment of damage and potential risks was completed, nearby owners of private farms were allowed road and field access to mitigate the impacts of the occurrence on the local community. A CP Police Service officer was assigned to site security.

In a number of instances, members of the public were observed travelling unaccompanied in the accident site in active work zones; some instances occurred during trans-shipping activities involving dangerous goods. One such public incursion was brought to the attention of the CP Police Service officer, who approached the person and guided them out of the occurrence site. CP had also retained an additional third-party security person to help restrict unauthorized access to the occurrence site. However, subsequently, additional instances of unauthorized site access were observed.

1.10.3 Previous TSB investigation that examined the effectiveness of site access protocols

The TSB previously investigated a main-track CP freight train derailment where the railway’s site access protocols were found to be a safety risk.

On 03 April 2013, at about 0750, CP freight train 420‑02 was proceeding eastward at 34.9 mph on the Heron Bay Subdivision when it experienced an undesired emergency brake application at Mile 9.16 near White River, Ontario.Footnote 20 The subsequent inspection determined that 22 cars (19 loads and 3 empties) had derailed, 7 of which were dangerous goods tank cars loaded with petroleum crude oil (UN 1267). During the derailment, a number of cars rolled down an embankment. Two of the dangerous goods tank cars released approximately 101 700 litres of product, and another non-dangerous goods tank car released approximately 18 000 litres of product. There were no injuries.

When the TSB arrived on site, there was no sign-in sheet to keep track of staff on site, and no safety briefing had been conducted to review the potential dangers of released product. The derailment was in a remote location, but access to the site was virtually unrestricted, with no visible safety perimeter. As a result of that investigation, the TSB made the following finding:

If information outlining the amount and type of dangerous goods product released is not communicated to emergency responders, and site control measures are not implemented to minimize exposure and hazards, there is an increased risk that personnel on site will be subjected to circumstances that can lead to injury.

Since 2013, CP has modified its procedures to include sign-in sheets, safety briefings, and visible safety perimeters.

1.11 TSB laboratory reports

The TSB completed the following laboratory report in support of this investigation:

- LP172/2018 – Train Dynamics Simulation.

2.0 Analysis

Neither the actions of the train crew nor the condition of the track contributed to the accident. The analysis will focus on the loading and securement of A-frame flat cars, the inspections conducted for car CP 421885, site management during response activities, and the availability of recordings from forward-facing cameras.

2.1 The accident

While proceeding eastward on the Winchester Subdivision, Canadian Pacific Railway (CP) freight train 142-14 derailed at Mile 36.6 when the leading end of loaded box car CPAA 211071 struck a stock rail 21 feet long that had fallen from the end of the preceding car, A-frame flat car CP 421885. Flange marks on the south rail were traced to wheels from the lead truck of car CPAA 211071, indicating that it was the first car to derail.

The lead truck of the car derailed approximately 400 feet west of the Élie-Auclair Road crossing (the point of derailment), but the car proceeded until it reached the Élie-Auclair Road crossing, where it struck the crossing surface, fully derailed, and separated from the train, leading to the derailment of the 8 trailing cars. The derailed cars destroyed the track structure east of the crossing as they slid off the bridge to the river below.

The emergency braking event was transmitted back through the train line. Because of the rapid buildup of longitudinal buff forces in the train on the tangent track during the derailment sequence, a second group of 12 cars derailed approximately 700 feet west of the crossing.

2.2 Loading and securement of car CP 421885

Before 2018, A-frame flat cars were loaded and secured at Weston Shops, in Winnipeg, Manitoba, in accordance with a long-standing, but undocumented, CP in-house practice. As part of this practice, material loaded beneath the A-frame was secured using steel banding that was routed through the car deck and around the centre beam.

In April 2018, when the Railway Association of Canada (RAC) issued Circular RAC 12010, new instructions were provided for the loading and securement of A-frame flat cars. These instructions included the requirement to use chains and anchor rings to secure track panels and cargo under the A-frame. In addition, sections of stock rail were required to be mounted to brackets on the side of the car using e-clips.

