27 September 2021

City Manager

City of Ottawa

110 Laurier Avenue West

Ottawa, Ontario K1P 1J1

Subject :

Rail Safety Advisory letter 617-02/21

Roller bearing failure resulting in derailment of Ottawa Light Rail Transit vehicle

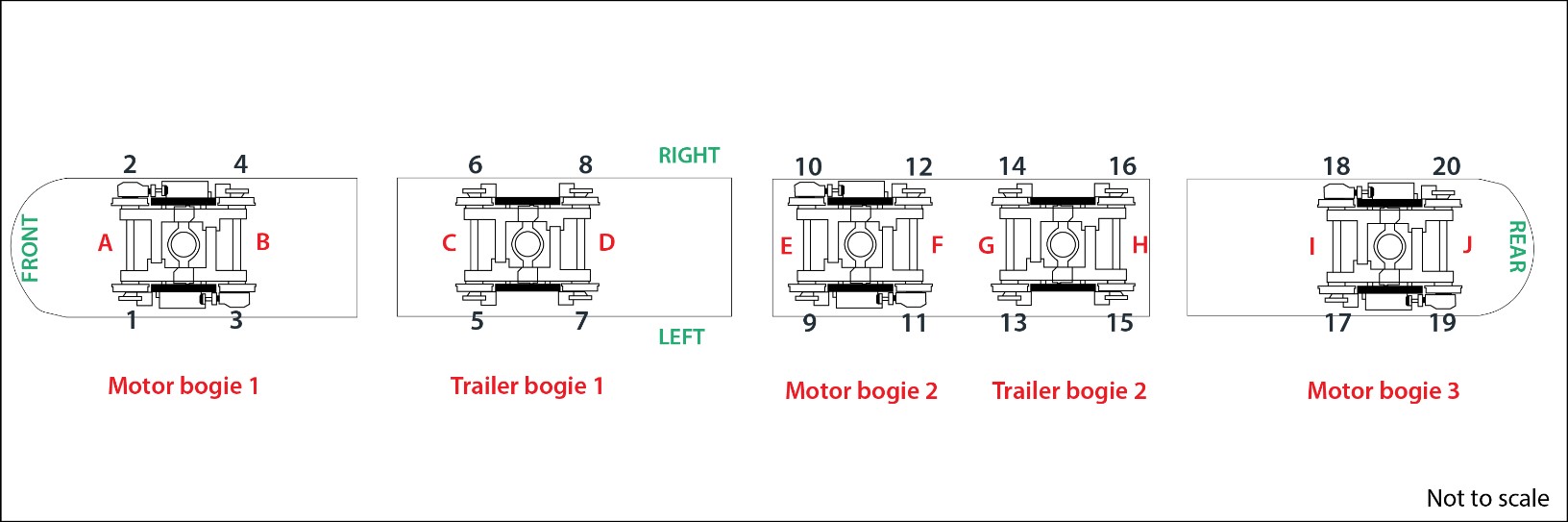

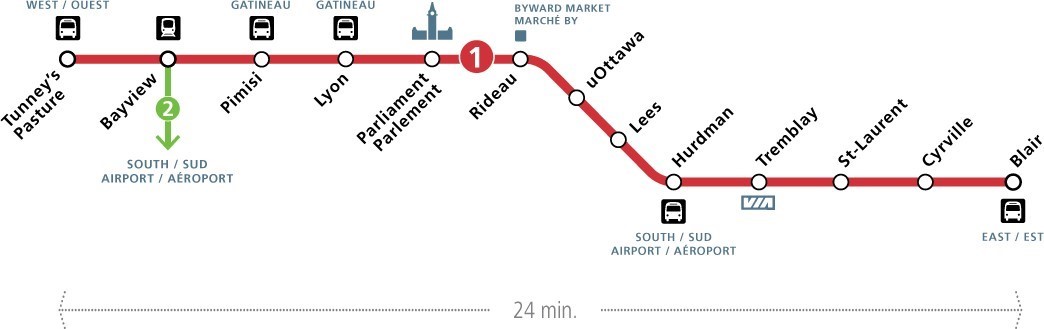

On 14 September 2019, Ottawa Light Rail Transit (OLRT) Stage 1 began with operation of its Confederation Line in Ottawa, Ontario. The vehicle selected for OLRT operations was the Citadis Spirit light rail vehicle (LRV) manufactured by Alstom; the vehicles are mounted on Iponam bogiesFootnote 1 (figures 1 and 2). OLRT purchased 34 such LRVs (numbered 1101 to 1134) for Stage 1 of its new light rail system. OLRT connects 2 LRVs together and operates 2 LRVs as 1 commuter train.