Following the publication of Circular RAC 12010, no task analysis was conducted and no written procedure developed for the loading and securement of A-frame flat cars. With the exception of the new provision to use anchor rings when securing material under the A-frame, CP believed that the circular reflected its current and long-standing loading and securement practices. As a result, the implementation of the circular at CP consisted only of verbal guidance to use the anchor rings when securing material under the A-frame. No additional specific training was provided to personnel involved in the loading and securement of A‑frame flat cars.

Starting in May 2018, CP personnel were using the modified loading and securement practice, which involved routing the steel banding used to secure cargo under the A-frame through the anchor rings of the car.

Thus, car CP 421885 had been loaded and secured using the undocumented modified practice in effect at CP following the publication of Circular RAC 12010. However, no written procedures or specific training had been developed for the loading and securement of track materials on A-frame flat cars following the implementation of Circular RAC 12010.

If written procedures for the safe loading and securement of rail cars are not developed and implemented, particularly for special-purpose cars, cargo may not be properly loaded and/or secured, increasing the risk of unsecured material falling off the rail car during train operations.

The practice illustrated in Circular RAC 12010 was to mount and secure rail sections to mounting brackets on the side of the A-frame flat car. In this occurrence, the stock rail was not secured to the mounting brackets on the side of the A-frame car. Furthermore, the load of crossties and stock rail had not been bundled together, and no chains were used. As a result, the stock rail had been loaded with unbundled crossties on the deck under the A-frame and secured using 2 loops of steel banding that was routed through the anchor rings.

This securement technique did not provide a sufficient lateral restraint. Over the 2400 kilometres (1500 miles) travelled by the car under normal train operation, the load of crossties with the heavier stock rail on top gradually shifted laterally and fell over, allowing the 2 loops of steel banding to come loose.

The rough surface of the ties limited longitudinal movement while they were stacked on the A-frame flat car. However, because it was not adequately secured, the smooth stock rail was able to slide back and forth longitudinally on top of the ties. The loosened stock rail, rubbing back and forth against the banding, progressively weakened it. Eventually, 1 of the 2 loops of steel banding broke and, as the train approached Élie-Auclair Road, the stock rail slid toward the trailing end of the car, tilted up, and fell off the end of car CP 421885 under the following car, CPAA 211070.

2.3 Inspections of car CP 421885

Between Winnipeg and the derailment location, car CP 421885 had received at least 9 trackside/pull-by visual inspections, which were intended to identify dangerous conditions (including shifted loads), and no exceptions had been reported.

When train 420-13 arrived in Toronto on 15 July 2018, it was also inspected by a certified car inspector. The car adjacent to CP 421885 was bad-ordered for a mechanical defect and removed from the train. However, no exceptions were reported for car CP 421885. The car also received a mechanical pre-departure inspection on 16 July 2018, and no exceptions were noted.

While the visual appearance of loaded A-frame cars can make it difficult to reliably identify a shifted load, according to yard video camera images, the load on car CP 421885 was in a shifted condition when the car was at White River, after having travelled approximately 1080 kilometres (670 miles) on train 420-13. There were other visual cues of a shifted load on video camera images upon the car’s arrival in Toronto on 15 July 2018, as well as upon its subsequent departure on train 142-14 on 16 July 2018.

Despite multiple visual inspections of car CP 421885 between its departure from Winnipeg and the derailment location, including several inspections after the load had shifted, the shifted load was not identified. As a result, the car continued in service until the derailment of train 142-14 in Saint-Polycarpe, Quebec.

2.4 Inspections at Weston Shops

At CP’s Weston Shops, A-frame cars are inspected for proper securement after loading. This inspection task had been assigned to a supervisor. In this occurrence, although the assigned supervisor had not been formally trained on the specifics of the Open Top Loading Rules Manual in effect, he had 8 years of on-the-job experience with CP’s securement practices, on which the RAC Circular was based.

The top load securement on car CP 421885 was not inspected to RAC standards before the car was released for shipment to its destination.

If railway personnel who are tasked with verifying top loading securement are not formally trained to assess top loading, cargo that is not appropriately secured may not be identified, increasing the risk of unsecured materials falling off the car.

2.5 Site management during response activities

Like other major railway companies, CP has an incident command / unified command system for emergency response situations, including occurrences when dangerous goods are released. The incident command / unified command system supports safe and timely action to bring the rail system back into service while ensuring the safety of the public and the environment. CP’s incident command / unified command system includes designating and enforcing exclusion zones for workers as well as maintaining adequate records.

This derailment occurred close to the town of Saint-Polycarpe. Shortly after the derailment, barriers were set up on the main access road to the occurrence site. Only one CP Police Service officer was observed providing site security. During the initial assessment, a formal process (i.e., sign-in sheet) was established to document the movement of workers and the public into and out of the exclusion zone. However, site control procedures were not sustained.

To mitigate the impacts of the occurrence on the local community, CP allowed road and field access to the owners of nearby private farms. However, on multiple occasions, members of the public were observed within the site exclusion zone. Their presence was brought to the attention of CP personnel, and site security was reinforced with an additional third-party security person, but incursions continued. Some of the unsupervised access occurred during trans-shipping activities involving dangerous goods. Access control and sign-in deficiencies were also noted in the response to the CP derailment in White River, Ontario, in 2013.

If an occurrence exclusion zone is not reliably secured for the duration of an occurrence, particularly when dangerous goods are involved, unauthorized persons and/or persons without the appropriate personal protection equipment can enter the zone, increasing the risk of injury or death.

2.6 Availability of recordings from forward-facing cameras

While not currently required by regulation, a video recording from a forward-facing camera is often helpful in understanding the circumstances leading to an accident.

In this occurrence, although forward-facing cameras had been installed on the occurrence train and on the last passing train, the railway indicated that the video recordings from these cameras were not available.

3.0 Findings

3.1 Findings as to causes and contributing factors

These are conditions, acts or safety deficiencies that were found to have caused or contributed to this occurrence.

- The derailment occurred when the leading end of loaded box car CPAA 211071 struck a stock rail 21 feet long that had fallen from the end of the preceding car, A-frame flat car CP 421885.

- With only the lead truck derailed, car CPAA 211071 proceeded until it reached the Élie-Auclair Road crossing, where it struck the crossing surface, fully derailed, and separated from the car ahead, leading to the derailment of the 8 trailing cars.

- Because of the rapid buildup of longitudinal buff forces in the train on the tangent track during the derailment sequence, a second group of 12 cars derailed approximately 700 feet west of the crossing.

- No written procedures or specific training had been developed for the loading and securement of track materials on A-frame flat cars following the implementation of the Railway Association of Canada Circular RAC 12010.

- The stock rail had been loaded with unbundled crossties on the deck under the A-frame and secured using 2 loops of steel banding that was routed through the anchor rings.

- The securement technique did not provide a sufficient lateral restraint.

- Under normal train operation, the load of crossties with the heavier stock rail on top gradually shifted laterally and fell over, allowing the 2 loops of steel banding to come loose.

- One of the 2 loops of steel banding broke and, as the train approached Élie-Auclair Road, the stock rail slid toward the trailing end of the car, tilted up, and fell off the end of car CP 421885.

- Despite multiple visual inspections of car CP 421885 between its departure from Winnipeg, Manitoba, and the derailment location, including several inspections after the load had shifted, the shifted load was not identified.

- The top load securement on car CP 421885 was not inspected to Railway Association of Canada standards before the car was released for shipment to its destination.

3.2 Findings as to risk

These are conditions, unsafe acts or safety deficiencies that were found not to be a factor in this occurrence but could have adverse consequences in future occurrences.

- If written procedures for the safe loading and securement of rail cars are not developed and implemented, particularly for special-purpose cars, cargo may not be properly loaded and/or secured, increasing the risk of unsecured material falling off a rail car during train operations.

- If railway personnel who are tasked with verifying top loading securement are not formally trained to assess top loading, cargo that is not appropriately secured may not be identified, increasing the risk of unsecured materials falling off a car.

- If an occurrence exclusion zone is not reliably secured for the duration of an occurrence, particularly when dangerous goods are involved, unauthorized persons and/or persons without the appropriate personal protection equipment can enter the zone, increasing the risk of injury or death.