Among other components, each bogie is equipped with 4 resilient wheel assemblies and 2 axle assemblies. Each axle assembly includes 2 wheel hubs and 2 cartridge roller bearing sub-assemblies (cartridge assemblies) connected by a solid splined axle (Figure 3). The wheels are secured to the exterior of each hub by bolts to complete the bogie assembly. The axle transmits the weight of the vehicle to, and provides a smooth rolling movement for, the wheelset.

The cartridge assembly integrates the splined axle with the rotating part of the wheel that allows the wheels to turn. Each cartridge assembly includes 2 tapered roller bearing assemblies, and the whole assembly is held together tightly by a large locking nut (thrust nut), which is torqued at 3000 newton-metres of torque.Footnote 2 A cartridge assembly is installed on each end of a splined axle, secured with bolts.

Each cartridge assembly is manufactured by Texelis in Limoges, France, then shipped to Canada for installation.

The accident

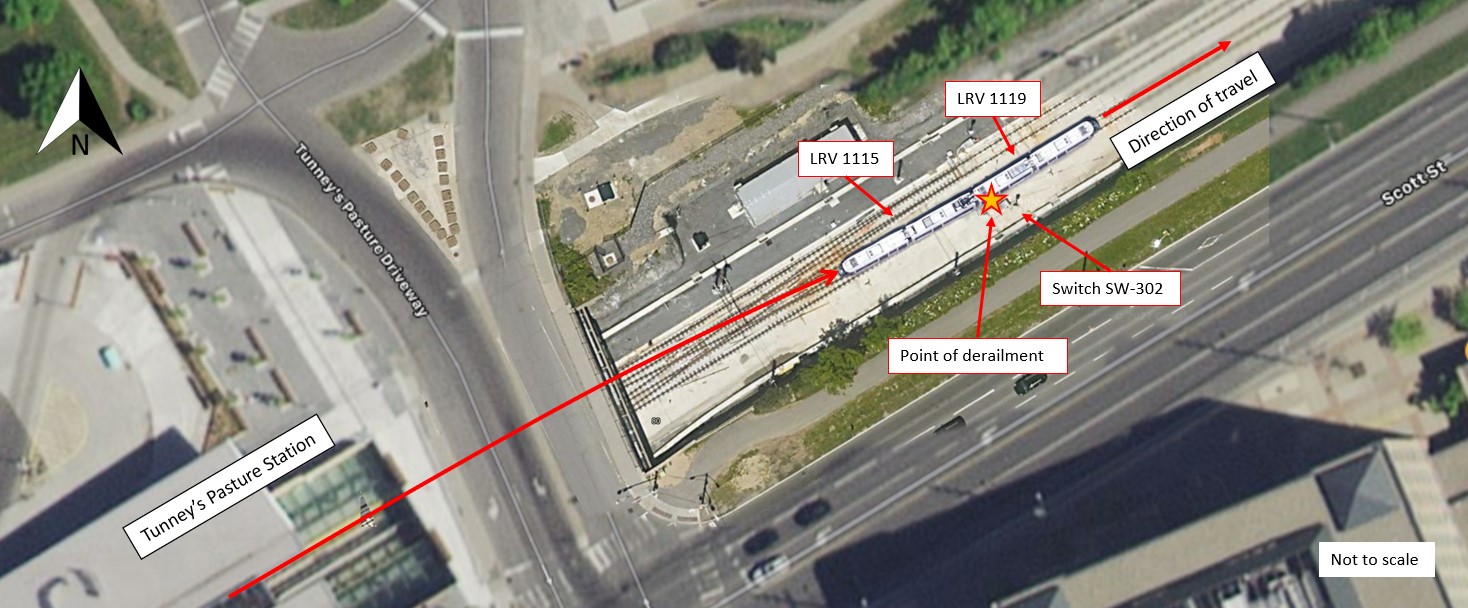

On 08 August 2021 at about 2034,Footnote 3 an eastbound OLRT commuter train (the train) was proceeding from the north track to the south track over the SW-302 south crossover switch at a speed of about 30 km/h when it derailed about 90 m east of Tunney’s Pasture Station in Ottawa, Ontario (Figure 4). There were no passengers on board at the time of the accident.