3.3 Other findings

These items could enhance safety, resolve an issue of controversy, or provide a data point for future safety studies.

- Although forward-facing cameras had been installed on the occurrence train and on the last passing train, the railway indicated that the video recordings from these cameras were not available.

4.0 Safety action

4.1 Safety action taken

4.1.1 Transportation Safety Board of Canada

On 09 October 2018, the TSB issued Rail Safety Advisory 07/18, entitled “Securement of loads on flat cars equipped with an A-frame structure.” It indicated that “Transport Canada may wish to review the adequacy of CP’s open top loading practices, particularly when transporting track materials on flat cars equipped with an A-frame structure.”Footnote 21

On 15 January 2019, Transport Canada responded to the rail safety advisory, indicating the following:

CP informed Transport Canada (TC) that the Railway’s current loading practices are based on the newly developed standards by the Railway Association of Canada (RAC) and the Association of American Railroads on open top loading for track panels of mixed lengths on flat cars equipped with a permanent A-frame structure. TC inspectors conducted a follow-up and verified that CP employees were trained on the proper loading inspection procedures. As such, TC believes that CP has adequately addressed the issue.

4.1.2 Canadian Pacific Railway

Following the occurrence, Canadian Pacific Railway (CP) took the following actions:

- It completed a review of internal top loading practices in August 2018 and documented procedures for securing loads on flat cars equipped with an A-frame structure.

- It issued a written procedure on 03 August 2018, entitled Track Panels Loading on Flat Cars. The procedure requires supervisors to inspect loads that have been secured on flat cars equipped with an A-frame structure. The inspection includes a requirement to confirm and verify securement using a checklist before a car is released into service.

- It conducted training on the new procedure.

- It developed, validated, and implemented training for employees on securing loads on flat cars equipped with an A-frame structure in accordance with the published Railway Association of Canada (RAC) circular.

In addition, CP inspected and modified its A-frame cars to include a steel material containment box for securement of palletized or loose items and close-out panels on the A-end and B-end of the cars.

This report concludes the Transportation Safety Board of Canada’s investigation into this occurrence. The Board authorized the release of this report on 13 November 2019. It was officially released on 09 December 2019.

Appendices

Appendix A – Railway Association of Canada, Circular RAC 12010: Track Panels of Mixed Lengths on Flat Cars Equipped with Permanent A-Frame Structure

Appendix B – TSB-reported occurrences involving load-related conditions for non-bulk materials during train operations and/or switching (2014 to 2018)

| Occurrence number | Occurrence type | Cause code in TSB Rail Occurrence Data System | Date | Location | Railway | Occurrence summary |

|---|---|---|---|---|---|---|

| R18H0093 | Non-main-track train derailment | M206 – Improper trailer tiedown | 2018-09-10 | Vaughan, ON | CP | During an inspection, empty intermodal car CP 524363 was found with one set of trucks derailed on work track 8 at the Vaughan intermodal yard. There were no injuries. |

| R18D0069 | Main-track train derailment | M202 – Load fell from car | 2018-07-16 | Saint-Polycarpe, QC | CP | A CP train, proceeding east on the Winchester Subdivision, derailed 22 cars (33 car bodies) at Mile 36.6 (Soulanges). Several dangerous goods were involved, with one car with dangerous goods falling into a river. No dangerous goods leaked. No injuries were reported. Emergency Services and Rail Officials responded. TSB investigators deployed. |

| R18T0004 | Main-track train collision | M206 – Improper trailer tiedown | 2018-01-06 | Aldershot, ON | CN | A GO Transit–Metrolinx commuter train, proceeding east on track 3 of the CN Oakville Subdivision, was struck by lading protruding from a westward CN train proceeding on track 2 at Mile 33. A GO locomotive (GO 608) sustained damage to a side mirror. There were no injuries. |

| R17W0116 | Non-main-track train derailment | M204 – Improperly loaded car | 2017-05-24 | Winnipeg, MB | CP | While shoving into customer facility (A-75) track 6, a CP train assignment derailed A-end truck on car CP 330998 (load of scrap metal). There were no injuries. |