The train consisted of LRV 1115 and LRV 1119. It was being moved from Tunney’s Pasture Station to OLRT Belfast Yard Maintenance and Storage Facility for repairs when the derailment occurred. Both LRVs remained upright.

Site examination identified that while the train was traversing the crossover the No. 3 wheel climbed the rail and derailed to the field side of the south track. The mate No. 4 wheel on the same axle derailed to the gauge side of the north rail and came to rest between the rails. The concrete ties and the tie plates of the south track sustained impact damage.

Events leading to the derailment

Analysis of recorded information indicated the following:

- At 1325, the splined axle on the No. 3 wheel likely failed as the LRV travelled eastward between Cyrville and Blair stations (Figure 5). A review of event recorder and vehicle logs showed that LRV 1119 had experienced multiple wheel slip warnings during this time.

- After reaching Blair Station, the train proceeded westward on its regular route.

- At 1450, the train operator reported a burning smell. The train was parked at the north platform of Tunney’s Pasture Station to wait for a technician to assess a potential “sticking brake” on LRV 1115.

- At 1500, a technician identified burn marks on a brake disk on LRV 1115. The brake was isolated and the calipers were released. The train was removed from service and held at Tunney’s Pasture Station until later in the evening. With the reported problem believed to have been identified, LRV 1119 was not inspected.

- Between 2015 and 2025, a technician attended to the brakes on LRV 1115, observed the train move back and forth on the north track, and cleared the train to return to the maintenance and storage facility.

- At 2030, the train departed Tunney’s Pasture Station with the technician on the train.

- Immediately after crossing from the north track to the south track, the train experienced an unusually rough ride as it exited the crossover switch. The train was brought to a controlled stop, and a subsequent inspection identified that the No. 3 and No. 4 wheels on LRV 1119 were derailed.

- To minimize service disruptions, it was decided to re-rail the train after 2300.

- As the train was being re-railed, it was discovered that the No. 3 wheel was no longer attached to the axle.

- The No. 3 wheel had severed from the axle due to a previously undetected catastrophic roller bearing failure and subsequent axle journal burn-off (Figures 6 and 7).

- Roller bearing rollers were later found on the track near uOttawa Station. This suggests that, as the train travelled westward between 1325 and 1450, a cartridge assembly failed and some rollers were expelled.

Alstom’s root cause failure analysis suggested that the roller bearing failure was related to the loosening of the large locking nut that holds the cartridge assembly together.

Risk mitigation measures implemented following the derailment

At about 0330 on 09 August 2021, it was decided that the entire OLRT LRV fleet required further inspection for loose cartridge assemblies before resuming operations.

The following risk mitigation measures were put into place:

- The entire OLRT LRV fleet was grounded for 5 days while cartridge assembly axial endplay clearance measurements were completed on the fleet (20 per LRV). Measured clearances in excess of 0.1 mm are considered to be loose and the associated cartridge assembly must be replaced with a new assembly.

- LRVs that had no loose or failed cartridge assemblies were released back into service.

- In addition to the failed No. 3 cartridge assembly on LRV 1119, the inspections identified a total of 17 loose cartridge assemblies on 9 other LRVs with measured clearances that ranged from 0.12 mm to 0.89 mm.

- All failed or loose cartridge assemblies were replaced with new ones before the LRVs were returned to service.

- A new periodic inspection was implemented. The inspection requires the LRV to be elevated in order to inspect the cartridge assemblies from beneath the bogies. With the use of a pry bar, axial endplay clearance measurements are recorded for each cartridge assembly. Loose cartridge assemblies must be replaced. This additional labour-intensive inspection is required for each LRV, every 7500 km, on an ongoing basis.

Since the cartridge assemblies were newly installed during a fleet-wide bogie retrofit program in late 2019 to early 2020, the average mileage for those with excess clearances recorded was about 117 000 km. The bogies on LRV 1119 were retrofitted in December 2019 and new cartridge assemblies were installed at that time. Since then, up until the derailment on 08 August 2021, LRV 1119 motor bogie 1 had accumulated 145 974 km.