| R17C0059 | Main-track train derailment | M208 – Improperly loaded trailer/container on flat car | 2017-02-22 | Three Hills, AB | CN | A CN train assignment operating south at 26.5 mph with 149 loads, 9016 tons, and 9361 feet long, stopped in emergency at Mile 65.1 of the Three Hills Subdivision (north of Perks siding). One car (line 35), CP 523117, derailed 2 axles. CN determined that the point of derailment was Mile 61.2 of the Three Hills Subdivision (south of Three Hills). There were no injuries, and no dangerous goods were involved. |

| R15E0167 | Main-track train derailment | M206 – Improper trailer tiedown | 2015-11-14 | Joffre, AB | CN | CN train L55551-14 (operating conventional, 1 load, 14 empty cars, 588 tons, 995 feet long) derailed a loaded pipe flat car, ICG 978918, at Mile 18.4, Brazeau Subdivision. The front truck derailed, and the car was leaning. There were no injuries, and no dangerous goods were involved. |

| R15T0254 | Non-main-track train derailment | M201 – Load shifted | 2015-11-02 | London, ON | CP | The CP yard crew on assignment TL11-02, while proceeding east with 19 cars in London Yard, observed line 14, car WCTR 866859 (a loaded bulkhead flat car), begin to shift and derail, causing 3 broken rails and extensive damage to the lead track. There were no injuries, and no dangerous goods were involved. |

| R15T0158 | Main-track train derailment | M204 – Improperly loaded car | 2015-07-18 | Bowmanville, ON | CN | CN train Q14921-18, travelling westward, derailed 7 loaded intermodal platforms at Mile 292.5 of the Kingston Subdivision, blocking both main tracks. The cars were derailed on either side of the bridge over Bowmanville Creek. There was about 1000 feet of track damage, with considerable damage to the bridge ties on the north track. CN determined that the derailment occurred when an improperly loaded steel cylinder broke through the floor of its container, caught in the rail bed, and ripped open 2 containers in the bottom of the following car body. There were no injuries, and no dangerous goods were involved. |

| R15T0043 | Rolling stock collision with object | M202 – Load fell from car | 2015-03-07 | Parry Sound, ON | CP | On CP train CWR-13 (continuous welded rail train), operating on the CN Bala Subdivision, a rail came off the train and struck a power pole and crossing sign (at Gibson Street) between Mile 150 and Mile 149.9. No injuries were reported. |

| R14E0236 | Non-main-track train derailment | M201 – Load shifted | 2014-12-22 | Fort Saskatchewan, AB | CN | CN 604 yard assignment was shoving flat car PTTX 141051 (loaded with rail) into track VC80 at Scotford Yard when the load shifted and the car derailed. The car remained upright, and the load did not spill. There were no injuries, and no dangerous goods were involved. |

| R14W0314 | Main-track train derailment | M202 – Load fell from car | 2014-12-12 | Booth, SK | CN | CN train M31541-10, proceeding west on the Watrous Subdivision, experienced a train-initiated emergency brake application at Mile 85.5. The inspection revealed that 35 cars derailed (lines 3-35, 62, and 63), including a dangerous goods car (line 33) loaded with isopropanol (UN 1219). There were no injuries. RCMP and CN officials responded. A TSB investigator was deployed. |

| R14E0223 | Non-main-track train derailment | M202 – Load fell from car | 2014-12-06 | Edmonton, AB | CN | CN train YCBS02 derailed when the load shifted on bad-ordered car CN 618049 while the car was being set out in track VF13 at the Clover Bar Yard. The load shifted again, and the car derailed upright. Approximately 160 feet of rail rolled. There were no injuries, and no dangerous goods were involved. |

| R14E0097 | Rolling stock damage without derailment or collision | M201 – Load shifted | 2014-07-01 | Lloydminster, AB | CN | CN train crew on freight L-507-42-30, while inspecting cars in customer track LL-03, discovered tank car SHQX 8122 had damage on its side. The damage was caused by a shifted load on a nearby gondola car. No dangerous goods were involved. No injuries were reported. |