Roller bearing heat detection

Cartridge assemblies for OLRT LRVs are always located inboard of the wheels. With this arrangement, the condition of the roller bearings cannot be effectively inspected visually and their operating temperatures cannot be monitored by traditional wayside hot bearing detectors that are set up to monitor roller bearings located outboard of the wheels on freight cars. Furthermore, OLRT has no wayside or on-board system in place to monitor the operating temperature of axle roller bearings that are located inboard of the wheels. Consequently, an overheated roller bearing within the cartridge assembly can potentially fail catastrophically without being observed or detected. As demonstrated in this occurrence, such a failure can also lead to derailment if there is no intervention.

Regulatory oversight

The Transport Canada–approved Railway Passenger Car Inspection & Safety Rules (Passenger Car Safety Rules) prescribe the minimum safety standards for passenger rail cars in Canada and state the following:

- Section 3. DEFINITIONS, item 3.12 defines a passenger car as a “railway vehicle intended to provide transportation of passengers and baggage in either commuter or intercity service, which includes cab cars and a DMU (Diesel Multiple Unit).”

- Section 23. DEFECTIVE WHEEL BEARING SENSING, item 23.1 states that “[a]n overheated bearing detector and alarm system, or other appropriate method of heat detection, shall be provided for each inboard mounted bearing.”

VIA Rail Canada Inc. (VIA) Renaissance passenger cars are all equipped with axle roller bearings that are mounted inboard of the wheels. In accordance with the Passenger Car Safety Rules, all VIA Renaissance passenger cars are also equipped with on-board axle roller bearing heat detection systems. When the system detects a roller bearing overheating, it warns the crew so that the train can be slowed or stopped before a catastrophic roller bearing failure occurs.

However, the Passenger Car Safety Rules do not apply to OLRT commuter LRVs. An agreement between Transport Canada and the City of Ottawa (the City) states that the Confederation Line is not considered to be a railway for the purposes of the Railway Safety Act. The agreement authorizes the City to regulate any matter covered by the Railway Safety Act relating to the design, construction, operation, and safety and security of the railway, which includes developing and applying its own rules or regulations.

Consequently, even though the OLRT Confederation Line commuter rail system is a federal transportation undertaking subject to the jurisdictional authority of the federal government, federal transportation legislation and regulations do not apply to, and Transport Canada does not regulate, this system. Nonetheless, OLRT is required to report rail occurrences to the TSB, and the TSB retains jurisdiction to investigate them under its federal mandate.

The City did identify that a provision for heat detection equipment on the wayside or on the LRV was considered during the design phase of the Alstom Citadis Spirit for OLRT, but it was not identified as a requirement because regular maintenance activities were considered sufficient.

A Consolidated Safety File for the OLRT–Ottawa LRV project was created to document potential hazards, mitigating strategies, and safety-related activities for the LRV project. The document identified the potential for a “locked axle” as a hazard at least twice. The mitigation strategy to address this known hazard was regular maintenance that included visual inspections for grease leakage every 25 000 km. However, a locked axle can occur for a number of reasons, and there was no specific reference to a catastrophic roller bearing failure leading to axle journal burn-off.

Since the LRV 1119 bogie retrofit, motor bogie 1 on LRV 1119 had accumulated 145 974 km and would have been subjected to at least 5 inspections as outlined in the risk mitigation strategy in the Consolidated Safety File. Now that a catastrophic roller bearing failure has actually occurred within a cartridge assembly and resulted in a derailment, the preventive risk mitigation strategy that relied on regular maintenance and visual inspections has proven to be insufficient to protect against such bearing failures.

As demonstrated by this derailment, there can be serious consequences resulting from an overheated roller bearing failure on an LRV in commuter passenger service. OLRT may wish to ensure that it has heat detection systems in place to monitor temperatures of LRV cartridge roller bearing assemblies in order to detect overheated roller bearings in a timely manner and intervene before an in-service catastrophic roller bearing failure occurs.

The TSB would appreciate being informed of what action, if any, will be taken in this regard.

Yours sincerely,

Original signed by

Paul Treboutat

Director, Investigations (Rail/Pipeline)

Transportation Safety Board of Canada

CC.

-

Director General, Rail Safety

Transport Canada -

Project Manager

Alstom Transport -

Chief Executive Officer

Rideau Transit Maintenance - General Manager

Transit Services City of Ottawa -

Chief Safety Officer

Safety, Compliance, Training and Development Transportation Services

City of Ottawa